Device for treating waste water by electron beam irradiation method

A technology for electron beam irradiation and wastewater treatment, applied in the direction of light water/sewage treatment, etc., can solve problems such as unsatisfactory treatment effect, and achieve significant economic and social benefits, low treatment cost, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

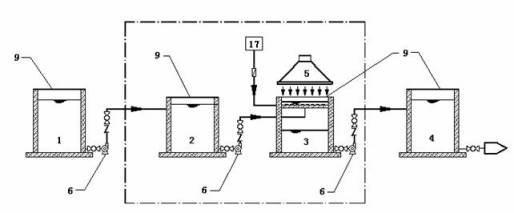

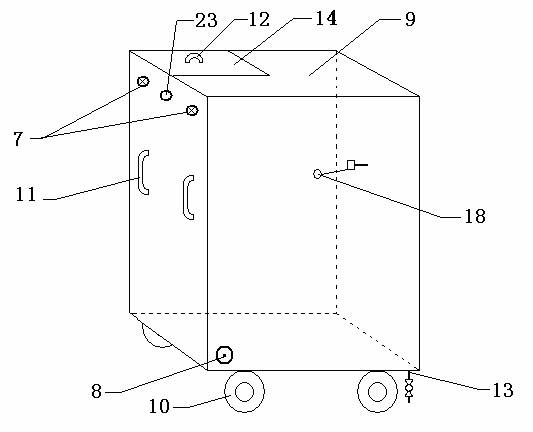

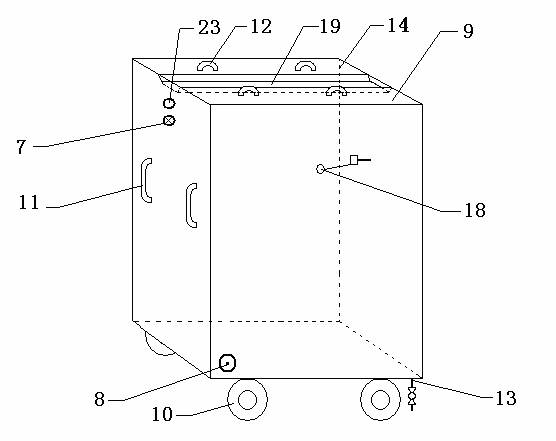

[0033] see figure 1 , a device for treating wastewater by electron beam irradiation, mainly comprising a wastewater collection pool 1, an irradiation treatment pool 3 and a clean water pool 4 connected in sequence through a water delivery pipe, and an electron accelerator 5 is arranged directly above the irradiation treatment pool 3 . see figure 2 , each water delivery pipe is installed with water pump 6 respectively, the water inlet 7 of each water delivery pipe is located at the top of each pond side wall, the water outlet 8 of each water delivery pipe is located at the bottom of each pond side wall, and the top of each pool is provided with can open and close The pool cover9. An irradiation preparation pool 2 is added between the waste water collection pool 1 and the irradiation treatment pool 3, and the irradiation preparation pool 2 can be used as a buffer pool between the waste water collection pool 1 and the irradiation treatment pool 3, and can also play a role in s...

Embodiment 2

[0045] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0046] In this embodiment, this wastewater treatment process device can treat pharmaceutical fine chemical production wastewater such as ethyl benzoyl acrylate and 3,5-dihydroxytoluene. For wastewater containing pesticide residues, the accelerator accelerates the energy of electrons The electron beam intensity of the electron accelerator 5 is 0.6mA, the treatment time is 40 seconds, the removal rate is above 90%, and the chromaticity is reduced to close to 0. In this embodiment, the irradiation technology is used to effectively degrade the pharmaceutical intermediates in the wastewater, reduce the level of organic pollutants and the content of total organic carbon in the water body, and meet the emission standards. The treatment method greatly reduces the treatment cost and improves the economic benefit. In addition, the treatment effect of this technology...

Embodiment 3

[0048] The technical solutions of this embodiment are basically the same as those of Embodiment 1 and Embodiment 2, except that:

[0049] In this embodiment, this wastewater treatment process flow device can purify industrial circulating water. For example, for wastewater containing phthalates, the energy of the accelerated electrons of the electron accelerator 5 is 0.1MeV, and the electron beam current intensity is 0.1mA, the treatment time is 20 seconds, and the removal rate reaches over 98%. In this embodiment, effective treatment of the circulating water is achieved by developing effective treatment technologies for related pollutants. Among them, the degradation rate of phenolic substances reaches more than 95%, which meets the requirements of recycling and solves the key problems of enterprises. At present, with the help of the research group, 150,000 tons of circulating water have been effectively treated.

[0050] Radiation technology is generally carried out under n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com