Low-energy scanning electron microscope system, scanning electron microscope system and sample detection method

An electron microscope, sample technology, applied in circuits, discharge tubes, measuring devices, etc., to achieve the effect of improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

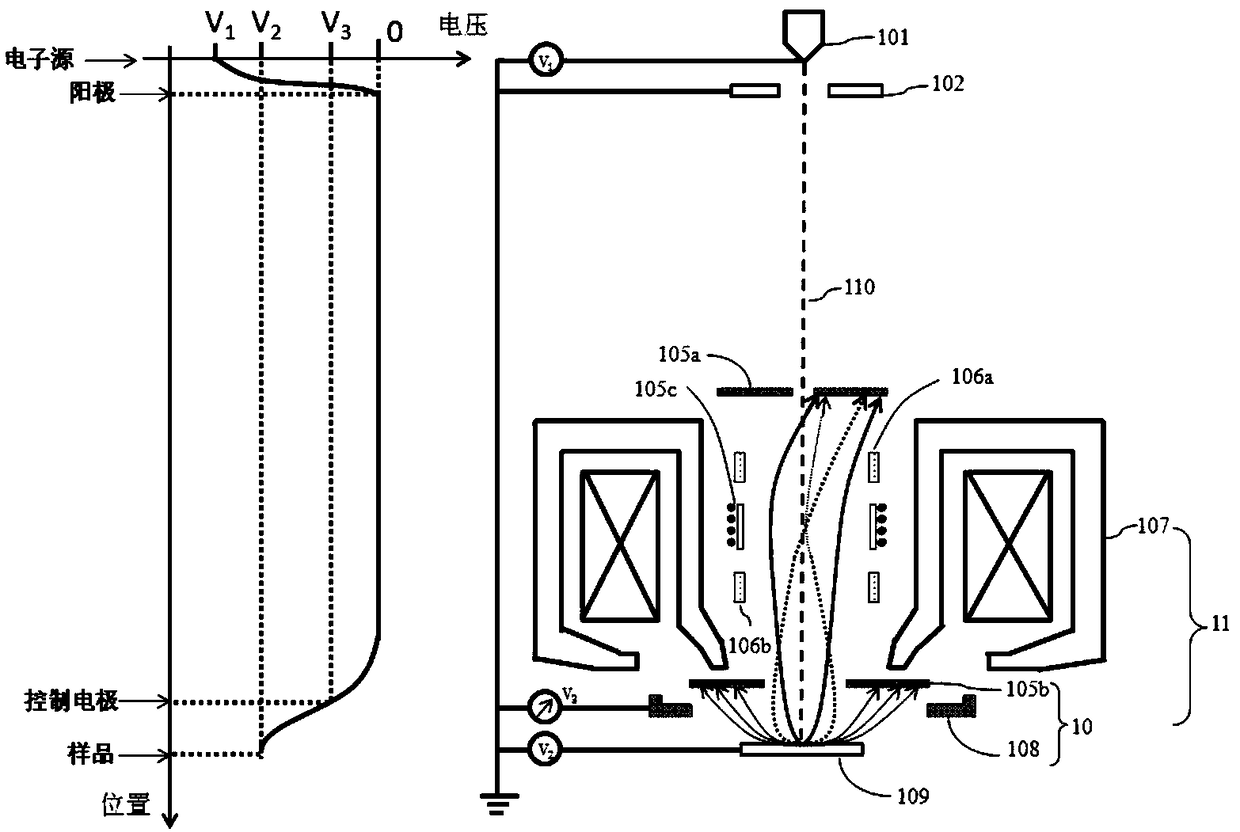

[0114] In view of the above problems, Embodiment 1 of the present invention provides a low-energy scanning electron microscope system, and the composition structure of the scanning electron microscope system is as follows: figure 1 As shown, it includes: a first electron source 101, an electron accelerating structure, a composite objective lens 11 composed of a magnetic lens 107 and an electric lens 10, a first deflection device 106, and a first detection device 105; wherein, the first electron source 101, for generating an electron beam; in an optional embodiment, the first electron source is a first electron source of field emission, such as a first electron source of thermal field emission, or a first electron source of cold field emission , compared with the thermal emission source made of tungsten wire and lanthanum hexaboride material, it has better current density and brightness, and has a smaller virtual source, which can reduce the size of the beam spot generated by th...

Embodiment 2

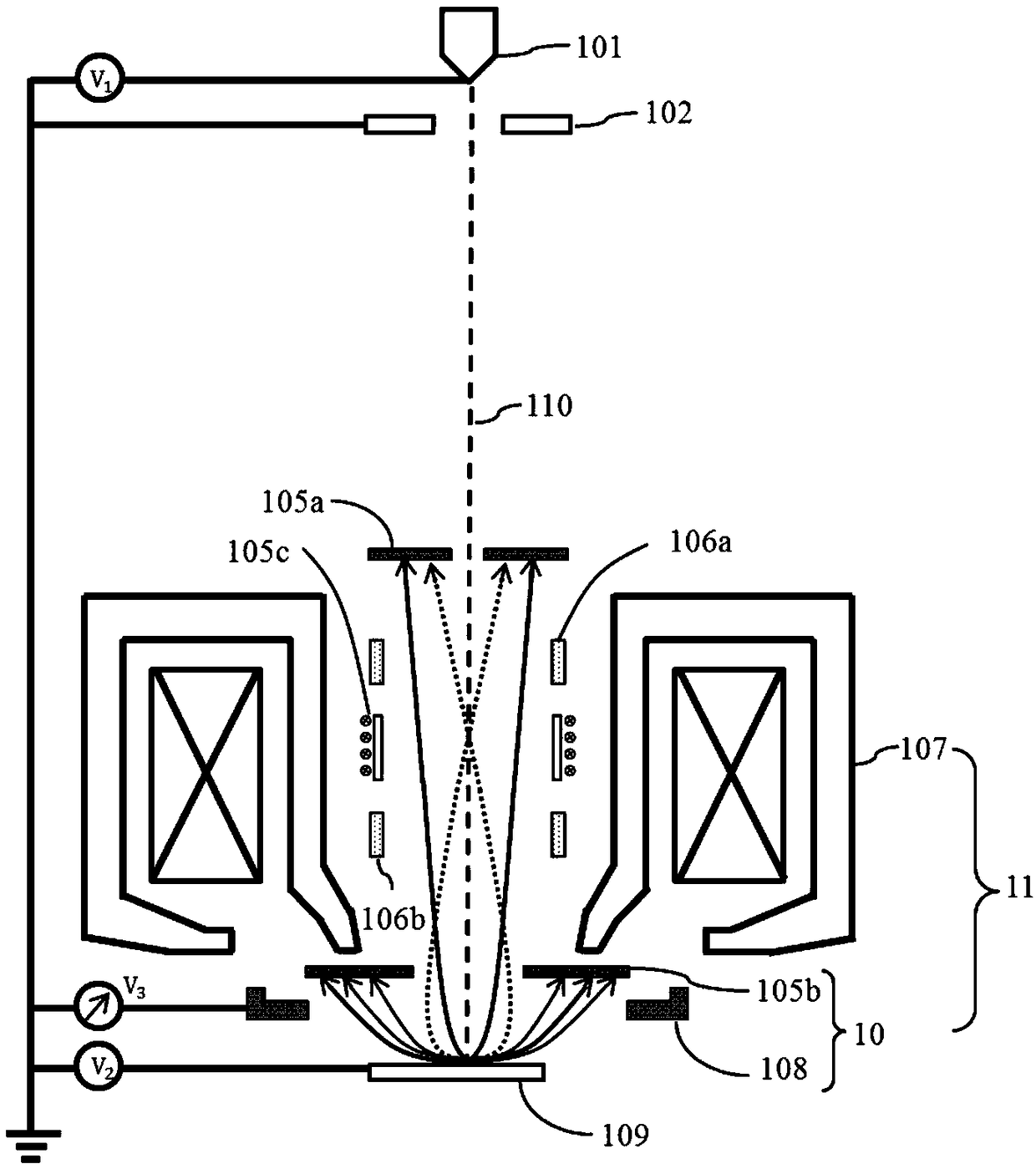

[0147] The low-energy scanning electron microscope system provided by the second embodiment of the present invention is similar to the scanning electron microscope system provided by the first embodiment of the present invention, the difference is that the composition structure of the scanning electron microscope system provided by the second embodiment of the present invention also includes The electron beam adjustment device is arranged below the anode 102 along the optical axis 110, and is used to change the characteristics of the electron beam after passing through the anode 102; the characteristics of the electron beam at least include: the beam current density of the electron beam and the diameter of the electron beam .

[0148] In an alternative embodiment, such as Figure 4 As shown, the electron beam adjustment device is a converging device 103, which is arranged below the anode 102 along the exit direction of the initial electron beam, and is used to converge the ele...

Embodiment 3

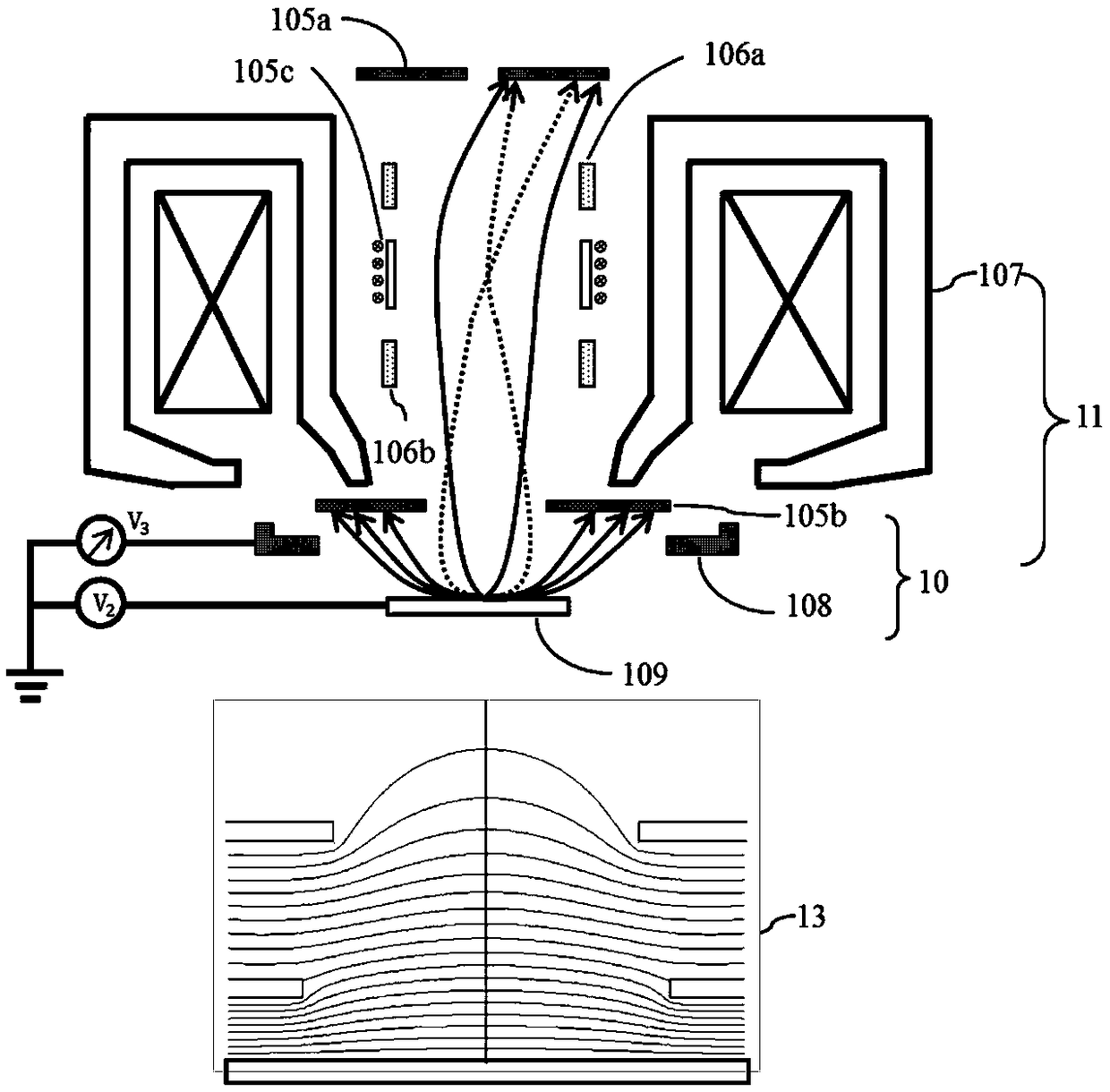

[0151] The low-energy scanning electron microscope system provided in Embodiment 3 of the present invention is similar to the low-energy scanning electron microscope systems provided in Embodiment 1 and Embodiment 2 of the present invention. The difference is that the composition and structure of the low-energy scanning electron microscope system provided by Embodiment 3 of the present invention, such as Figure 5aAs shown, compared with the low-energy scanning electron microscope system provided in Embodiment 1 of the present invention, the electron beam adjustment device is a diaphragm 104, and the diaphragm 104 is located below the anode along the optical axis direction, and is used for scanning the electron beam passing through the anode 102 The electron beam is filtered.

[0152] Or the composition structure of the low-energy scanning electron microscope system provided by Embodiment 3 of the present invention, such as Figure 5b As shown, compared with the low-energy sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com