Thin-wall crosslink low smoke cables for ships communication or control signal and preparation method thereof

A technology for controlling signals and ships, applied in the direction of communication cables, cable/conductor manufacturing, insulated cables, etc., can solve the problems of ordinary ship cables with large outer diameter, large bending radius, and large laying space, etc. The effects of expansion, small bending radius, and reduced laying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

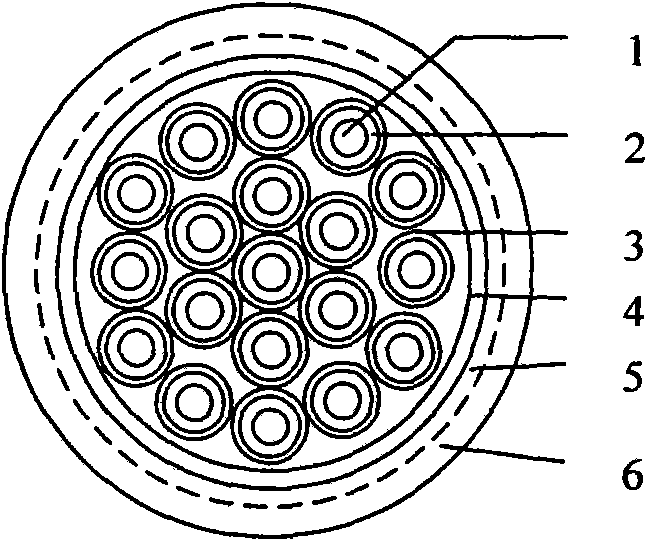

[0017] Control attached figure 1 , thin-walled cross-linked low-smoke control cables for ship control signals, the structure of which is that each strand uses a multi-strand tinned copper wire stranded conductor 1, and each tinned copper wire stranded conductor 1 is extruded and irradiated The insulating layer 2 made of linked polyethylene, the outer layer of the insulating layer 2 is a shielding layer 3 braided with tinned copper wire, and the outer layer of the shielding layer 3 is made of low-smoke halogen-free tape. The cladding 4, the outer layer around the cladding 4 is an armor 5 braided with tinned copper wire, and the outer layer of the armor 5 is a sheath 6 made of radiation cross-linked polyolefin.

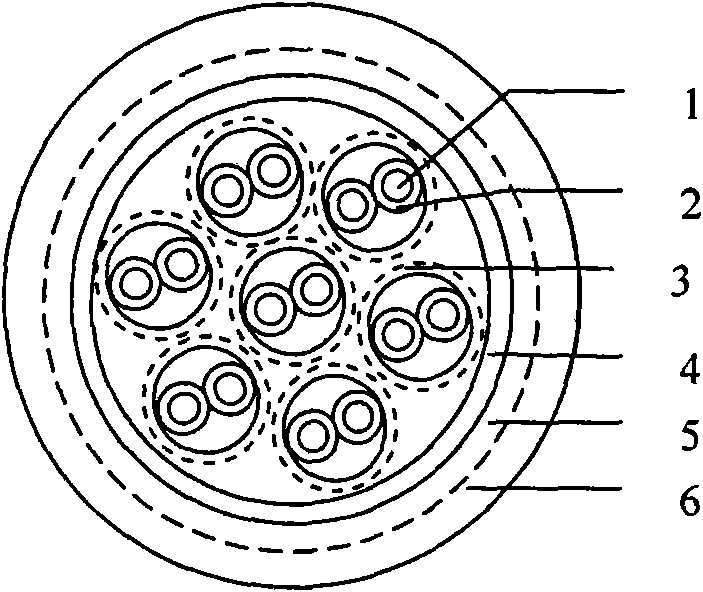

[0018] Control attached figure 2 , Thin-walled cross-linked low-smoke communication cables for ship communication signals. Its structure is that each strand adopts multi-strand tinned copper wire stranded conductor 1, and an insulating layer 2 made of extruded irradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com