Patents

Literature

48results about How to "High adhesiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

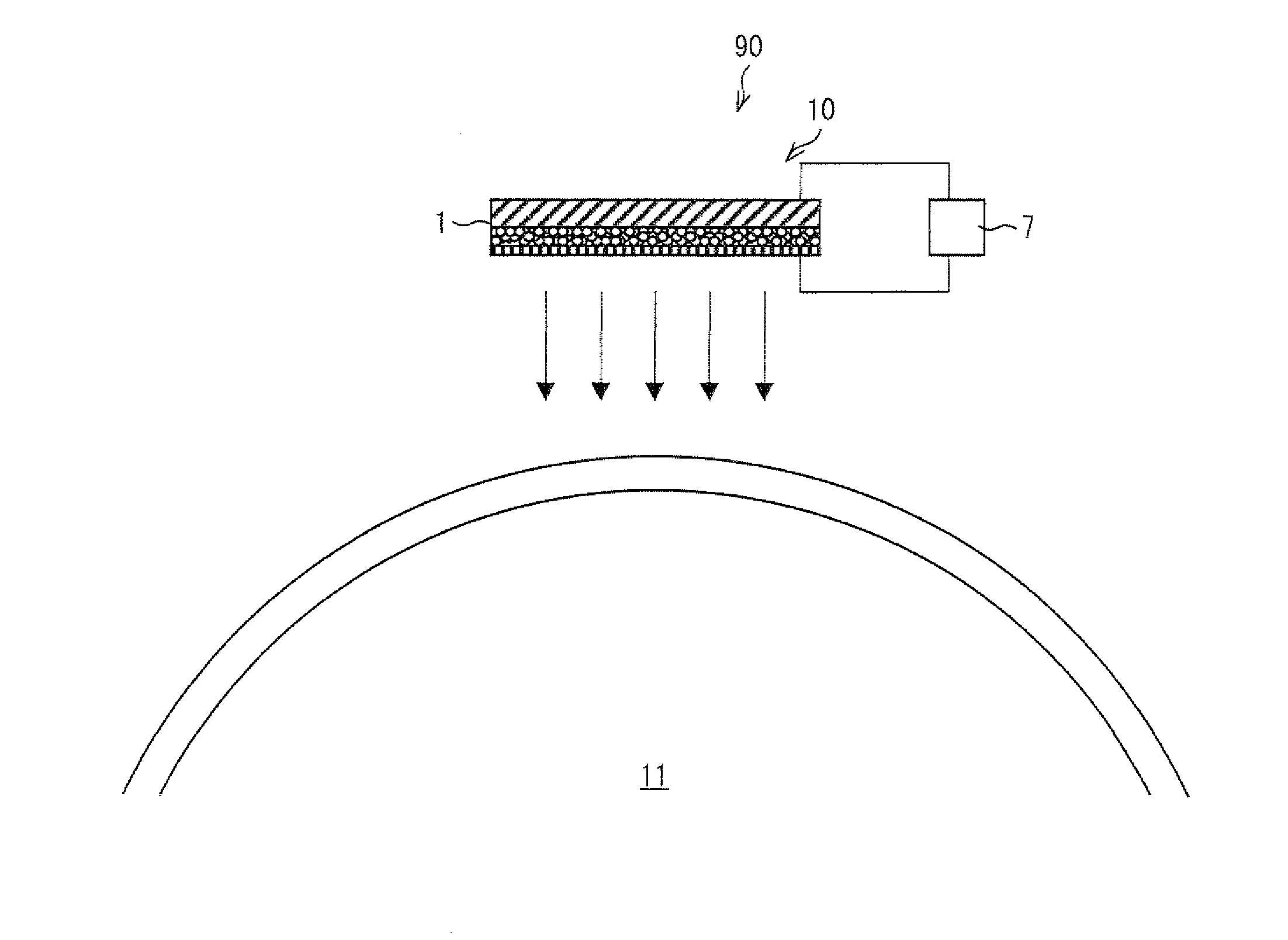

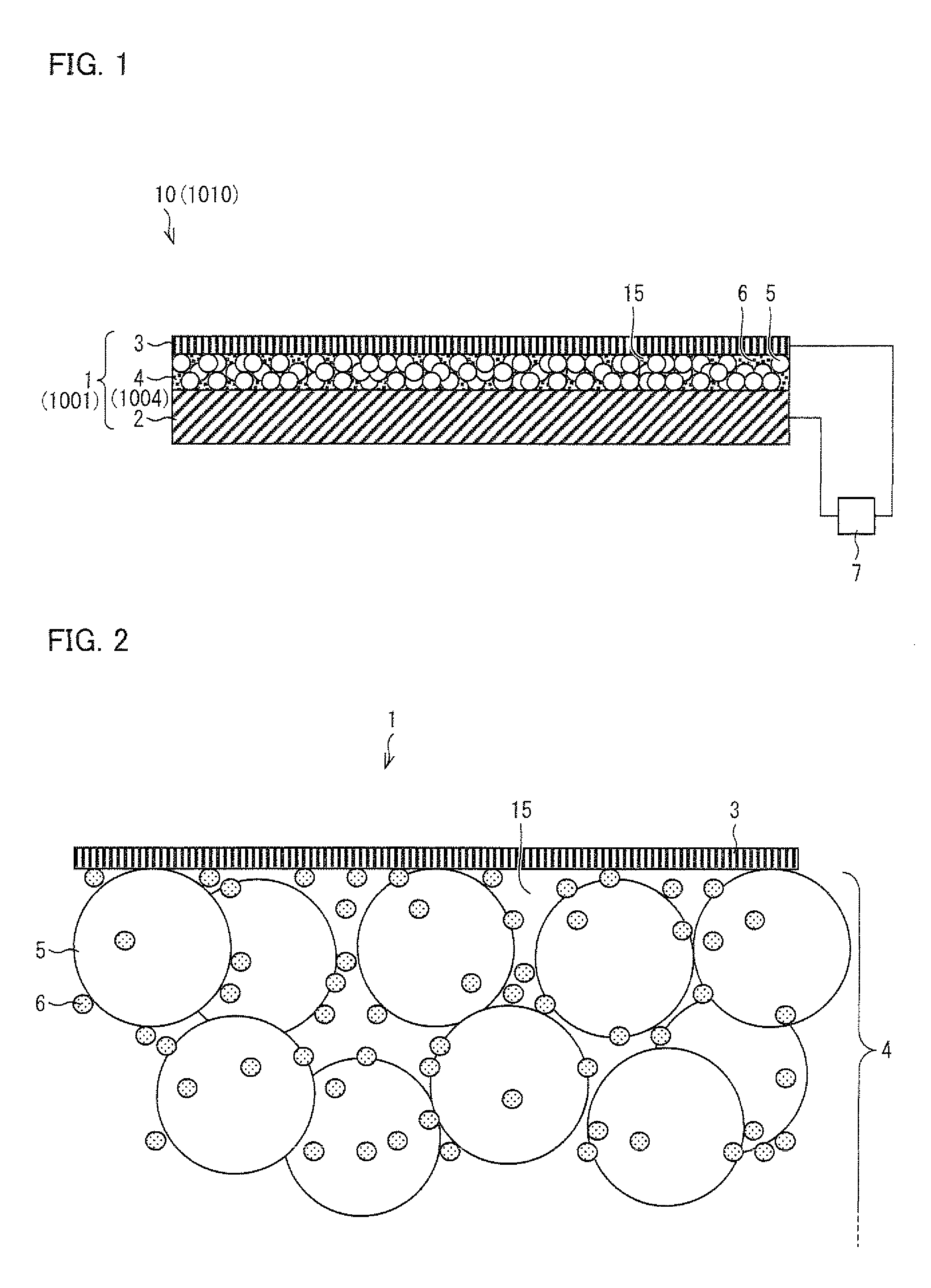

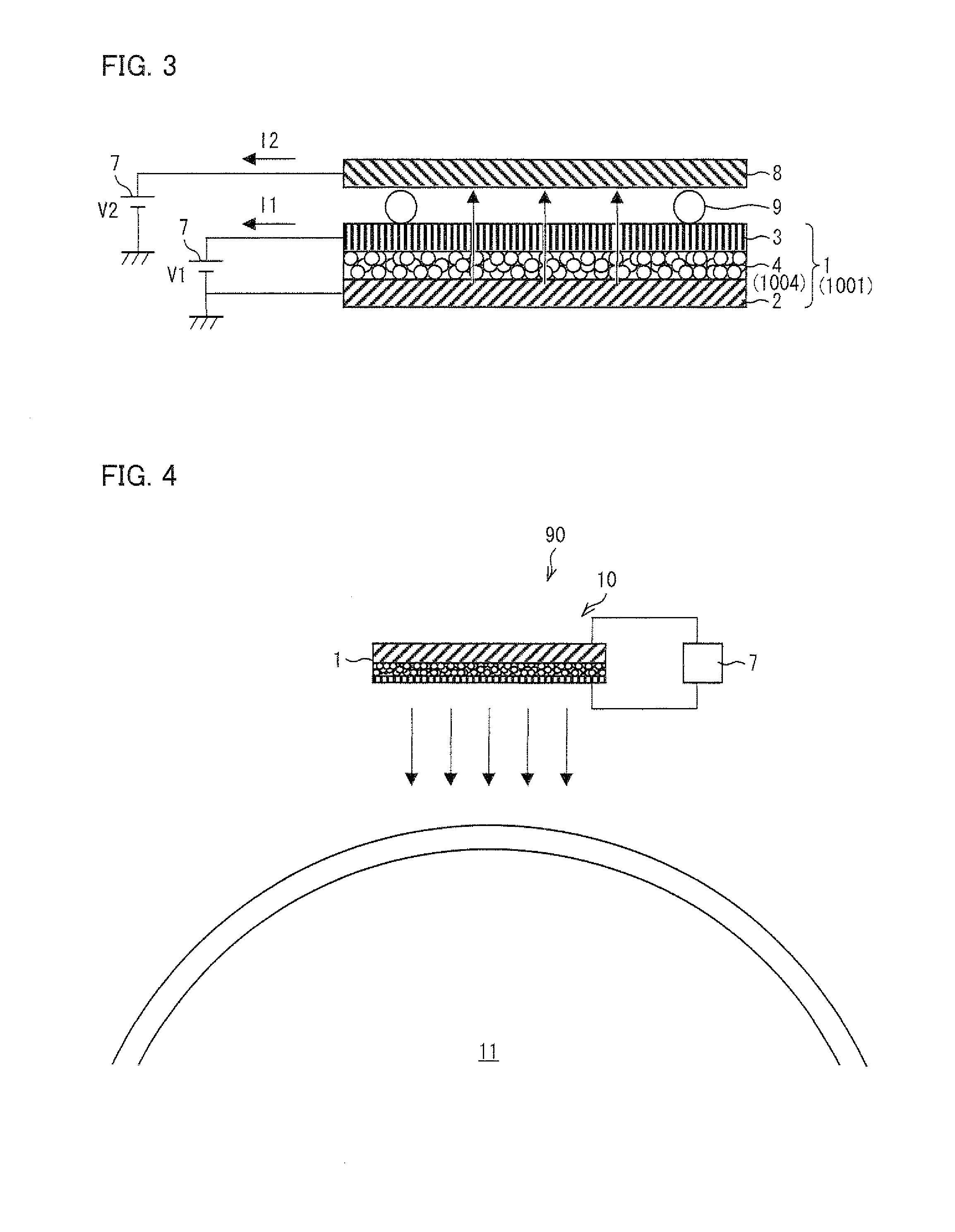

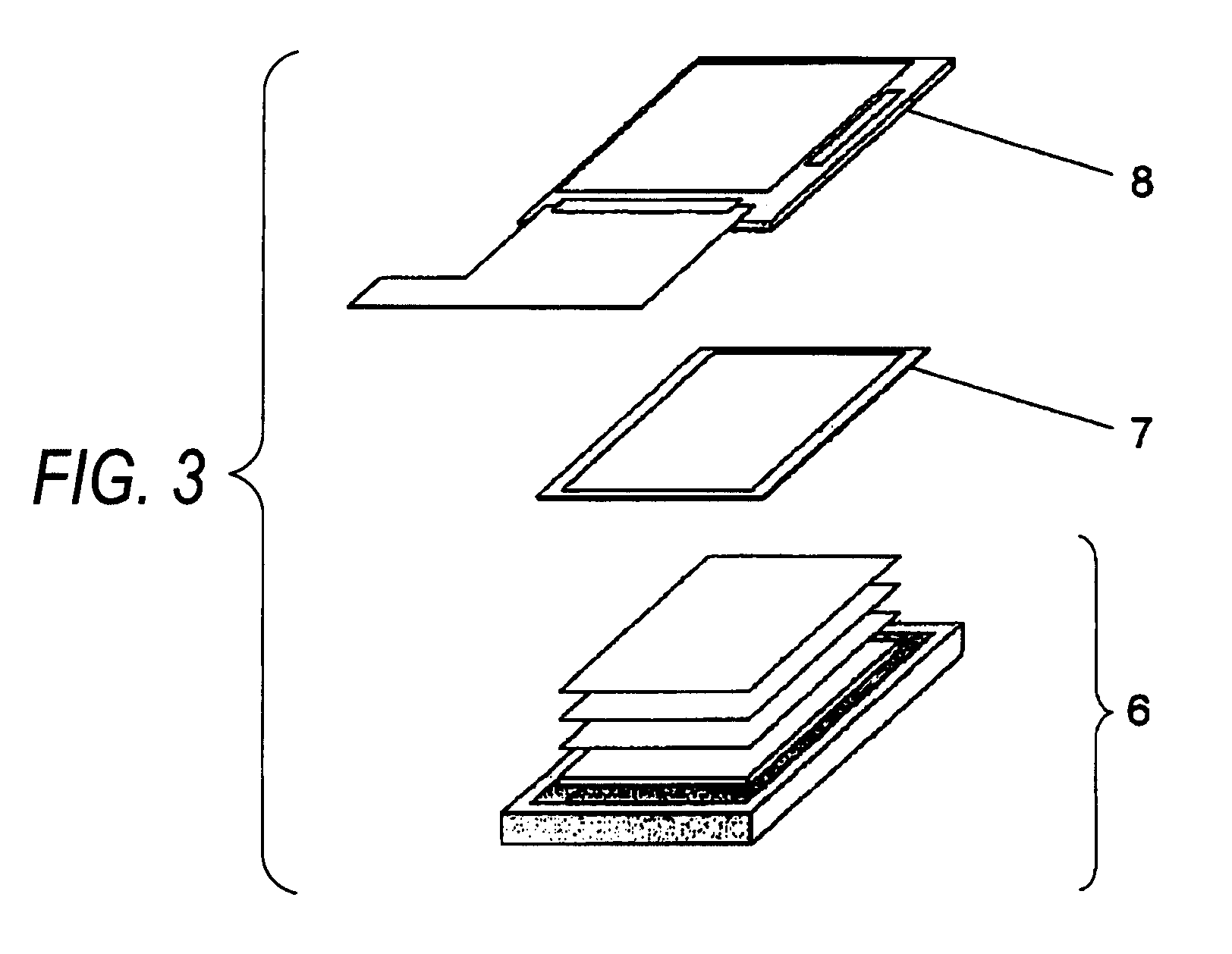

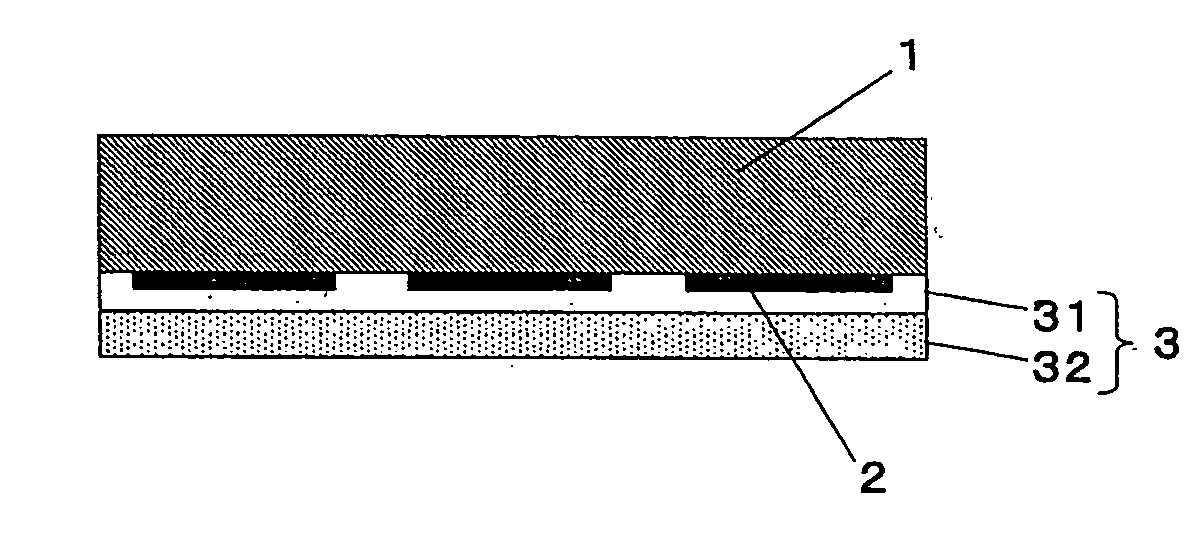

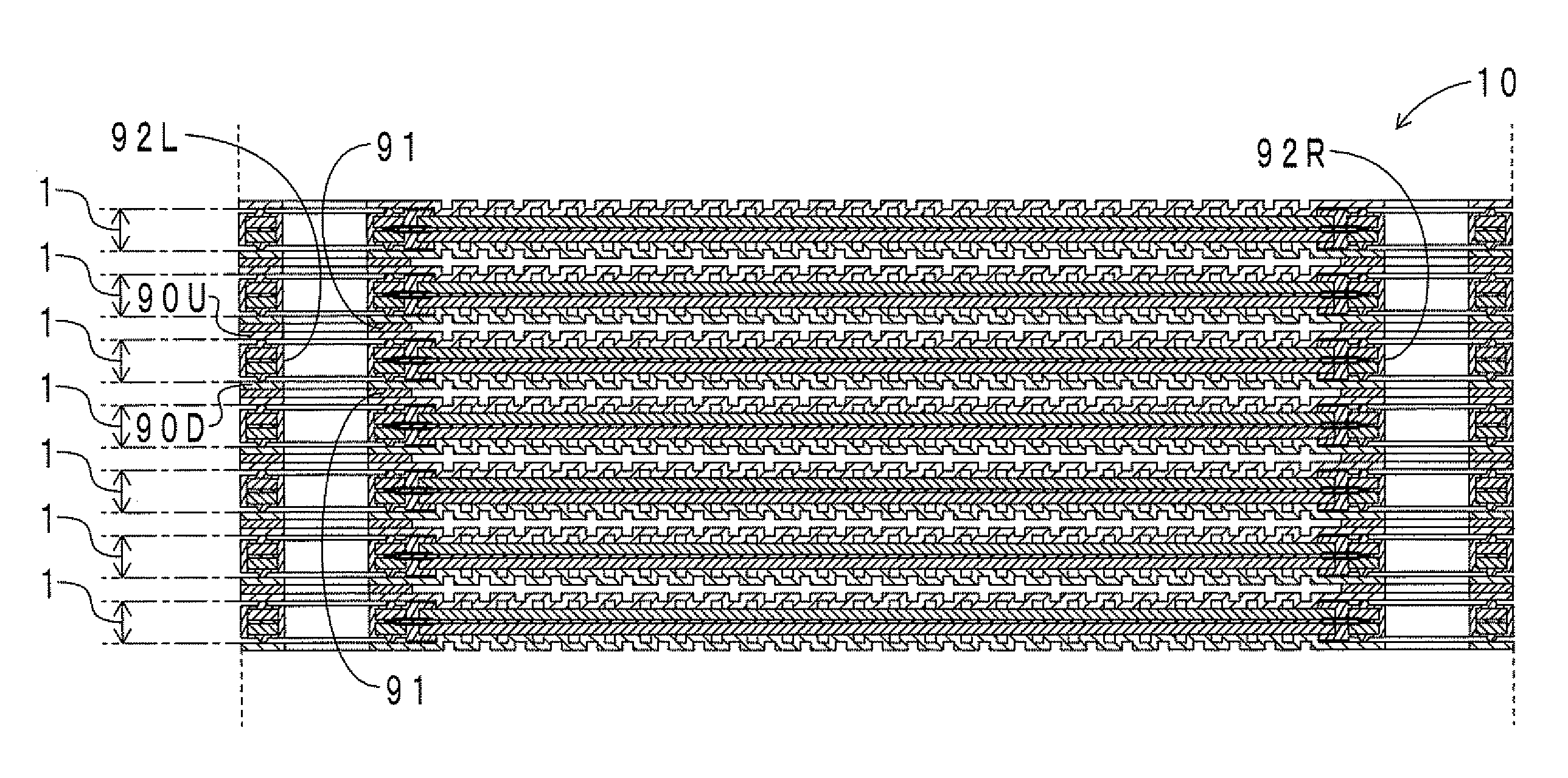

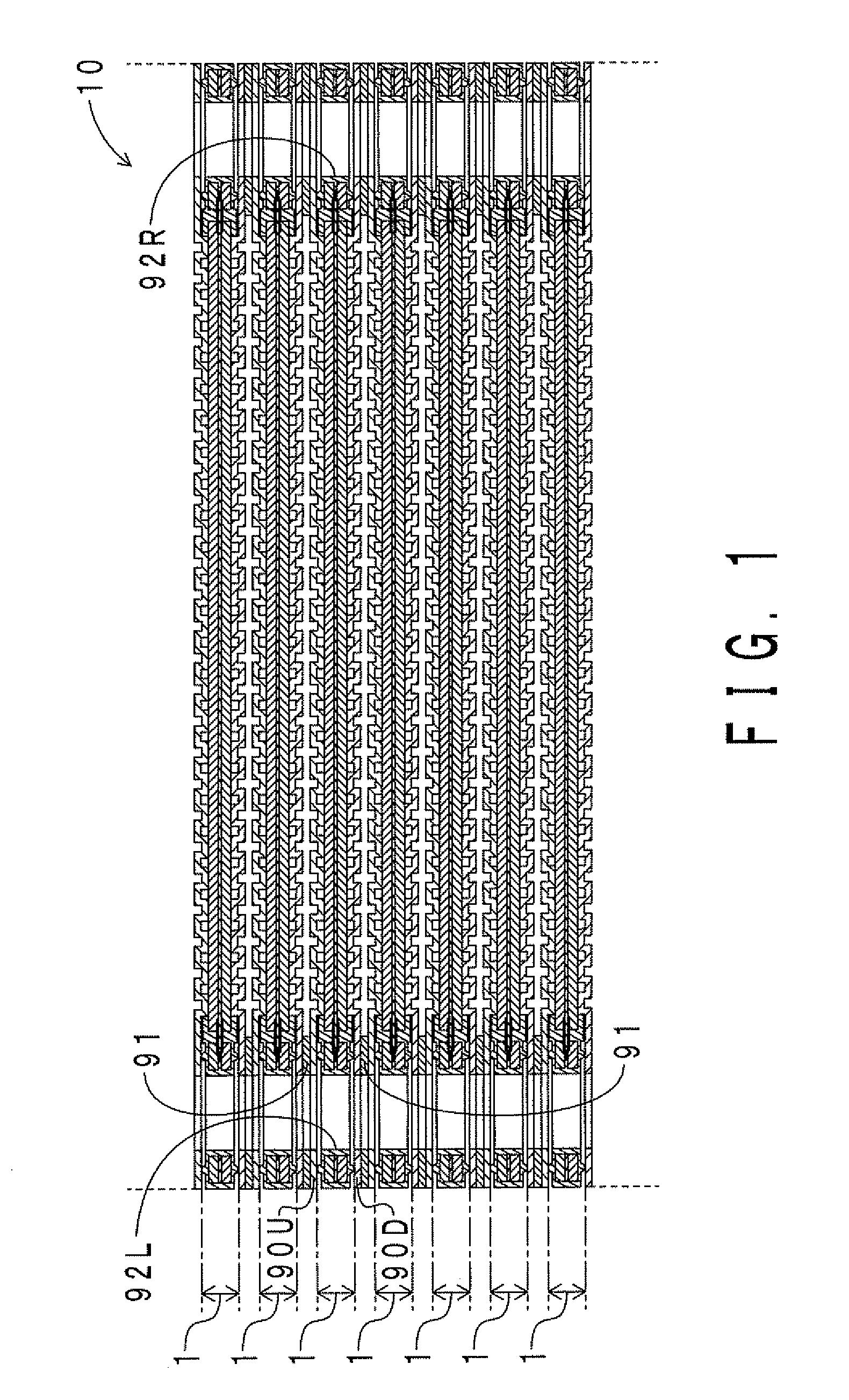

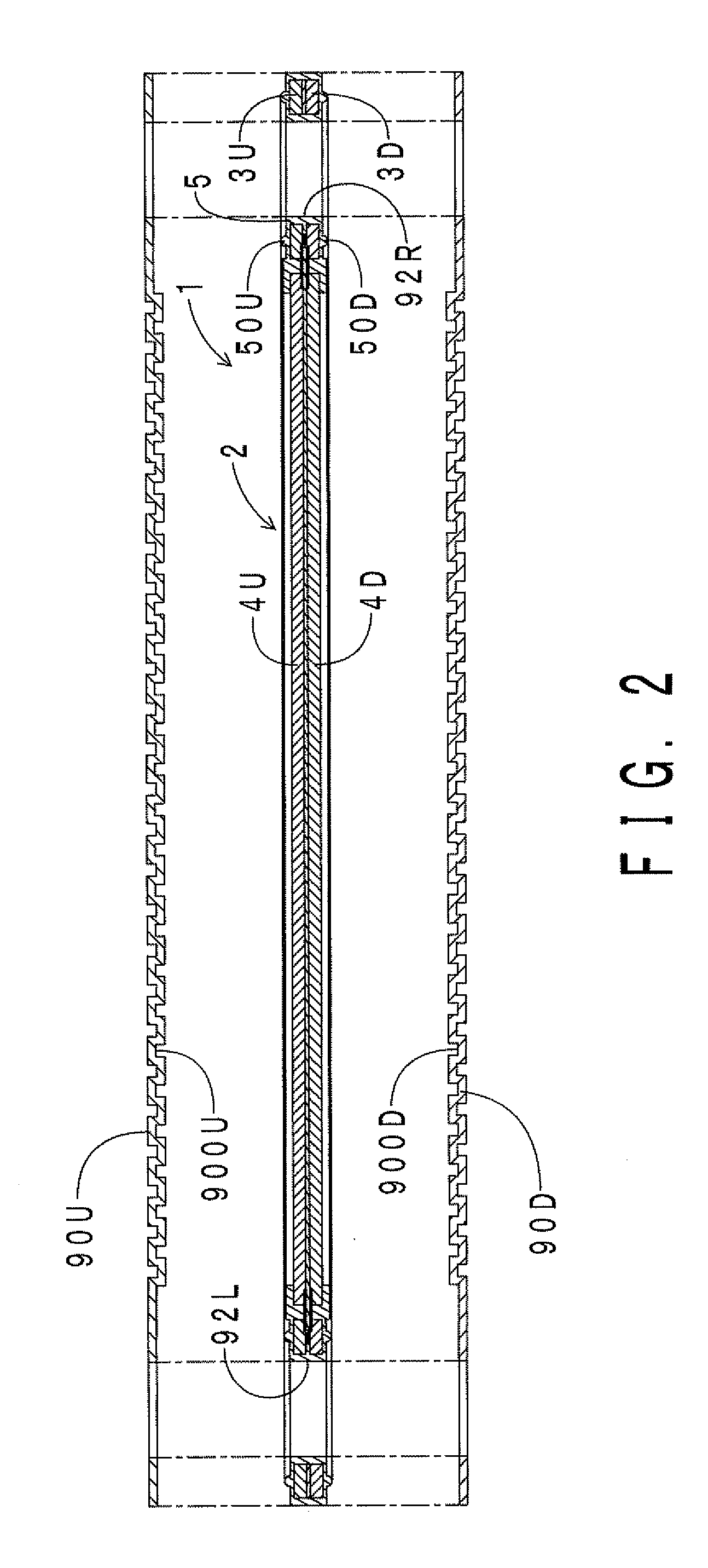

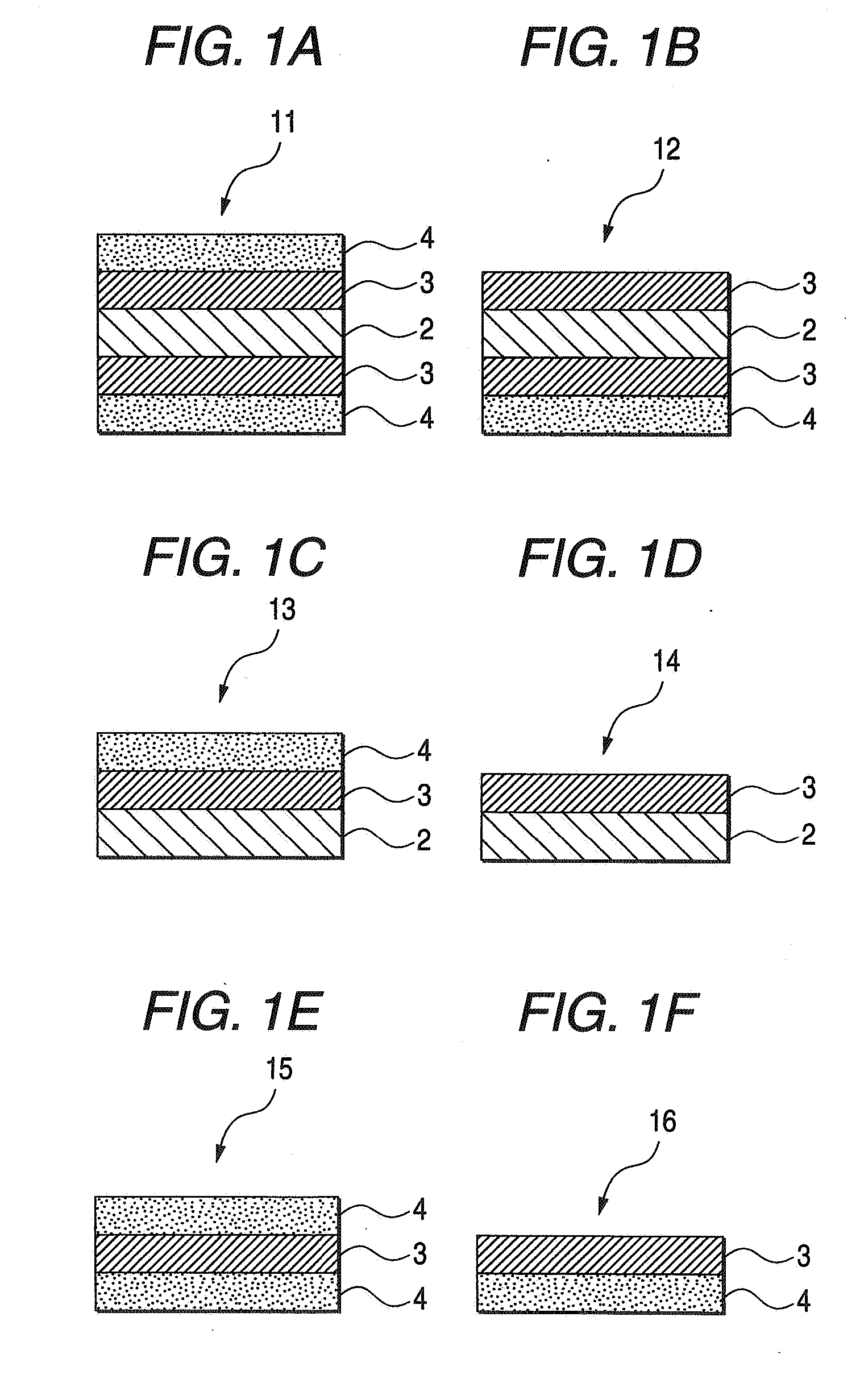

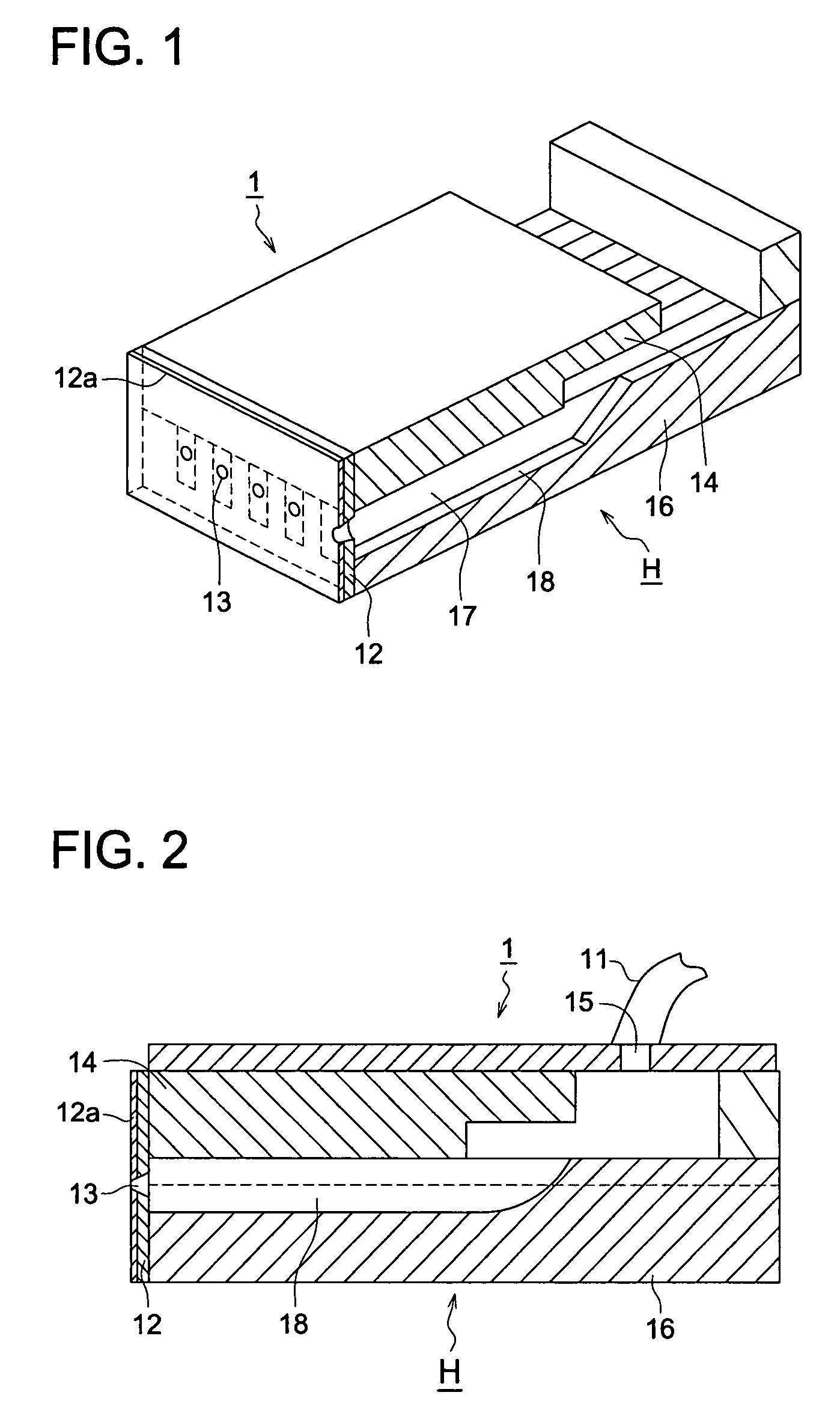

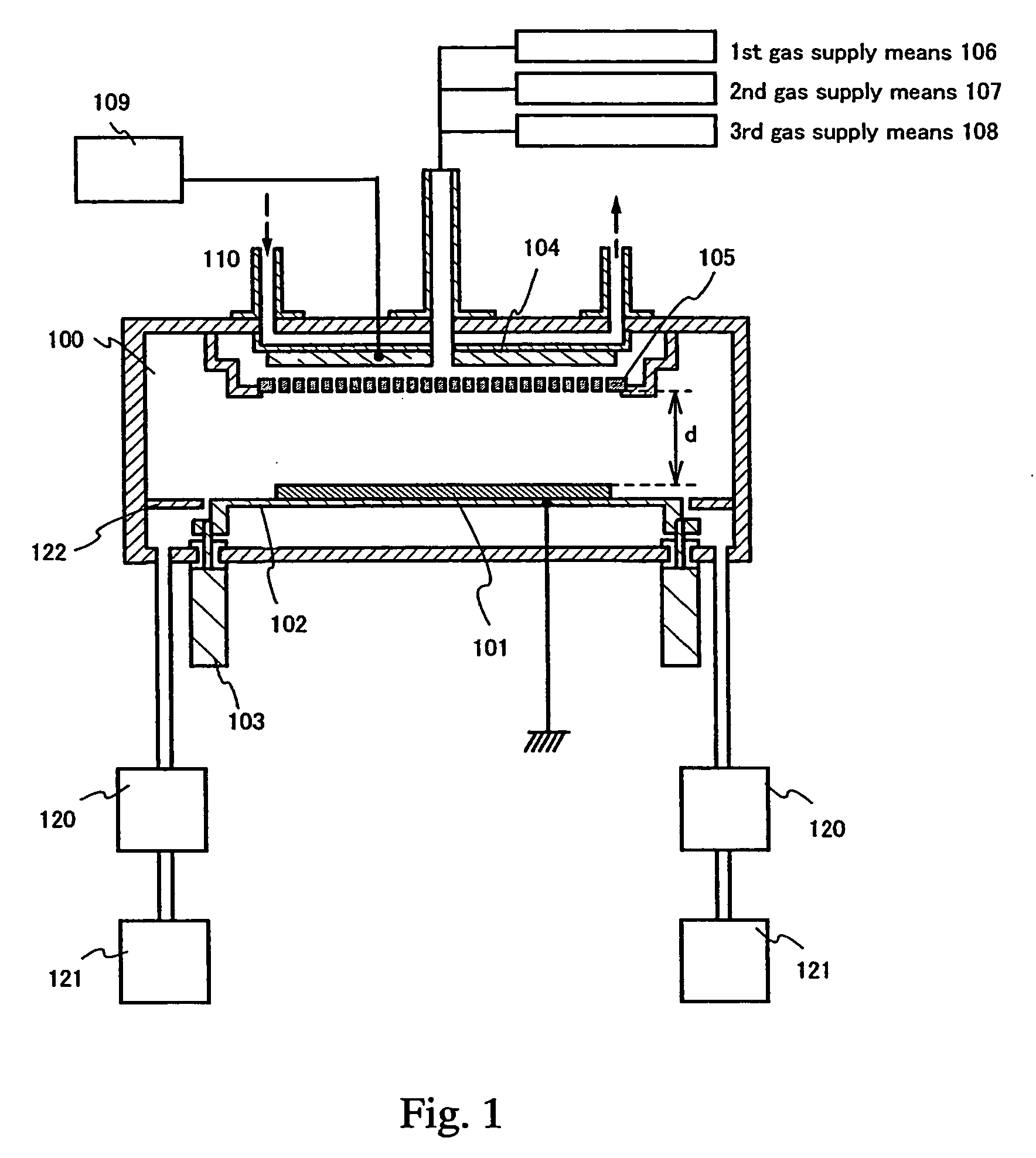

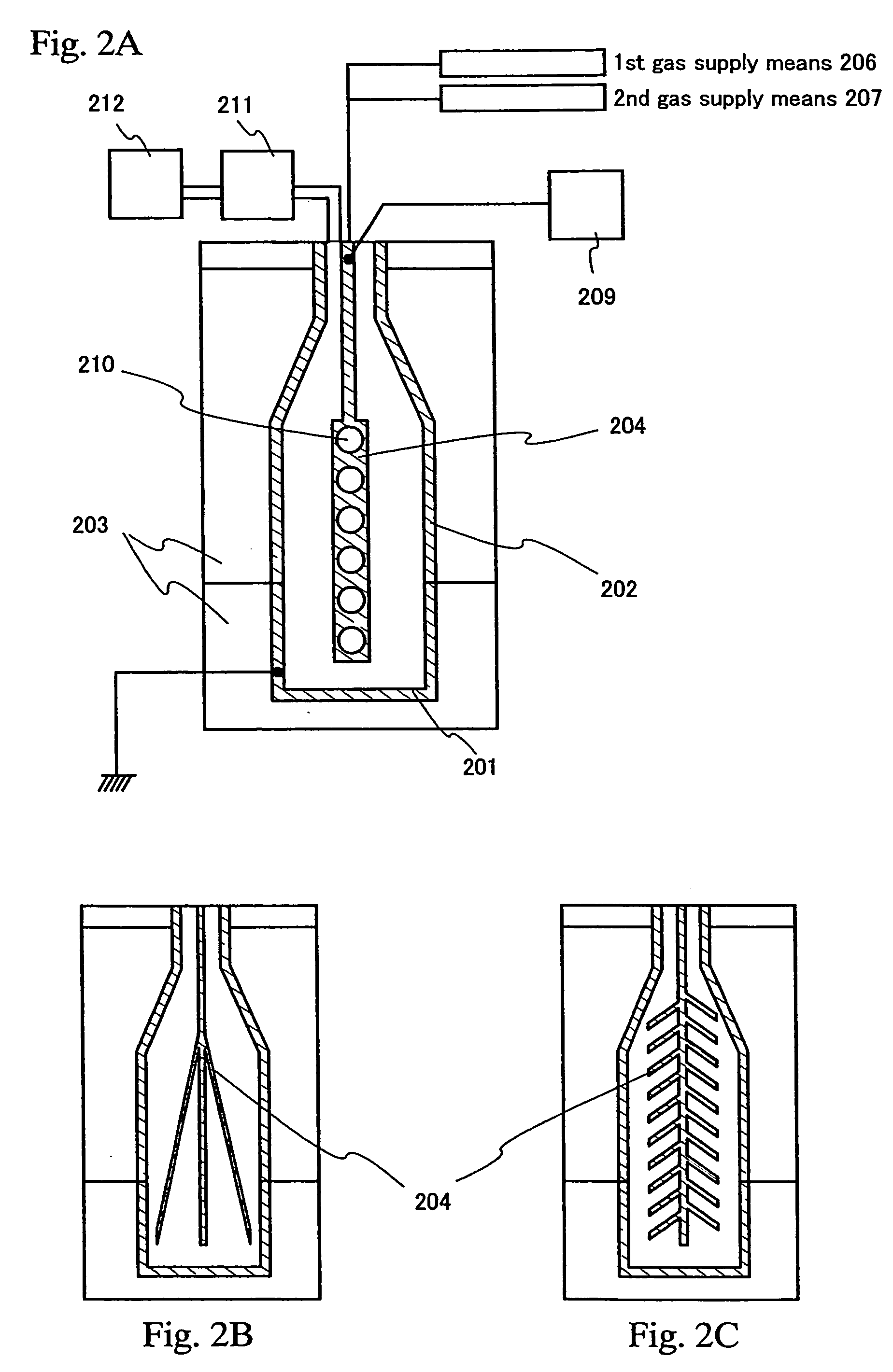

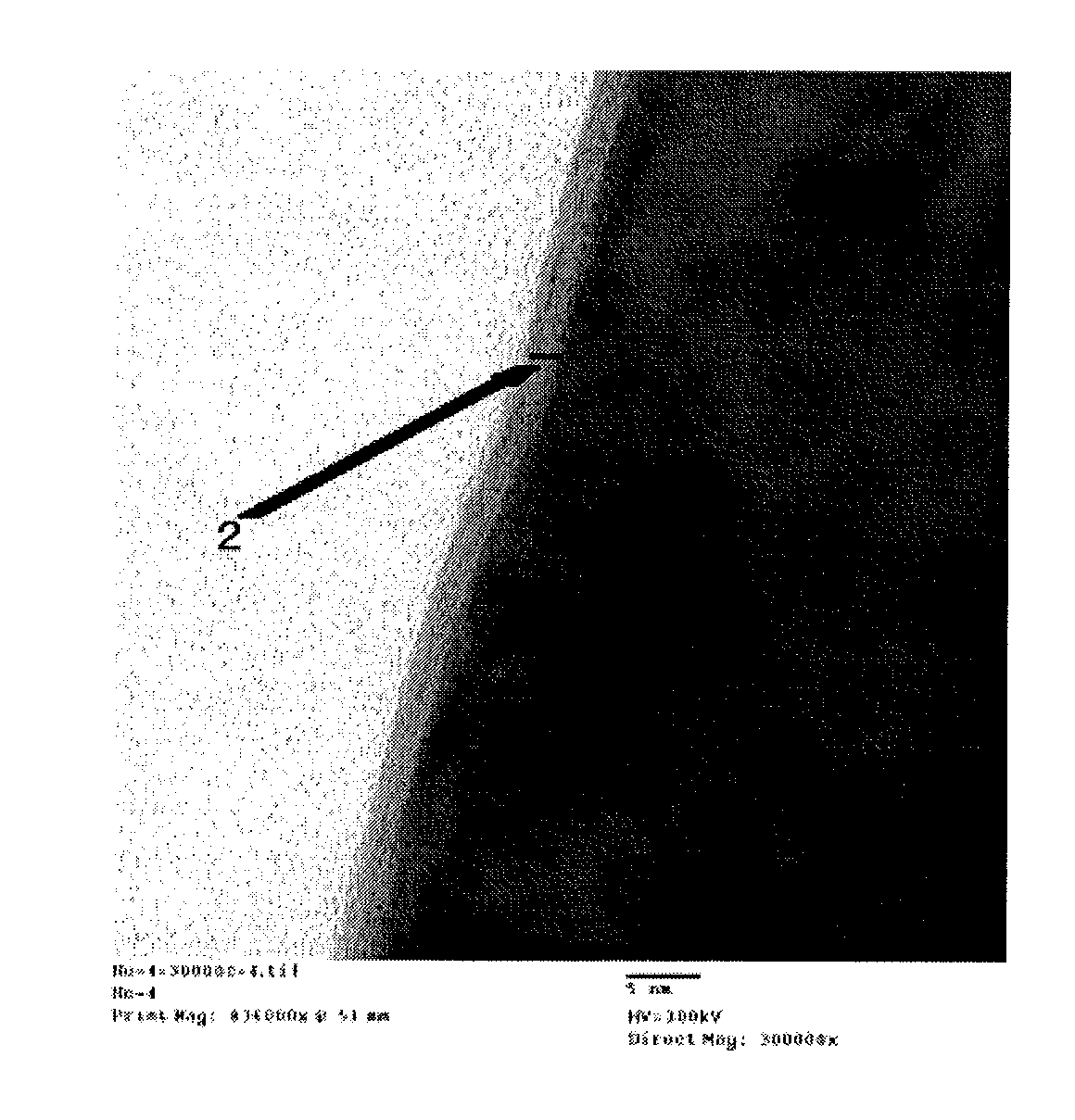

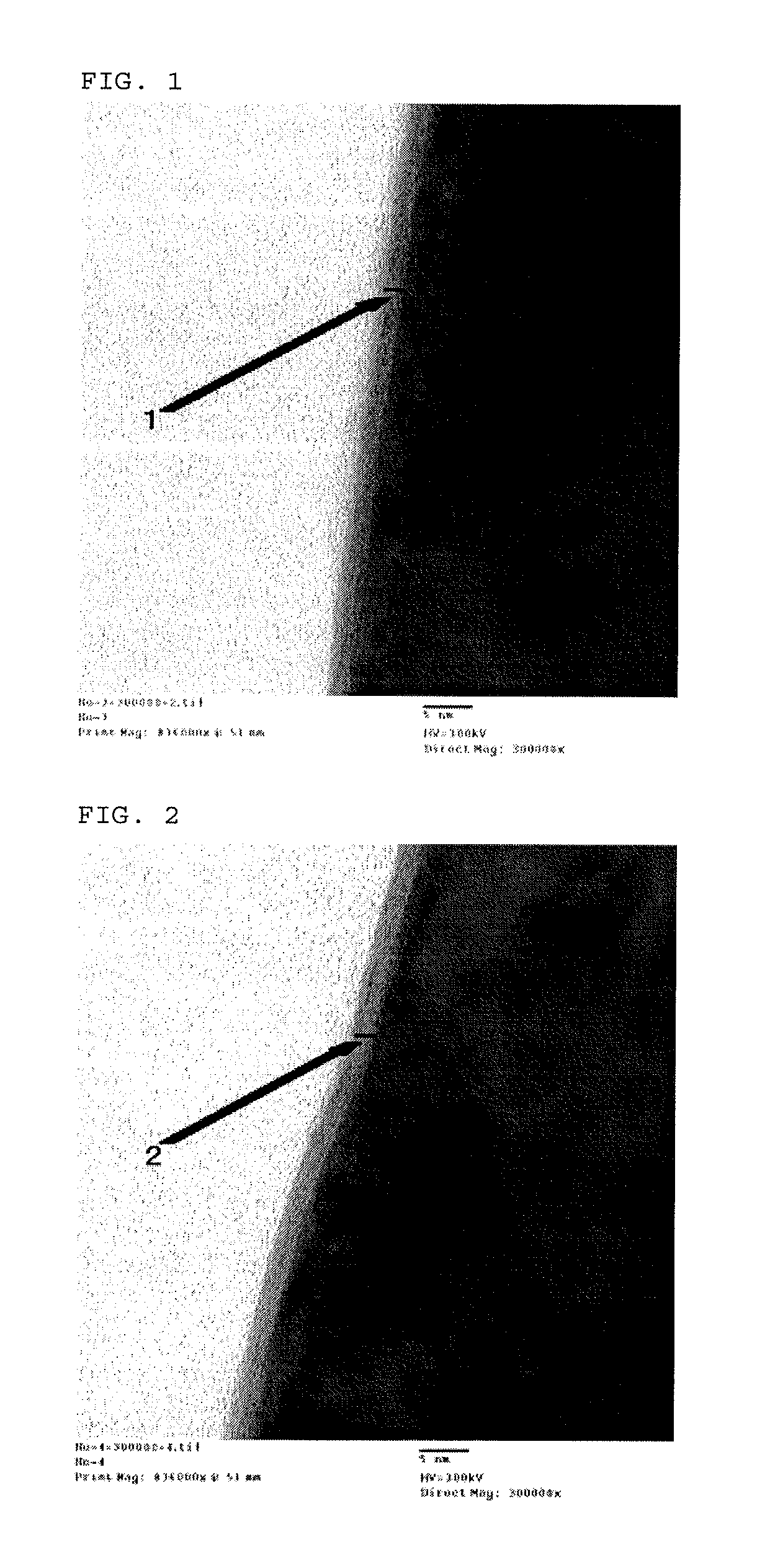

Electron emitting element, electron emitting device, light emitting device, image display device, air blowing device, cooling device, charging device, image forming apparatus, electron-beam curing device, and method for producing electron emitting element

ActiveUS20100215402A1Uniform performanceHigh adhesivenessControl electrodesNanoinformaticsThin film electrodeMolecular physics

An electron emitting element of the present invention includes an electron acceleration layer between an electrode substrate and a thin-film electrode. The electron acceleration layer includes a binder component in which insulating fine particles and conductive fine particles are dispersed. Therefore, the electron emitting element of the present invention is capable of preventing degradation of the electron acceleration layer and can efficiently and steadily emit electrons not only in vacuum but also under the atmospheric pressure. Further, the electron emitting element of the present invention can be formed so as to have an improved mechanical strength.

Owner:SHARP KK

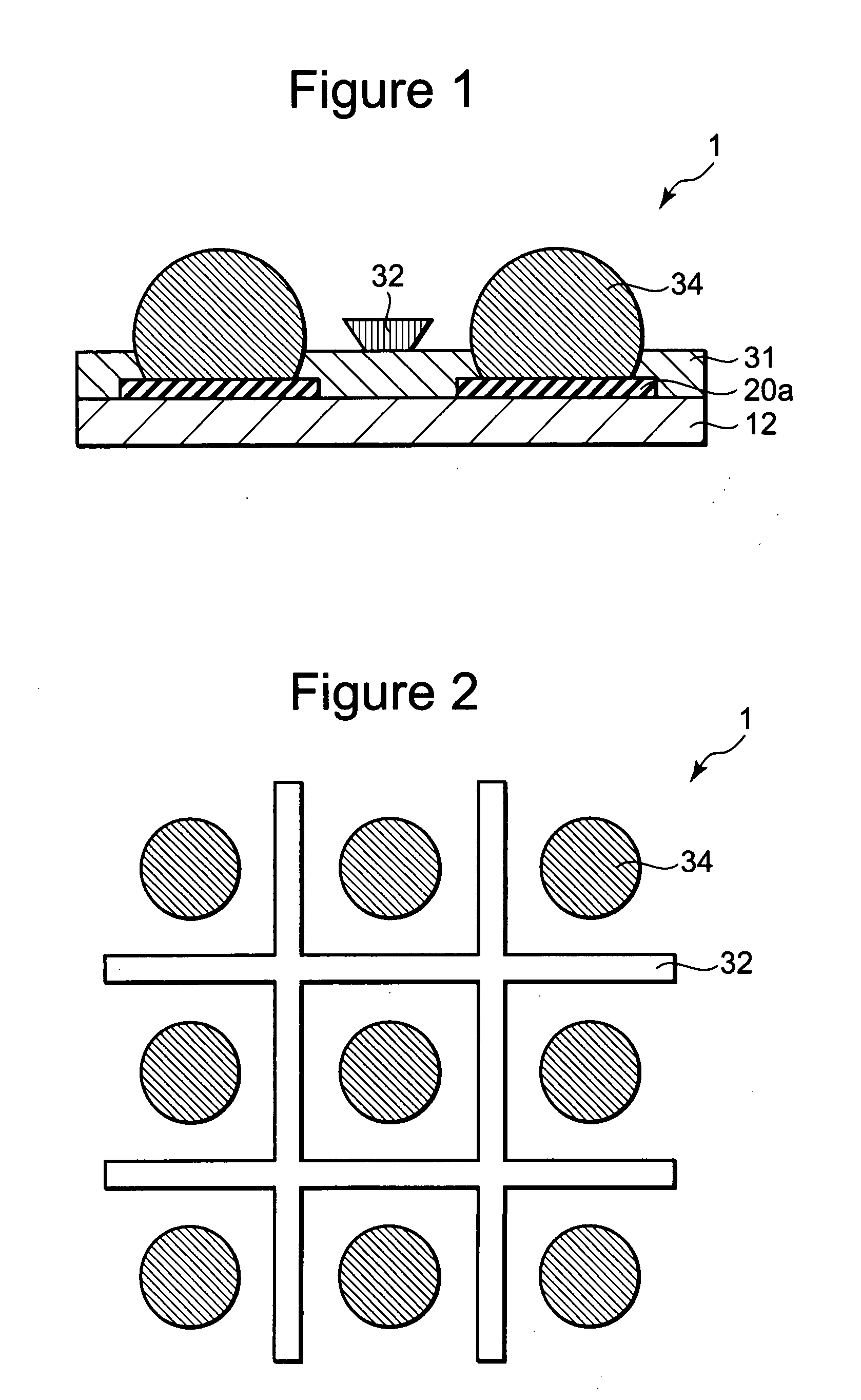

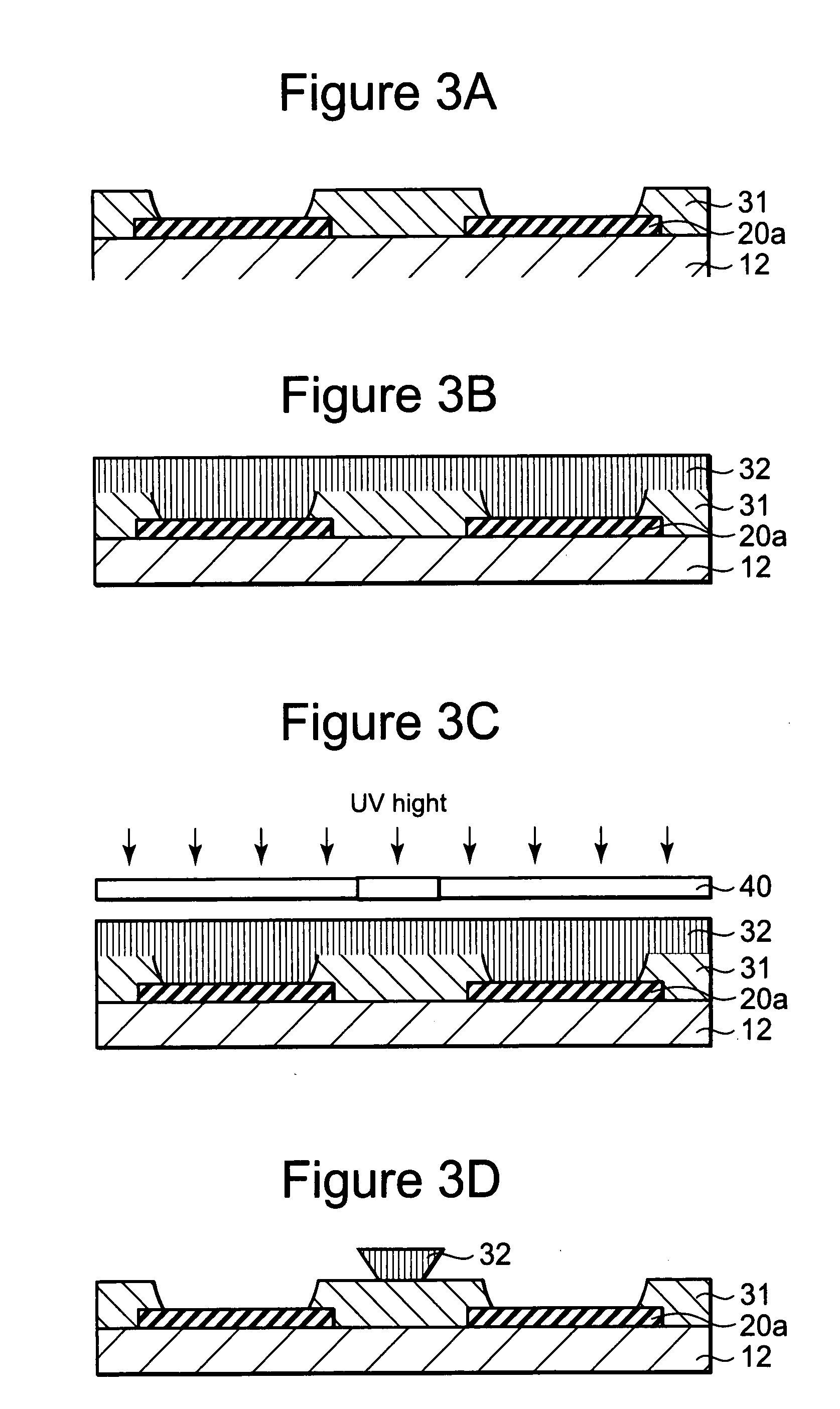

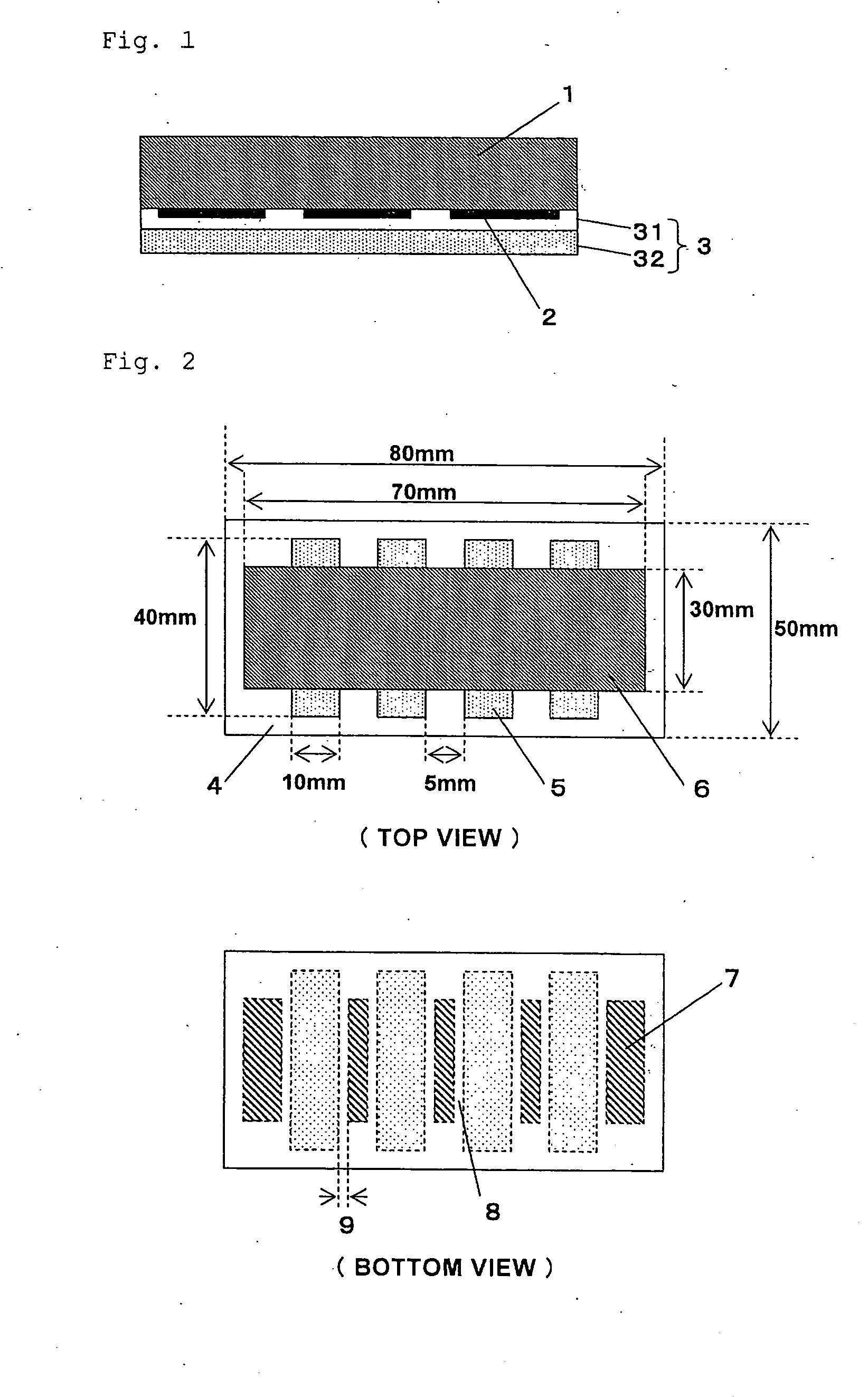

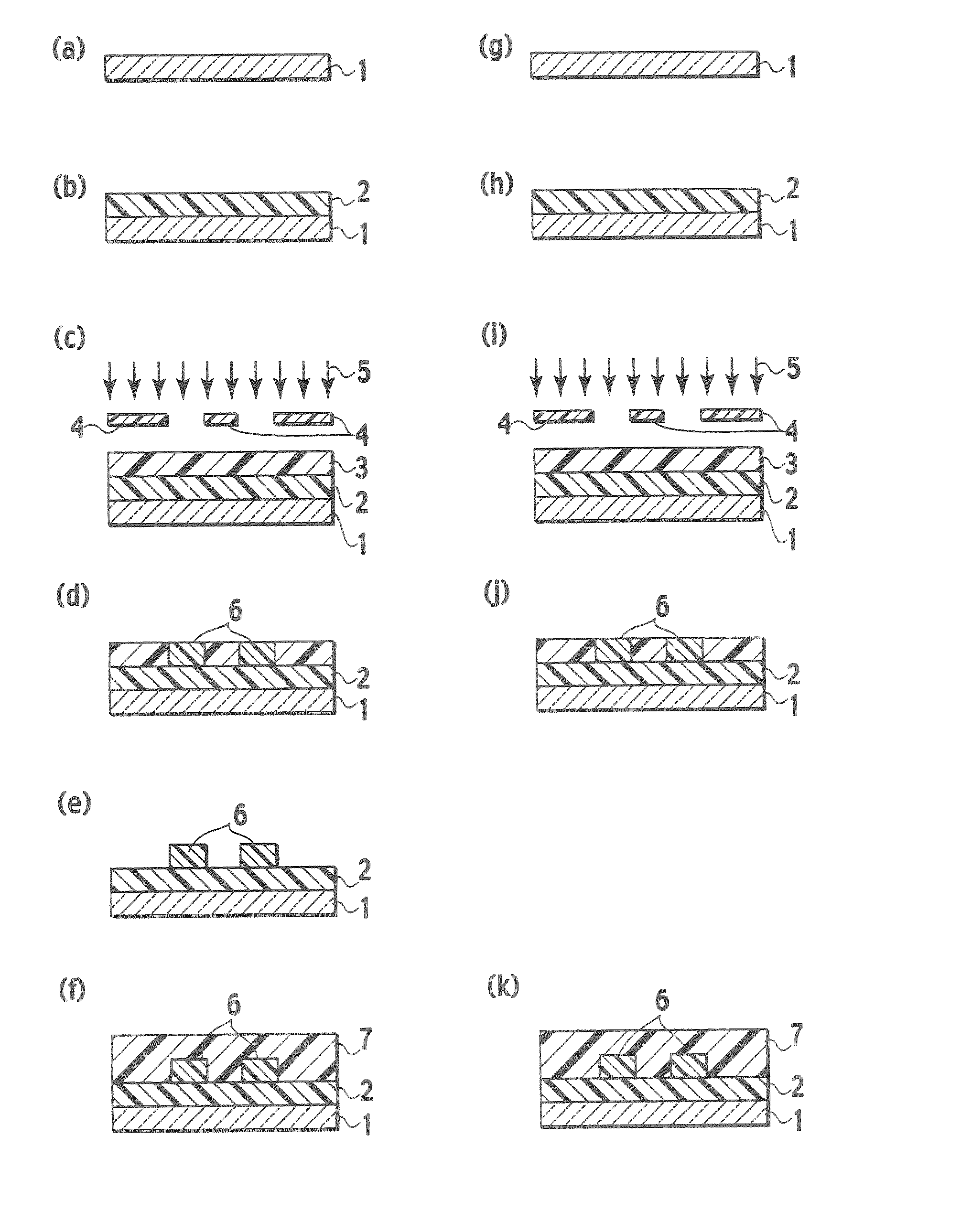

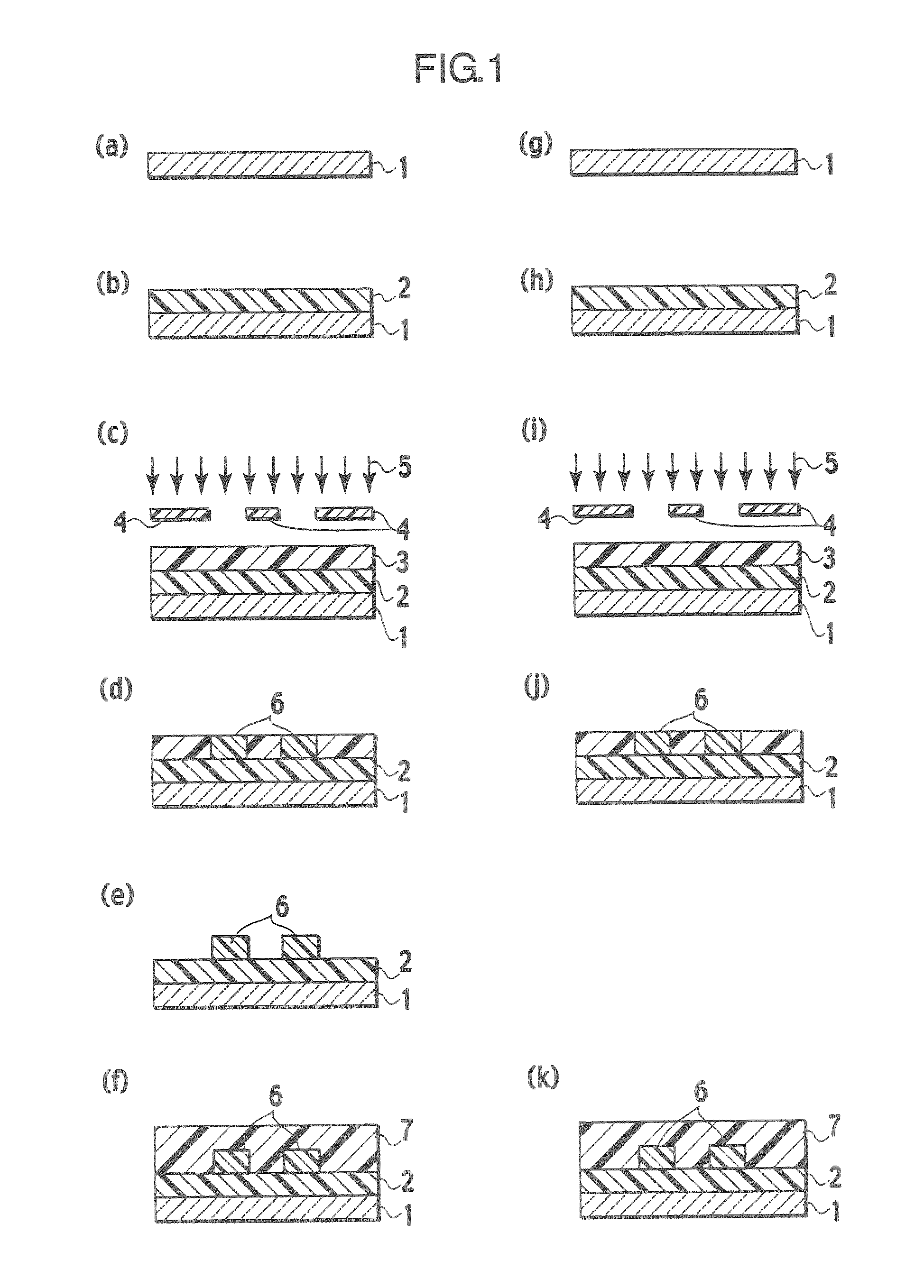

Printed wiring board having plural solder resist layers and method for production thereof

InactiveUS20080135279A1High adhesivenessConstant widthLiquid surface applicatorsSecond resist patternSolder maskResist

A printed wiring board includes: a substrate main body; a solder resist layer provided on the substrate main body and having a first opening in which a part of the solder bump is formed; and a solder resist layer provided on the solder resist layer and having a second opening through which the solder bump is formed. The shape of the second opening is non-analogous to the shape of the first opening when viewed as plane-wise.

Owner:RENESAS ELECTRONICS CORP

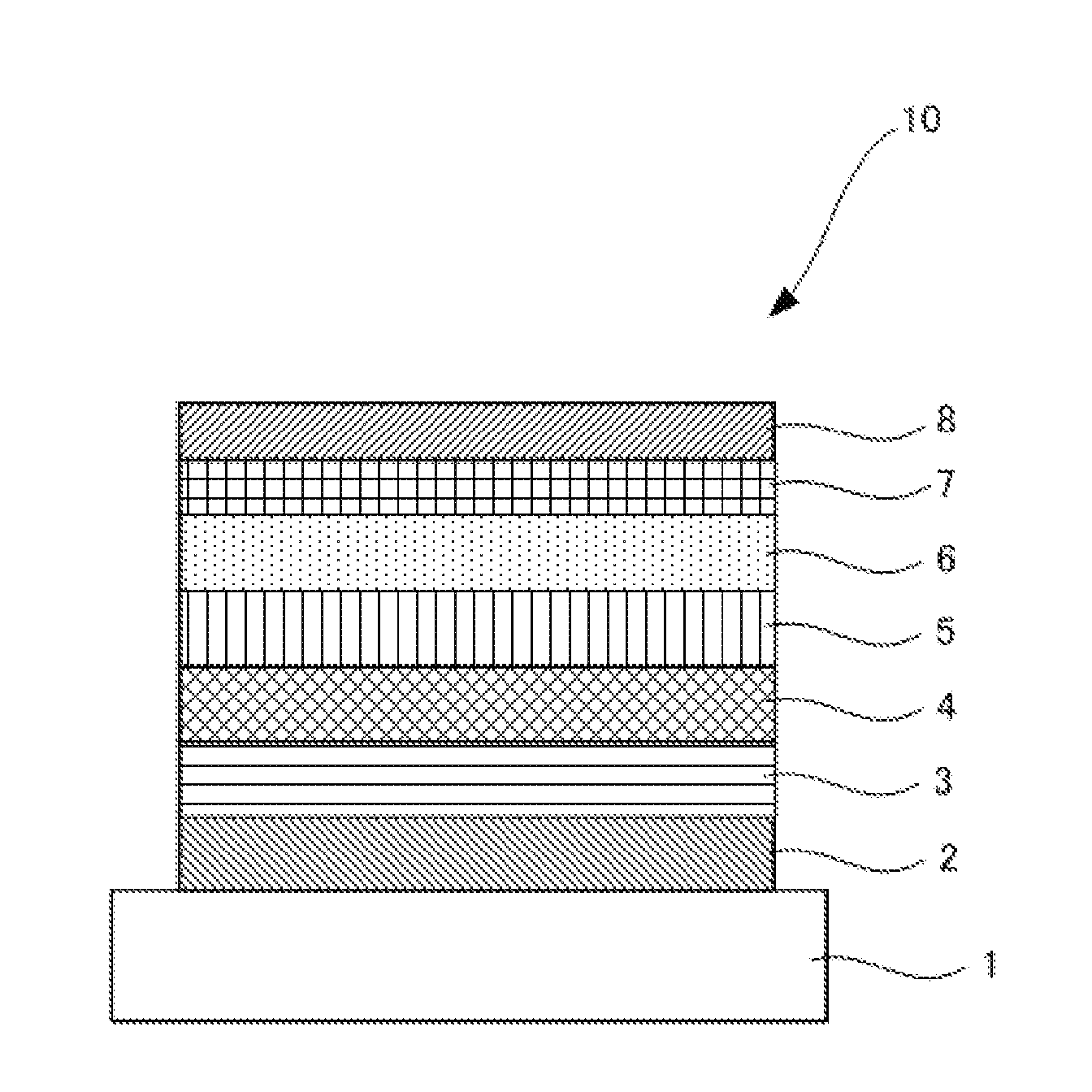

Double-sided pressure-sensitive adhesive sheet and liquid-crystal display

InactiveUS20100021668A1High adhesivenessExcellent peelabilityFilm/foil adhesivesLayered productsLiquid-crystal displaySheet film

The invention relates to a double-sided pressure-sensitive adhesive sheet for use in fixing a liquid-crystal display module unit to a backlight unit in a liquid-crystal display, the double-sided pressure-sensitive adhesive sheet including at least one heat-peelable pressure-sensitive adhesive layer containing heat-expandable microspheres. According to the double-sided pressure-sensitive adhesive sheet of the invention, since the pressure-sensitive adhesive layer has high adhesiveness and a liquid-crystal display module unit can be tenaciously fixed to a backlight unit with the pressure-sensitive adhesive sheet, excellent adhesion reliability can be attained. Furthermore, since this pressure-sensitive adhesive sheet can be easily made peelable by a heat treatment, it has excellent suitability for reworking.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive sheet for solar panel, solar panel using the pressure-sensitive adhesive sheet, and method for manufacturing solar panel using the pressure-sensitive adhesive sheet

InactiveUS20110030756A1High adhesivenessExcellent fittabilityPV power plantsFilm/foil adhesivesPressure sensitiveElectrical battery

A pressure-sensitive adhesive sheet for a solar panel according to the present invention is a pressure-sensitive adhesive sheet for use to seal silicon cells and includes a fluorine-containing resin film base and, on at least one side thereof, a pressure-sensitive adhesive layer. The pressure-sensitive adhesive sheet for a solar panel according to the present invention, when used to seal silicon cells, enables the manufacture of a solar panel with improved productivity and workability, while avoiding problems caused by vacuum hot pressing, such as damage to the wiring and process contamination due to squeezing out of the sealing resin.

Owner:NITTO DENKO CORP

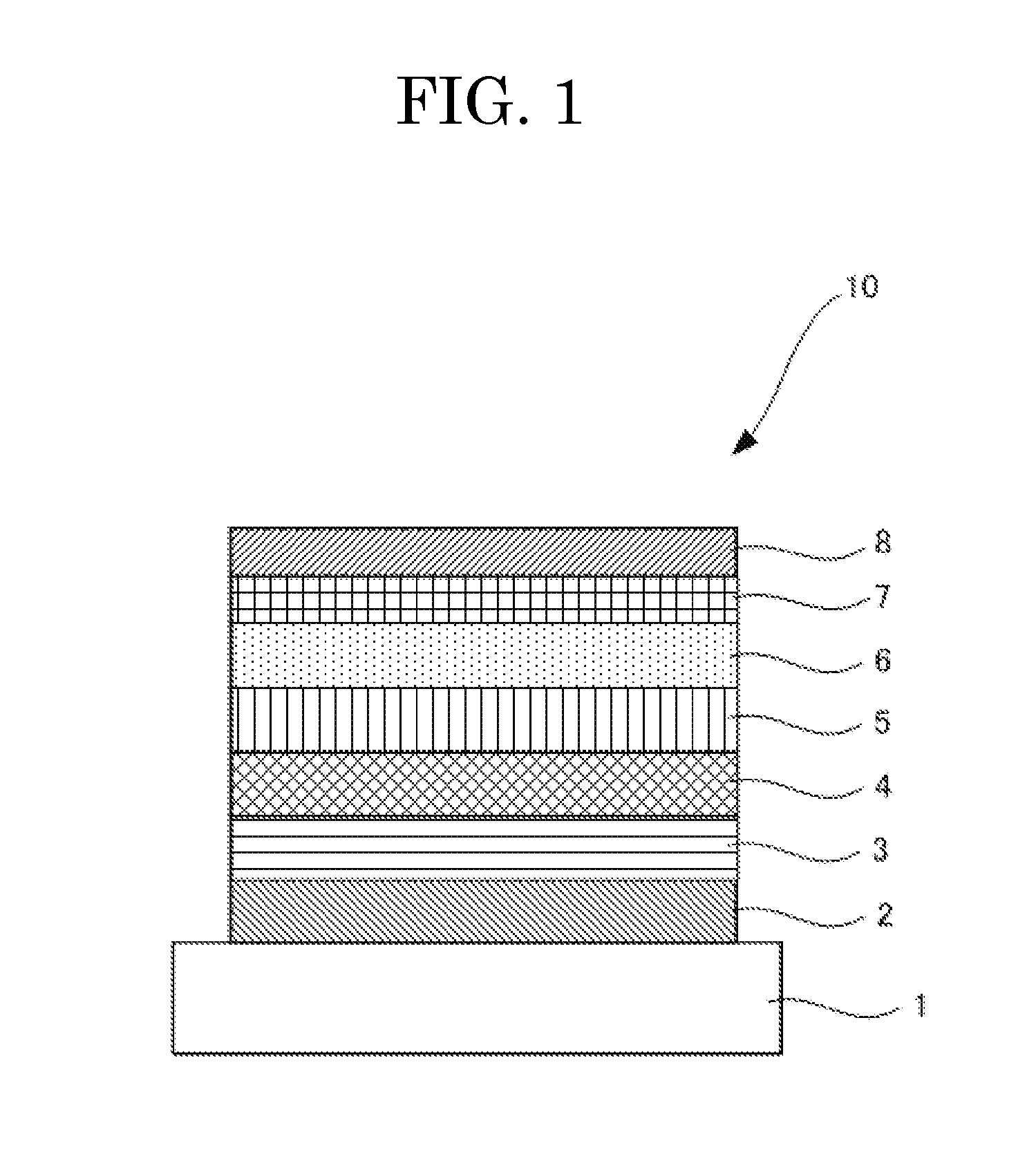

Organic electroluminescent element and method for producing the same

InactiveUS20120126219A1Increased durabilityHigh interlayer adhesivenessSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceOrganic chemistry

An organic electroluminescent element including: a first electrode; at least one organic deposition layer; and a second electrode, the first electrode, the organic deposition layer, and the second electrode being formed in this order, wherein the organic deposition layer satisfies the relationship 0.093<Ra / t<0.340 where Ra denotes a surface roughness of a surface of the organic deposition layer, the surface being at the side of the second electrode, and t denotes a thickness of the organic deposition layer.

Owner:UDC IRELAND

Inkjet ink and inkjet recording method

ActiveUS20120033011A1Excellent stabilityHigh glossinessDuplicating/marking methodsInksWater solubleOrganic solvent

Provided is an inkjet ink comprising at least water, a pigment, a resin, a water-soluble organic solvent, and a surfactant, wherein the resin comprises a copolymer resin synthesized from a monomer that includes a (meth)acrylic monomer, and the copolymer resin has an acid value of not less than 50 mgKOH / g and not more than 200 mgKOH / g, a glass transition temperature (Tg) not less than 20 and not more than 100° C., and a weight-average molecular weight (Mw) not less than 20,000 and not more than 100,000, and as a result, a high-quality image is formed in that abrasion resistance and adhesiveness on a non-absorptive recording medium are high, glossiness is high, and there is no ink mixing, and ejection performance is good and recovery through maintenance is excellent. Also provided is an inkjet recording method that uses the same.

Owner:KONICA MINOLTA IJ TECHNOLOGIES INC

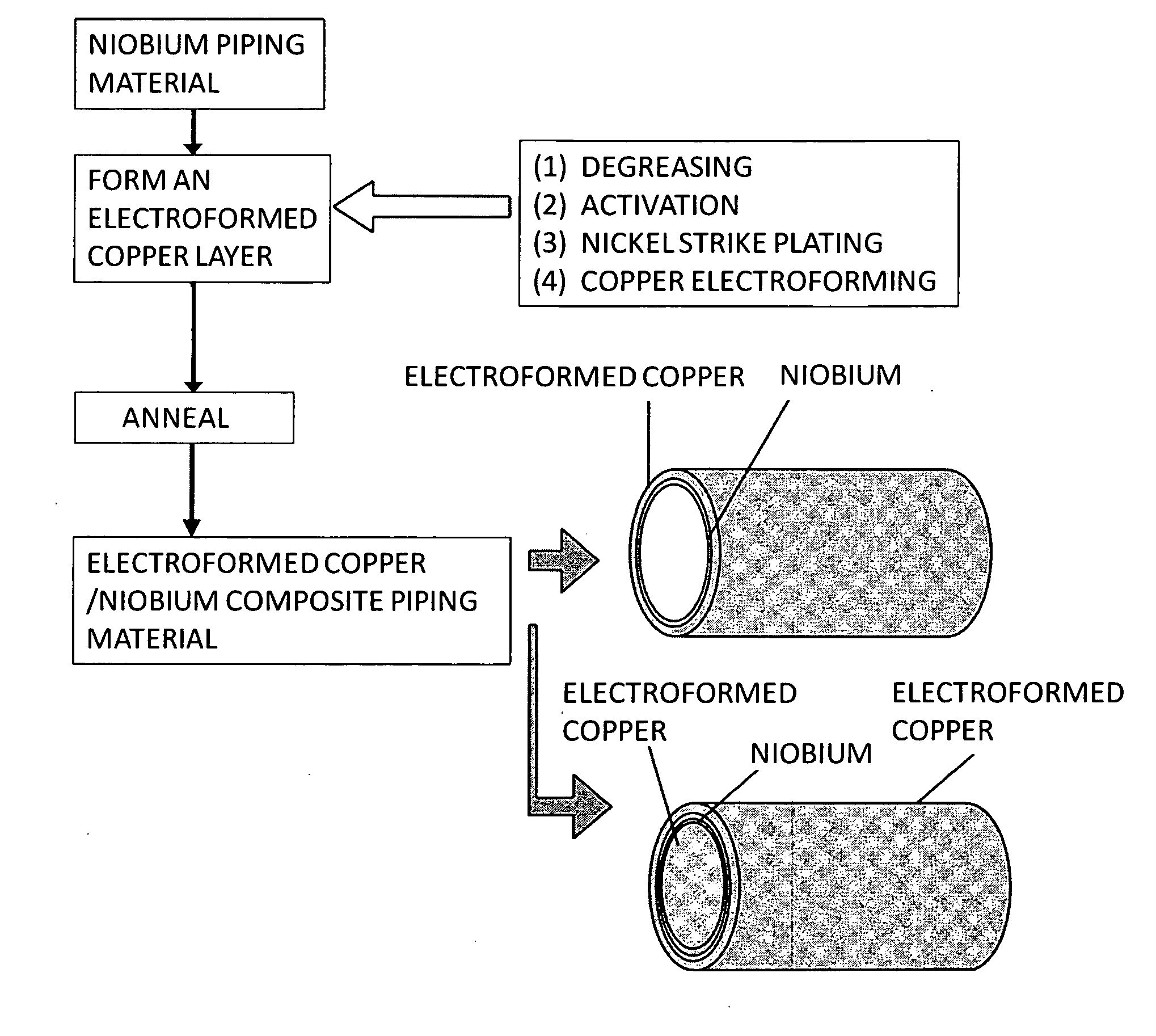

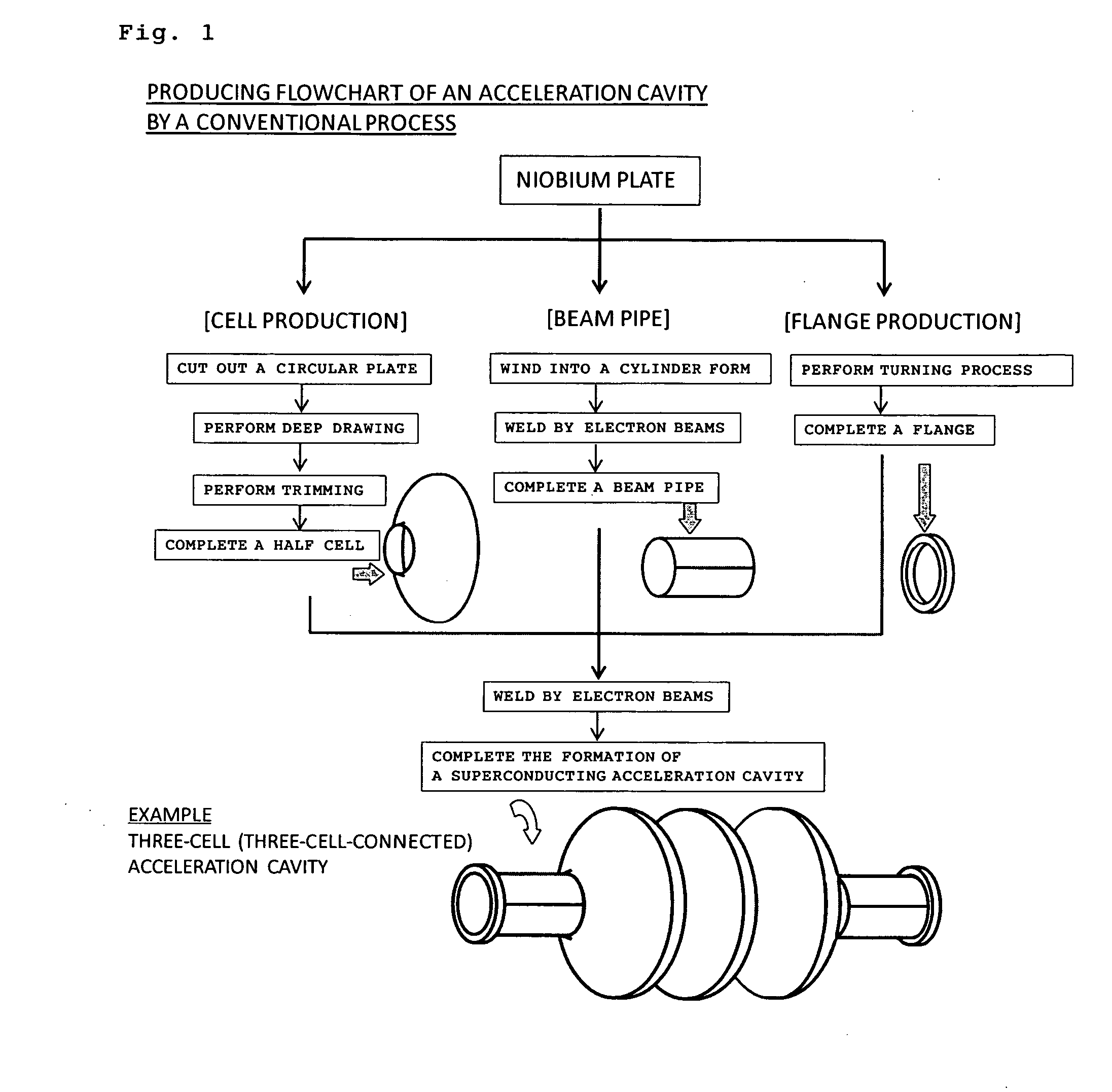

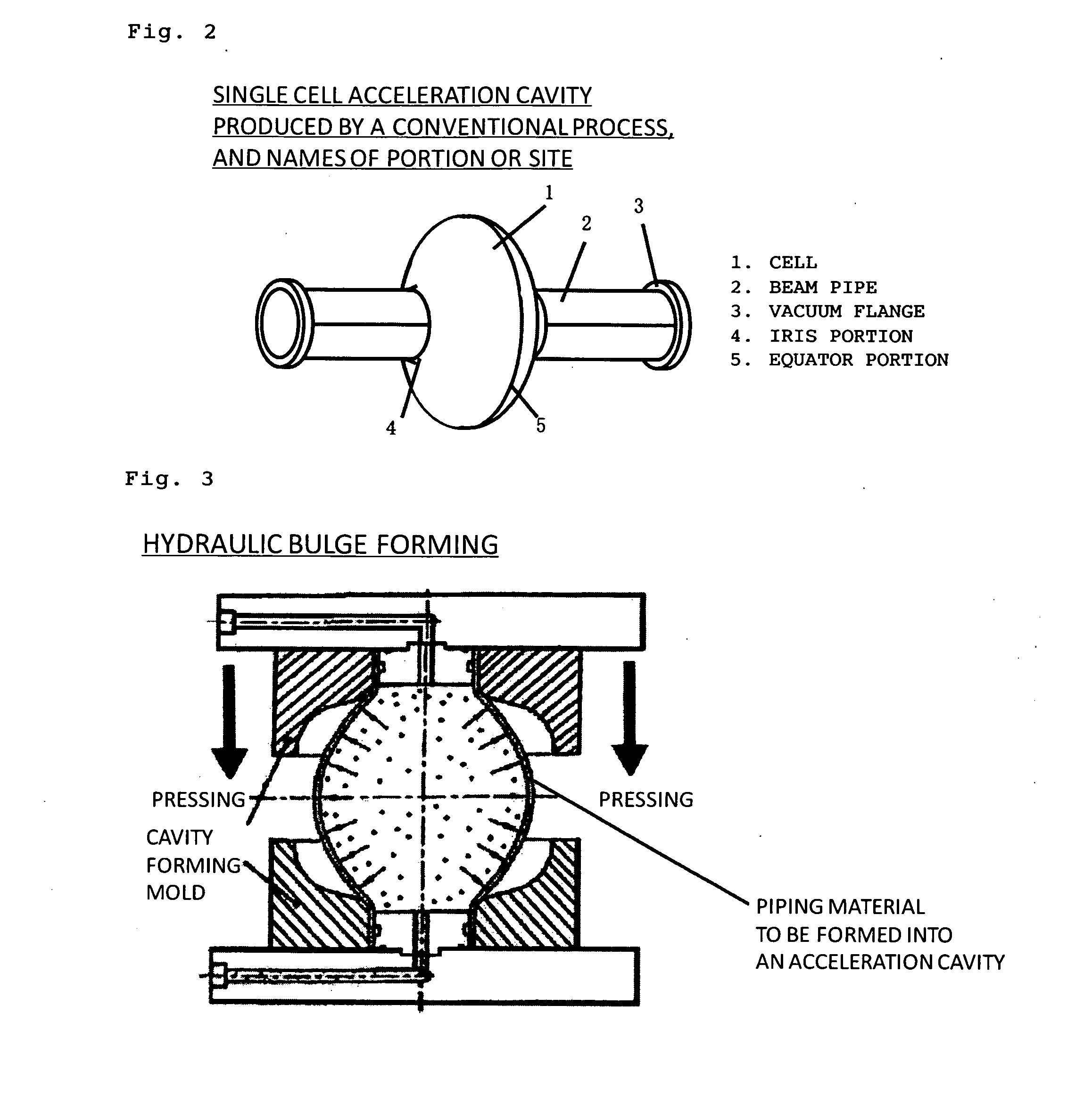

Copper/niobium composite piping material produced by copper electroforming, process for producing the same and superconducting, acceleration cavity produced from the composite piping material

InactiveUS20100066273A1High adhesivenessSufficient resistanceBlade accessoriesTransit-time tubesPipingMetallic Nickel

In order to produce industrially advantageously an electroformed copper / niobium composite piping material wherein an electroformed copper layer and a niobium thin piping material are strongly bonded to each other, the electroformed copper / niobium composite piping material can be produced by coating any one or each of the outer peripheral surface and the inner peripheral surface of a niobium thin piping material with a nickel thin film, coating the surface of the nickel thin film with copper by electroforming, and subsequently annealing the resultant.

Owner:HIGH ENERGY ACCELERATOR RESEARCH ORGANIZATION +1

Protective film for laser processing and processing method using the same

InactiveUS20100294423A1High adhesivenessPrevent carbonization and adherenceLamination ancillary operationsLaminationMeth-Optoelectronics

Disclosed is a protective film for laser processing, which has high adhesiveness and is capable of protecting an object to be processed with a uniform thickness, while being prevented from carbonization / adhesion due to thickness variations. In addition, this protective film for laser processing is free from the problem of waste water contamination when it is removed. Also disclosed is a laser processing method using such a protective film. Specifically disclosed is a protective film for laser processing, which contains a (meth)acrylate copolymer and a radiation-polymerizable (meth)acrylate having an unsaturated bond.

Owner:DENKA CO LTD

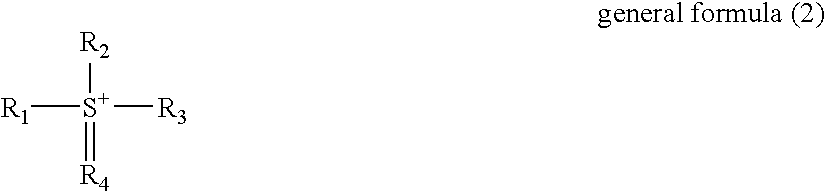

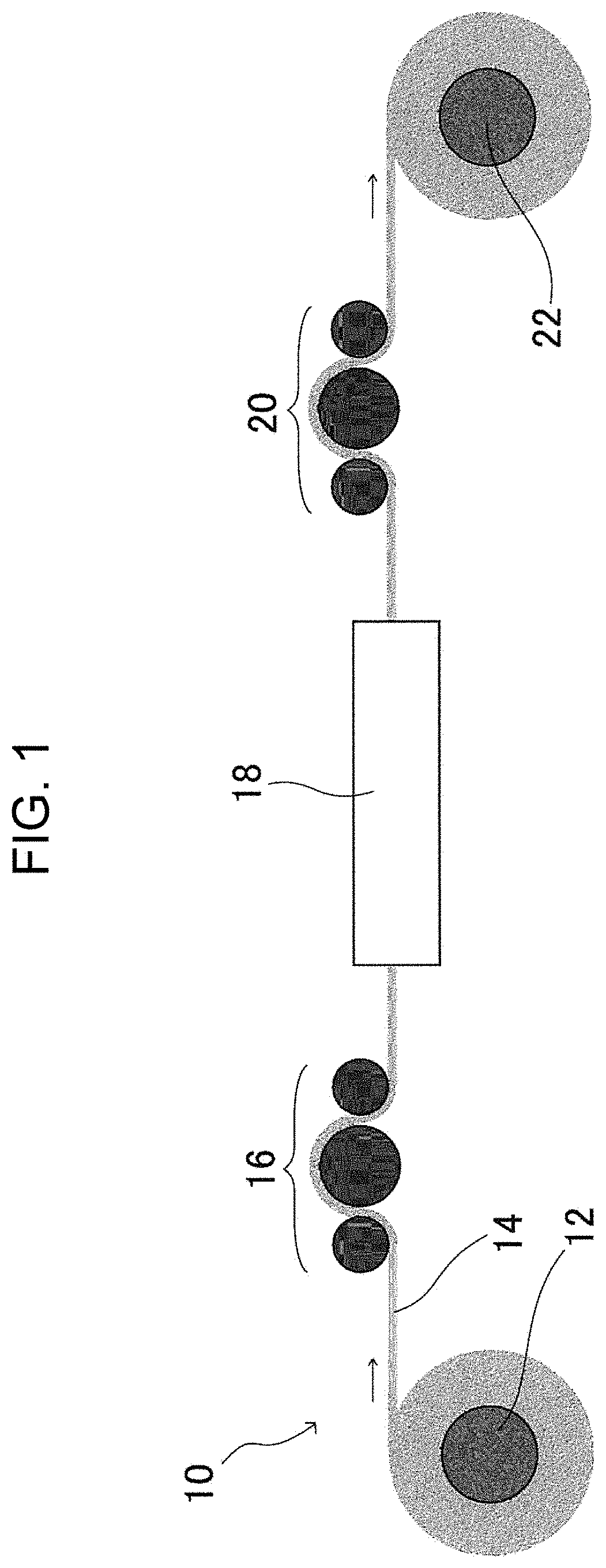

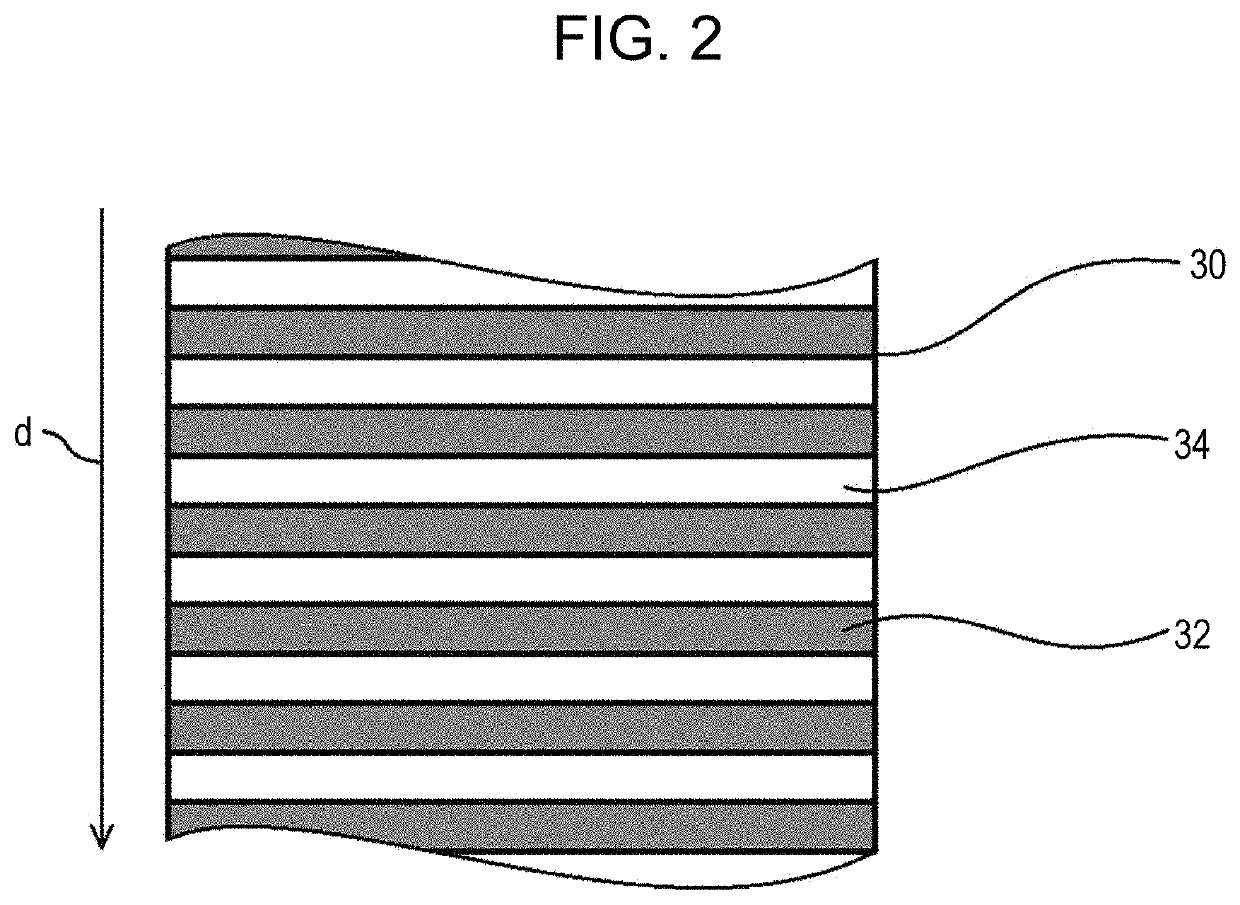

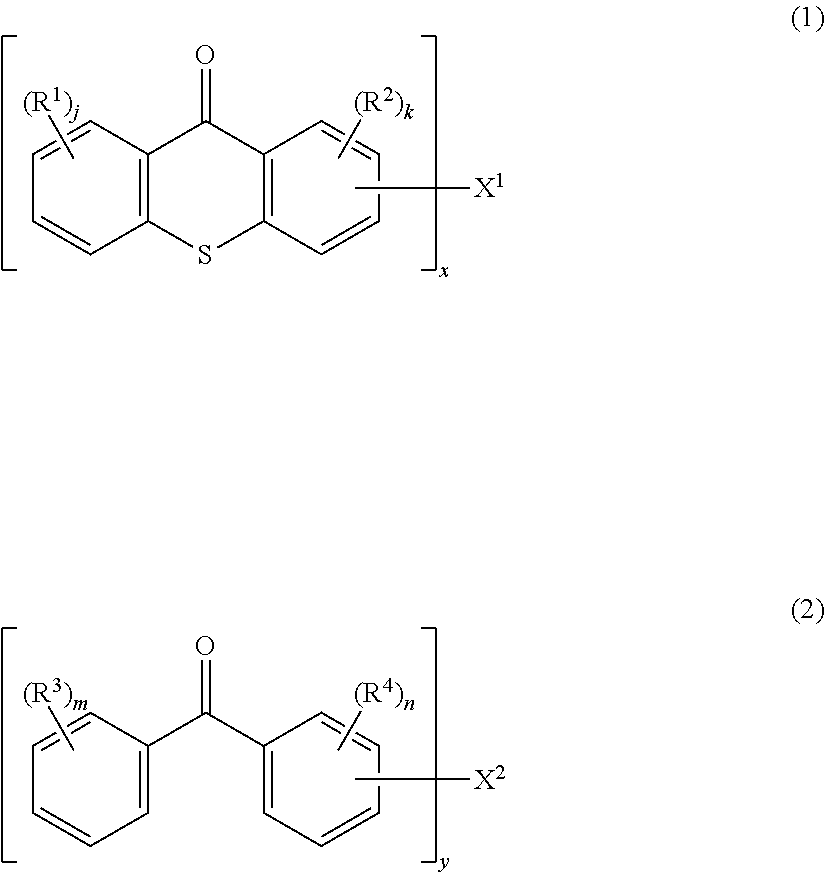

Polymerizable Composition

InactiveUS20080044149A1Easy curingPromote formationCladded optical fibreLamination ancillary operationsSulfoniumIrradiation

According to the invention, there is provided a polymerizable composition which is cured by irradiation with a small amount of energy line, and offers excellent adhesiveness and transparency. The composition comprises an acid generator (A) containing a sulfonium cation and a borate anion represented by the following general formula (1), and a cationic polymerizable compound (B). General formula (1) [BYmZn]− general formula (1) Wherein, Y represents a fluorine or chlorine atom, Z represents a phenyl group substituted with two or more groups selected from a fluorine atom, cyano group, nitro group, and trifluoromethyl group, m represents an integer from 0 to 3, n represents an integer from 1 to 4, and m+n=4.

Owner:TOYO INK SC HOLD CO LTD

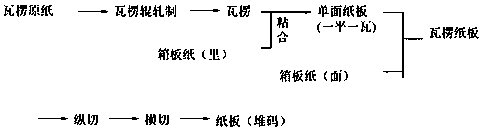

Production process of waterproof corrugated paperboard

InactiveCN106363960AHigh adhesivenessGood crashworthinessMechanical working/deformationNon-macromolecular adhesive additivesCardboardBonding strength

The invention relates to the technical field of paperboard processing, in particular to a production process of a double-faced waterproof corrugated paperboard. The production process comprises the steps that firstly, glue is prepared; secondly, body paper is preheated, and the preheated body paper is attached to a single facer for production after passing through a paper guide roller from a paper support; thirdly, single-faced paperboards produced through the single facer in the second step are conveyed to cross a bridge, and then preheated; fourthly, the single-faced paperboards in the third step are sequentially pasted with glue A and glue B, and bonded to form the corrugated paperboard; and fifthly, the corrugated paperboard bonded in the fourth step is heated and dried, and then the surfaces of the two sides of the heated and dried corrugated paperboard are coated with super hydrophobic and oileophobic interface coating. The bonding degree of the glue used in the production process of the double-faced waterproof corrugated paperboard is high, the waterproof and impact-proof performance is good, and the excellent-performance glue is adopted in cooperation of the super hydrophobic and oileophobic interface coating, so that the corrugated paperboard produced through the process is good in waterproof performance and high in bonding strength.

Owner:KUNSHAN MINGPENG PAPER IND

Fuel cell, fuel cell stack, and method for manufacturing fuel cell

ActiveUS20090214917A1Improve sealabilityHigh adhesivenessFinal product manufacturePrimary cellsCross-linkFuel cells

A fuel cell includes a membrane electrode assembly (MEA) having an electrolyte membrane and a pair of electrodes arranged on both sides of the electrolyte membrane in the thickness direction, a pair of frames having a frame shape and holding an outer periphery portion of the electrolyte membrane, a pair of gas diffusion layers arranged inside the pair of frames and on both sides of the MEA in the thickness direction, and a gasket covering at least a part of the pair of frames. The fuel cell further includes a first cross-linking adhesive member formed of rubber which includes a membrane accommodating portion having an indented shape for accommodating the outer periphery portion of the electrolyte membrane and a first intermediate portion interposed between the pair of frames and which is subjected to cross-linking adhesion with the outer periphery portion of the electrolyte membrane and the pair of frames.

Owner:SUMITOMO RIKO CO LTD

Pressure-sensitive adhesive sheet

ActiveUS20060116455A1High adhesivenessReduce occurrenceFilm/foil adhesivesSynthetic resin layered productsPressure sensitiveChemistry

A pressure-sensitive adhesive sheet contains at least a pressure-sensitive adhesive layer containing an acrylic pressure-sensitive adhesive containing an acrylic polymer composition containing an acrylic polymer as a main component and a tackifier containing a tackifying resin as a main component, wherein reflection rate and attached amount in the fogging test in accordance with German Industrial Standard DIN 75201 are 70% or more and 2.0 mg or less, respectively. In the acrylic pressure-sensitive adhesive which forms the pressure-sensitive adhesive layer, a ratio of components having a molecular weight of 300 or less is preferably 4.2% by weight or less based on the total amount of solid matter of the acrylic pressure-sensitive adhesive. Furthermore, in the tackifying resin in the tackifier, a ratio of components having a molecular weight of 300 or less is suitably 4.2% by weight or less based on the total amount of solid matter of the tackifying resin.

Owner:NITTO DENKO CORP

Production method of corrugated board

InactiveCN110356050AReasonable process designReduce manufacturing costMechanical working/deformationNon-macromolecular adhesive additivesEconomic benefitsPulp and paper industry

The invention provides a production method of a corrugated board. The production method comprises the following steps: step I, making glue; step II, preheating a corrugated medium, and then rolling the preheated corrugated medium by a corrugated roller to obtain corrugated paper; step III, preheating inside paper and face paper to be hung on a paper rack, sending the corrugated paper to a gluing machine for gluing through a transfer device, pressing the face paper and the inside paper on the corrugated paper, and mounting the corrugated board in the gluing machine; step IV, drying the corrugated board for sizing, and then cooling; step V, separating paper and pressing lines according to the required specification, and then cutting the corrugated board by a slitting machine and a crosscutting machine according to press lines; and step VI, stacking the cut corrugated boards, and storing the corrugated boards in a warehouse. Compared with the prior art, the production method has the following technical effects that the corrugated board prepared by the production method has a reasonable process design and low production cost. The gluing degree of the used glue in the production methodis high, the strength of the corrugated board is high, and the corrugated board has a good economic benefit and a good use effect.

Owner:南京市高淳包装材料厂

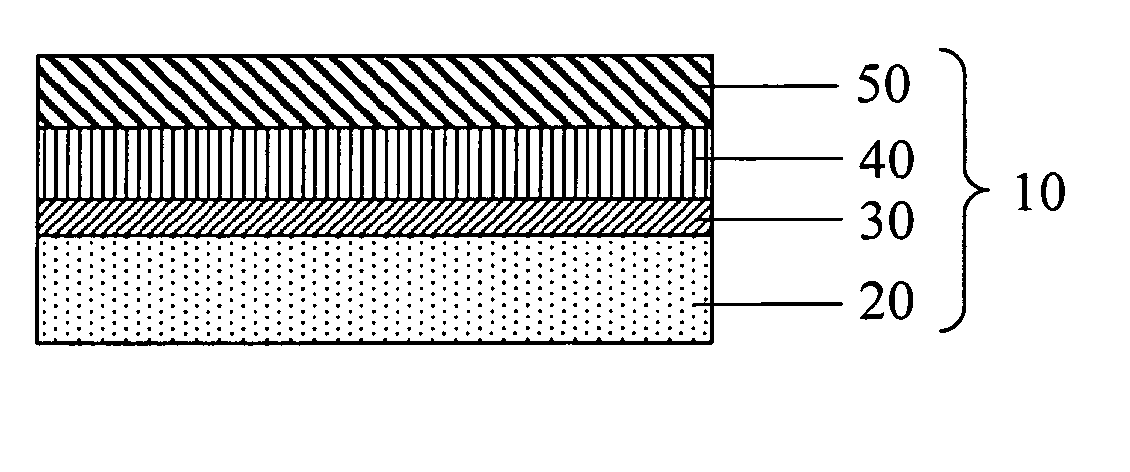

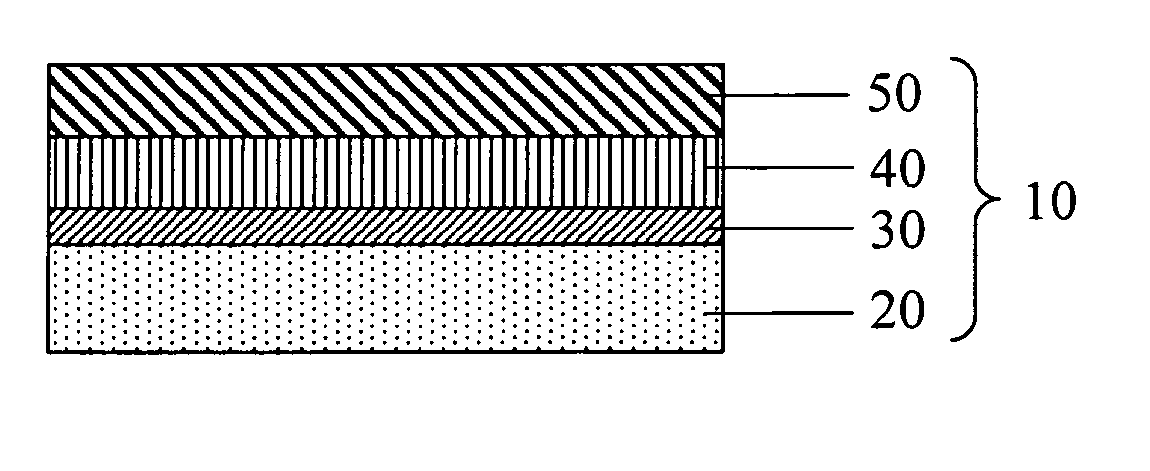

Water-based hot-foam adhesive panel

InactiveUS8574698B2High adhesivenessImprove stabilitySynthetic resin layered productsElectrical equipmentWater basedSolvent free

An environmentally friendly water-based heat-expandable adhesive panel, having high adhesiveness and containing solvent-free resins, comprises a substrate layer functioning as a base layer, a primer layer coated on the substrate layer and a heat-expandable layer coated on the primer layer, which is for use in an electronic or plastic component processing process to adhesively fix electronic or plastic components in place temporarily and separate, upon completion of the processing process and commencement of a component-reactivating process, the components from the water-based heat-expandable adhesive panel by heating the water-based heat-expandable adhesive panel at a fixed temperature for a specific period of time, so as to reduce volatile organic compound (VOC) emissions and effectuate environmental protection.

Owner:NANYA PLASTICS CORP

Ink-jet recording head producing method

InactiveUS20070202261A1Improve uniformityHigh adhesivenessPretreated surfacesCoatingsRecording headWater soluble

A method of producing an ink-jet recording head, comprises steps of: coating a coating liquid containing an aqueous dispersion of a fluororesin and water-soluble polyamidoimide onto at least an ink jetting surface of the ink-jet recording head; and thereafter, conducting a heat treatment onto the coating layer formed on the ink jetting surface so that an ink repelling layer is formed on the ink jetting surface.

Owner:KONICA MINOLTA INC

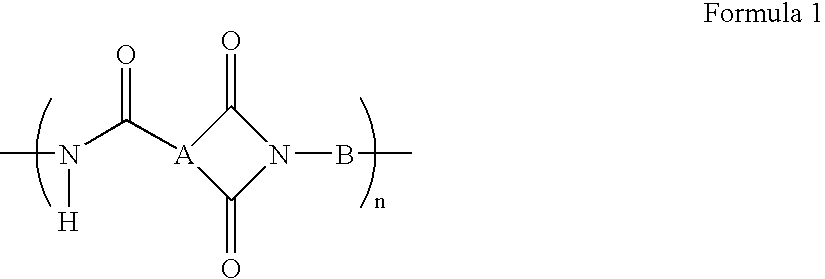

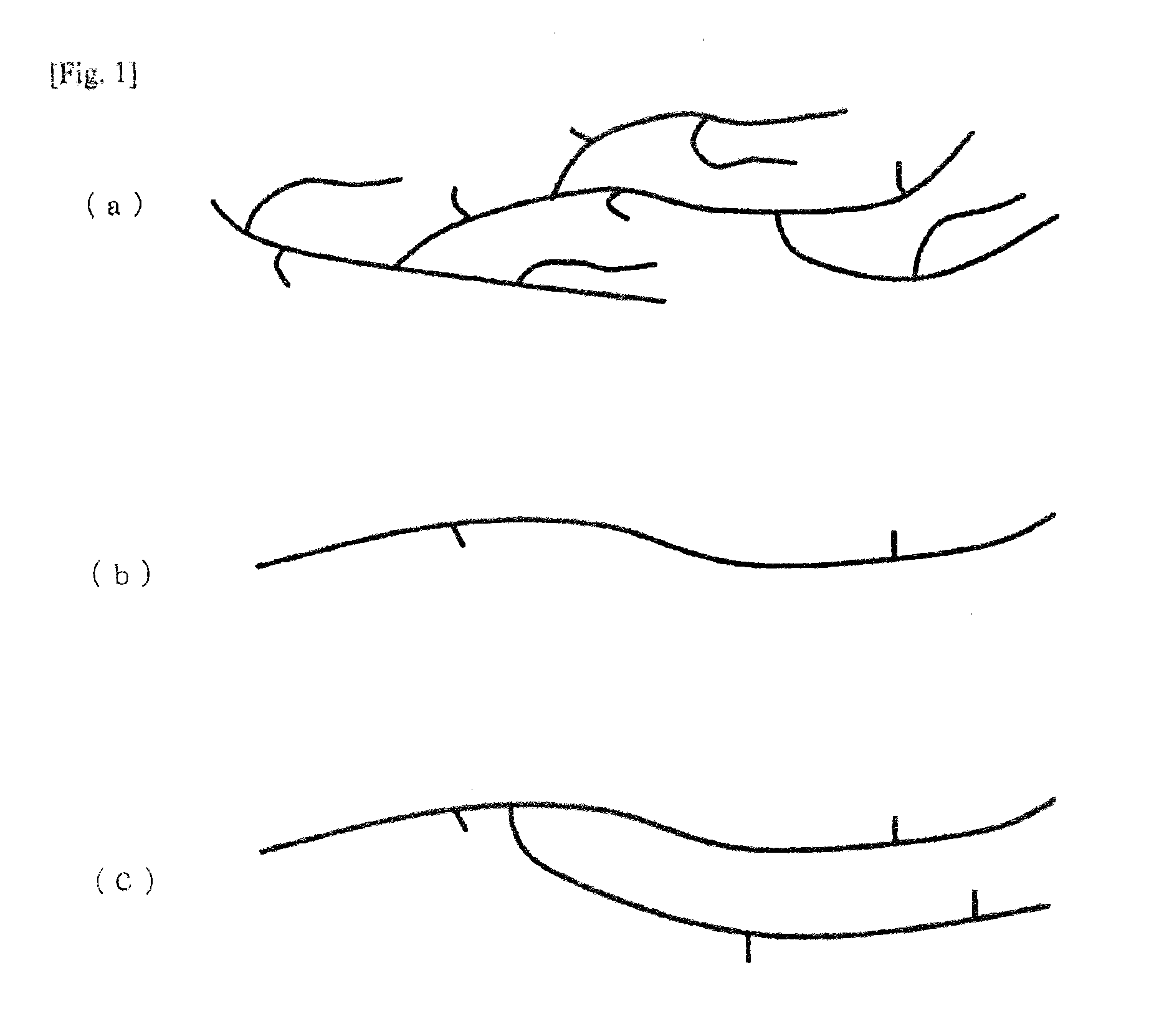

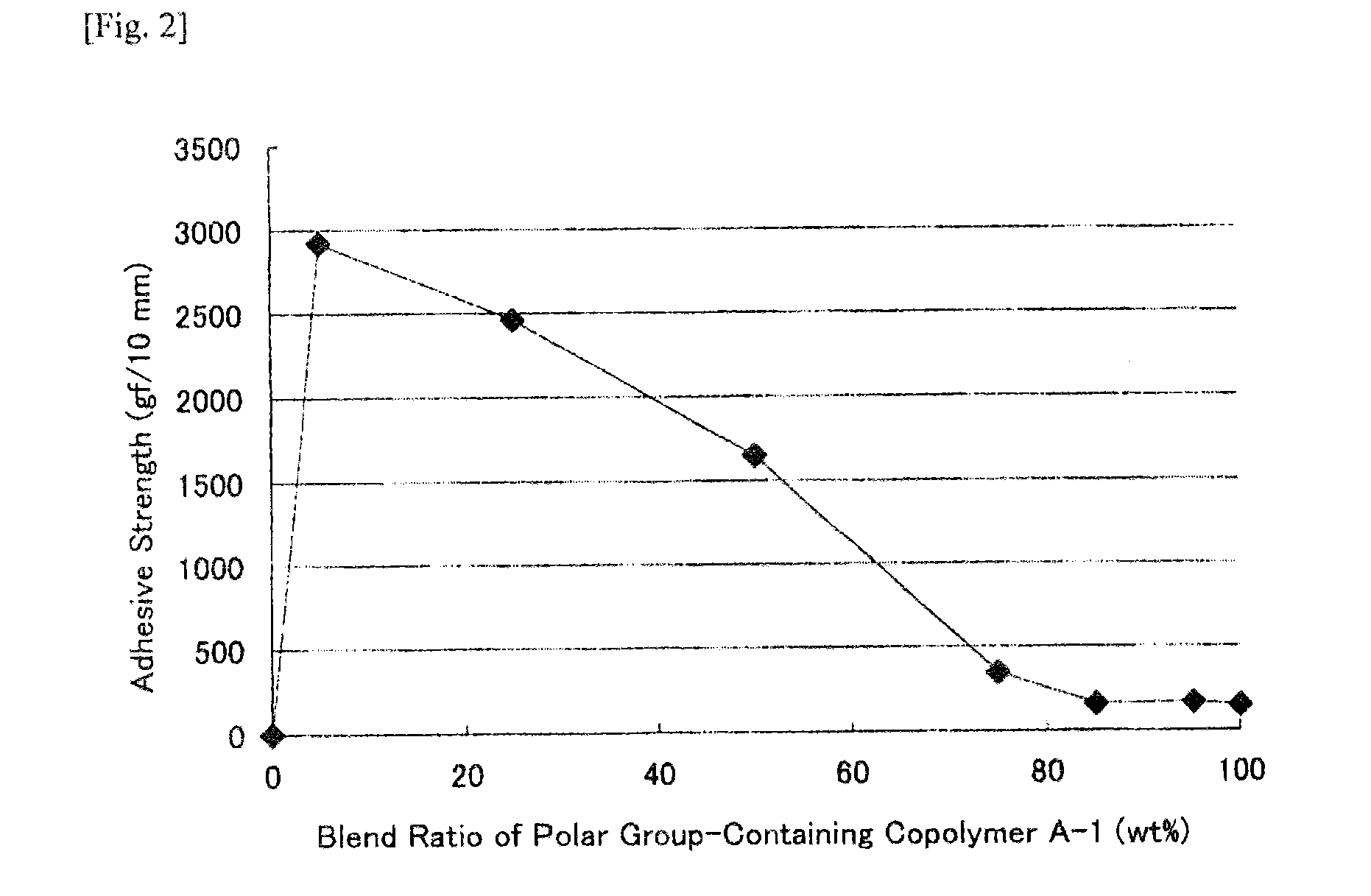

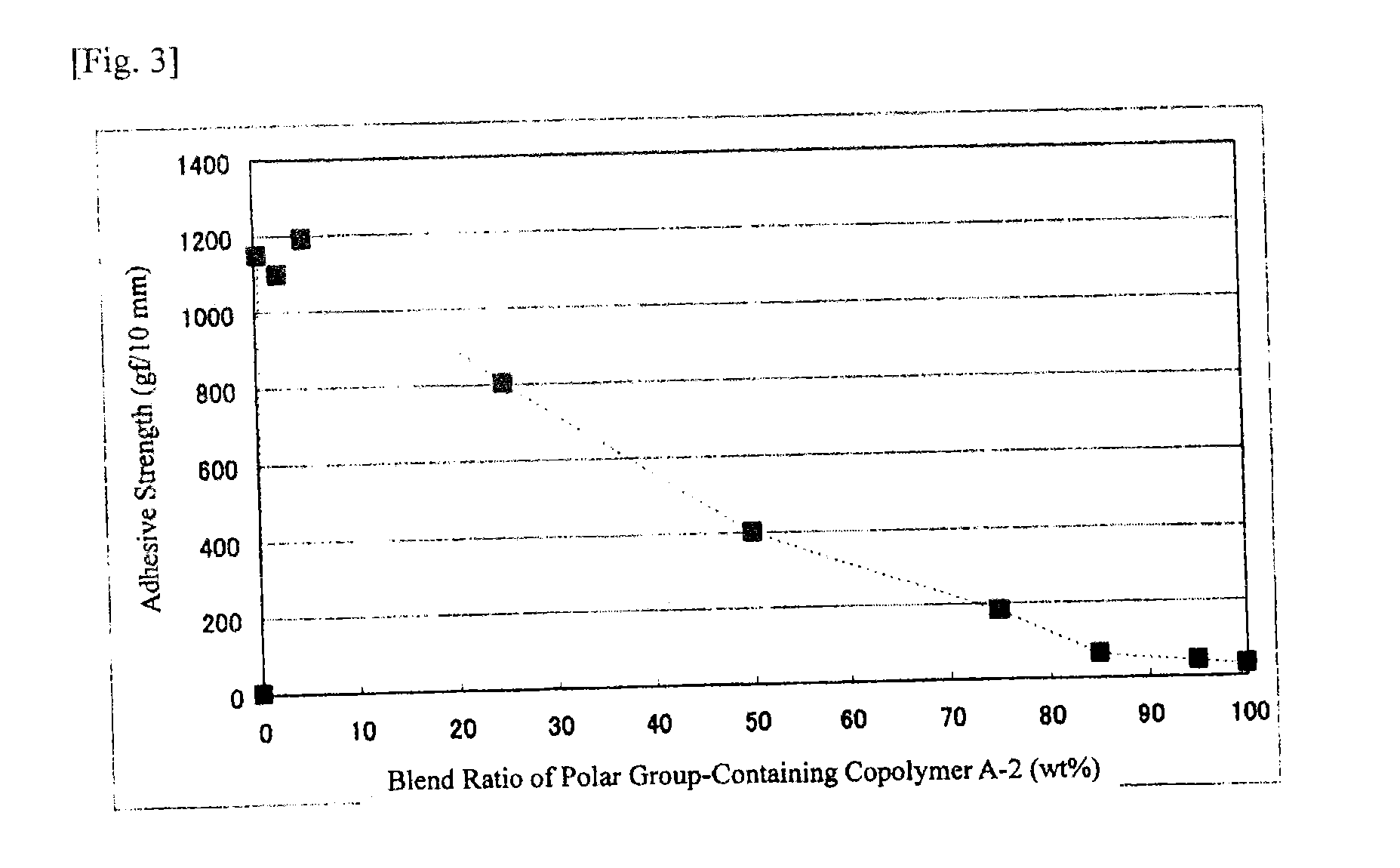

Polar group-containing olefin copolymer, multinary polar olefin copolymer, olefin resin composition, and adhesive material, laminate, and other application products using same

InactiveUS20150004344A1Increase stickinessImprove adhesionAdhesive articlesBottlesNorborneneCarboxylic group

The present invention relates to a polar group-containing olefin copolymer (A′) which is produced through polymerization using a transition metal catalyst, which has a weight-average molecular weight falling within a specific range and which contains a polar group-containing monomer within a specific range; a multinary polar olefin copolymer (A″) indispensably containing a polar monomer component that has a norbornene skeleton and a carboxyl group or an acid anhydride group and having three or more types of monomer units; and a resin composition (C) containing a specific amount of a polar group-containing olefin copolymer (A) and a specific amount of an olefin resin (B).

Owner:JAPAN POLYETHYLENE CORP +1

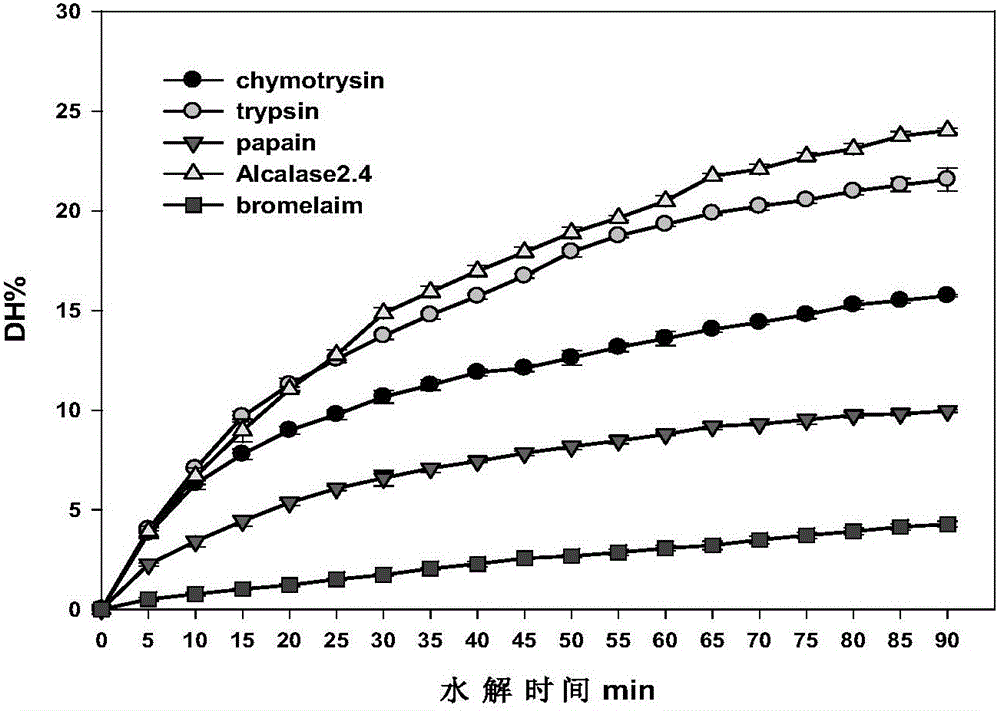

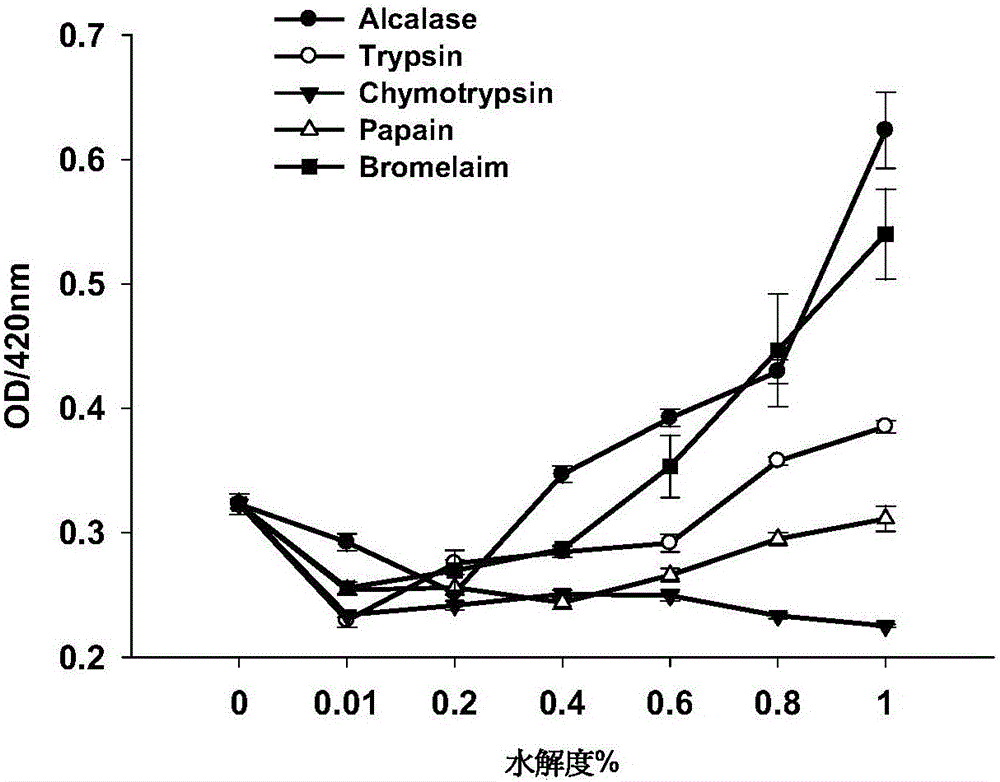

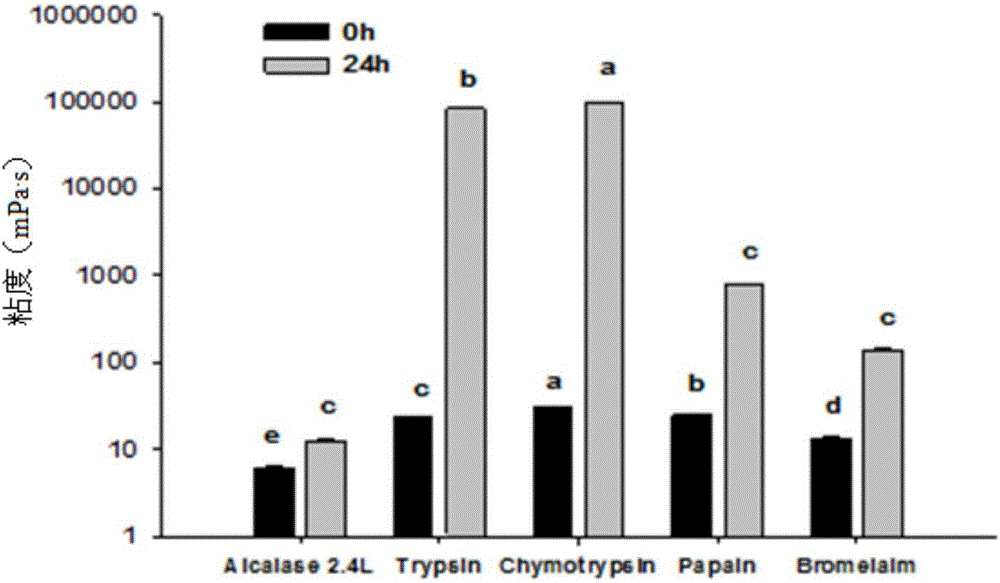

Preparation method of soluble polymers prepared by compound enzyme modified whey protein

InactiveCN105918611AHigh viscosityImprove gelationAnimal proteins working-upWhey proteinRoom temperature

The invention discloses a preparation method of soluble polymers prepared by compound enzyme modified whey protein and belongs to the technical field of protein preparations. The invention aims to solve the technical problems that viscosity changes of existing enzyme modification induced gel are not obvious or slow in growth speed with the prolonging of the refrigerating time and gelling ability is poor, so that the gel is not suitable for application. The method comprises the following steps: whey protein solution is stirred and pre-heated, protease is added for hydrolyzing, after being hydrolyzed, the hydrolyzed whey protein is sealed with a preservation film, the sealed hydrolyzed whey protein is heated instantly to enable the enzymes to be inactivated, the heated hydrolyzed whey protein is cooled with water to 50 DEG C, 5.0 U / g of mTGase is added, the mixture is reacted for 1 h, the mixture is heated to 85 DEG C for 5 min to enable the enzyme to be inactivated, and the obtained sample is cooled to a room temperature to obtain the soluble polymers. The whey protein soluble polymers produced by the method are transparent in appearance, suitable in viscosity, easy to apply, stable and high in gel properties.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

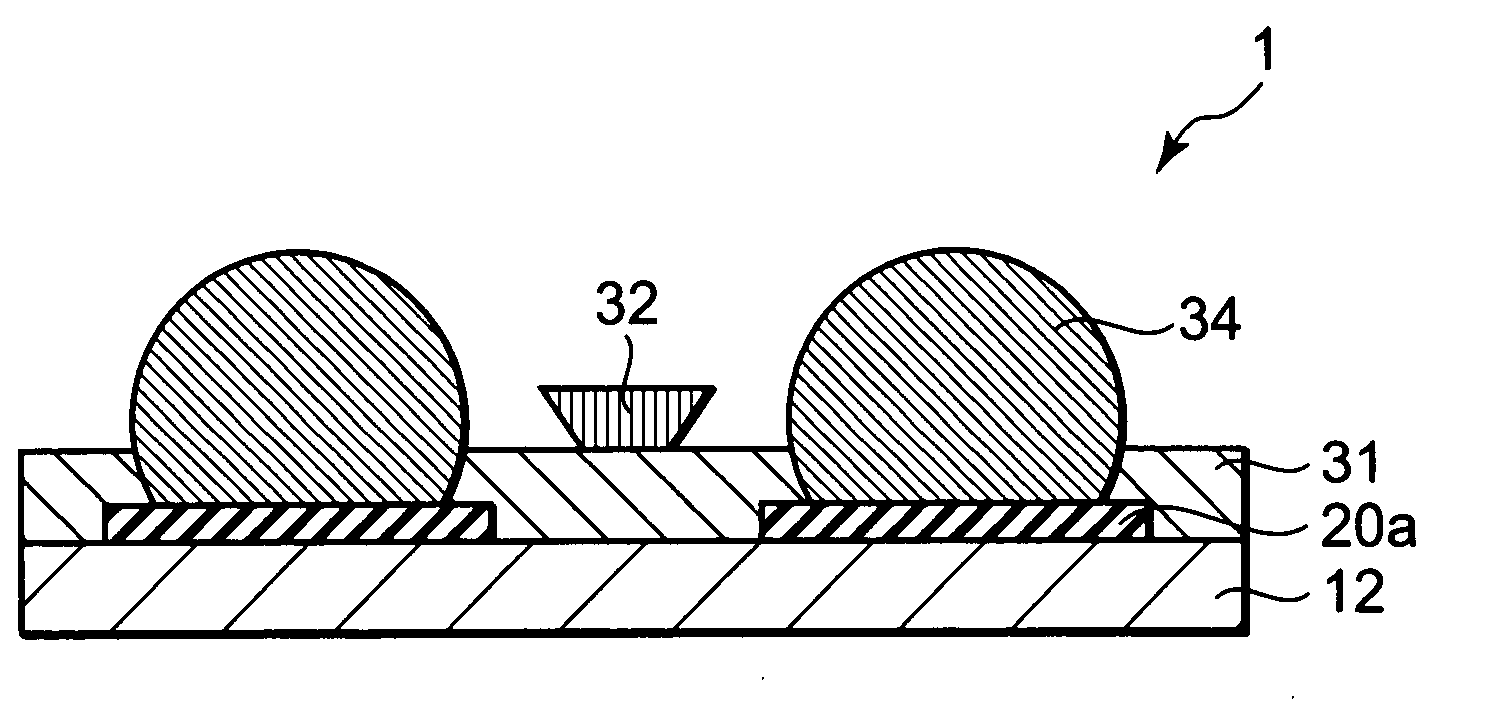

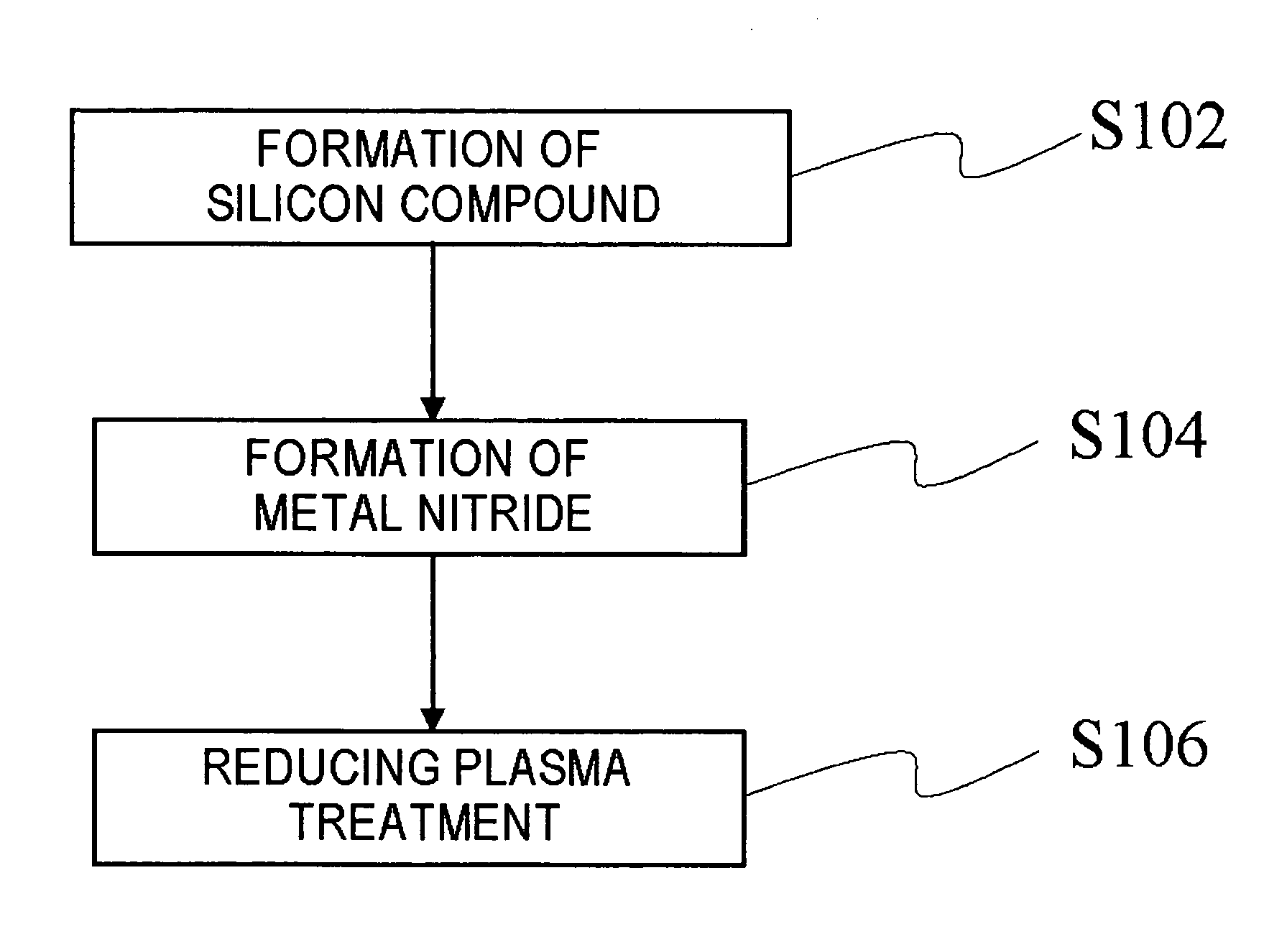

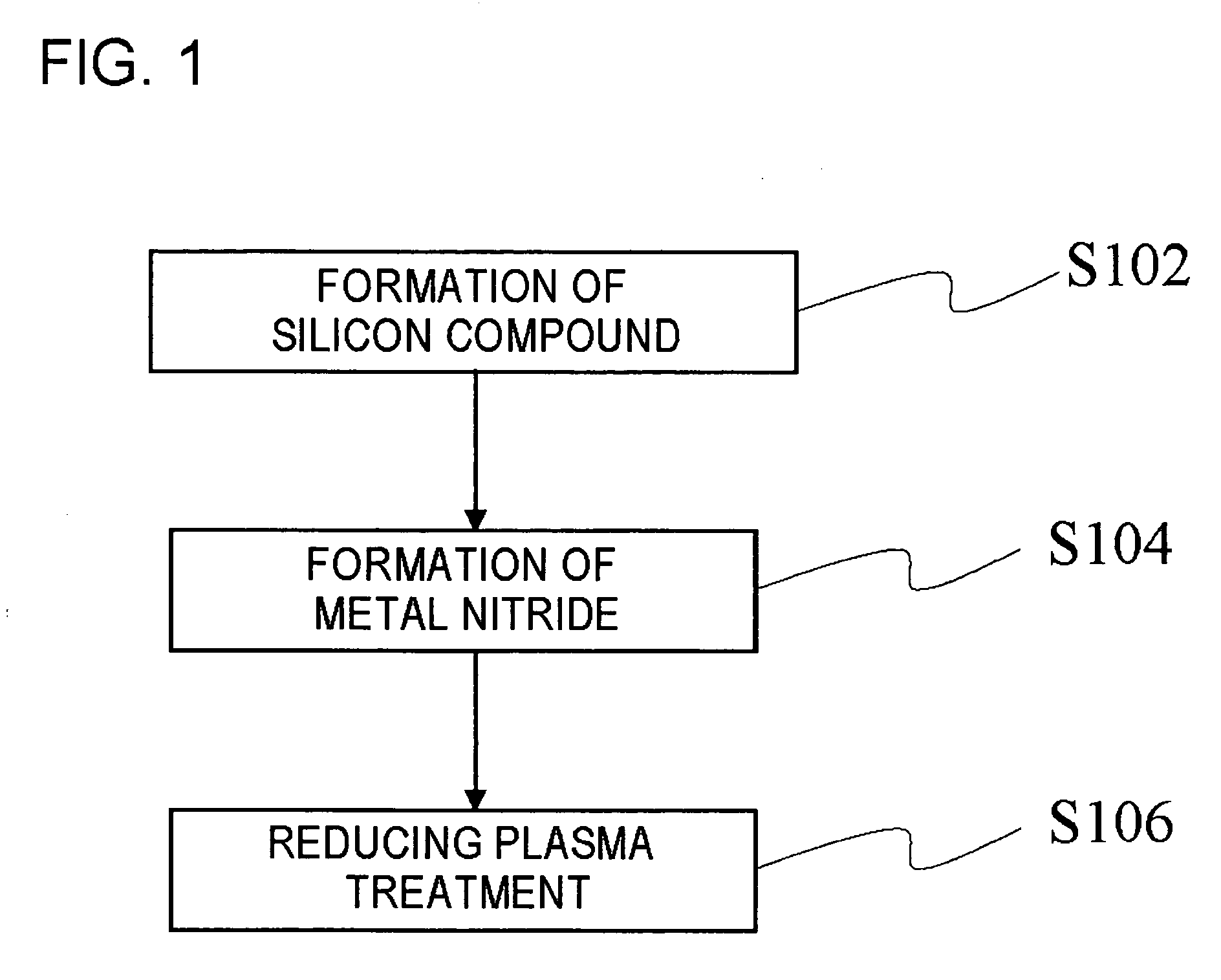

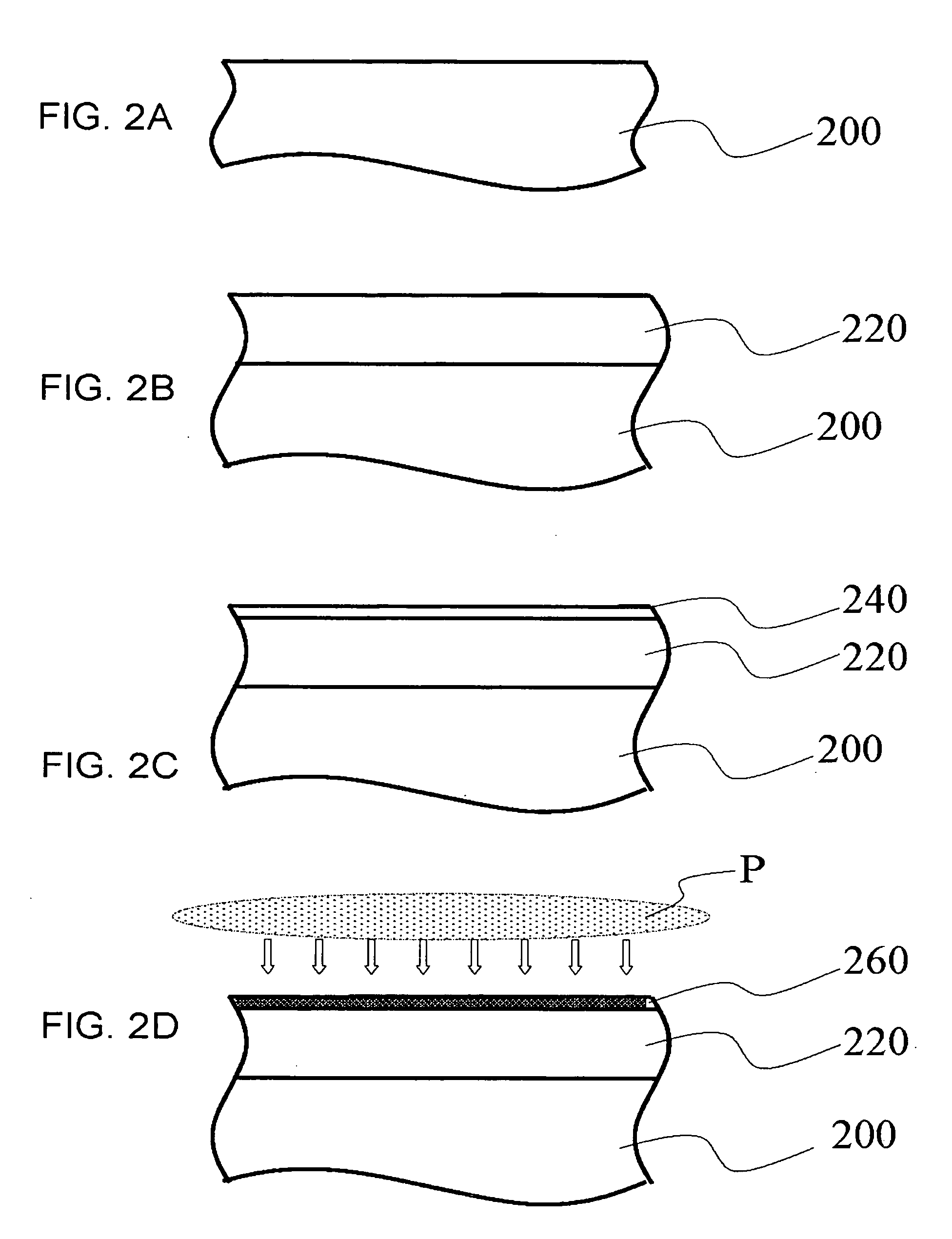

Semiconductor device and method of manufacturing the same

InactiveUS20060115963A1Large industrial advantageHigh adhesiveness and diffusion barrier propertySolid-state devicesSemiconductor/solid-state device manufacturingSecondary layerNitrogen

An object of the invention is to provide a semiconductor device which includes a barrier metal having high adhesiveness and diffusion barrier properties and a method of manufacturing the semiconductor device. The invention provides a semiconductor device manufacturing method including forming a first layer made of a material containing silicon on a base substance; forming a second layer containing metal and nitrogen on the first layer; and exposing the second layer to active species obtained from plasma in an atmosphere including reducing gas.

Owner:NEC ELECTRONICS CORP

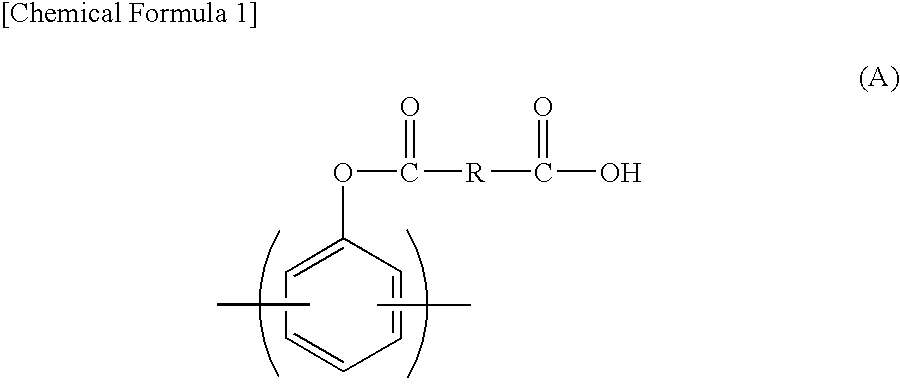

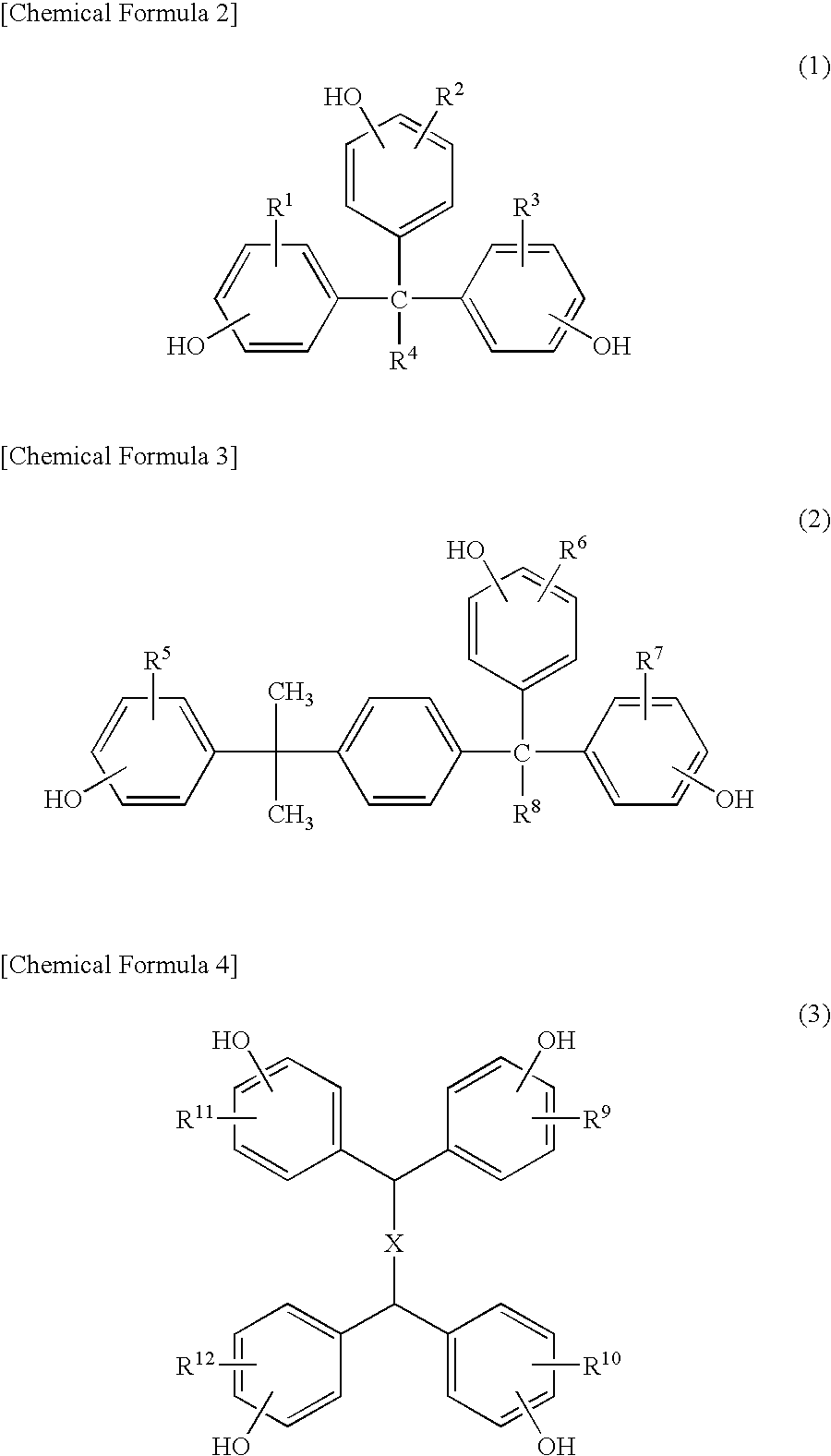

Photosensitive resin composition and photosensitive element

InactiveUS8034529B2High adhesivenessIncrease contrastDiazo compound compositionsPhotosensitive materials for photomechanical apparatusPolymer scienceImage contrast

A photosensitive resin composition comprising (a) a compound obtained by reacting a polybasic acid anhydride with the phenolic hydroxyl groups of a novolac-type phenol resin, and (b) a 1,2-quinonediazide compound. The photosensitive resin composition, which comprises component (b) composed of a 1,2-quinonediazide compound in combination with a component (a) obtained by reacting a polybasic acid anhydride with the phenolic hydroxyl groups of a novolac-type phenol resin, exhibits sufficiently high photosensitivity, image contrast, resolution and adhesiveness.

Owner:HITACHI CHEM CO LTD

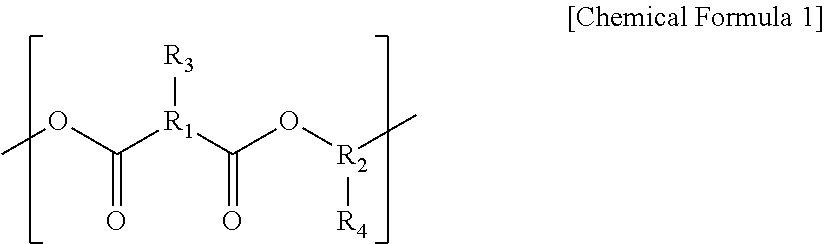

Removable water-dispersible acrylic pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet

InactiveUS20140242384A1Improve removabilityHigh adhesivenessNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceMeth-

The present invention provides an acrylic water-dispersible pressure-sensitive adhesive composition that can prepare a removable adhesive layer having low contamination of an adherent. The acrylic water-dispersible pressure-sensitive removable adhesive composition according to the present invention comprises an acrylic emulsion polymer (A) comprising an alkyl (meth)acrylate ester and a carboxyl group-containing unsaturated monomer as essential raw material constitutive monomers and prepared by polymerization with a reactive surfactant containing no oxyalkylene group.

Owner:NITTO DENKO CORP

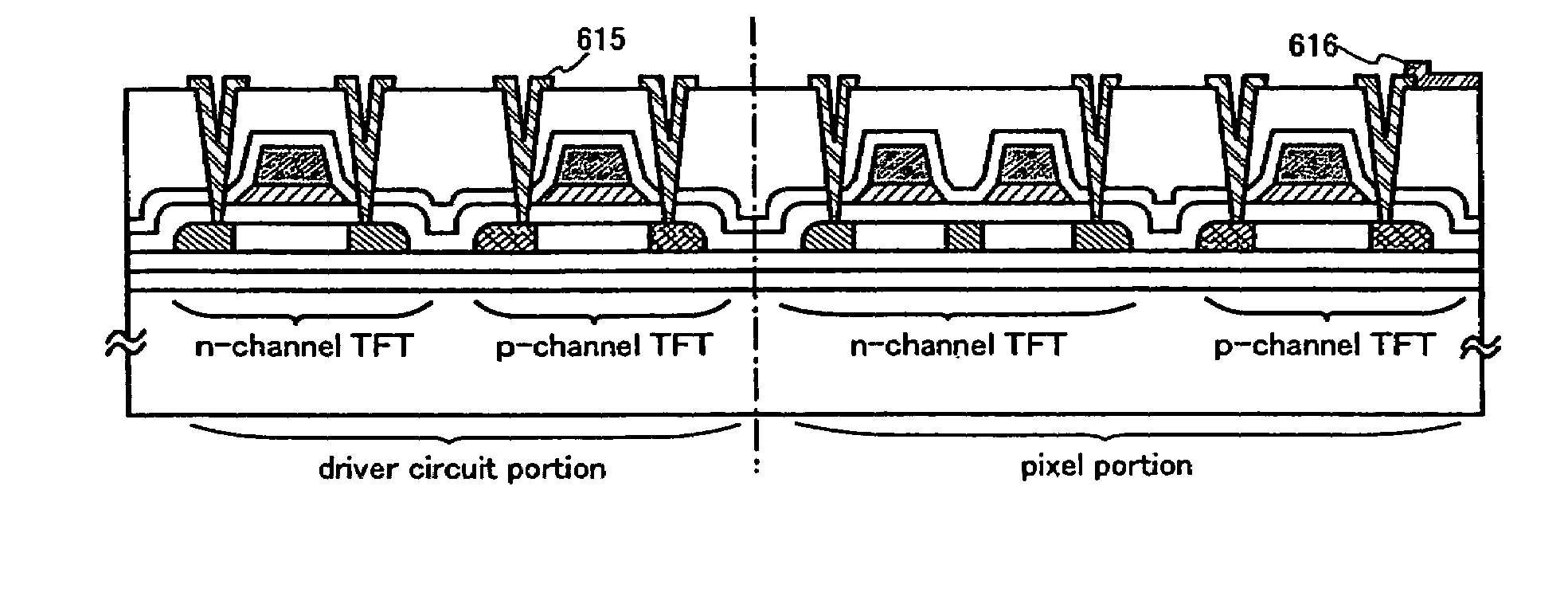

Composition of carbon nitride, thin film transistor with the composition of carbon nitride, display device with the thin film transistor, and manufacturing method thereof

InactiveUS20080206909A1Improve sturdinessReduce frictional resistanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTectorial membraneHydrogen concentration

Owner:SEMICON ENERGY LAB CO LTD

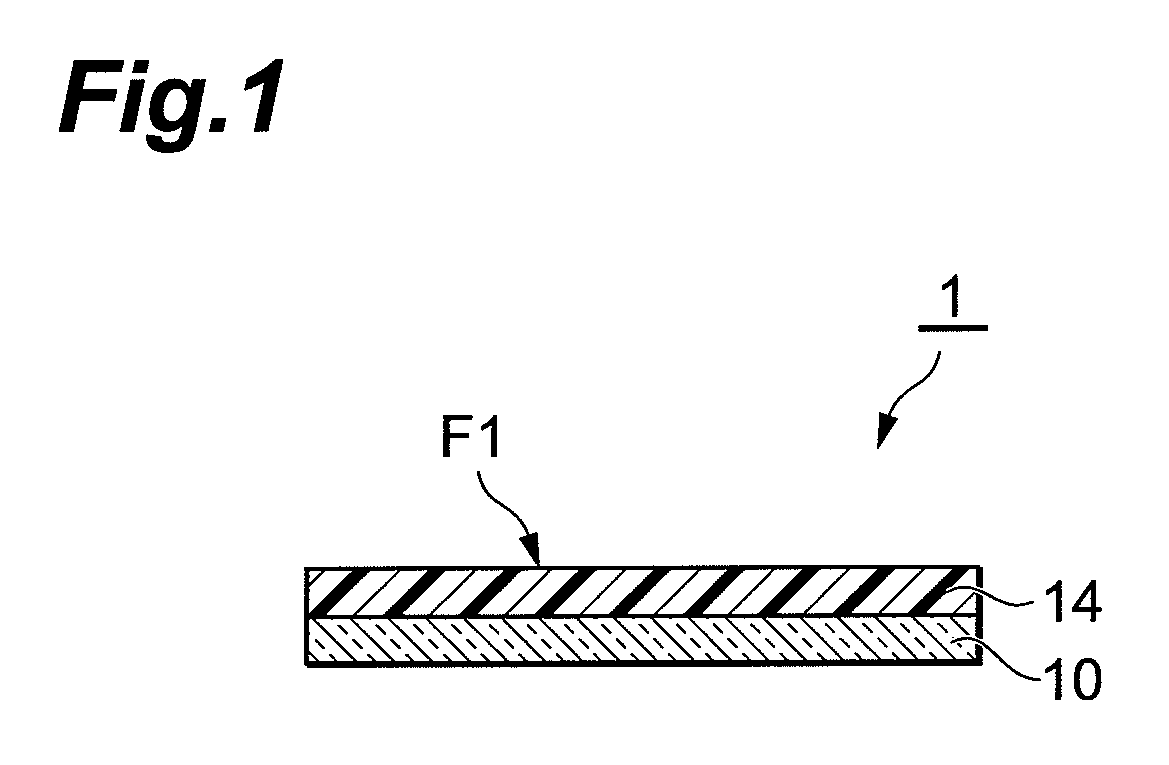

Optical film having high adhesiveness and polarizing plate comprising the same

InactiveUS20190033495A1Zero retardationHigh adhesivenessSynthetic resin layered productsLaminationPolarizerChemistry

The optical film according to the present invention has a feature that it can implement zero retardation and have high adhesiveness to a PVA element, which is a polarizing plate, even while using an acrylic resin having no ring structure in the main chain.

Owner:LG CHEM LTD

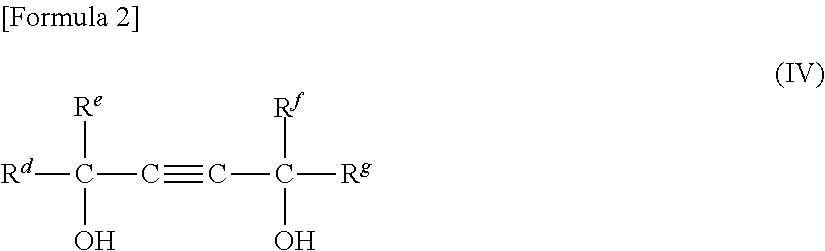

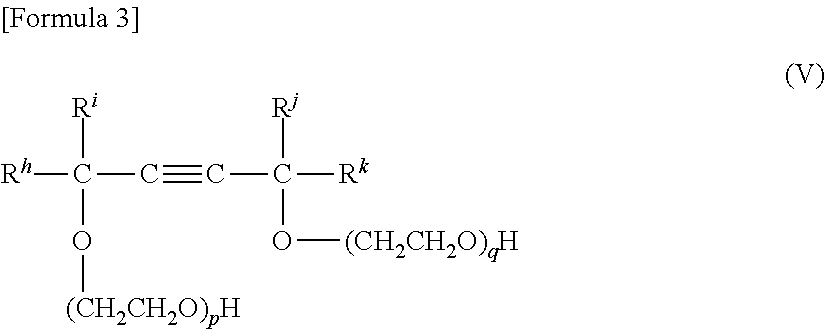

Adhesive

ActiveUS20190119534A1Excellent flexibilityHigh adhesivenessNon-macromolecular adhesive additivesUnsaturated ether polymer adhesivesAdhesive cementChemistry

Owner:DAICEL CHEM IND LTD

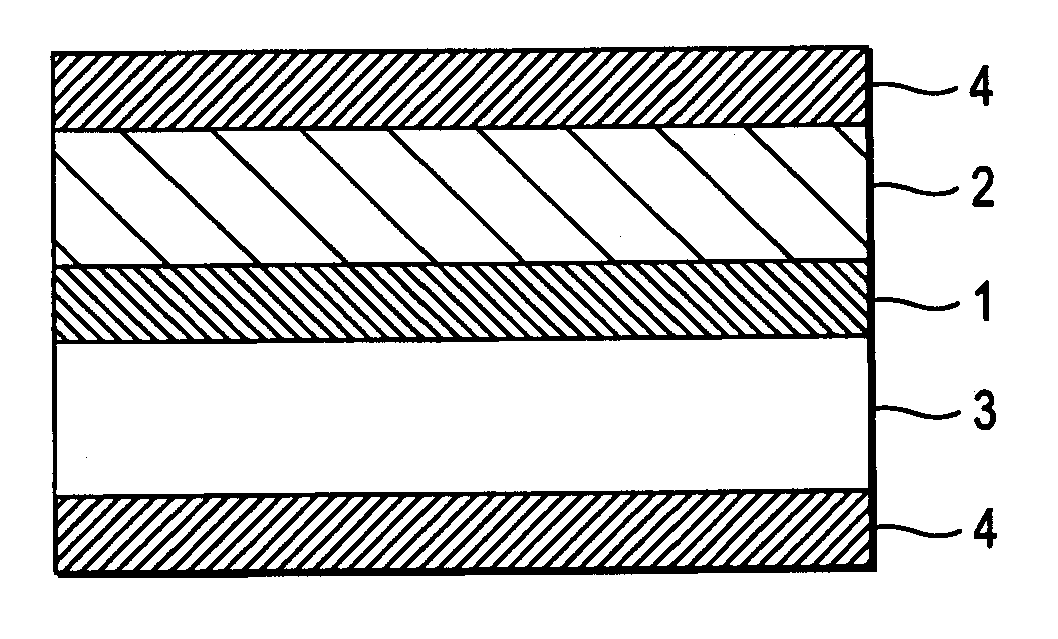

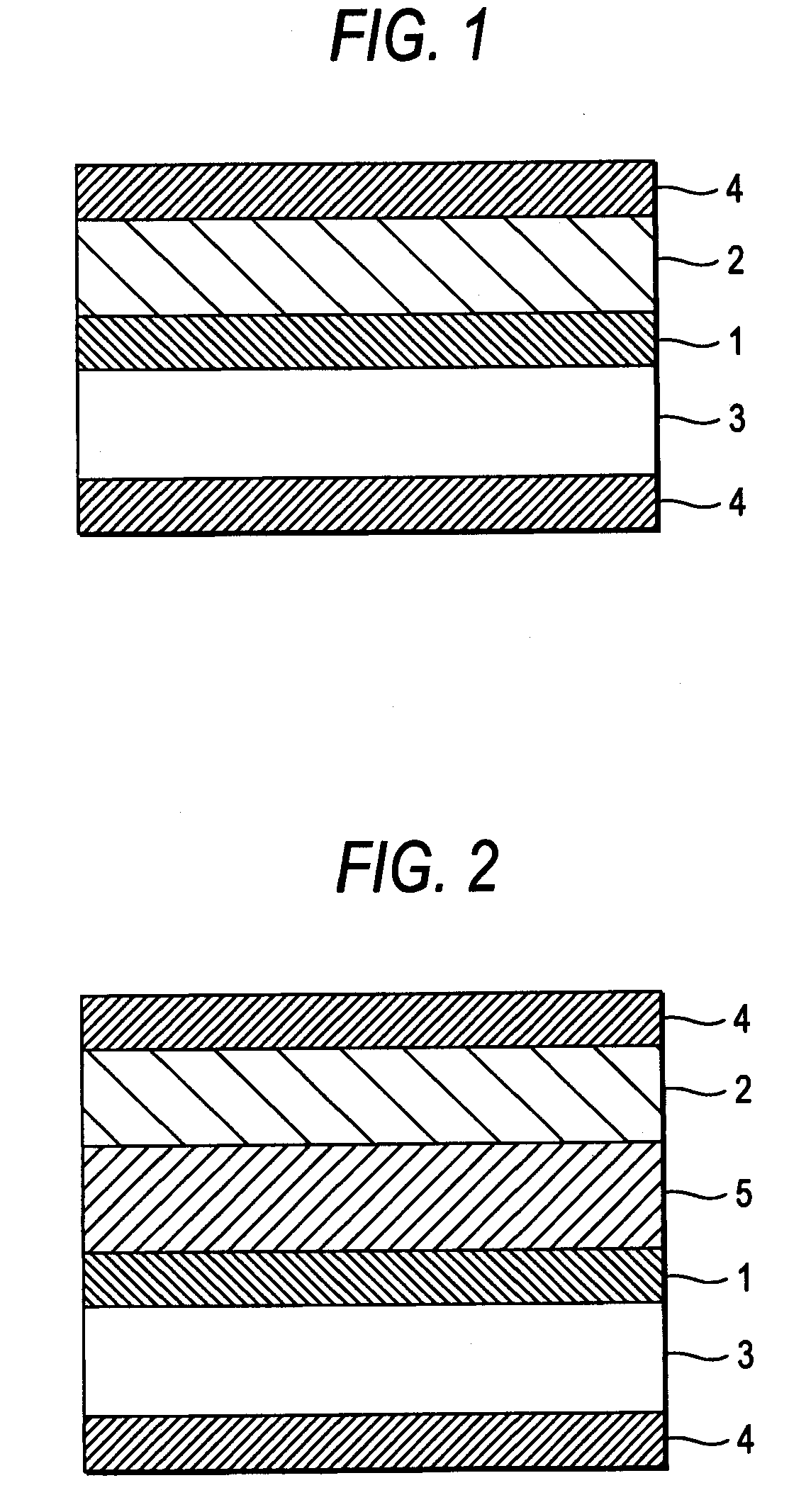

Interlayer film for laminated glass, and laminated glass

InactiveUS20170015800A1High adhesivenessHigh handleabilitySynthetic resin layered productsGlass/slag layered productsPolyvinyl alcoholPlasticizer

The present invention aims to provide an interlayer film for laminated glass having all of high rigidity, handleability, adhesiveness to glass, and high transparency. The present invention also relates to a laminated glass including the interlayer film for laminated glass. The present invention relates to an interlayer film for laminated glass including: a polyvinyl acetal resin; a metal atom; and a plasticizer, the interlayer film for laminated glass having a ratio (B / A) between a work of rupture A at 23° C. and a work of rupture B at 40° C. of 0.55 or higher, the work of rupture A and the work of rupture B being obtained by measurement of tear strength in conformity with JIS K-7128-3.

Owner:SEKISUI CHEM CO LTD

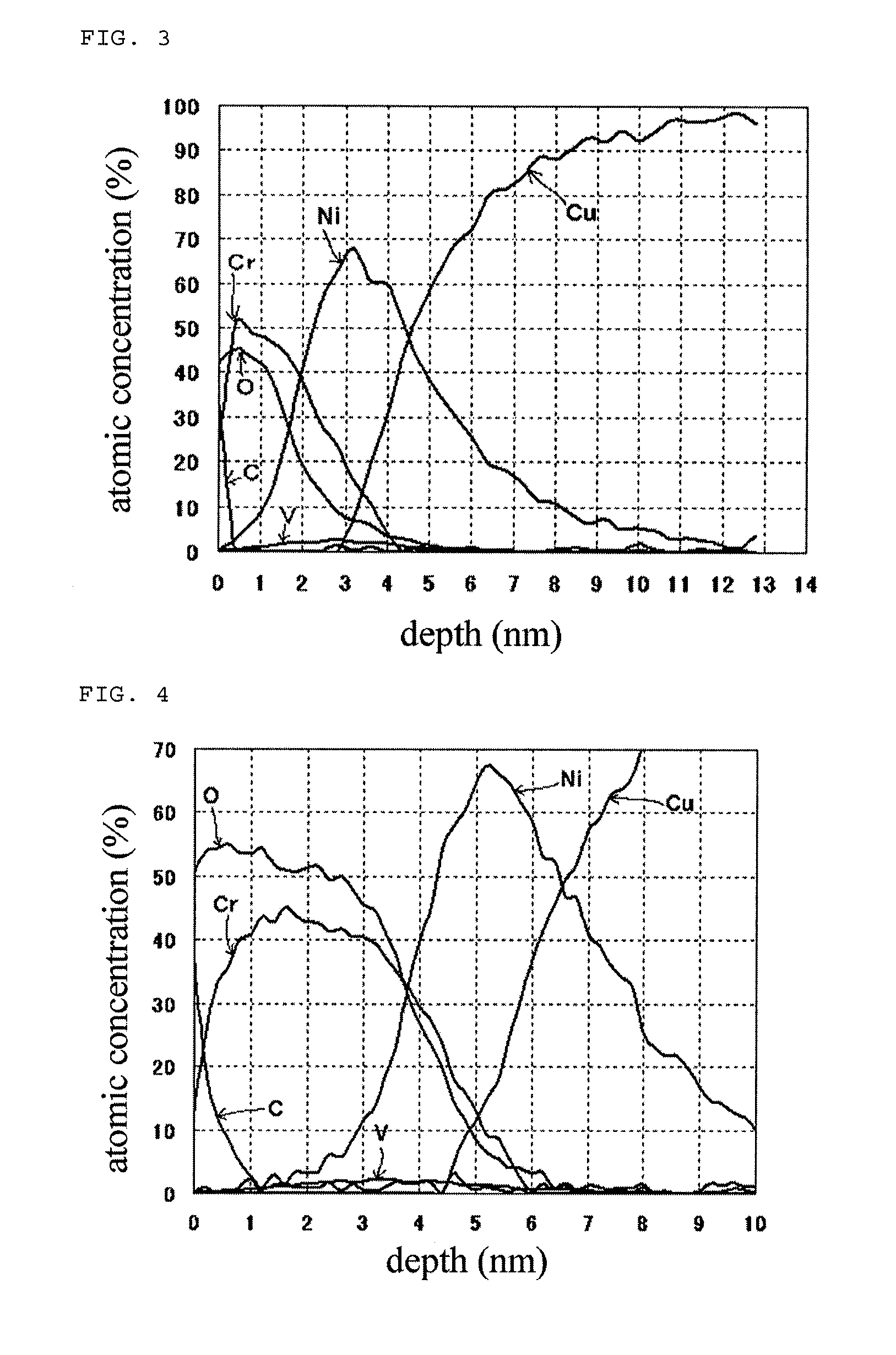

Copper foil for printed wiring board

ActiveUS20130240257A1Suitable for fine pitchEasy to make costVacuum evaporation coatingSputtering coatingCopper foilAlloy

Provided is a copper foil for a printed wiring board, the copper foil being suitable for achieving finer pitch, favorable in terms of manufacturing cost, and excellent both in etching ability and adhesion to an insulating substrate. The copper foil for a printed wiring board comprises a copper foil base material and a covering layer for covering at least a portion of a surface of the copper foil base material, wherein the covering layer is formed by an nickel-vanadium alloy layer containing nickel and vanadium, and a chromium layer, laminated in this order from the surface of the copper foil base material; the chromium layer contains chromium in an amount of 15-210 μg / dm2; the nickel-vanadium alloy layer contains nickel and vanadium in a combined covering amount of 20-600 μg / dm2; and the nickel-vanadium alloy layer contains vanadium in an amount of 3-70 wt %.

Owner:JX NIPPON MINING& METALS CORP

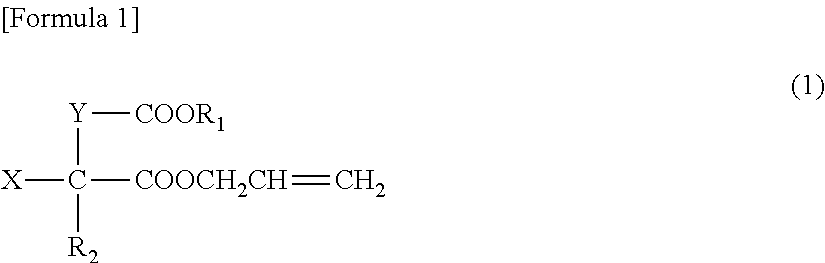

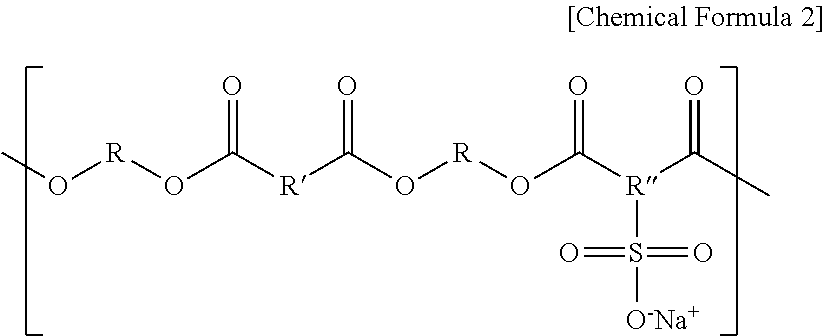

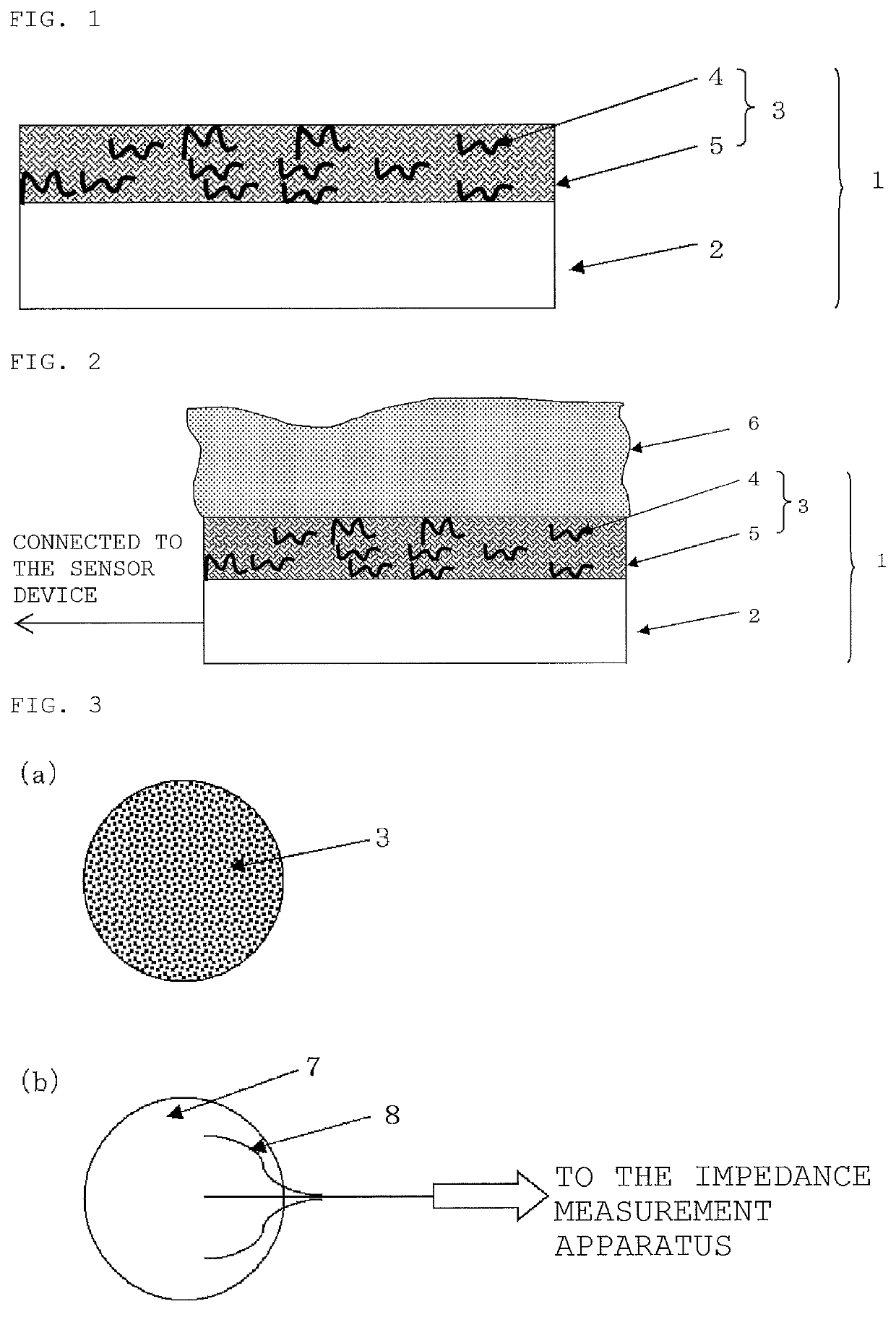

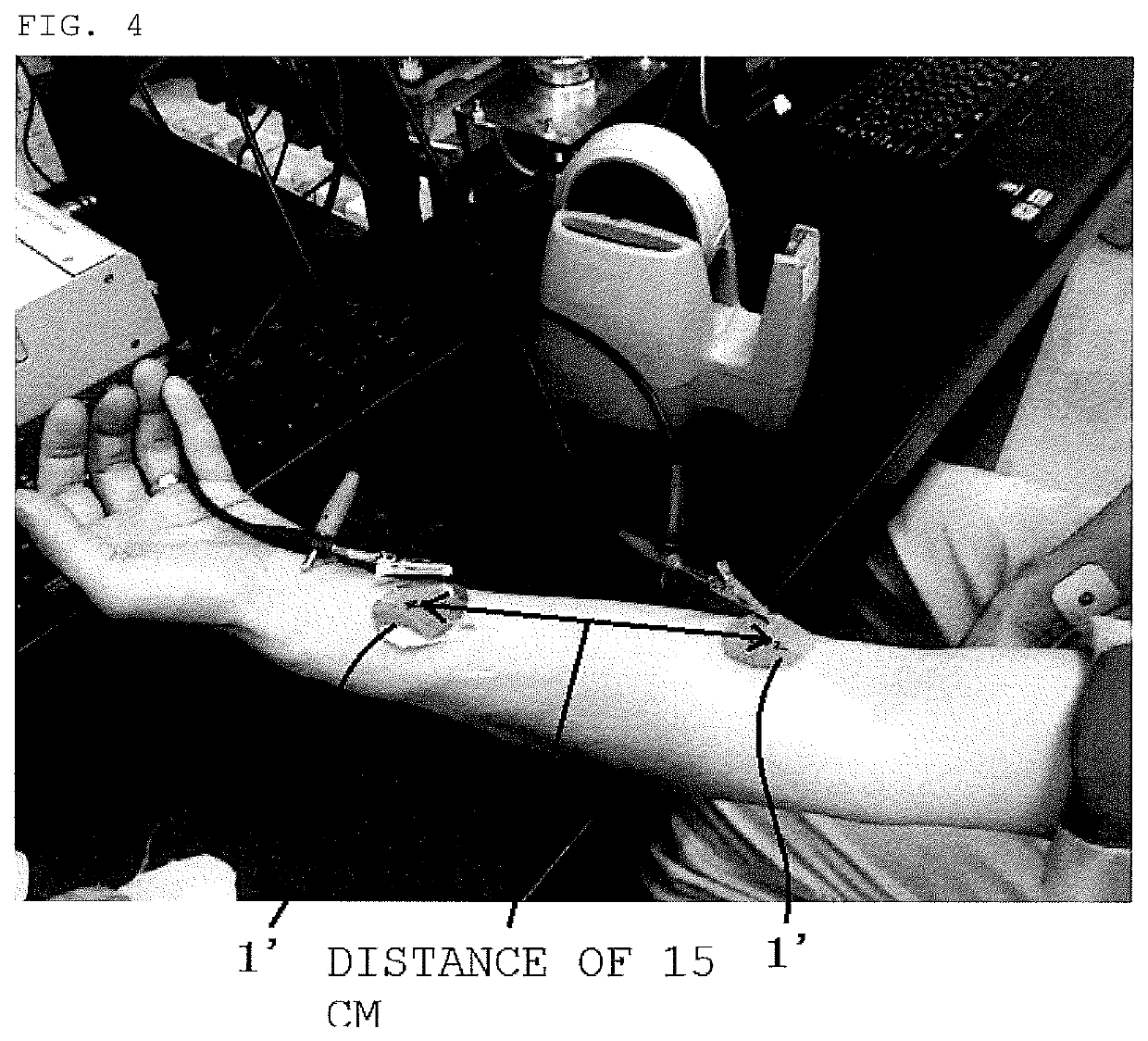

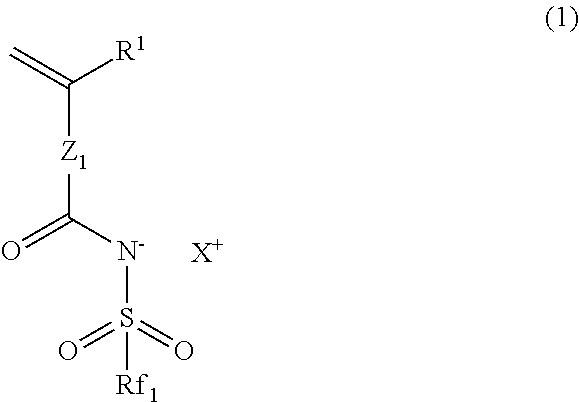

Polymerizable monomer, polymer compound, biological electrode composition, biological electrode, and method for producing biological electrode

ActiveUS10726967B2Guaranteed normal transmissionLight weightSurgeryNon-conductive material with dispersed conductive materialContact layerLiving body

The present invention provides: a biological electrode composition formable a living body contact layer for a biological electrode which is excellent in conductivity and biocompatibility, as well as light in the weight thereof and producible at a low cost, and in addition, which does not cause a significant decrease in the conductivity thereof regardless of under a water-wet condition and a dry condition; a polymer compound which can be suitably used for the biological electrode composition; a polymerizable monomer suitable as a raw material of the polymer compound; a biological electrode having a living body contact layer formed of the biological electrode composition; and a method for producing the same; and wherein, the polymerizable monomer is represented by the following general formula (1).

Owner:SHIN ETSU CHEM IND CO LTD

Inkjet ink and inkjet recording method

ActiveUS8777392B2High adhesivenessIncrease resistanceMeasurement apparatus componentsDuplicating/marking methodsPolymer scienceMeth-

Provided is an inkjet ink including at least water, a pigment, a resin, a water-soluble organic solvent, and a surfactant, wherein the resin consist of a copolymer resin synthesized from only a (meth)acrylic monomers, and the copolymer resin has an acid value of not less than 50 mgKOH / g and not more than 200 mgKOH / g, a glass transition temperature (Tg) not less than 20 and not more than 100° C., and a weight-average molecular weight (Mw) not less than 20,000 and not more than 100,000, and as a result, a high-quality image is formed in that abrasion resistance and adhesiveness on a non-absorptive recording medium are high, glossiness is high, and there is no ink mixing, and ejection performance is good and recovery through maintenance is excellent. Also provided is an inkjet recording method that uses the same.

Owner:KONICA MINOLTA IJ TECHNOLOGIES INC

Ink jet recording method and method for manufacturing laminated printed matter

ActiveUS20190337319A1High adhesivenessIncrease stickinessDuplicating/marking methodsInksEngineeringRadiation

An ink jet recording method includes the steps of ejecting an active-radiation-curable ink composition onto a recording medium by an ink jet process and curing the ejected ink composition by irradiation with active radiation. During transporting of the recording medium in the ejecting and curing steps, an unwinding stress in the recording medium is larger than a winding stress in the recording medium. The recording medium has a thickness of 10μm to 100 μm. Also provided is a method for manufacturing laminated printed matter using printed matter produced by the ink jet recording method.

Owner:FUJIFILM CORP

Method for treatment of recessed structures in dielectric materials for smear removal

ActiveCN105579615AReduce etch rateReduce the numberHollow article cleaningInsulating layers/substrates workingAlcoholEther

The present invention relates to a method for treatment of recessed structures in a dielectric material for smear removal during the manufacture of printed circuit boards, IC substrates and the like. The dielectric material is contacted with an aqueous solution comprising 60 to 80 wt.-% sulfuric acid and 0.04 to 0.66 mol / l peroxodisulfate ions and at least one stabilizing additive selected from alcohols, molecular ethers and polymeric ethers. Smear is removed from the recessed structures by the method according to the present invention without penetration of process chemicals into the dielectric material and a sufficiently low copper etching rate is achieved. Furthermore, the shelf life of said aqueous solution is improved even in the presence of copper ions.

Owner:ATOTECH DEUT GMBH

Magnetic recording medium, method of manufacturing the same and magnetic recording apparatus

InactiveUS7399386B2High adhesivenessReduce occurrenceMagnetic materials for record carriersBase layers for recording layersCarbon filmChemistry

A magnetic recording medium using a plastic substrate as a non-magnetic substrate includes an adhesive layer that prevents film expansion even under severe conditions. The adhesive layer has a chemical affinity to the plastic substrate and is formed on the surface of the plastic substrate, and an underlayer and subsequent layers are formed over the adhesive layer. A polymerized carbon film is used as the adhesive layer.

Owner:FUJI ELECTRIC DEVICE TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com