Preparation method for liquid phase stirring and mixing of white carbon black and natural rubber

A technology of mixing and mixing silica, which is applied in transportation and packaging, tire parts, rolling resistance optimization, etc., can solve the problems of increasing process steps, uneven mixing, and increasing costs, and achieves simple process, no dust pollution, Effect of improving strength and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

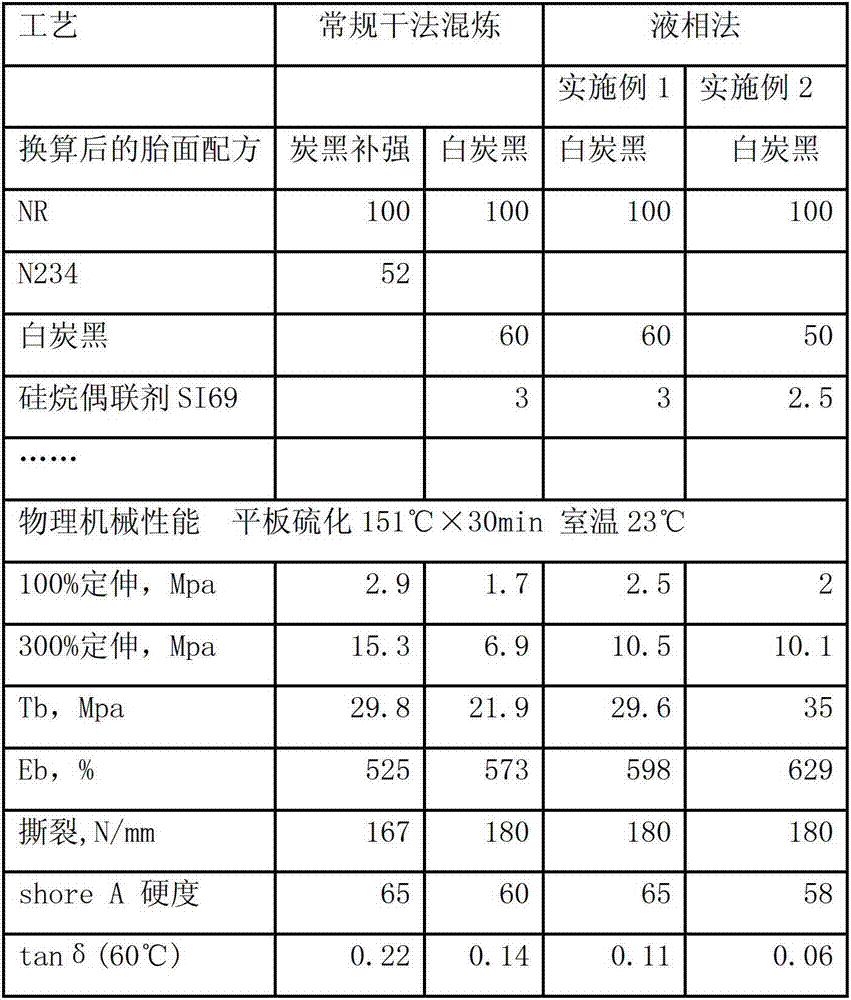

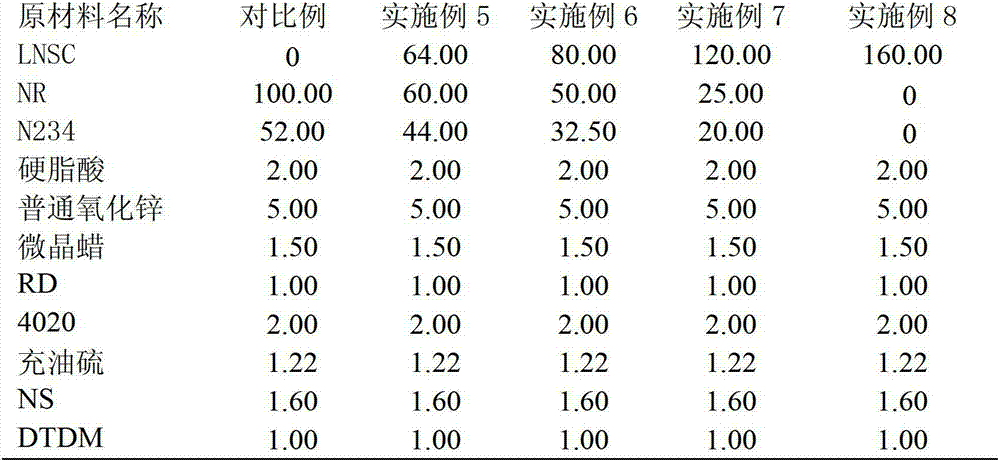

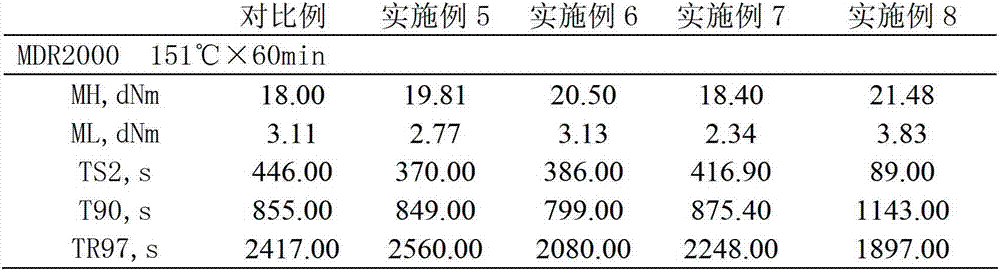

Examples

Embodiment 1

[0038] Centrifugal concentration of natural rubber latex and silica slurry

[0039] A. Preparation of slurry

[0040] A component

[0041] formula

Composition (%)

Silica slurry (25% content)

85.47

[0042] water

13.33

Si69

0.66

stabilizer

0.410

Anti-settling agent

0.020

Dispersant

0.103

[0043] B component

[0044] formula

Composition (%)

Concentrated Natural Rubber Latex

56.31

stabilizer

0.54

water

43.15

[0045] Each was stirred at 1500~2500rpm for 2~5 minutes.

[0046] B. Mix and stir, slowly add component A to component B while stirring at a high speed, the mass ratio of component A to component B is 0.8:1, the stirring speed is 2000~6000rpm, and stir for 10 minutes.

[0047] C. Slowly add 0.3kg of glacial acetic acid to the mixture and solidify instantly.

[0048] D. Press filtration, press on the...

Embodiment 2

[0055] Using fresh glue and silica paste collected directly from rubber trees

[0056] A. Preparation of slurry

[0057] A component

[0058] formula

Composition (%)

Silica slurry (25% content)

85.47

water

13.33

Si69

0.66

stabilizer

0.410

Anti-settling agent

0.020

[0059] Dispersant

0.103

[0060] B component

[0061] formula

Composition (%)

fresh glue

99.056

stabilizer

0.944

water

[0062] Each was stirred at 1500~2500rpm for 2~5 minutes.

[0063] B. Mix and stir, slowly add component A to component B while stirring at a high speed, the mass ratio of component A to component B is 1:1, the stirring speed is 2000~6000rpm, and stir for 10 minutes.

[0064] C. Slowly add 0.3kg of glacial acetic acid to the mixture and solidify instantly.

[0065] D. Press filtration, press on the press, squeeze out part of th...

Embodiment 3

[0072] 40phr Silica Content Formula

[0073] A. Preparation of slurry

[0074] A component

[0075] formula

Composition (PHR)

Silica slurry (25% content)

33.2

water

5.18

Si69

0.25

stabilizer

0.15

Anti-settling agent

0.008

Dispersant

0.04

[0076] B component

[0077] formula

Composition (PHR)

fresh glue

32.6

[0078] stabilizer

1.55

water

25

[0079] Each was stirred at 1500~2500rpm for 2~5 minutes.

[0080] B. Mix and stir, slowly add component A to component B while stirring at a high speed, the mass ratio of component A to component B is 1:1, the stirring speed is 2000~6000rpm, and stir for 10 minutes.

[0081] C. Slowly add 0.3kg of glacial acetic acid to the mixture and solidify instantly.

[0082] D. Press filtration, press on the press, squeeze out part of the liquid, and recycle.

[0083] E. Ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com