Preparation method of fine-grain cualmn shape memory alloy

A memory alloy and fine-grained technology, which is applied in the field of preparation of fine-grained CuAlMn shape memory alloys, can solve the problems of insufficient copper-based shape memory alloys and the inability to meet the requirements of high speed, high efficiency, intelligence and automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

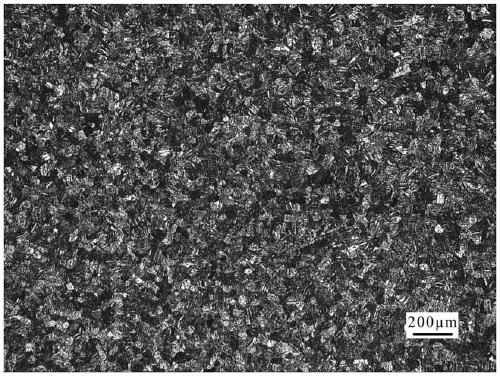

Embodiment 1

[0034] The first step is to prepare Al-based LaScB inoculant strips:

[0035] According to the ratio of Al: 93.40%, La: 3.57%, Sc: 1.43%, B: 1.60%, weigh the raw material Al-20%La, Al-3%B, Al-5%Sc master alloy and crush it , ultrasonic cleaning, drying treatment, and then put all the weighed raw materials into the WK-Ⅱ non-consumable vacuum electric arc furnace, and wait to be vacuumed to 5×10 -3 Start arcing and smelting after Pa, stop smelting after the intermediate alloy of the raw material is completely melted, and then reverse it after the obtained molten alloy is solidified, and re-melt it, repeating this 3 times to obtain a block Al-based LaScB inoculant Put the block inoculant into the water-cooled copper crucible of the LZK-#12A vacuum quenching furnace, and wait to be vacuumed to 5×10 -3 After Pa, the high-purity argon gas protection is introduced, and the block inoculant in the water-cooled copper crucible is completely melted by the flame of the moving pole, and t...

Embodiment 2

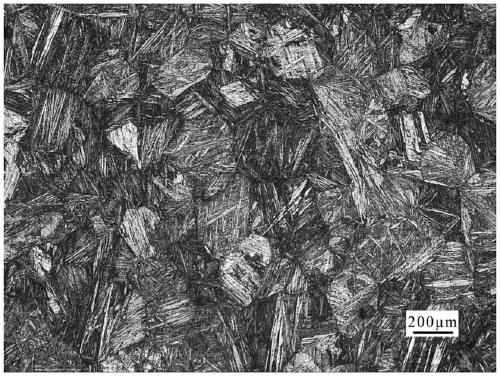

[0040] This embodiment is a comparative example.

[0041] The first step is to prepare Al-based LaScB inoculant strips:

[0042] With embodiment 1;

[0043] The second step is to prepare unrefined CuAlMn shape memory alloy:

[0044] According to the CuAlMn shape memory alloy, Al accounts for 11.9% of the total mass of CuAlMn, Mn accounts for 2.5% of the total mass of CuAlMn, and the rest is the composition of Cu matrix. Weigh the required amount of raw materials pure Cu, pure Al and pure Mn, and then respectively Take by weighing 1.0% of the total mass of the above-mentioned CuAlMn shape memory alloy composed of 8%Na 3 AlF 6 +8%KCl+84%NaCl refining agent, charcoal powder accounting for 0.2% of the total mass of the above-mentioned CuAlMn shape memory alloy, after that, pure Cu is placed in a graphite crucible in an intermediate frequency induction heating furnace, and the temperature is raised until Cu is melted Finally, add charcoal powder to cover the Cu solution, then a...

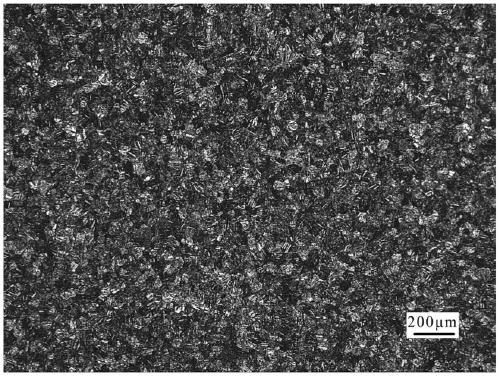

Embodiment 3

[0047] The first step is to prepare Al-based LaScB inoculant strips:

[0048] According to the ratio of Al: 93.40%, La: 3.57%, Sc: 1.43%, B: 1.60%, weigh the raw material Al-20%La, Al-3%B, Al-5%Sc master alloy and crush it , ultrasonic cleaning, drying treatment, and then put all the weighed raw materials into the WK-Ⅱ non-consumable vacuum electric arc furnace, and wait to be vacuumed to 5×10 -3 Start arcing and smelting after Pa, stop smelting after the intermediate alloy of the raw material is completely melted, and then reverse it after the obtained molten alloy is solidified, and re-melt it, repeating this 3 times to obtain a block Al-based LaScB inoculant Put the block inoculant into the water-cooled copper crucible of the LZK-#12A vacuum quenching furnace, and wait to be vacuumed to 5×10 -3 After Pa, the high-purity argon gas protection is introduced, and the block inoculant in the water-cooled copper crucible is completely melted by the flame of the moving pole, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com