Composite zinc-aluminum alloy coating material and hot-dip plating method

A zinc-aluminum alloy, hot-dip plating technology, applied in hot-dip plating process, metal material coating process, coating, etc. Smooth surface, improved corrosion resistance, good grain refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

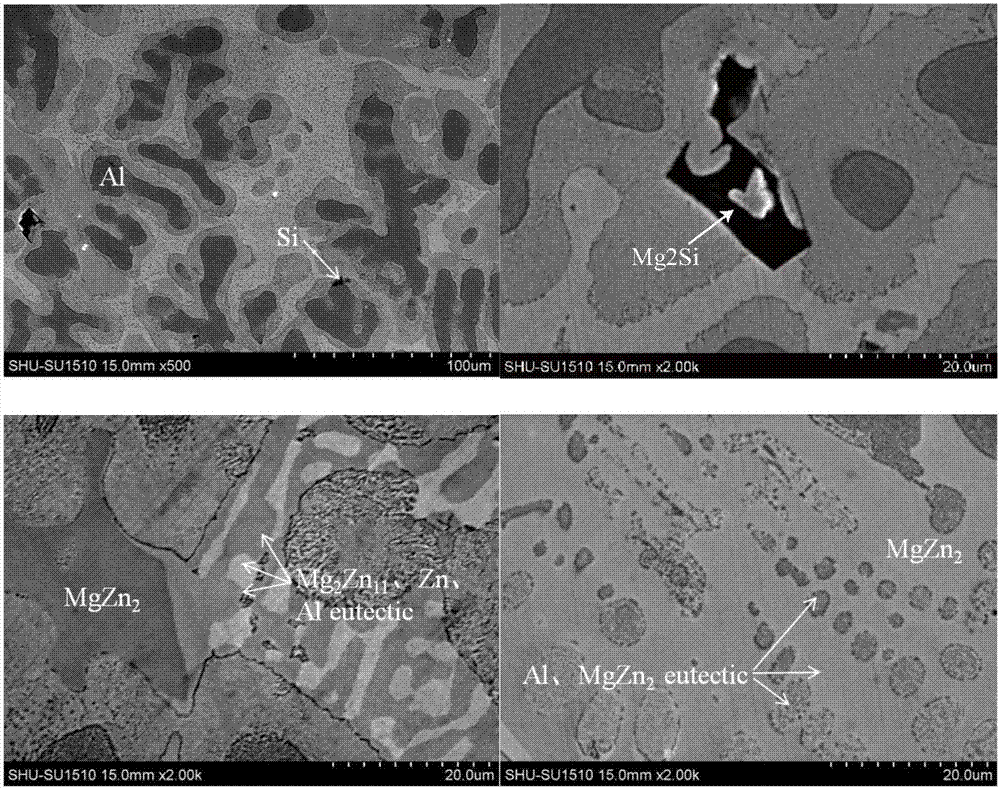

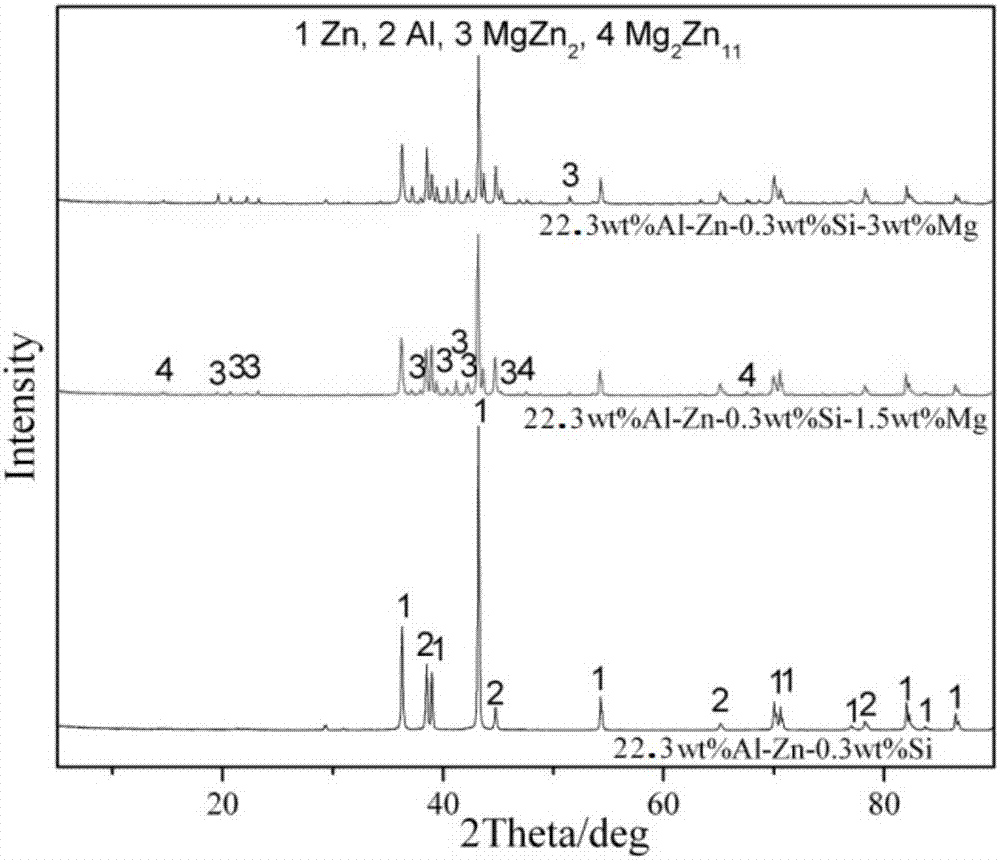

[0047] In this example, see figure 1 , image 3 , Figure 4 and Figure 6 , a composite zinc-aluminum alloy coating material, has the following main element composition and its weight percentage: the content of Al is 22.3wt.%, the content of Si is 0.3wt.%, the content of Mg is 1.5wt.%, and the rest is Zn, A Zn-Al-Si-Mg coating material is formed.

[0048] This embodiment is a hot-dip coating method for a composite zinc-aluminum alloy coating material that can reduce the amount of hot-dip aluminum-zinc bottom slag and improve the surface quality of the coating. This embodiment adopts a self-developed continuous hot-dip simulation device to prepare a hot Dip-plating Al-Zn-Si-Mg coated steel plate, comprises the steps:

[0049] a. Preparation process of hot-plating solution:

[0050] 1) Weighing and preparing raw materials according to the following elemental compositions and weight percentages required for preparing the composite zinc-aluminum alloy coating material: the co...

Embodiment 2

[0068] This embodiment is basically the same as Embodiment 1, especially in that:

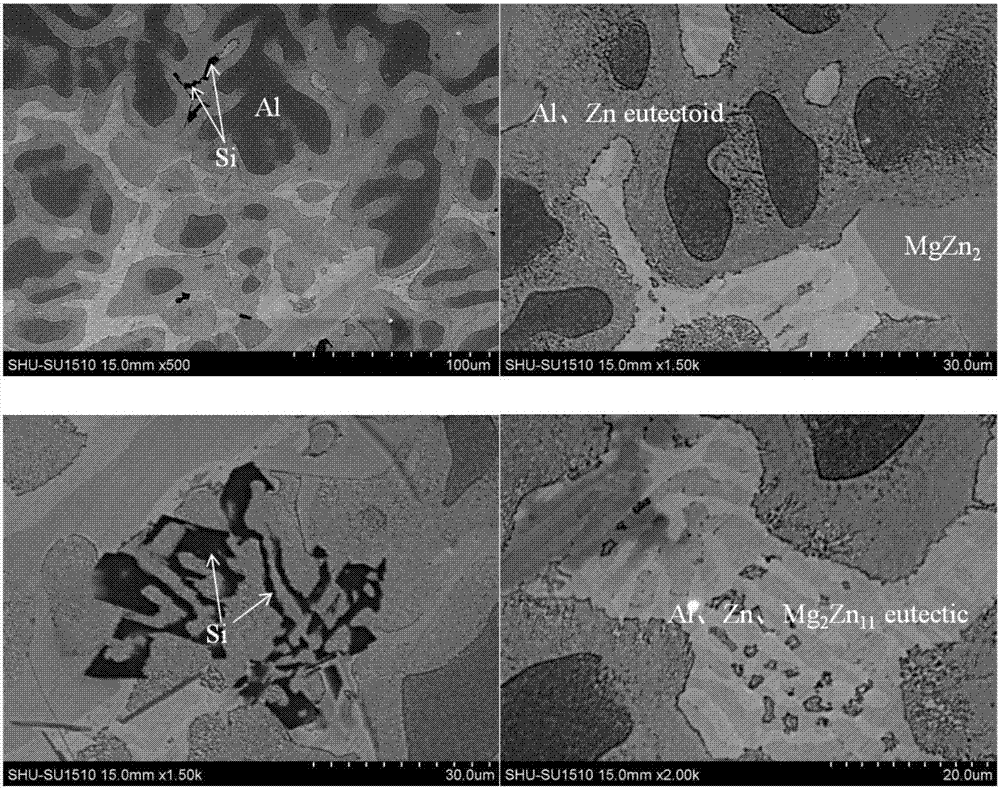

[0069] In this example, see Figure 2-4 , a composite zinc-aluminum alloy coating material, has the following main element composition and its weight percentage: the content of Al is 22.3wt.%, the content of Si is 0.3wt.%, the content of Mg is 3wt.%, and the rest is Zn, forming Zn-Al-Si-Mg coating material.

[0070] In this embodiment, a hot-dip coating method for a composite zinc-aluminum alloy coating material that can reduce the amount of hot-dip aluminum-zinc bottom slag and improve the surface quality of the coating uses a self-developed continuous hot-dip simulation device to prepare hot-dip Al -Zn-Si-Mg coated steel plate, comprising the steps of:

[0071] a. Preparation process of hot-plating solution:

[0072] 1) Weigh the prepared raw materials according to the following elemental compositions and weight percentages required for preparing the composite zinc-aluminum alloy coating m...

Embodiment 3

[0091] This embodiment is basically the same as the previous embodiment, and the special features are:

[0092] In this embodiment, a composite zinc-aluminum alloy coating material has the following main element composition and weight percentage: the content of Al is 22.3wt.%, the content of Si is 0.3wt.%, and the content of Mg is 3wt.%. The content of Ti is 0.05%, and the rest is Zn, forming a Zn-Al-Si-Mg-Ti coating material.

[0093] In this example, a hot-dip coating method for a composite zinc-aluminum alloy coating material that can reduce the amount of hot-dip aluminum-zinc bottom slag and improve the surface quality of the coating, adopts a self-developed continuous hot-dip simulation device to prepare a hot-dip Zn coating. -Al-Si-Mg-Ti coated steel plate, comprising the steps of:

[0094] a. Preparation process of hot-plating solution:

[0095] 1) Weigh and prepare the raw materials according to the following elemental compositions and weight percentages required for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com