Method for preparing Mg-Ti-B grain refiner for magnesium and magnesium alloy

A technology of grain refiner and magnesium alloy, which is applied in the field of metal materials, can solve problems such as difficult quantitative analysis of TiB, achieve good anti-recession ability, good grain refinement effect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

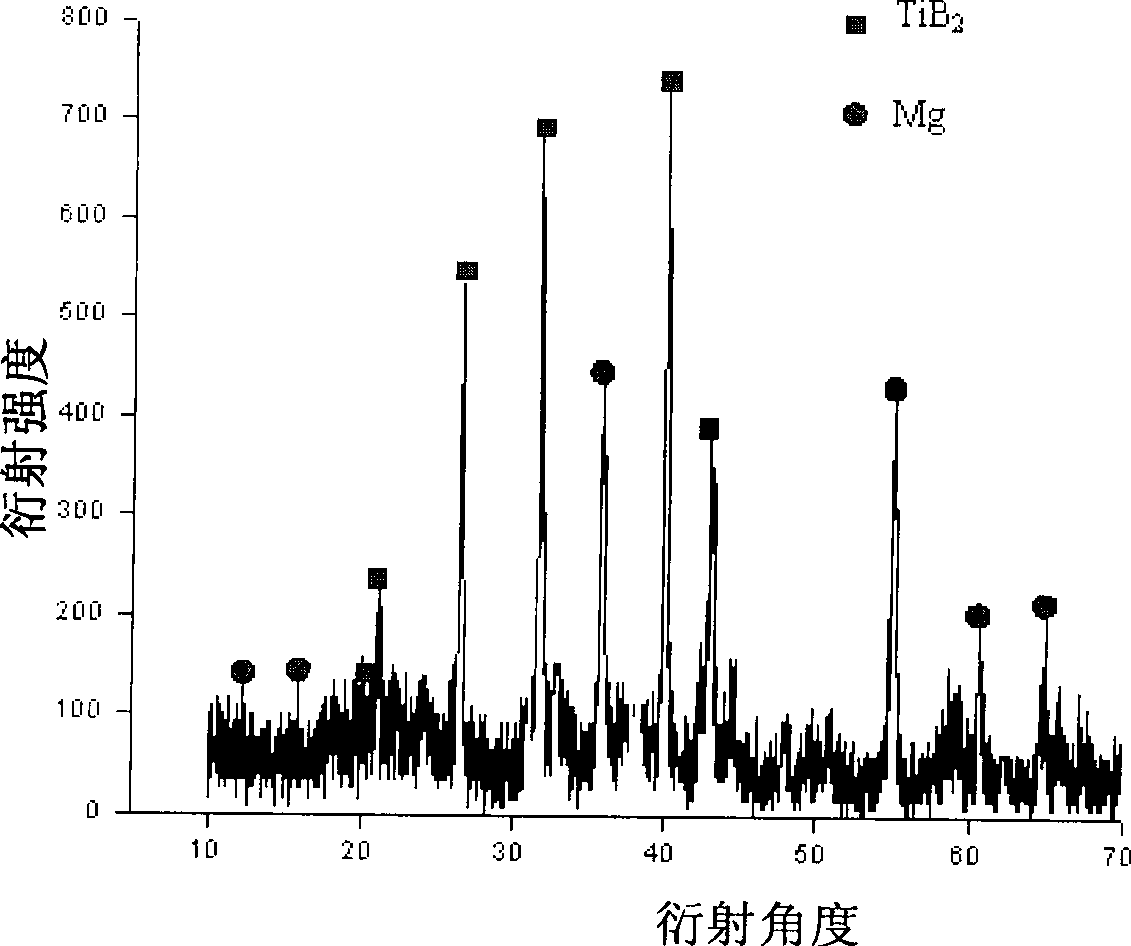

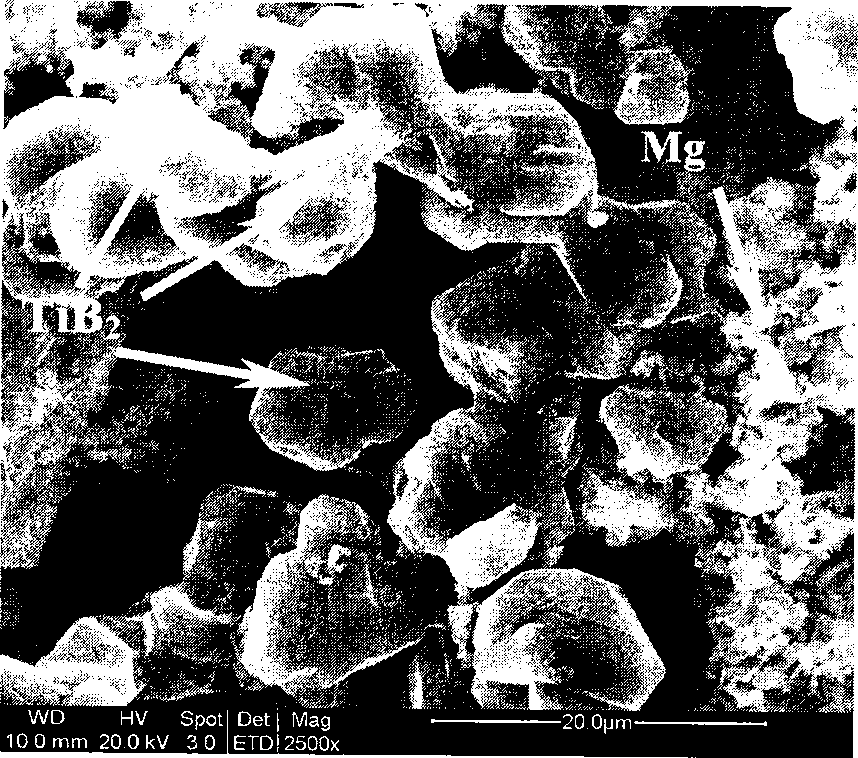

[0036] Example 1: Mg-80%TiB 2 Preparation of grain refiner

[0037] (1) Dry mix 55.10% titanium powder, 24.90% boron powder and 20% magnesium powder on a mixer for 12 hours by weight, then cold press into a prefabricated block with a relative density of 45%, wrap it with aluminum foil and dry it processed and buried in corundum crucibles;

[0038] (2) Use a box-type resistance furnace for isothermal treatment at 900°C for 100 minutes;

[0039] (3) Take out the prefabricated block to make Mg-80%TiB 2 grain refiner;

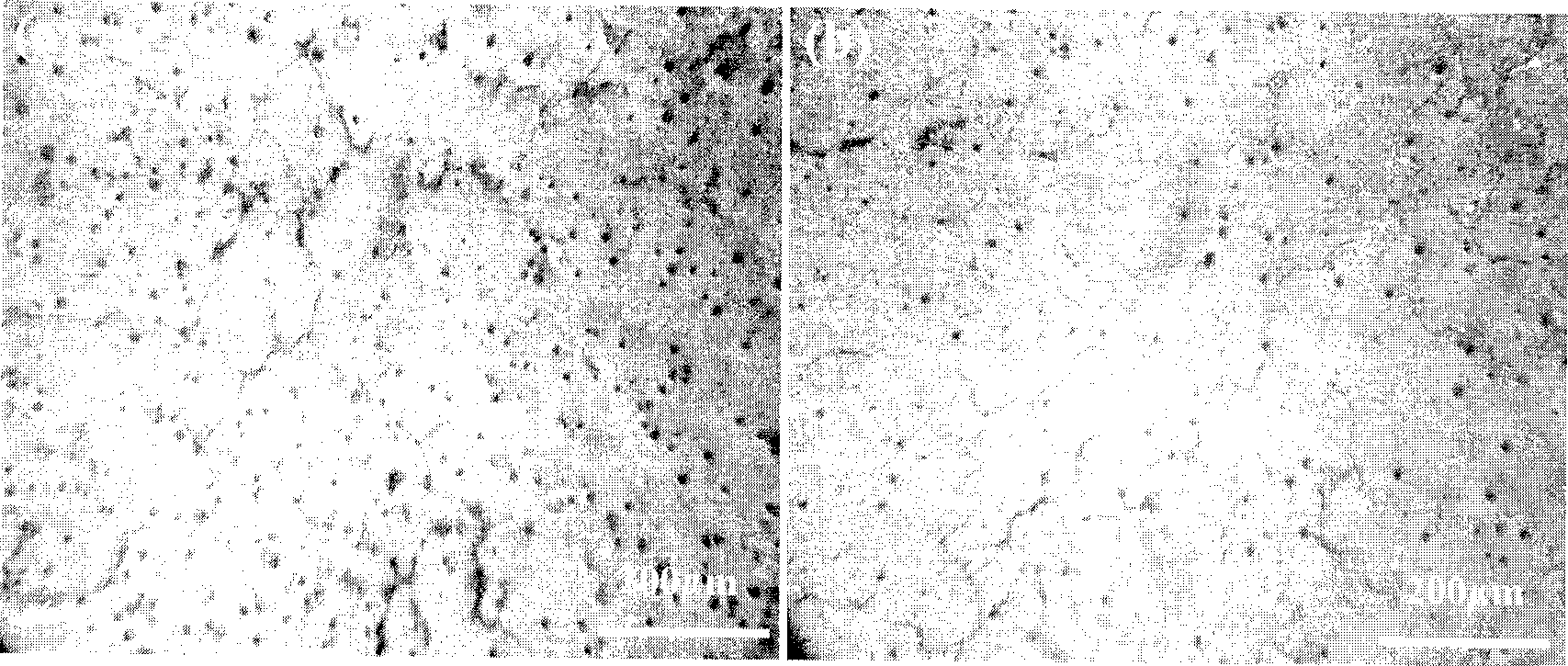

[0040] (4) After adding 0.5% of the grain refiner to the AZ91D magnesium alloy, the grain size of the alloy can be reduced from 96 μm to 53 μm.

example 2

[0041] Example 2: Mg-50%TiB 2 Preparation of grain refiner

[0042] (1) Dry mix 34.44% titanium powder, 15.56% boron powder and 50% magnesium powder on a mixer for 10 hours by weight, then cold press into a prefabricated block with a relative density of 50%, wrap it with aluminum foil Dried and buried in a corundum crucible;

[0043] (2) Use a box-type resistance furnace for isothermal treatment, and hold at 800°C for 120min;

[0044] (3) Take out the prefabricated block to make Mg-50%TiB 2 grain refiner;

[0045] After adding 1.4% of the grain refiner to the AZ91D magnesium alloy, the grain size of the alloy can be reduced from 96 μm to 58 μm.

example 3

[0046] Example 3: Mg-20%TiB 2 Preparation of grain refiner

[0047] (1) The titanium powder that is 13.78% by weight, the boron powder of 6.22% and the magnesium powder of 80% are cold-pressed into the prefabricated block of relative density 48% after 8 hours on the mixer, dry after wrapping with aluminum foil processed and buried in corundum crucibles;

[0048] (2) Isothermal treatment at 850°C for 180min in a box-type resistance furnace;

[0049] (3) Take out the prefabricated block to make Mg-20%TiB 2 grain refiner;

[0050] After adding 1.5% of the grain refiner to the AZ91D magnesium alloy, the grain size of the alloy can be reduced from 96 μm to 56 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com