Refining agent for crystalline grain of aluminium titanium carbon intermediate alloy

A technology of grain refiner and master alloy, applied in the field of AlTiC grain refiner, can solve the problem of low grain refinement effect, etc., and achieve the effect of good grain refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

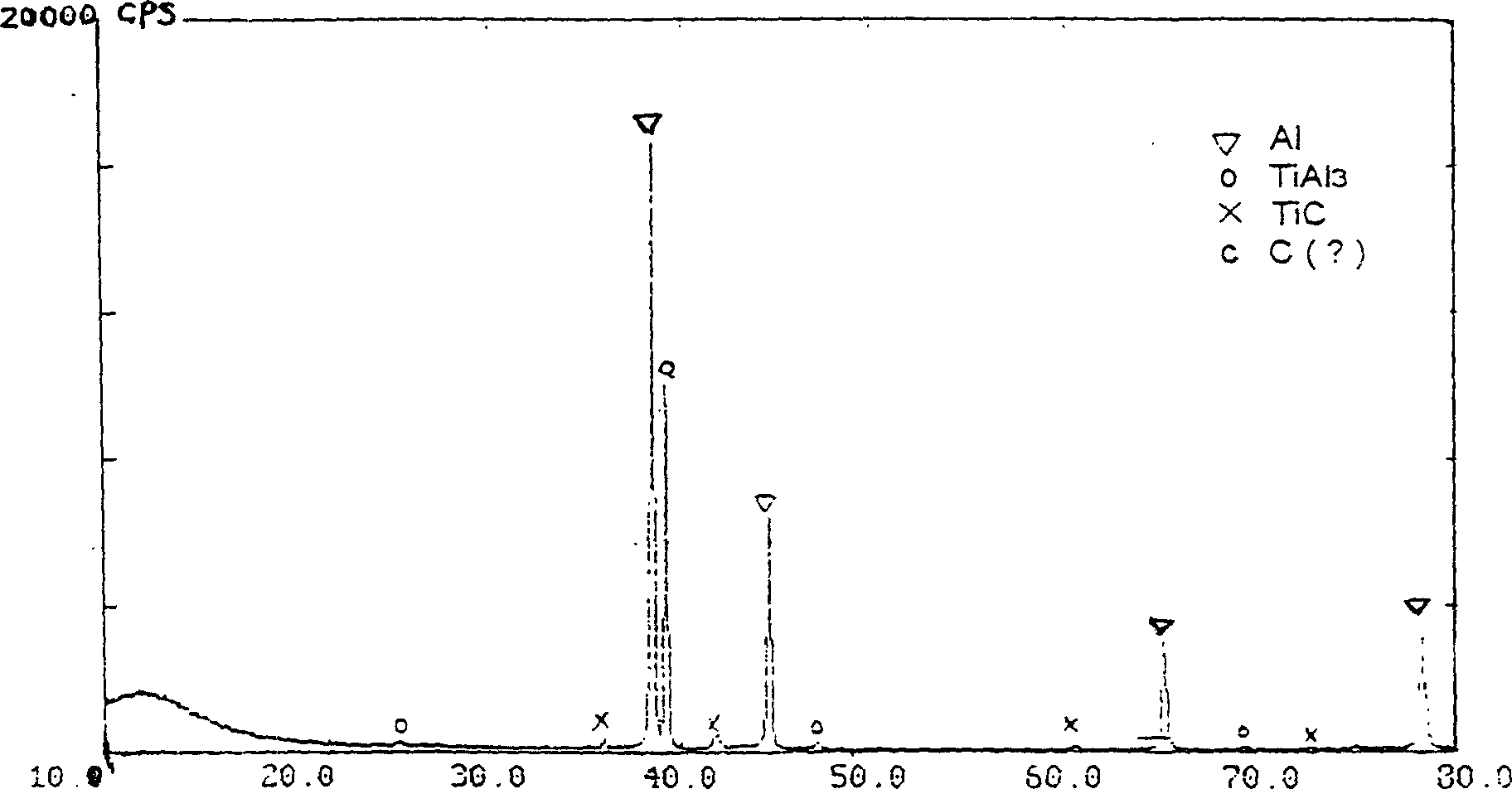

[0040] Use graphite crucible to melt 20kg99.7% Al and 1.1kg titanium sponge to aluminum and add sponge titanium to make Al5Ti alloy melt at a temperature of 800°C-900°C. Use the rotor of the rotary refining device to feed nitrogen or argon into 80 at 200rpm. gram of graphite powder, the carbon reacts with the titanium in the melt to form TiC. Graphite powder is kept at 200°C for more than 2 hours to remove moisture before use, and the average particle size is 20μm. The melt is overheated to above 1300°C for 5-10 minutes before casting to remove Al 4 C 3 and Ti 3 The cladding layer formed by AlC around TiC avoids weakening or destroying the effective nucleation ability of α-Al, and then the prepared AlTiC melt is completely cleaned of scum and cast into the required ingot. The result of quantitative analysis of carbon content of the AlTiC master alloy thus prepared was 0.35% C, and the result of grain refinement was that the average grain size of the sample was 85 μm.

example 2

[0042] According to Example 1, use 99.7% Al20kg, add 5.6kg KTF6 (potassium fluorotitanate) and 85 grams of activated carbon at a temperature of 750°C-800°C to react for 20-30 minutes, remove the scum, and heat up to 1100°C to add 0.16% AlTiC master alloy, the average grain size of the grain-refined sample is 97m.

example 3

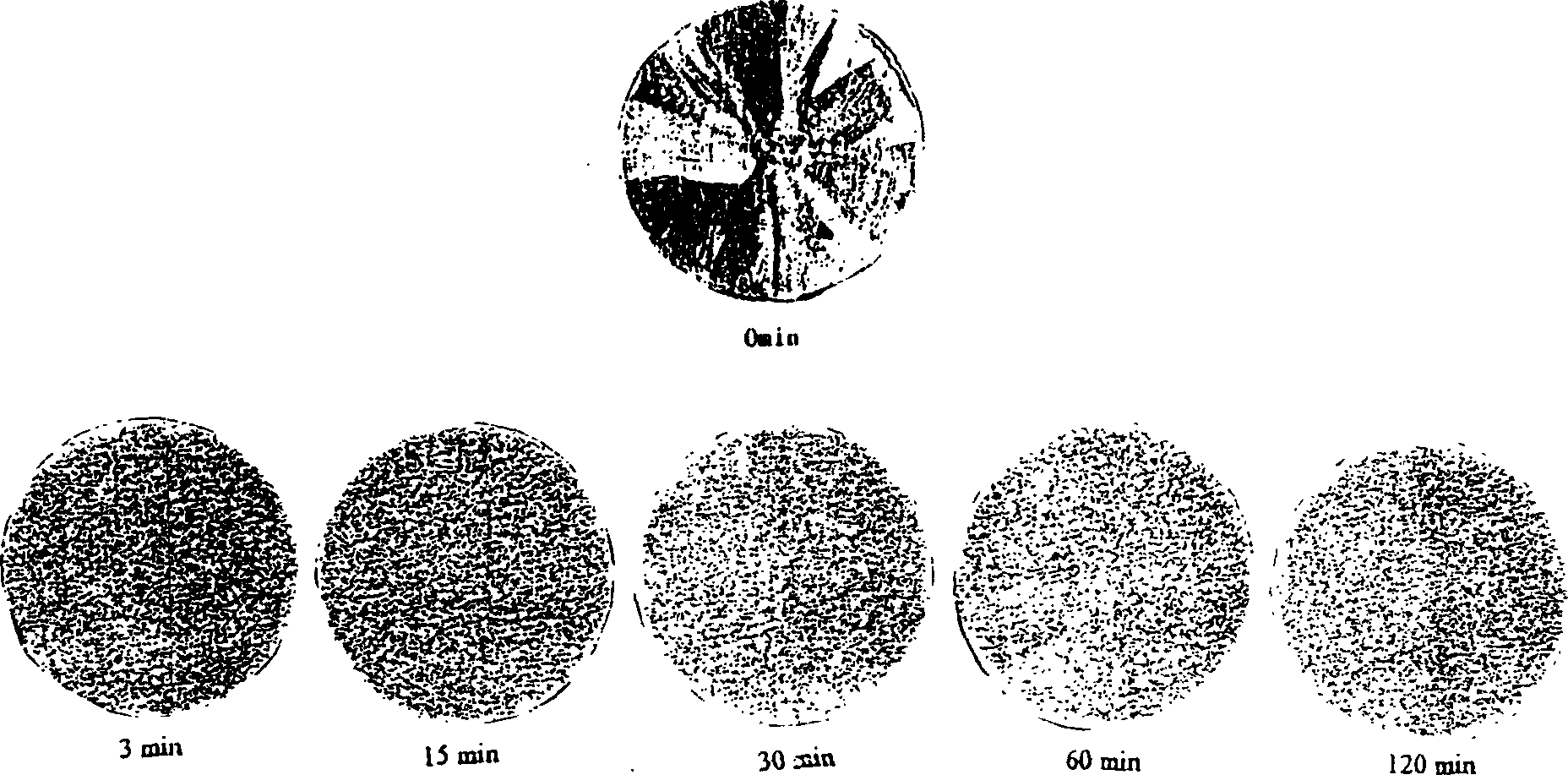

[0044] According to Example 1, add 2 kg of Al-5% Ti melt in a graphite crucible with a capacity of 5 kg at a temperature of 850 ° C, add 30 grams of carbon ink on the clean melt surface, and stir gently with a graphite rod for 10-15 minutes. The AlTiC alloy containing 0.05% C was prepared at the reaction temperature of ℃, and the average grain size of the cast sample was 145 μm. The refinement effect of the melt has not declined significantly after being kept in the mold at 725°C±5°C for 330 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com