Composite sulfur-fixing agent and application thereof

A technology of sulfur fixation agent and mixture, which is applied in flue gas treatment. In the field of desulfurization, it can solve the problems of no desulfurization catalytic effect and high cost of composite desulfurizer, achieve good sulfur fixation effect, increase desulfurization reaction time, and improve desulfurization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: The composition and mass percentage of the composite sulfur-fixing agent are: 5% copper slag (TZ), 95% calcium carbonate; 10% copper slag, 90% calcium carbonate; 20% copper slag, 80% calcium carbonate. Wherein the copper slag is the industrial waste slag separated from the smelting and depletion electric furnace of the copper mine of a copper company in Yunnan.

[0019] Table 1: Chemical composition of copper slag

[0020] .

[0021] Table 2: Content of main minerals in copper slag

[0022] .

[0023] (1) The property analysis of calcium carbonate / copper slag composite sulfur fixative is as follows:

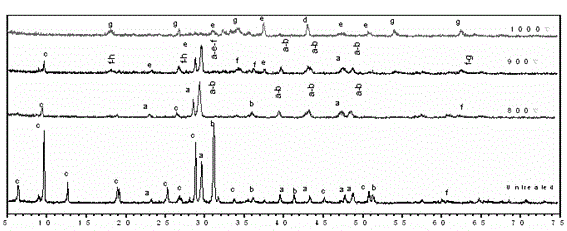

[0024] Through the XRD analysis of the calcium carbonate / copper slag composite sulfur fixative, it can be known that, as figure 1 It is shown that pyrolysis of composite sulfur fixation agent can release substances that are beneficial to catalyze sulfur fixation.

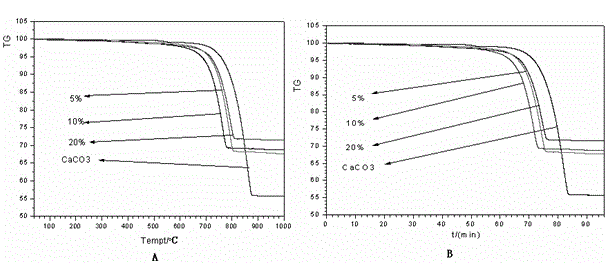

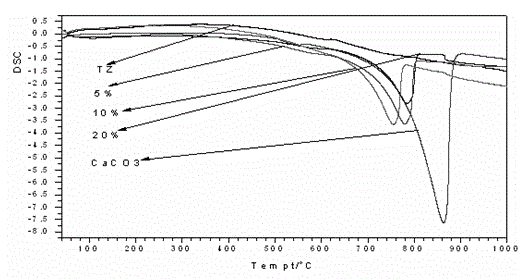

[0025] When adding copper slag in different proportions, CaCO 3 The relationship between...

Embodiment 2

[0041] Example 2: After uniformly mixing different proportions of copper slag and calcium oxide, carry out wet, semi-dry, and dry sulfur fixation tests on the test bench, wherein the volume fraction of each component of the simulated flue gas, the laboratory simulated flue gas Air intake rate, detection instrument are with embodiment 1, and experimental result is as table 7:

[0042] Table 7: When the amount of copper slag added is 15%, 25%, and 30%, the sulfur-fixing efficiency of calcium oxide / copper slag composite sulfur-fixing agent

[0043] .

Embodiment 3

[0044] Embodiment 3: After uniformly mixing copper slag and calcium hydroxide in different proportions, wet, semi-dry, and dry sulfur fixation tests were carried out on the test bench, wherein the volume fraction of each component of the simulated flue gas, the laboratory simulated smoke The air intake rate and detection instruments are the same as above, and the experimental results are shown in Table 8:

[0045] Table 8: When the amount of copper slag added is 35%, 40%, and 45%, the sulfur-fixing efficiency of calcium hydroxide / copper slag composite sulfur-fixing agent

[0046] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com