Fuel coal additive and preparation method thereof

A coal-fired additive, glycerin technology, applied in the field of coal-fired additives, can solve the problems of low efficiency and high cost, and achieve the effects of fast heating, reduced use cost and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The raw materials are weighed according to the following ratio (by mass percentage): 35% of glycerol; 12.1% of sodium peroxide; 20.7% of potassium hydroxide; 15% of borax; 8.7% of sodium silicate; According to the order of glycerol—water—potassium hydroxide—borax—sodium silicate—sodium peroxide, add the above-mentioned raw materials into the stirrer and stir. After all the above raw materials are added, continue to mix and stir for 120 minutes, and control the temperature of the mixture within the range of 60°C to 95°C to prevent the mixture from being oxidized and decomposed due to overheating. After the stirring is completed, wait for it to cool down to 40°C to 50°C, and put the mixture (that is, the additive stock solution) into barrels and put it into storage.

[0032] After determination, the physical and chemical parameters of the additive stock solution are:

[0033] 1. Water solubility - can be used as non-combustible, non-corrosive to iron.

[0034] 2. Specif...

Embodiment 2

[0047] The difference between embodiment 2 and embodiment 1 is: the proportioning of the raw material components taken by weighing is glycerol 36%, potassium hydroxide 20.5%, sodium peroxide 12%, borax 14%, sodium silicate 8% , Water 9.5%.

[0048] The using method of additive is the same as embodiment 1.

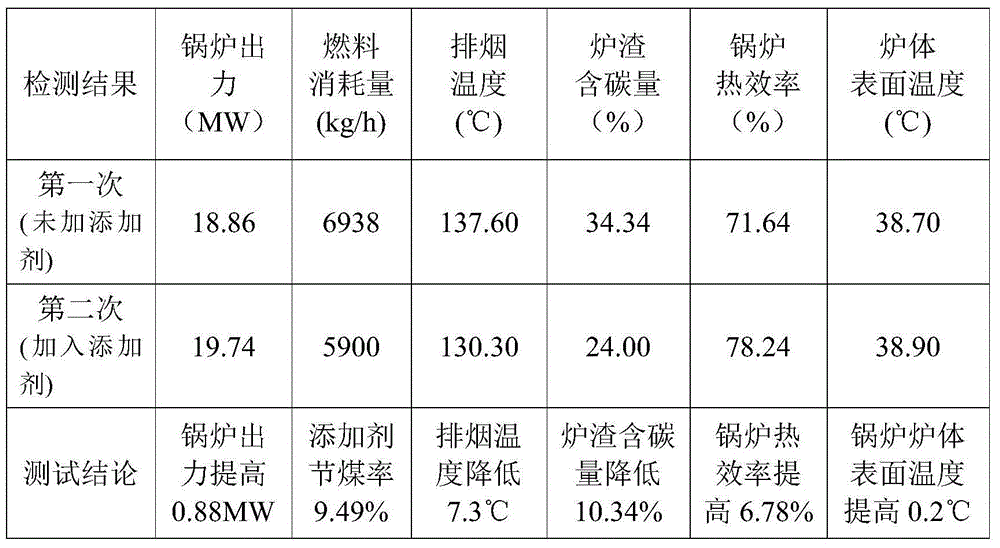

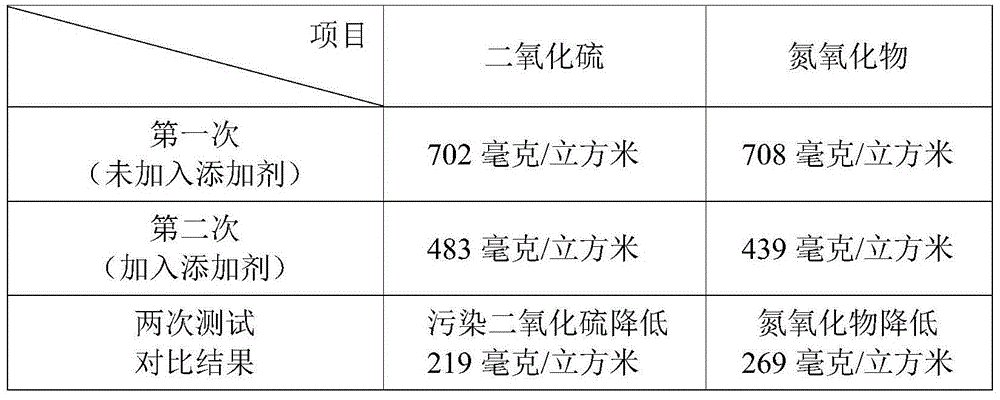

[0049] In the case of stable working conditions, the combustion of coal with additives and coal without additives is also compared to obtain the following parameters, as shown in Table 3:

[0050] table 3

[0051]

Embodiment 3

[0053] The difference between embodiment 3 and embodiment 1 and embodiment 2 is: the proportioning of the raw material components taken by weighing is glycerol 42.8%, potassium hydroxide 18.2%, sodium peroxide 11.2%, borax 13.5%, silicon Sodium acid 6.8%, water 7.5%.

[0054] The using method of additive is the same as embodiment 1.

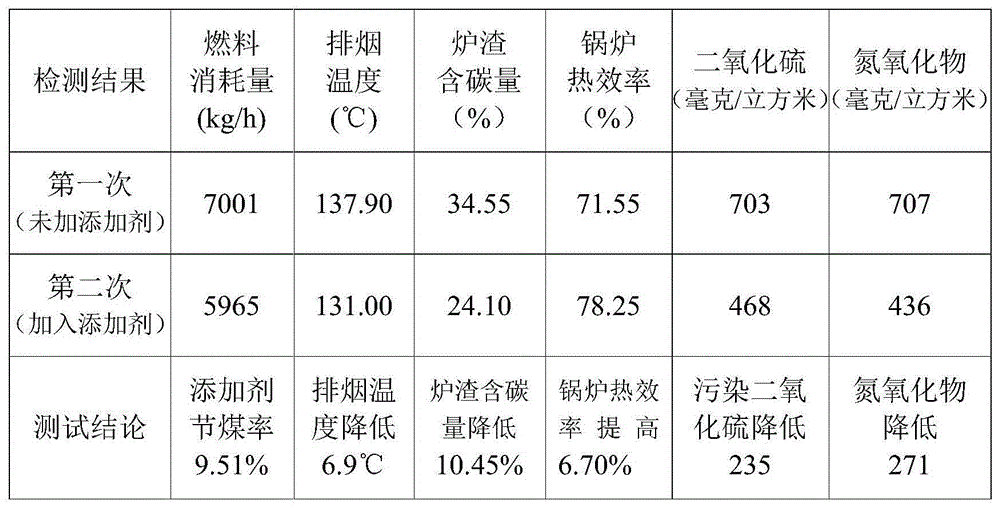

[0055] In the case of stable working conditions, the following comparative parameters are obtained for the combustion of coal with the same additives and the combustion without additives, as shown in Table 4.

[0056] Table 4

[0057]

[0058] In the present invention, glycerin can be mixed with coal gas for combustion at high temperature, thereby increasing the combustion calorific value, and simultaneously burning with smoke dust can serve the purpose of eliminating smoke. Potassium hydroxide or sodium hydroxide, releases K at high temperature + or Na + Ions and SO in flue gas 2 React with nitrogen oxides to generate sulfate and nitrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com