Mould pressing lid maker

A molding and capping machine technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve the problems of scientific, reasonable and sufficient cooling of bottle caps, uncompact structure of molded caps, and difficulties in machine debugging. Achieve the effect of scientific and reasonable cooling method, compact structure and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

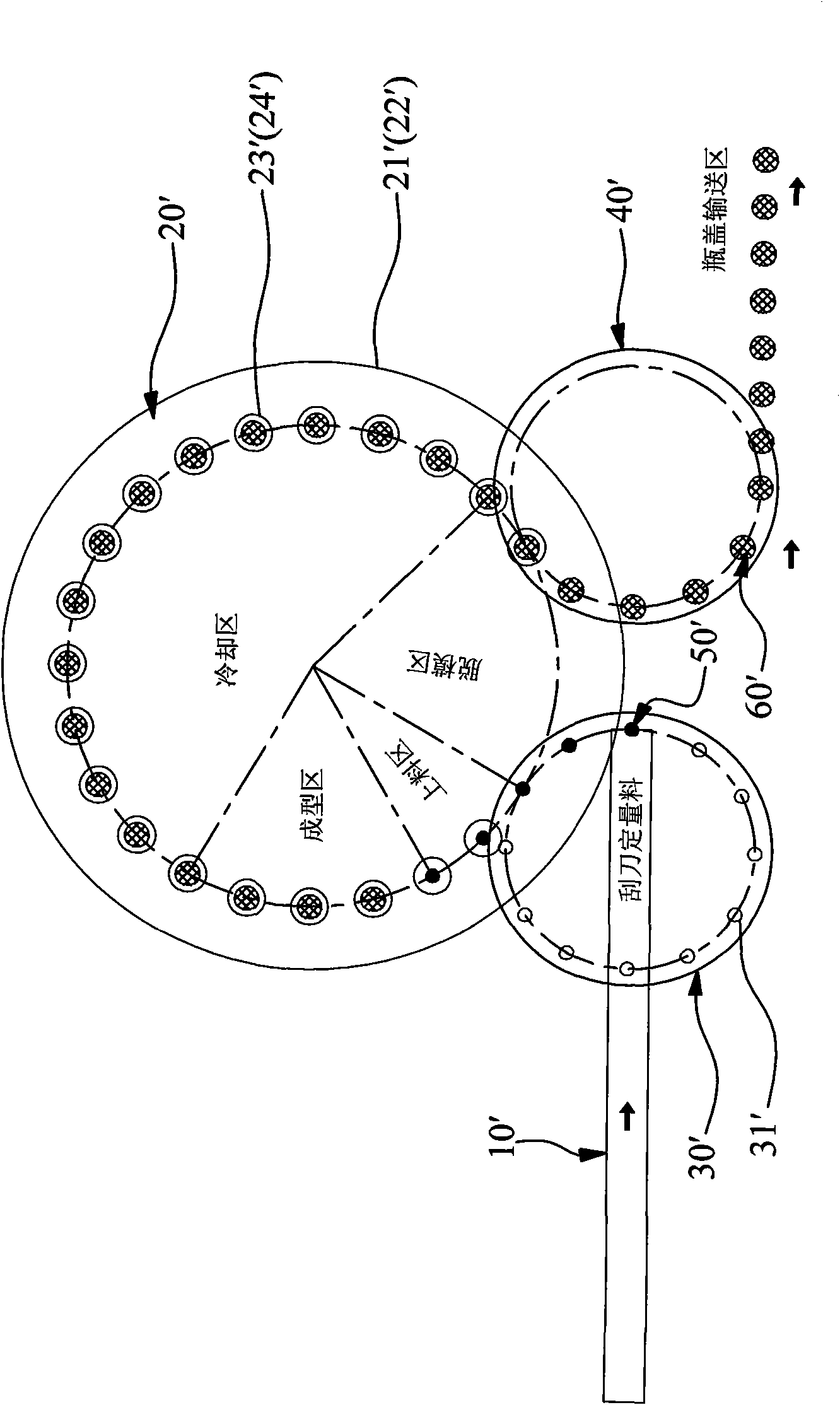

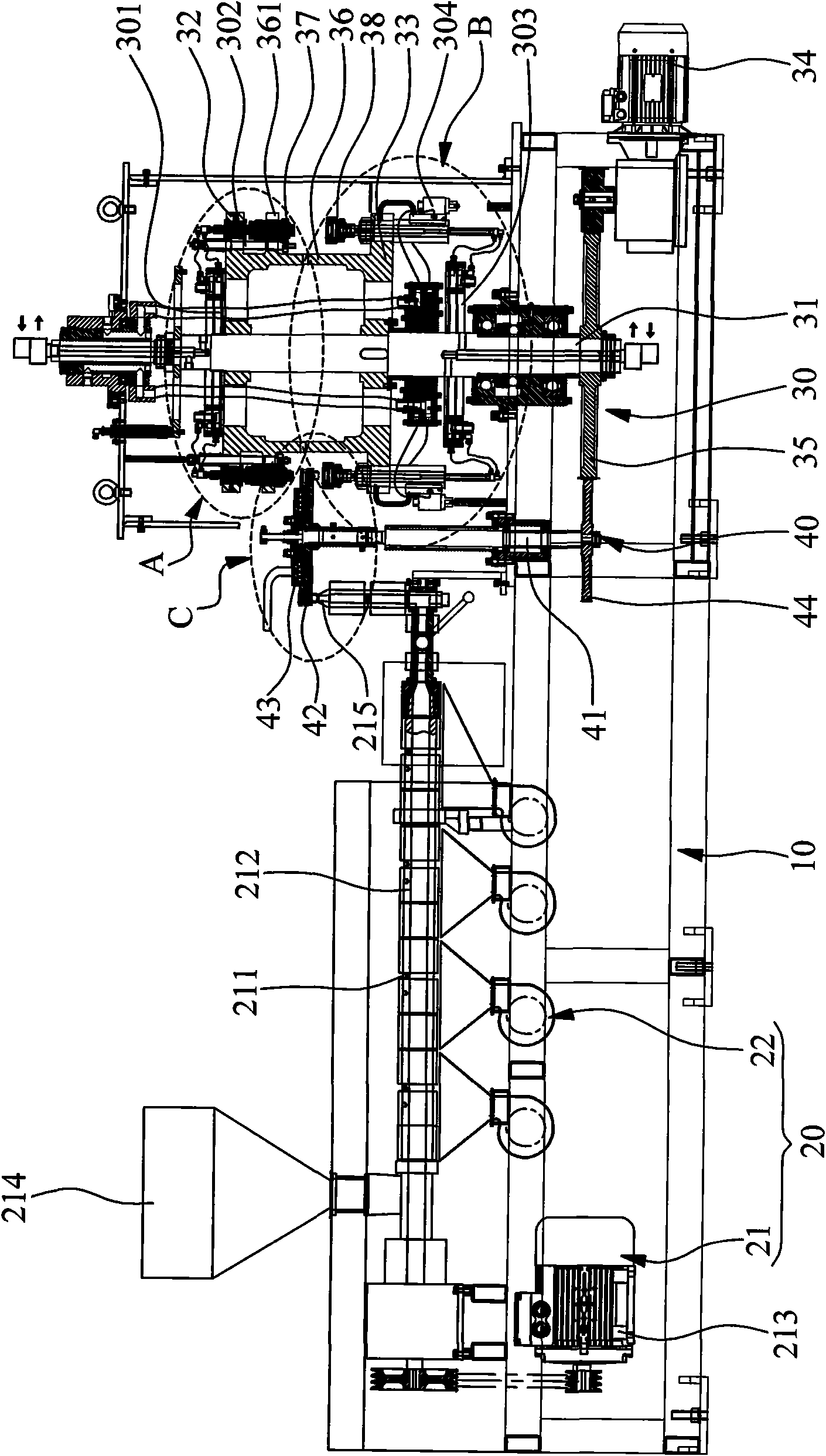

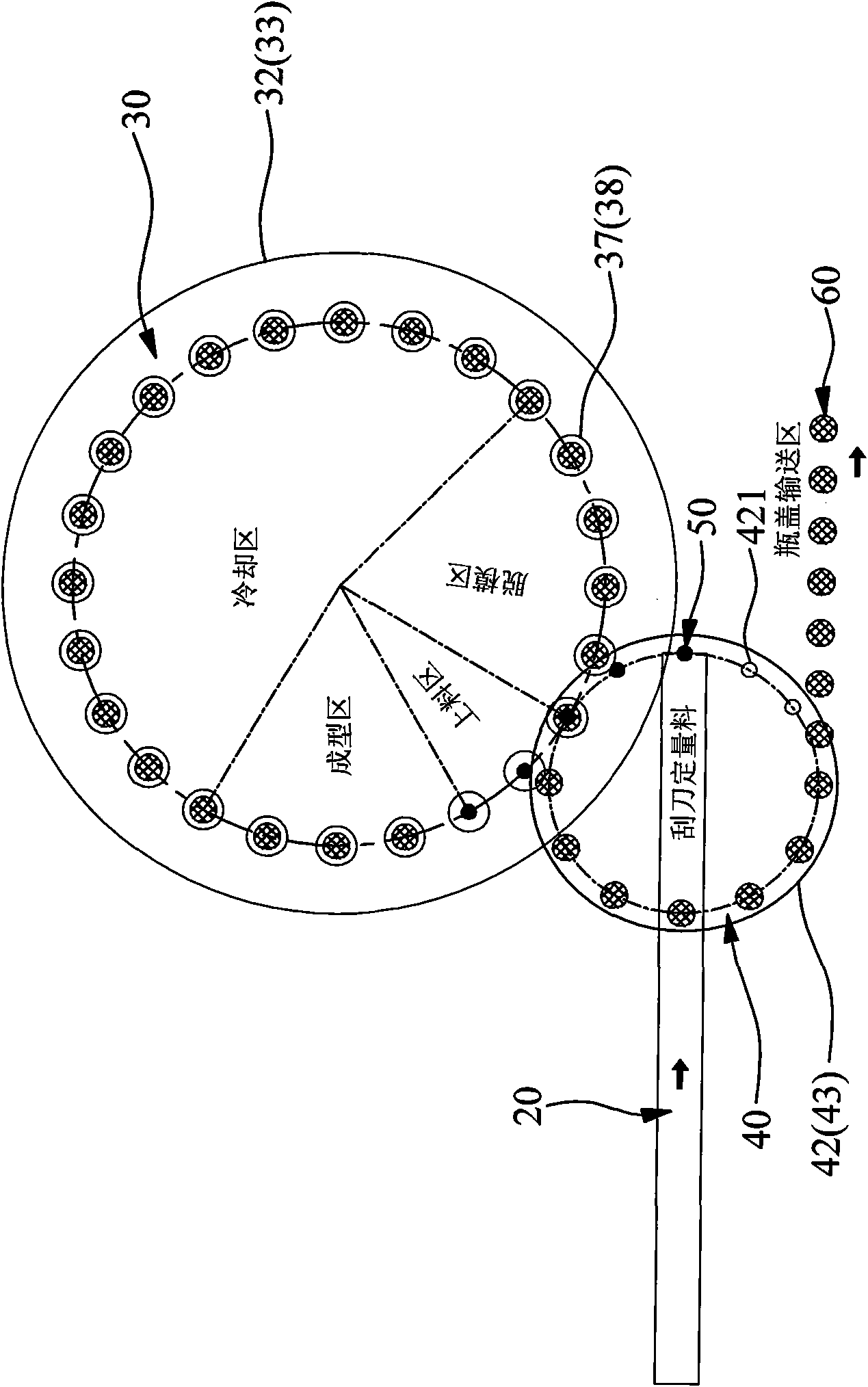

[0062] Please refer to Figure 2 to Figure 6 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a frame 10 on which an extrusion die set 20 , a pressing die set 30 and a feeding and discharging mechanism 40 are arranged.

[0063] Wherein, the extrusion die set 20 is installed on the left end of the frame 10 . The extrusion die set 20 is an eight-stage temperature-controlled extrusion die set, which at least includes an extrusion device 21 and a plurality of heating devices 22 . The extruder 21 includes an organic barrel 211, an extrusion screw 212 and a drive motor 213. The barrel 211 has a material channel, and the left and right ends of the barrel 211 are correspondingly provided with a hopper 214 and an extrusion 215 with an opening facing upwards. Both the hopper 214 and the extrusion port 215 are connected to the material passage of the barrel 211 . The extruding screw 212 is arranged in the feed channel of the afore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com