Zip-top can crushing device

A technology of crushing device and pop cans, which is applied in the fields of dust removal, grain processing, chemical instruments and methods, etc. It can solve the problems that affect the service life of the crusher, the quality of materials is not very good, pollute the environment, etc., and achieve simple structure and improve the quality of smelting , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

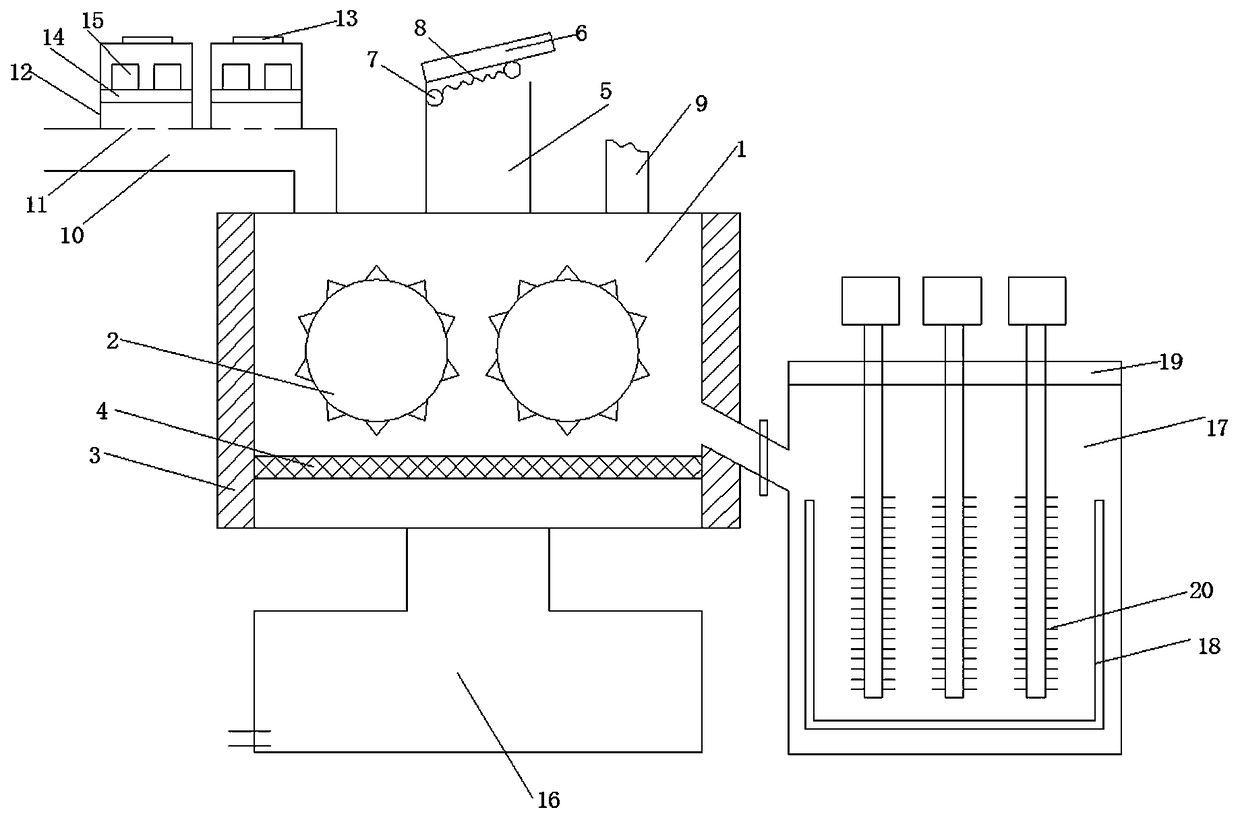

[0013] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

[0014] Such as figure 1 As shown, the present invention is a crushing device for pop cans, comprising a crushing box 1 and a feed pipe 5 arranged above the crushing box 1, and a sound-absorbing cotton layer 3 is arranged outside the crushing box 1 to reduce crushing. The noise generated in the process of popping cans, two toothed rollers 2 are arranged inside the crushing box 1, and the toothed rollers are high manganese steel toothed rollers produced by Henan Sias Wear-resistant Casting Co., Ltd., inside the crushing box 1 , the bottom of the toothed roller 2 is provided with a filter screen 4, the waste water collection tank 16 is set through a pipeline under the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com