Aluminium borosilicate glass with high elastic modulus and uses thereof

An aluminoborosilicate, high-elasticity technology, used in glass substrates for flat panel displays to manufacture TFT-LCD glass substrates, the application of this glass plate in flat panel displays can solve errors, affect electric fields and pixels, circuits defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

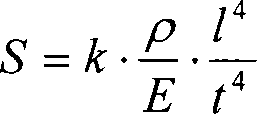

Method used

Image

Examples

Embodiment Construction

[0032] The invention provides an aluminoborosilicate glass with high modulus of elasticity, the composition of the glass expressed in weight percentage is: 55-63.5 SiO 2 , 8-10.5B 2 o 3 , 15-21Al 2 o 3 , 0-3.5MgO, 4-10CaO, 0-5SrO, 1-5.5BaO, 0.001-4Y 2 o 3 , 0-2.5La 2 o 3 , 0-0.5ZnO, 0-0.3ZrO 2 , 0.001-0.08R 2 O (R = Li, Na, K),

[0033] Among them, MgO+CaO+SrO+BaO is preferably 8-18, preferably SiO 2 +Al 2 o 3 is 70-80, among which, the preferred Al 2 o 3 The content is 15-18.5, preferably Y 2 o 3 The content is 0.1-4, the preferred MgO content is 1-3, more preferably 1.5-3, the preferred CaO content is 4-8.5, the preferred SrO content is 0-3, the preferred BaO content is 1-4, and more Preferably 1-3, preferably R 2 The O content is 0.01-0.06, and the glass also contains at least one clarifier selected from the following components: 0-1.5As 2 o 3 , 0-0.85b 2 o 3 , 0-1.5SnO 2 , 0-0.5CeO 2 , 0-2Cl.

[0034] The density of said glass is less than 2.55 g / cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com