Method for preparing beta-glucosidase fixed with magnetic nano-particle

A technology of magnetic nanoparticles and glucosidase, which is applied in the direction of fixing on/in the organic carrier, can solve the problems of short service life and storage period, expensive price and limitation of β-glucosidase, and achieve low cost , uniform shape, and high recovery rate of enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

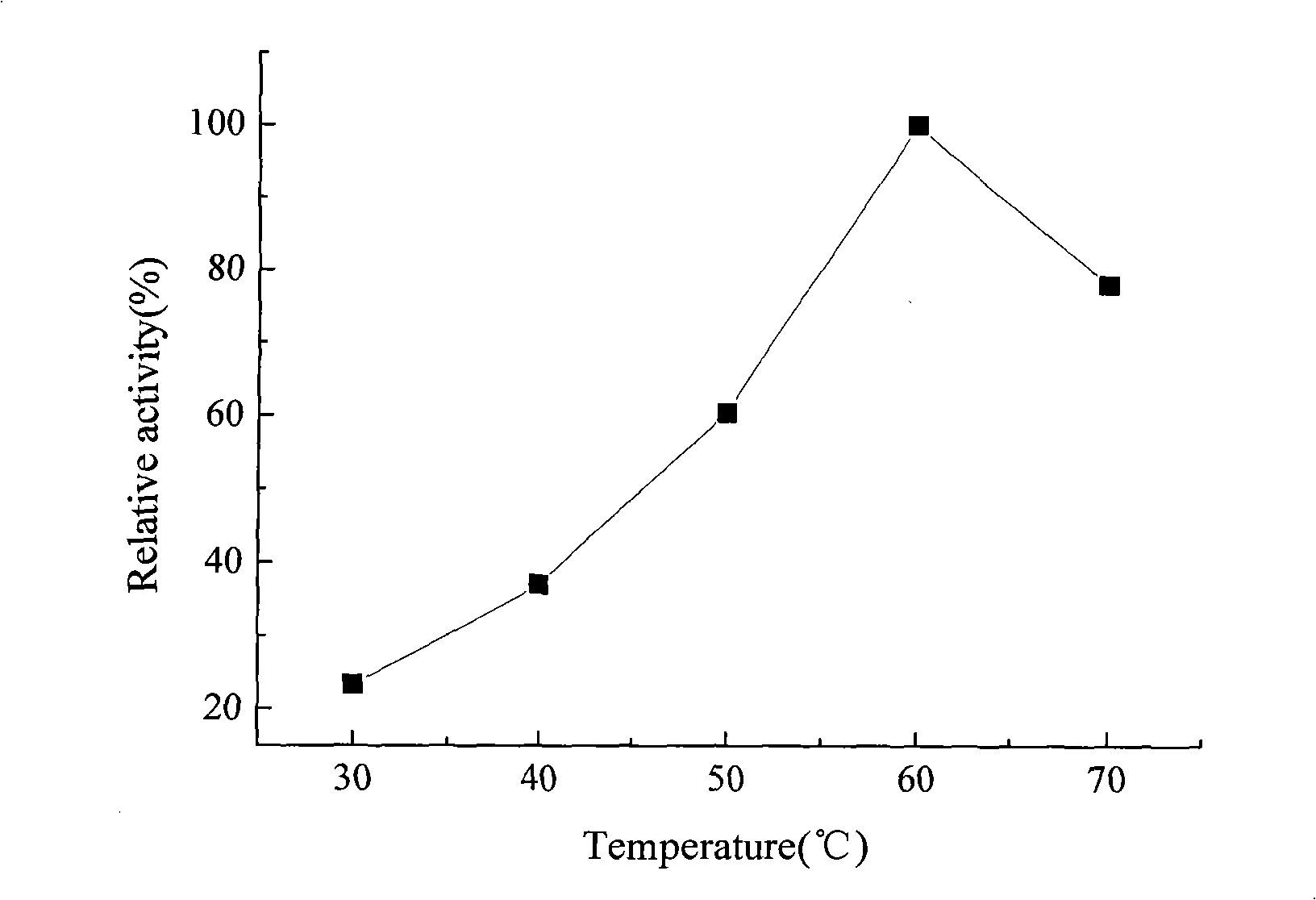

Embodiment 1

[0029] (1) Add 0.1MFe 2+ and Fe 3+ After mixing the chloride solution with a ratio of 1:2, use 4M NaOH to stir at a high speed at 80°C and pH=10.0 for precipitation reaction, then wash, filter, and dry the precipitate to obtain Fe with a size of 8-10 nm. 3 o 4 particles, in this chemical co-precipitation method to prepare nano-Fe 3 o 4 Due to the different chemical characteristics of the dispersion system used in the process of particle processing, it will have a certain impact on the performance of magnetic particles.

[0030] (2) Dissolving 1 g of chitosan in 100 mL of acetic acid solution with a mass fraction of 10% forms a uniform and transparent colloidal solution.

[0031] (3) the above-prepared Fe 3 o 4 The particles were poured into the chitosan solution, stirred for 20 minutes, washed repeatedly with distilled water until neutral, and dried for later use.

[0032] (4) Weigh 0.1 g of the absolute dry magnetic nanoparticles prepared above, add 1 mL of β-glucosida...

Embodiment 2

[0035] (1) Fe 2+ and Fe 3+ After the chloride solution is mixed in a ratio of 1:2, excess NaOH is used to stir at a high speed at a certain temperature and pH value for precipitation reaction, and then the precipitate is washed, filtered, and dried to obtain Fe with a size of 8-10 nm. 3 o 4 particles.

[0036] (2) Dissolving 1 g of chitosan in 100 mL of acetic acid solution with a mass fraction of 10% forms a uniform and transparent colloidal solution.

[0037] (3) the above-prepared Fe 3 o 4 The particles were poured into the chitosan solution, stirred for 20 minutes, washed repeatedly with distilled water until neutral, and dried for later use.

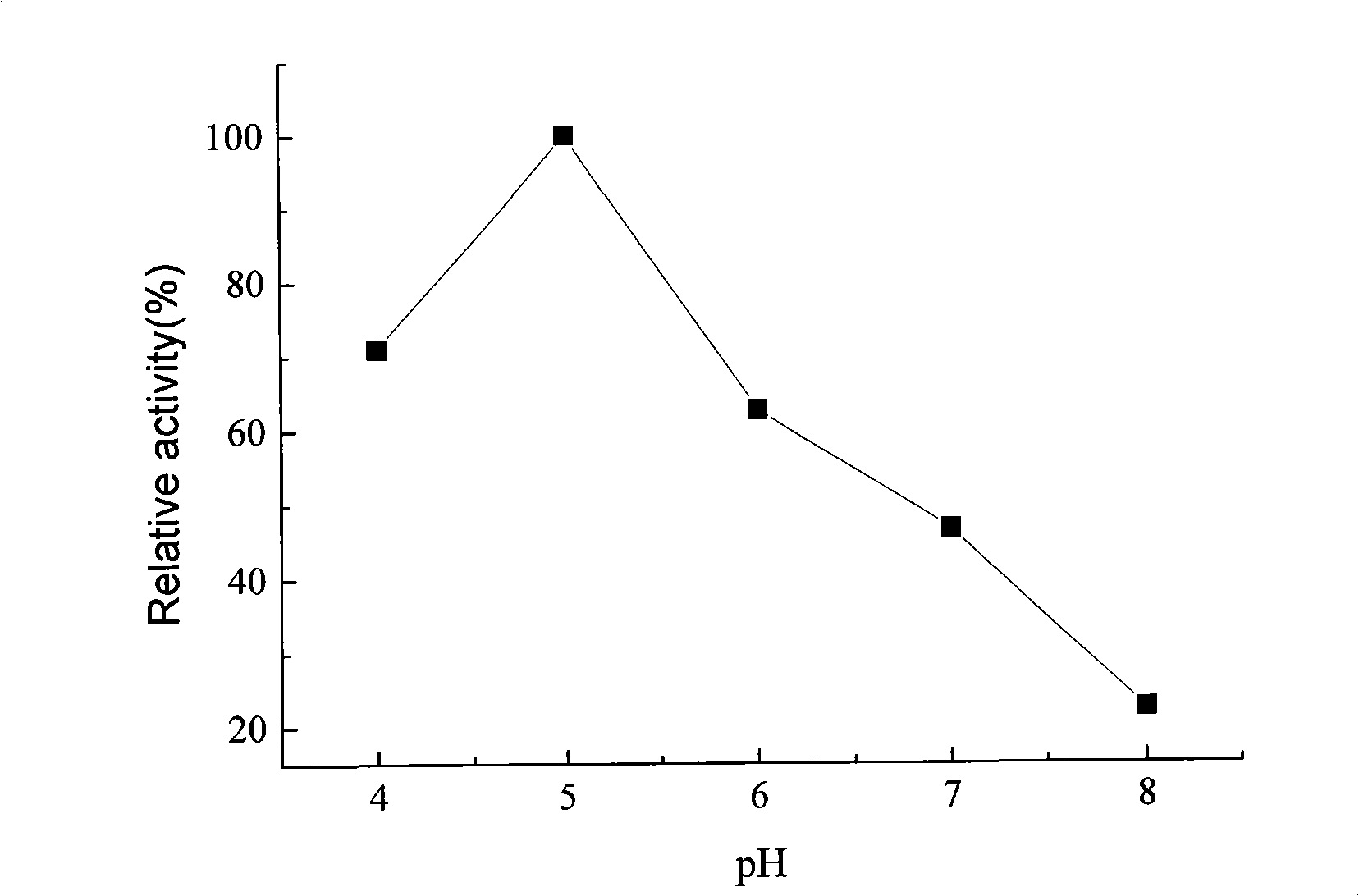

[0038] (4) Add 0.1M citric acid buffer solution with a pH value of 4.0, 5.0, 6.0, 7.0, 8.0 to the immobilized β-glucosidase solution and the free β-glucosidase solution respectively, and react at 45°C for 10 minutes and measure the activity of the enzyme.

Embodiment 3

[0040] (1) Fe 2+ and Fe 3+ After the chloride solution is mixed in a ratio of 1:2, excess NaOH is used to stir at a high speed at a certain temperature and pH value for precipitation reaction, and then the precipitate is washed, filtered, and dried to obtain Fe with a size of 8-10 nm. 3 o 4 particles.

[0041] (2) Dissolving 1 g of chitosan in 100 mL of acetic acid solution with a mass fraction of 10% forms a uniform and transparent colloidal solution.

[0042] (3) the above-prepared Fe 3 o 4 The particles were poured into the chitosan solution, stirred for 20 minutes, washed repeatedly with distilled water until neutral, and dried for later use.

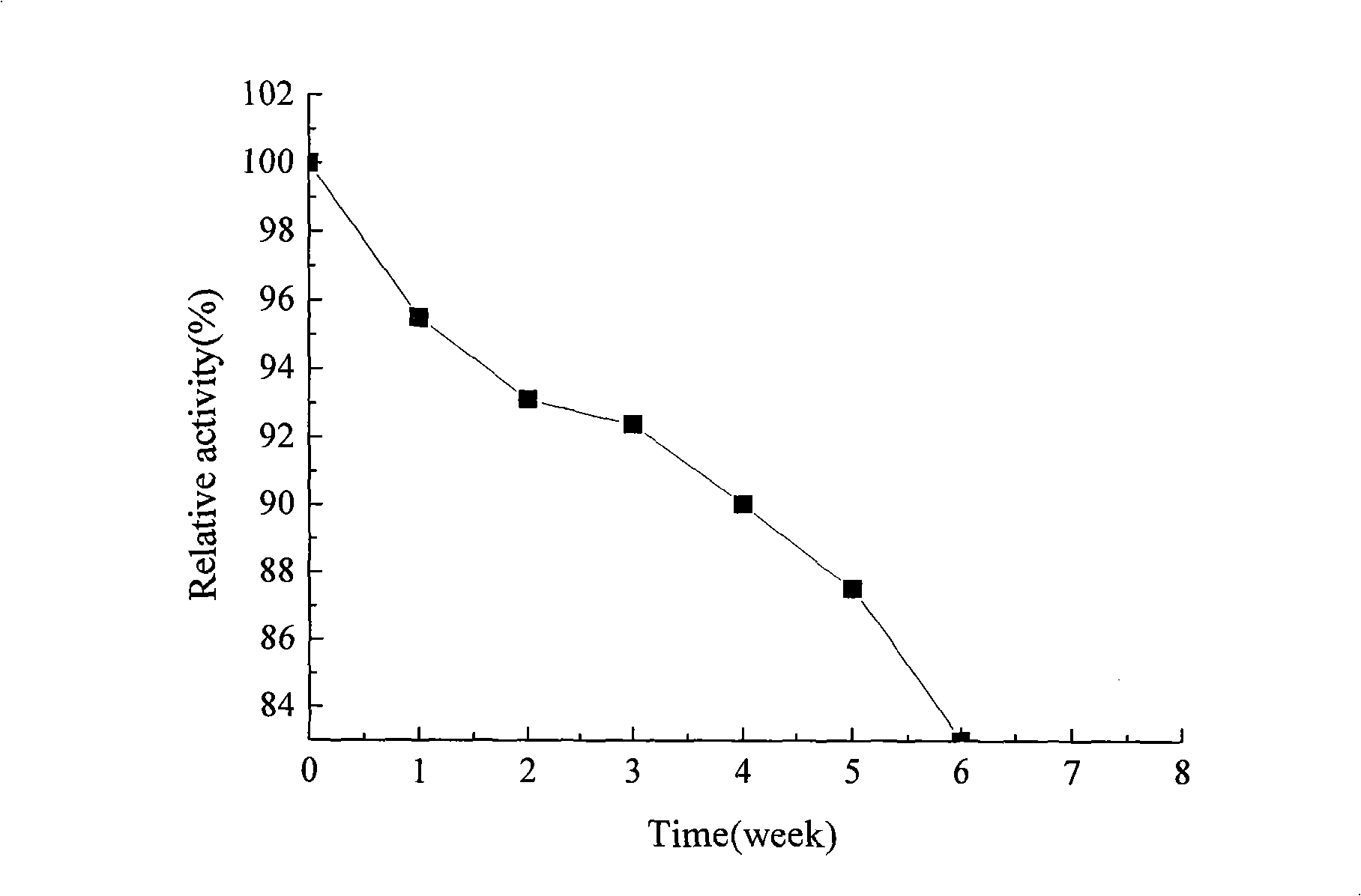

[0043] (4) Add 0.1 M citric acid buffer solution with pH=5.0 to the immobilized β-glucosidase solution and the free β-glucosidase solution respectively, react at 45° C. for 10 minutes, and measure the enzyme activity every other week.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com