Patents

Literature

59results about How to "High recovery rate of enzyme activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for immobilizing beta-glucosidase and hydrolyzing straw cellulose by cooperating beta-glucosidase with cellulase

InactiveCN102533717AEasy to shapeUniform shapeOn/in organic carrierFermentationAlglucerasePropanoic acid

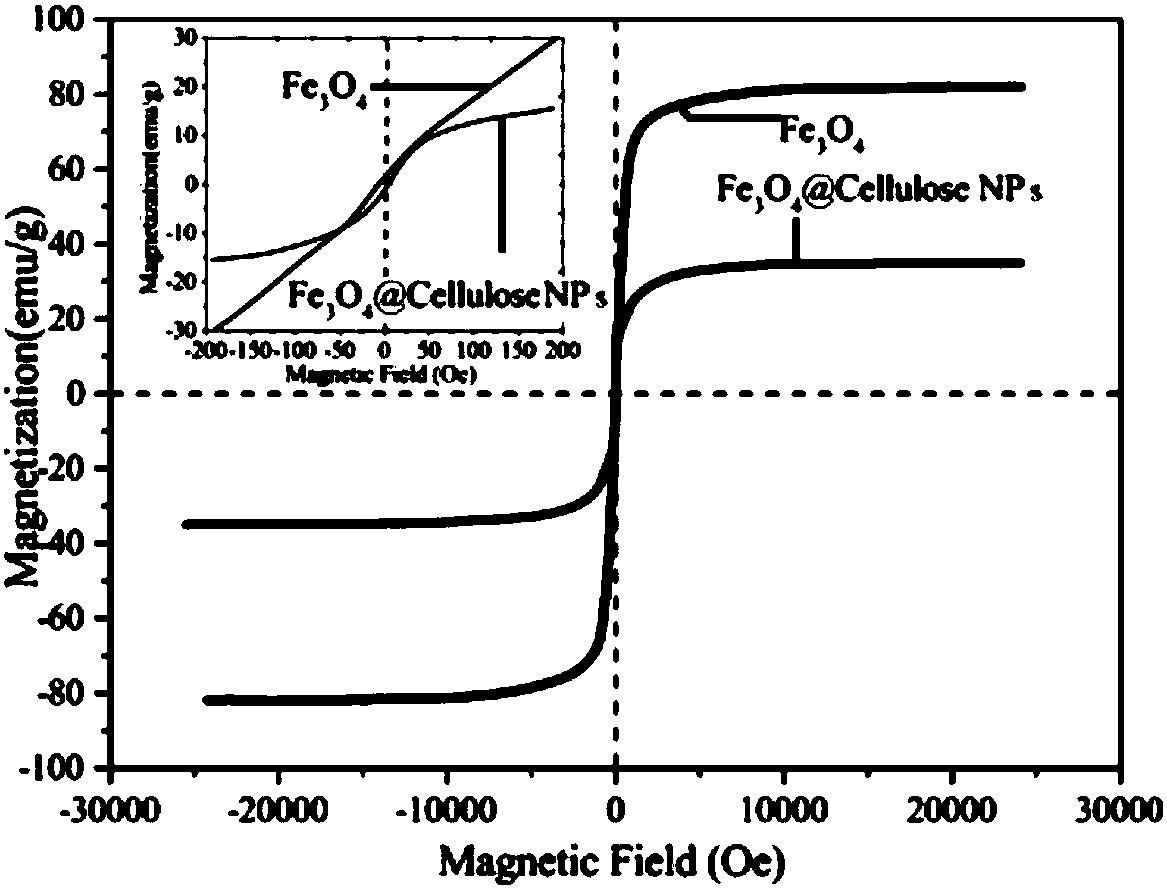

The invention relates to a method for immobilizing beta-glucosidase and hydrolyzing straw cellulose by cooperating the beta-glucosidase with cellulase, belonging to the technical field of biocatalysis. The method provided by the invention comprises the following steps of: (1) dissolving chitosan into a propionic acid solution to form a transparent and homogeneous colloid, mixing and stirring the colloid with Fe3O4 grains, dropwise adding a NaOH solution to obtain magnetic microspheres, and carrying out crosslinking on the magnetic microspheres in a glutaraldehyde solution to obtain an immobilized carrier; (2) adding the immobilized carrier into a beta-glucosidase solution for adsorption to obtain a magnetic immobilized beta-glucosidase, hydrolyzing a cellobiose substrate by using the magnetic immobilized beta-glucosidase, and measuring the enzyme activity of the magnetic immobilized beta-glucosidase; and (3) degrading maize straws by coordinating the magnetic immobilized beta-glucosidase with the cellulase. The immobilized beta-glucosidase prepared by the method has the characteristics of homogeneous shape, large specific surface area, high mechanical strength, high enzyme activity and easiness in recovery; and the immobilized beta-glucosidase can hydrolyze the straw cellulose by coordinating with the cellulase to increase the yield of hydrolyzed sugar, and the stability in repeated use is good, so that the cost for the enzymatic hydrolysis of the straw cellulose can be lowered.

Owner:JIANGNAN UNIV

Process of chitosan-arginine resin anion immobilizing chymotrypsin

Owner:CHONGQING UNIV

Preparation method of immobilized enzyme

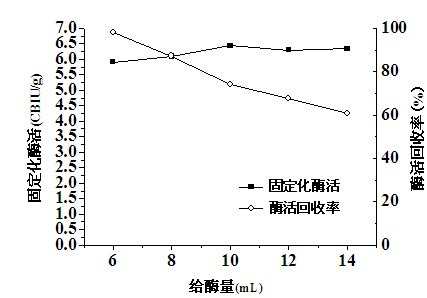

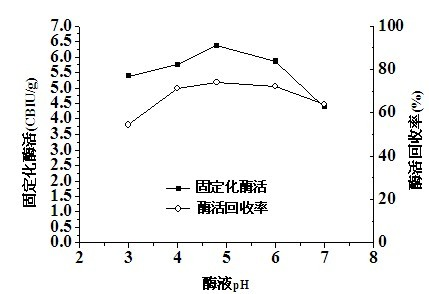

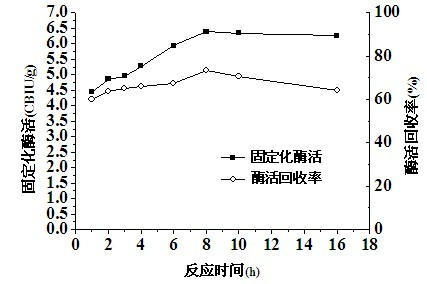

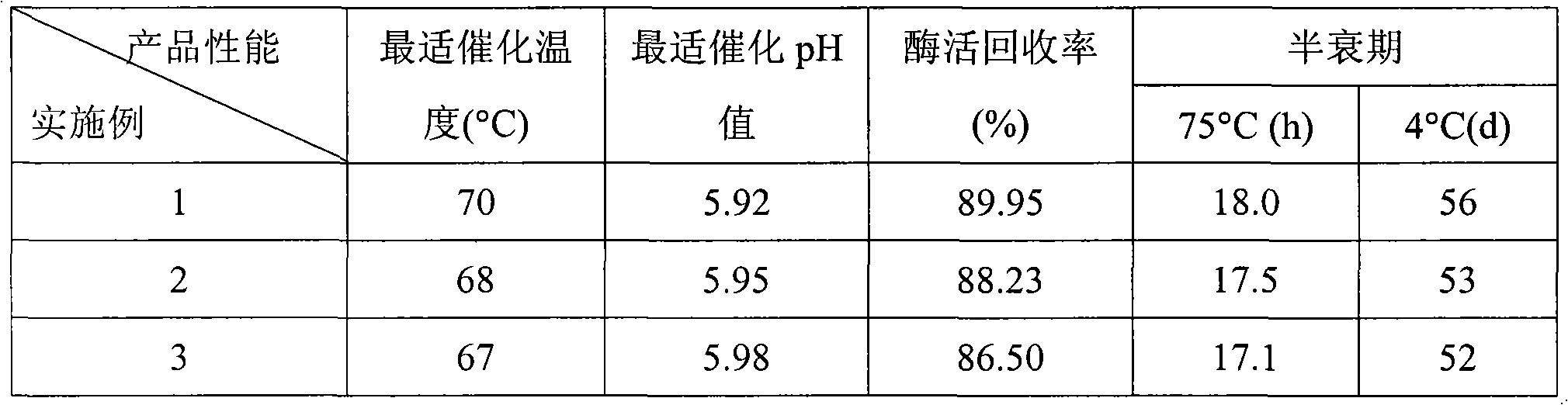

InactiveCN107893065AMild conditionsHigh recovery rate of enzyme activityOxidoreductasesOn/in organic carrierSolventIon

The invention discloses a preparation method of an adsorption-film covering combined immobilized enzyme. The preparation comprises the following steps: (1) dissolving an enzyme in a buffer solution toprepare an enzyme solution, mixing the enzyme solution with an adsorption material, carrying out oscillating adsorption for a certain time, and filtering out, to obtain an adsorbent immobilized enzyme; (2) dissolving a film covering protective agent in a buffer solution to prepare a protective agent solution, placing the adsorbent immobilized enzyme in the protective agent solution, carrying outoscillation treatment for a certain time, filtering out and draining, to obtain an adsorbent immobilized enzyme treated by the protective agent; (3) dissolving a film covering material in a solvent toprepare a film covering solution, mixing the adsorbent immobilized enzyme treated by the protective agent with the film covering solution, carrying out oscillating film covering for a period of time,and filtering out and drying; and (4) finally, swashing with deionized water or a buffer solution to obtain the adsorption-film covering combined immobilized enzyme. The preparation method has the advantages of mild conditions of the adsorption and film covering processes, high recovery rate of enzyme activity, high stability of the immobilized enzyme, simple operation and low cost.

Owner:宁夏乙征生物工程有限公司

Bacillus velezensis LfF-1 strain and application thereof in protease production

ActiveCN110551661AIncrease vitalityHigh recovery rate of enzyme activityBacteriaHydrolasesProtease preparationBatch fermentation

The invention discloses a Bacillus velezensis LfF-1 strain and application thereof in protease production. The Bacillus velezensis LfF-1 strain is separated for a first time, the strain is preserved in the Guangdong Microbiological Culture Collection Center in August 16, 2019, and the preservation number is GDMCC NO: 60741. The strain has a remarkable capability for producing protease through fermentation, and types of cultures produced through protease fermentation can be enriched; a protease preparation can be produced by using the strain through a fermentation tank replenishing on-batch fermentation process, the activity of the protease is as high as 17.84 ten thousand U / g, the enzyme activity recovery rate is as high as 96.8%, types of conventional commercial protease can be greatly enriched, and the production efficiency of the protease preparation can be improved; and in addition, the method for producing the protease from the strain through fermentation is simple and feasible, and has wide application prospects in producing protein foods, functional peptide products or feed additives.

Owner:LINGNAN NORMAL UNIV

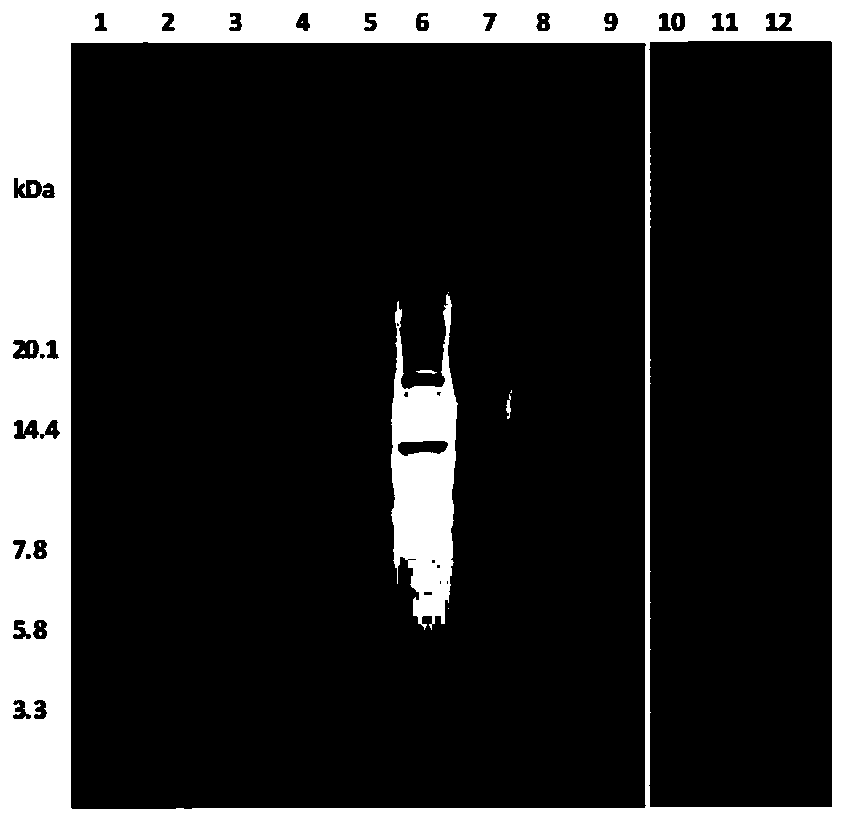

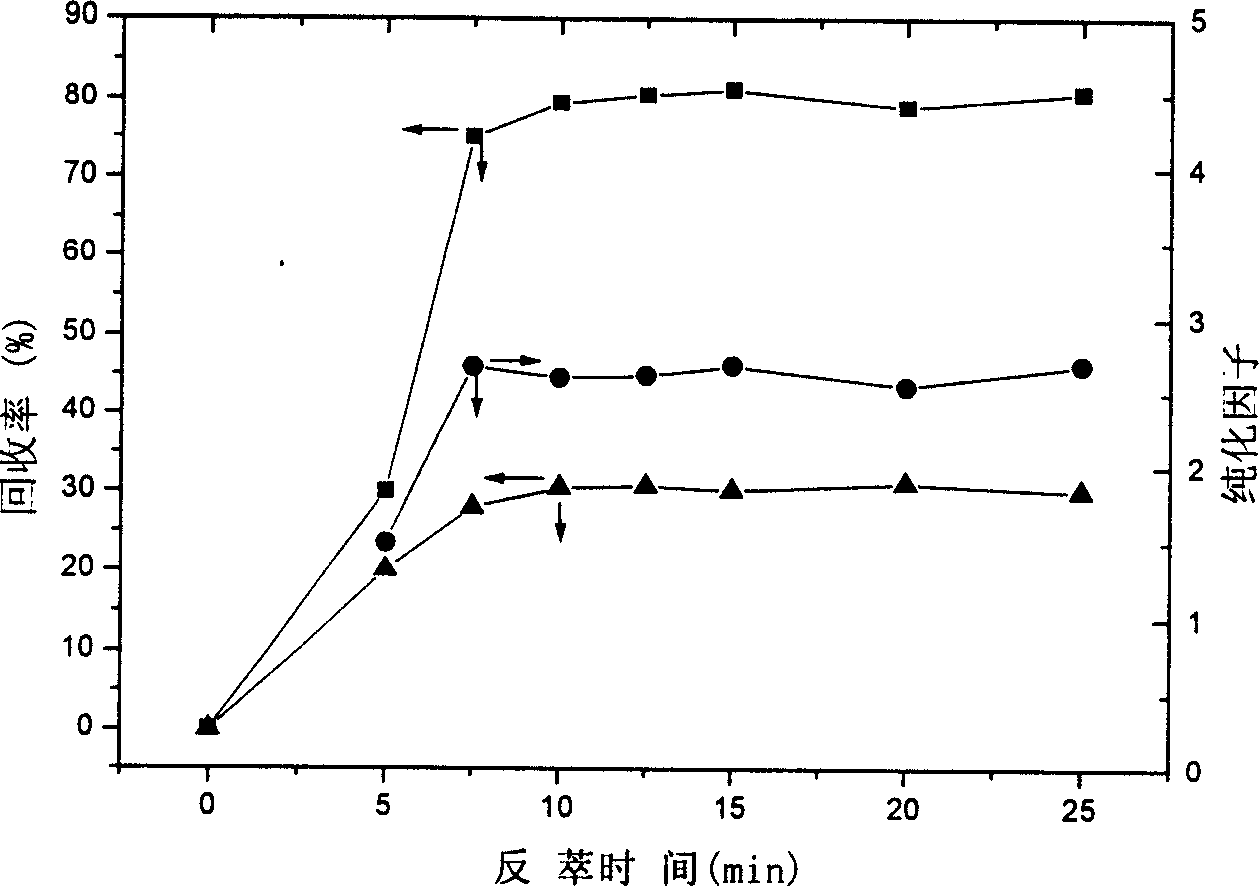

Process for separating and purifying natto kinase by reverse micelle method

InactiveCN1690196AEfficient extractionEfficient strippingTransferasesFood scienceKinaseContinuous operation

The invention relates to a method for separating and purifying bean-kinase in opposition-micelle process, in particular to a new method for extraction and purification of bean-kinase of bean-kinase coarse extraction liquid prepared from fermenting the solid or liquid directly in mother liquid, including the steps of extraction and back extraction; and the related extraction steps contains: proportionally mixing the bean-kinase coarse extraction as aqueous phase with opposition-micelle solution, extracting in 10 to 35 Deg. C, and letting bean-kinase into opposition-micelle solution; back extraction in back extraction liquid, centrifuging in 20 to 45 Deg. C, separating and the purified bean-kinase water solution prepared. It can solve the present problem that craft of purifying bean-kinase is complicated and cycle is long. The recovery ratio of enzyme is more than 80 percent, and the purifying factor more than 3, and at the same time has an effect of concentration decolouration. The cycle is short and facilitating to continuous operation and enlarging by separating and purifying bean-kinase with opposition-micelle process.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

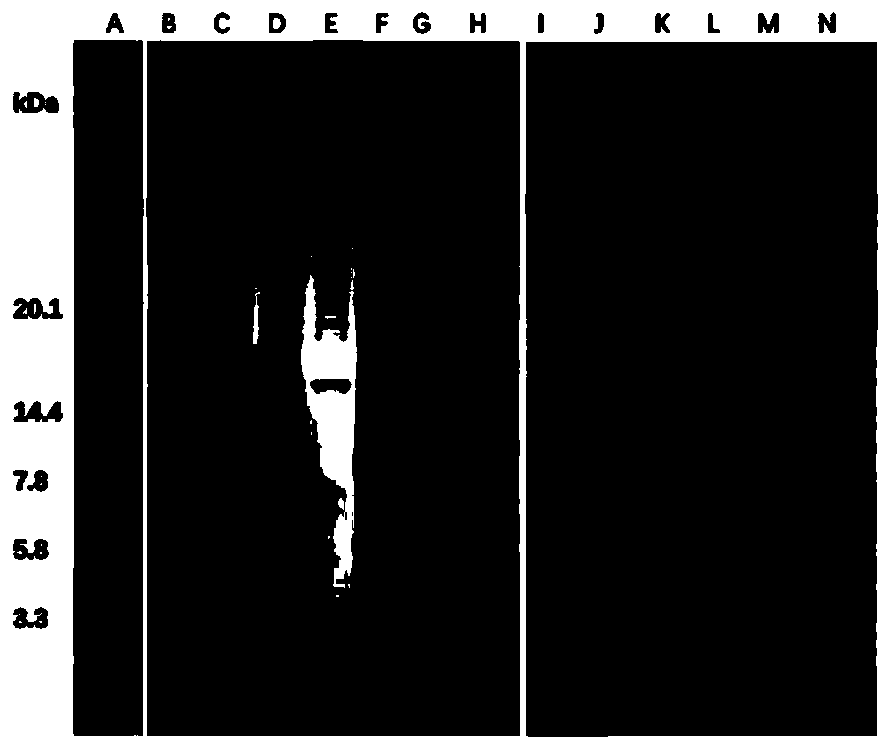

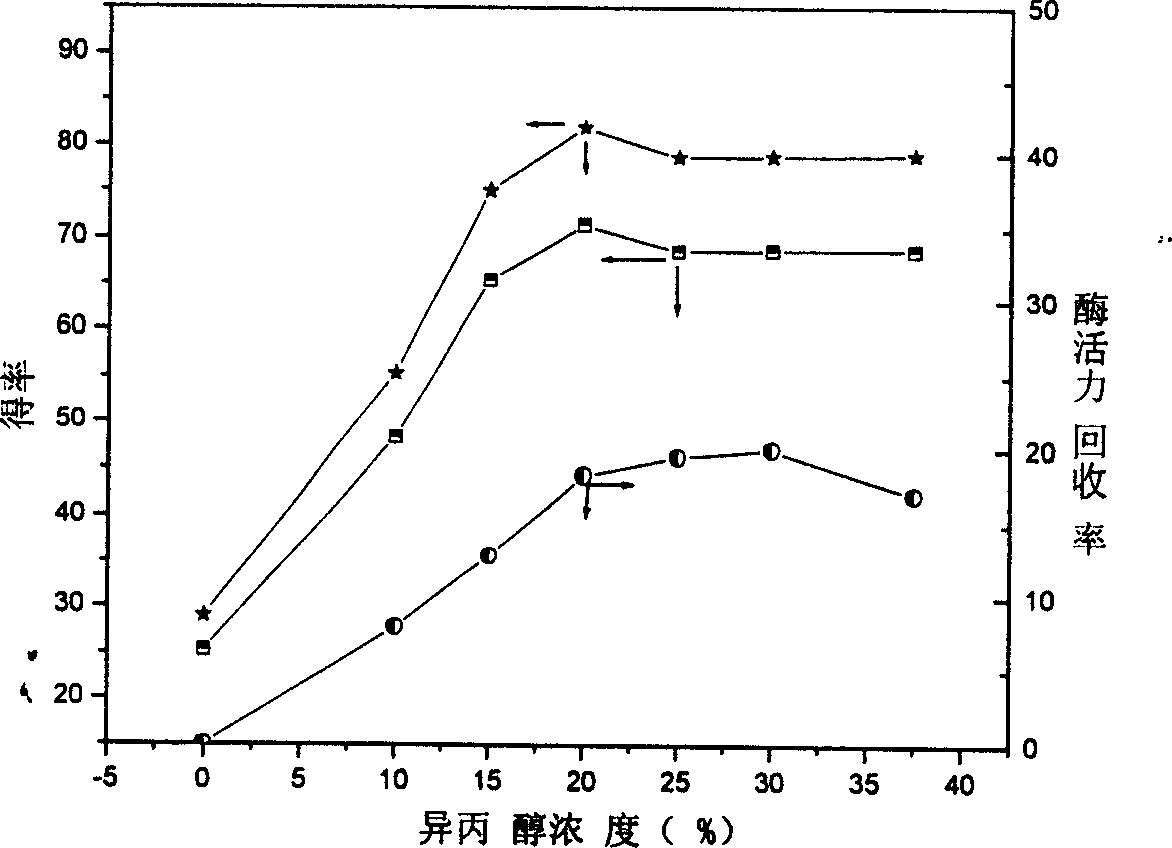

Method for separating purified protamine using reverse micelle method

InactiveCN101357935AHigh recovery rate of enzyme activityContinuous operationPeptide preparation methodsIonic strengthOrganic solvent

The invention belongs to the technical field of separation and purification of bio-active substances, more particularly relates to a method for directly separating and purifying the protamine from crude protamine extract with a reverse micelle method. The invention aims at solving the problems of complex process, multiple steps and long cycle of present protamine purification. The invention directly separates, purifies the protamine from the crude protamine extract by adopting the reverse micelle solution which consists of a surfactant and an organic solvent and can realize the high-efficient extraction and back extraction of the protamine by adjusting the conditions of extraction processes such as pH of water phases, ionic strength, phase ratio, contact time of two phases; the highest enzyme recovery rate can reach more than 96 percent and the purification factor reaches more than 2.1. The process has the effects of both concentration and decoloration. In addition, the separation and purification of the protamine with the reverse protamine technology have the advantages of short cycle, convenient continuous operation and being easily amplified.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

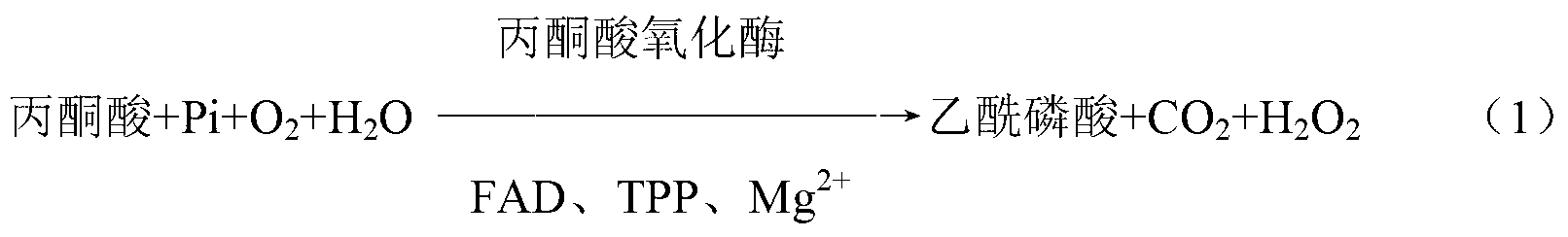

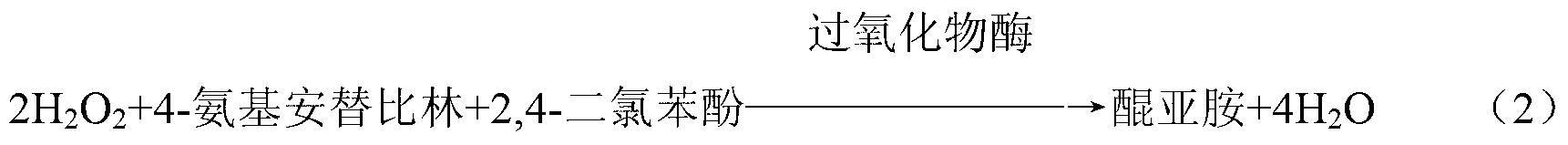

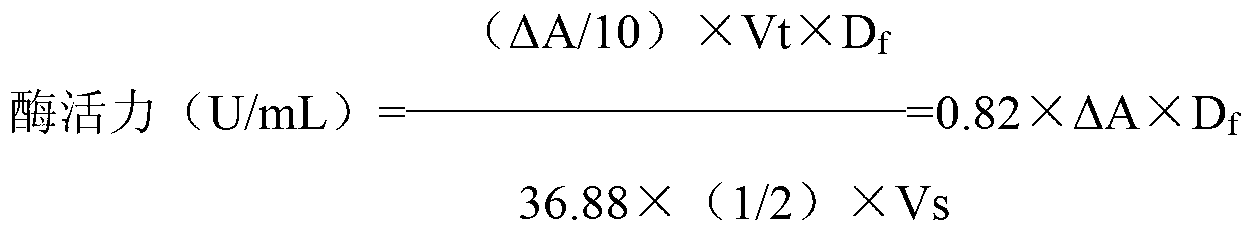

Method for preparing pyruvic oxidase

The invention relates to a method for preparing pyruvic oxidase. The method comprises the steps as follows: (1), cultivation of microbial cells containing the pyruvic oxidase, centrifugal collection of bacterial cells, and cell disruption; (2), preparation of a polyethylene glycol / inorganic salt two-aqueous phase extraction system solution; (3), three times of extraction separation by the aid of a two-aqueous phase extraction system, and obtaining of an inorganic salt solution of the pyruvic oxidase; and (4), flirtation and concentration of an ultrafiltration membrane, freezing and drying of a trapped fluid, and preparation of a pyruvate oxidase product. The method can prepare the pyruvic oxidase continuously in a large scale, the preparation technology of the oxidase is simple and convenient, the production period is short, the operation condition is mild, the recovery rate of the oxidase activity is high, and the production cost of the pyruvic oxidase is lower.

Owner:QILU UNIV OF TECH

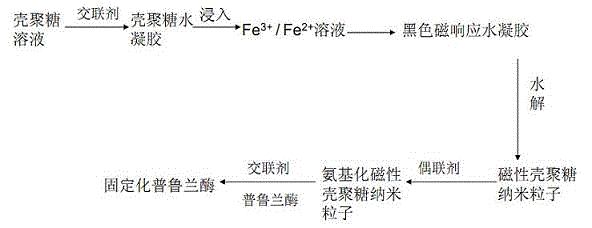

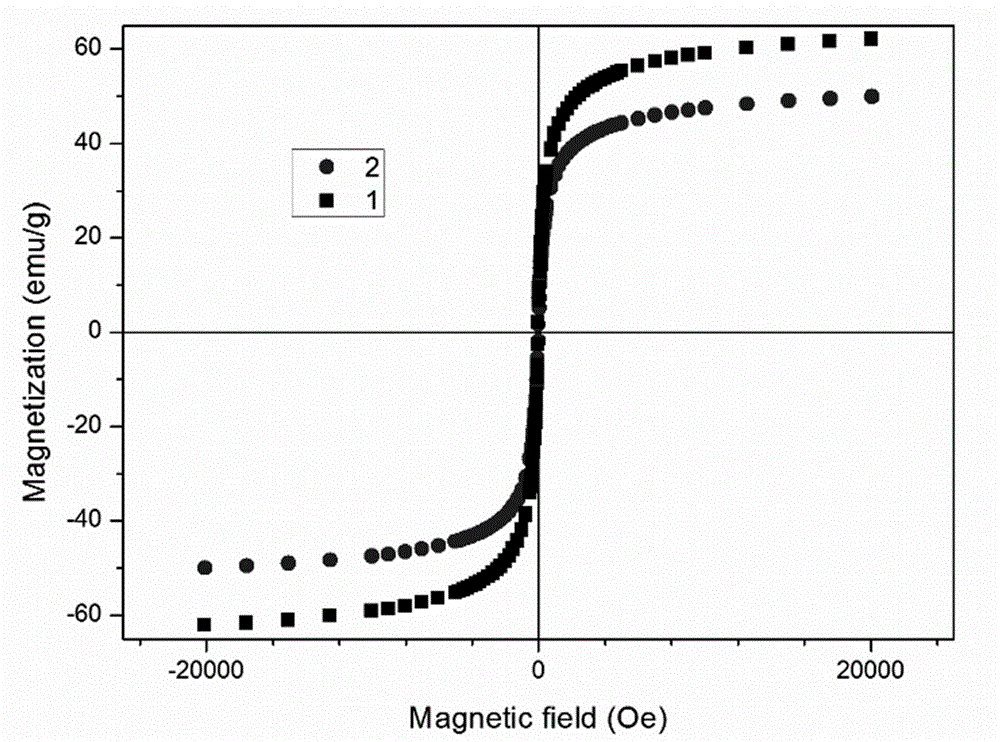

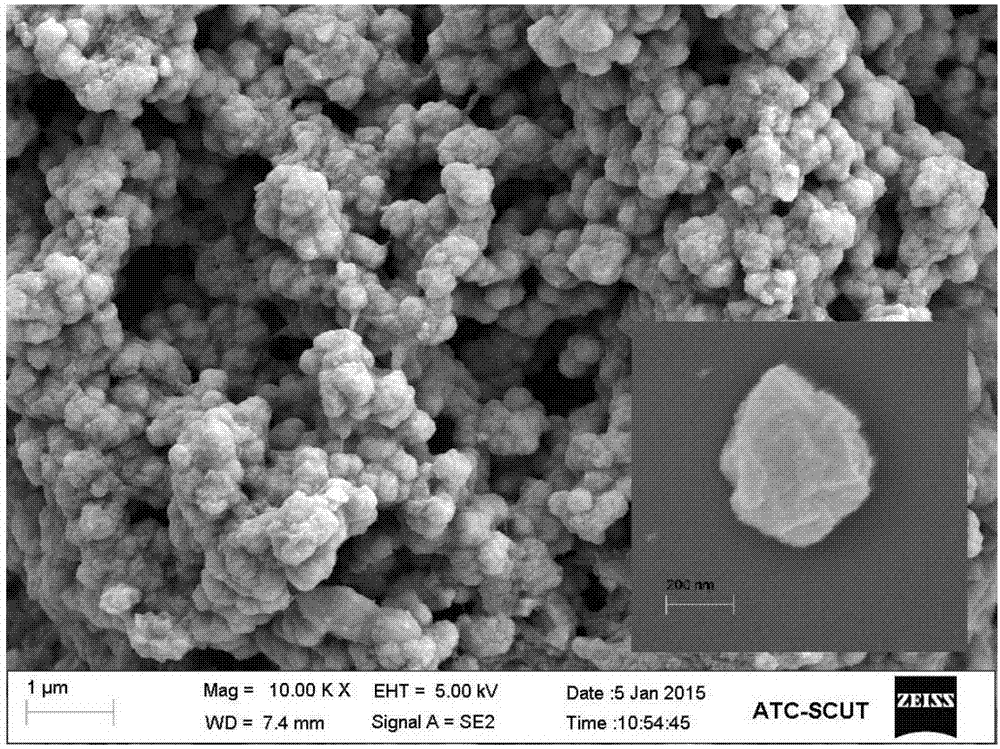

Method for fixing pullulanase with chitosan magnetic nanoparticles

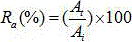

InactiveCN104099317AOvercoming the complexity of preparationOvercome costsOn/in organic carrierOn/in inorganic carrierCross-linkMagnetite Nanoparticles

A method for fixing pullulanase with chitosan magnetic nanoparticles comprises the steps as follows: (1) the chitosan magnetic nanoparticles are prepared; (2) amination treatment is performed on surfaces of the chitosan magnetic nanoparticles; (3) the chitosan magnetic nanoparticles after amination treatment and the pullulanase form covalent bonds in the presence of a cross-linking agent to fix the pullulanase. Compared with a traditional pullulanase fixing method, the method has the advantages that a carrier prepared with a chitosan hydrogel induction method is firstly used for fixing the pullulanase, and the method is simple in step, mild in condition and environment-friendly.

Owner:JIANGNAN UNIV

Method for producing N-acetyl glucosamine by enzymatically degrading chitin

InactiveCN104388496AFast water absorptionEasy to operateMicroorganism based processesEnzymesEngineeringMicrobiology

The invention discloses a method for producing N-acetyl glucosamine by enzymatically degrading chitin. The method comprises the following steps: step 1, producing chitinase by microbial fermentation; step 2, obtaining a crude enzyme solution; step 3, concentrating the enzyme solution; step 4, producing N-acetyl glucosamine. The invention firstly provides the method for producing N-acetyl glucosamine by enzymatically degrading chitin, and an enzyme production medium is low in cost and short in production cycle. The material used in the step of concentrating the enzyme solution can be recycled, the operation process is easy, and the enzyme recovery is high. A measure of preventing bacterial contamination is adopted in the degradation process, so that the purpose that the N-acetyl glucosamine with high medical value is efficiently and quickly produced by using cheap chitin with low value as a raw material is achieved, and the method has significant economic and social benefits.

Owner:NANJING UNIV OF TECH

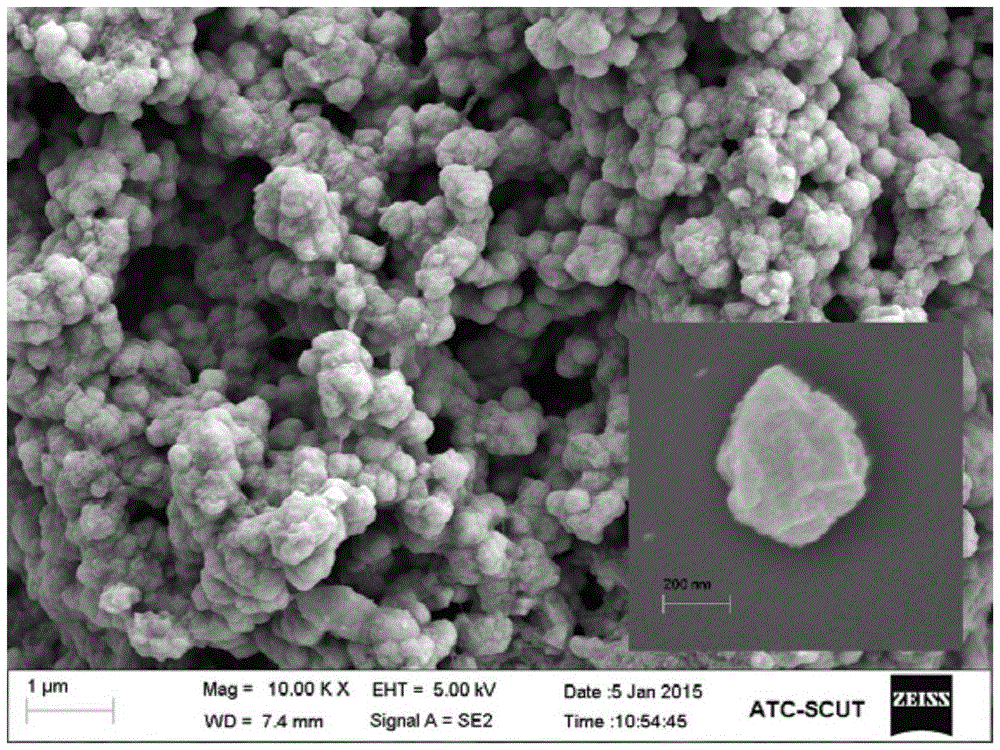

Novel immobilized enzyme preparation, and preparation method and application thereof

InactiveCN106520747AImprove stabilityEasy to fixOn/in organic carrierPeroxidaseMetal-organic framework

The invention belongs to the field of biological catalysis, and particularly relates to a novel immobilized enzyme preparation, and a preparation method and application thereof. The preparation method of the novel immobilized enzyme preparation comprises the following steps: combining nano magnetic chitosan microspheres and a metal-organic framework material having so many properties such as multiple pores, large specific area, multiple metal sites and the like through graft copolymerization to obtain a nano magnetic chitosan-metal organic framework material having a core-shell structure with a porous network structure; and mixing the nano magnetic chitosan-metal organic framework material used as a carrier and an enzyme solution, and immobilizing at 0-25 DEG C for 1-12 hours to obtain the novel immobilized enzyme preparation. The method can immobilize enzymes such as lipase, proteinase, peroxidase and the like, and has the advantages of low cost, high immobilization efficiency, favorable enzyme stability, high enzyme loading amount and high enzyme recovery rate; no bifunctional reagent is used in the immobilization process; and the method is simple to operate, low in cost and mild in reaction.

Owner:GUANGZHOU KAIYAO ASSET MANAGEMENT CO LTD

Method for preparing immobilized adenosylmethionine synthetase and adenosylmethionine

InactiveCN101985616AHigh recovery rate of enzyme activityExcellent continuous operation performanceChemical industryOn/in organic carrierS-Adenosyl-l-methionineImmobilized enzyme

The invention relates to a method for preparing immobilized adenosylmethionine synthetase and adenosylmethionine. The method has the following technical characteristics of: crosslinking amino resin carrier Seplite LX-1000HA and glutaraldehyde solution; and reacting the amino resin carrier crosslinked with glutaraldehyde with solution of recombinant adenosylmethionine synthetase to obtain the immobilized adenosylmethionine synthetase. The amino resin carrier has high protein fixation rate, the recovery rate of the enzyme activity of the immobilized adenosylmethionine synthetase is high, and the stability and continuous operation performance are good. When the immobilized adenosylmethionine synthetase is used for producing the adenosylmethionine, the reaction operation is simple, the production cycle is short, and products are easy to purify; the immobilized enzyme can be recycled, the production cost is greatly reduced, the production efficiency is improved, and a new way is provided for industrialized production of the adenosylmethionine.

Owner:江苏中丽新材料有限公司 +1

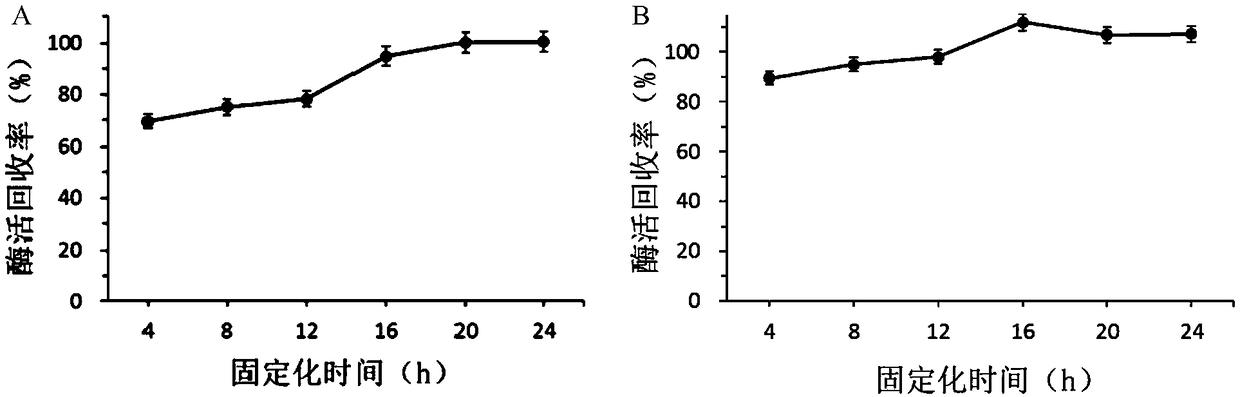

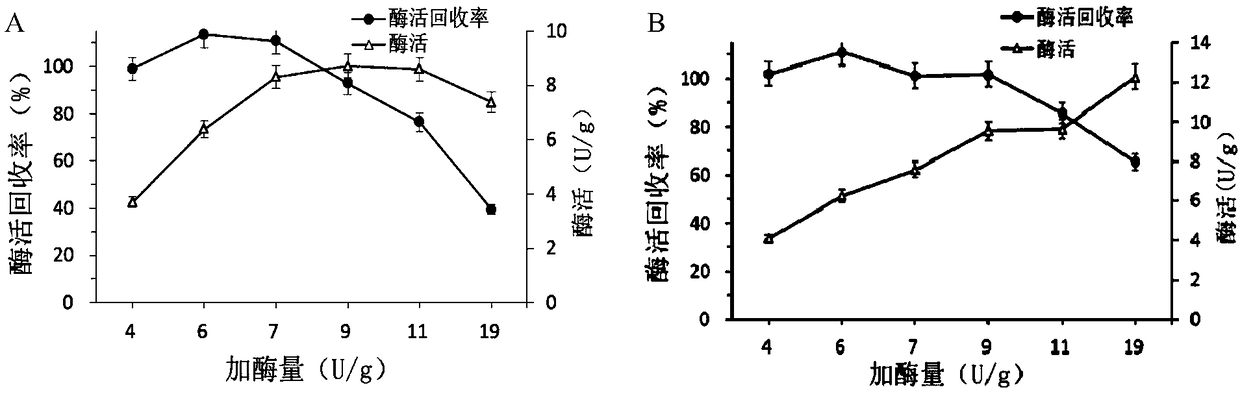

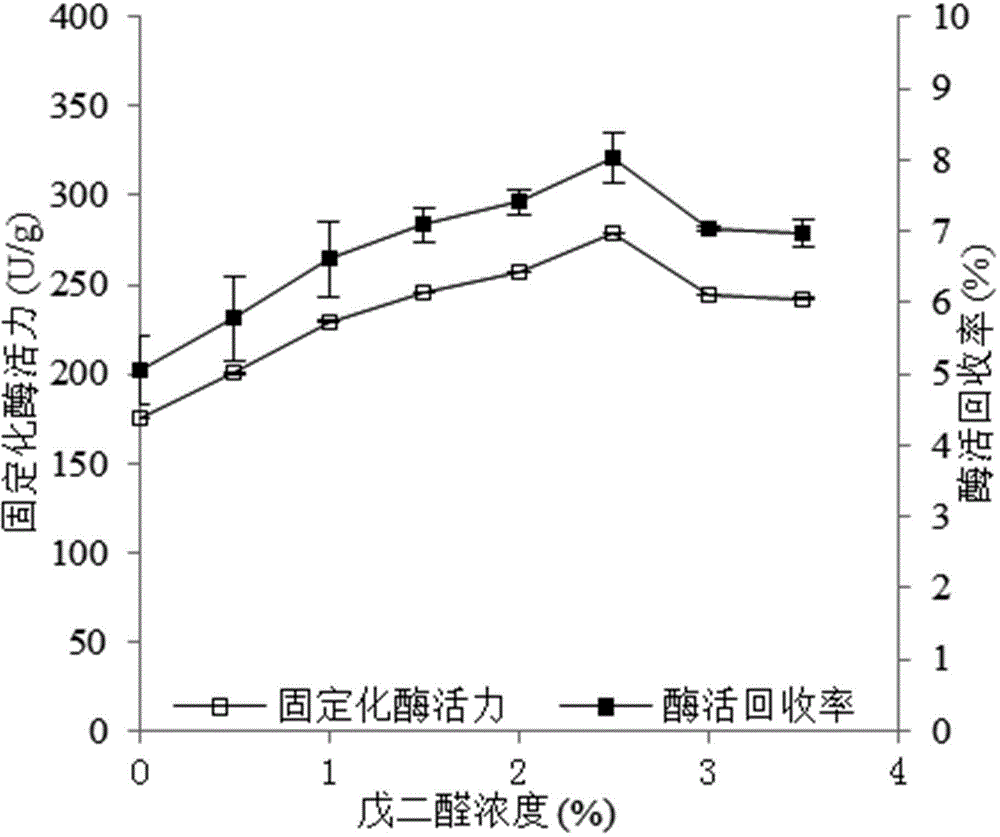

Immobilization method of sucrose phosphorylase

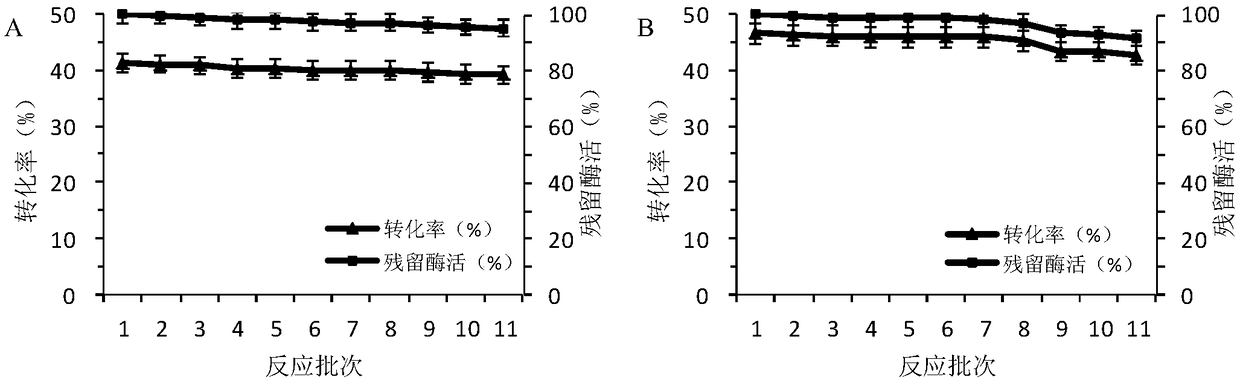

ActiveCN109371006AHigh recovery rate of enzyme activityEasy to separate and purifyOn/in organic carrierFermentationSucrose phosphorylaseSaccharophagus degradans

The invention discloses an immobilization method of sucrose phosphorylase, and belongs to the technical field of bioengineering. According to the immobilization method, recombinant bacillus subtilis Spase / pBSMuL3 serves as a production bacterial strain, the enzyme activity of the LX-1000EA immobilized sucrose phosphorylase is 7.75 U / g, and the enzyme activity recovery rate reaches 110.85%; the enzyme activity of the LX-1000EA immobilized sucrose phosphorylase is 9.54 U / g, and the enzyme activity recovery rate reaches 101.82%. Within the same conversion time, continuous operation is conducted for eleven times by takingwith 0.5 M sucrose and 0.5 M glucose as a substrate, amination resin LX-1000EA immobilized Spase keeps the 39.15% of the conversion rate of 39.15% and the 94% of the residualenzyme activity of 94%; and amination resin LX-1000HA immobilized Spase keeps the 42.5% the conversion rate of 42.5% and the residual enzyme activity of 91%. The result shows that the Immobilization method is easy to operate, the enzyme activity of an immobilization enzyme has no loss, the application effect is quite good, and the immobilization enzyme immobilization method has high industrial application potential.

Owner:JIANGNAN UNIV RUGAO FOOD BIOTECH RES INST +1

Process of catalytically synthesizing salidroside from beta-glucosaccharase crosslinking aggregate

The invention provides a process of catalytically synthesizing salidroside from beta-glucosaccharase crosslinking aggregate (beta-glucosaccharase CLEAs); in the synthesis stage of the salidroside, a reaction system is a 1-butyl-3-methylimidazole hexafluorophosphate / water-mimicking solvent / 1,4-dioxane / buffer solution, the water-mimicking solvent is ethyl acetate, the unit enzyme activity of the beta-glucosaccharase CLEAs is 1.3-1.6U / ml, the ratio of the volume summation of 1-butyl-3-methylimidazole hexafluorophosphate and ethyl acetate to the volume of the 1,4-dioxane is 2: 3-3: 2, the volume percent in the buffer solution is 12-18%, the reaction temperature is 48-52 DEG C, and the reaction time is 5-9 days. The concentration of the product salidroside can be greatly improved, and the high beta-glucosaccharase CLEAs residual relative enzyme activity can be maintained.

Owner:福建东亮生物科技有限公司

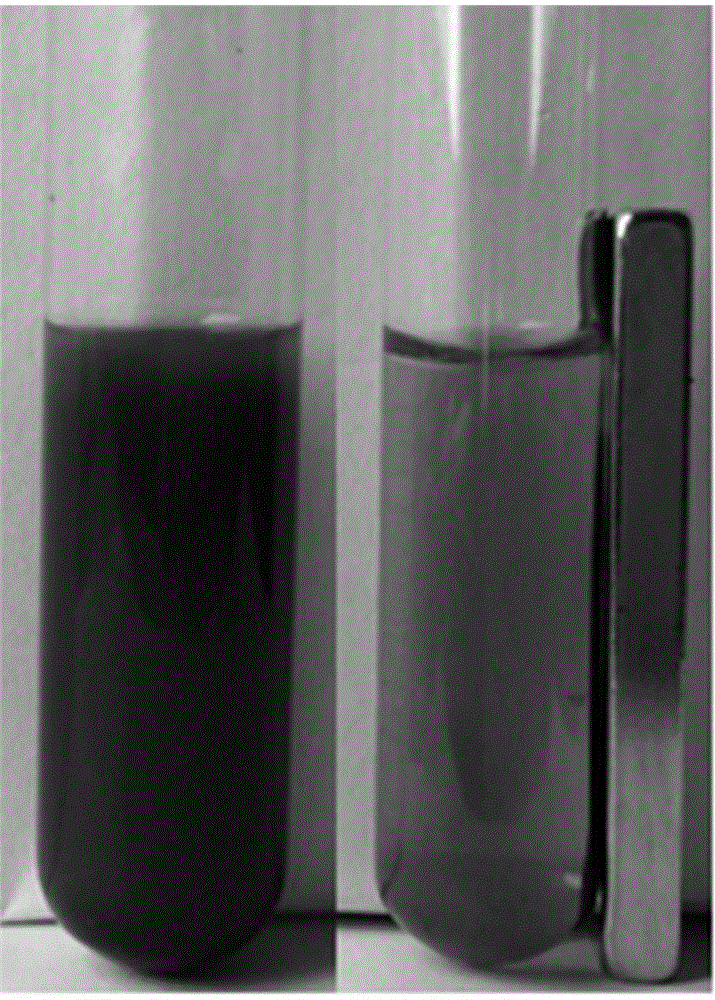

Immobilized kappa-carrageenan enzyme and method for preparing kappa-carrageenan oligosaccharide by adopting immobilized kappa-carrageenan enzyme

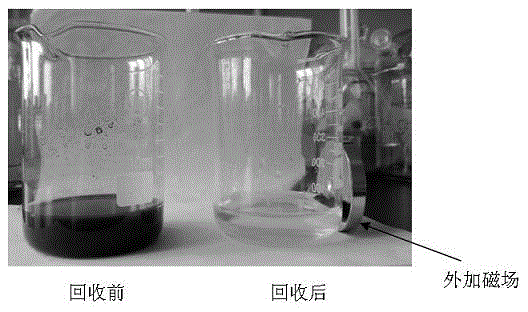

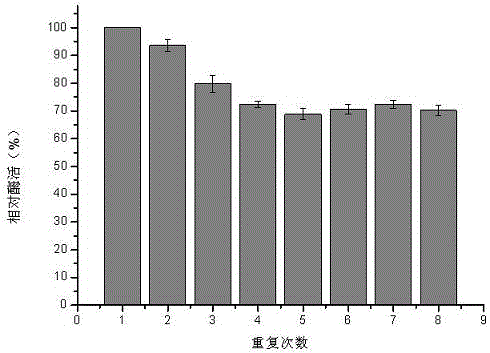

ActiveCN104894100AImprove stabilityEasy to separateFermentationOn/in inorganic carrierCarrageenanCarboxyl radical

The invention discloses an immobilized kappa-carrageenan enzyme and a method for preparing kappa-carrageenan oligosaccharide by adopting the immobilized kappa-carrageenan enzyme. The method comprises steps as follows: (a), ferroferric oxide magnetic nanoparticles are prepared with a Fe<2+> and Fe<3+> coprecipitation method, oleic acid is added under the alkaline condition to perform embedding, potassium permanganate is added for oxidizing double bonds of the oleic acid, and carboxyl-functionalized ferroferric oxide magnetic nanoparticles are obtained; (b), glutaraldehyde is taken as a crosslinking agent and has a crosslinking reaction with the carboxyl-functionalized ferroferric oxide magnetic nanoparticles, magnetic separation is performed on a carrier by means of an applied magnetic field, a kappa-carrageenan enzyme liquid is added for immobilization after the carrier is cleaned, cleaning is performed for multiple times after immobilization ends, uncombined free enzymes are removed, and the immobilized kappa-carrageenan enzyme is obtained; (c), kappa-carrageenan is hydrolyzed with the adoption of the prepared immobilized kappa-carrageenan enzyme, and the kappa-carrageenan oligosaccharide is prepared. The process is simple, the enzyme activity recovery rate is high, the immobilized enzyme has good stability, can be repeatedly used and is suitable for industrial production, and a product is easy to separate.

Owner:JIMEI UNIV

Method for separating and purifying nattokinase by magnetic microsphere

The invention provides a method for separating and purifying beankinase with magnetic microsphere. The method includes adding the magnetic microsphere coupled with friendly aglucon on the surface into fermentation liquor of beankinase, slowly mixing and sufficiently mixing them under an ambient temperature to make the beankinase specifically adsorb on the magnetic microsphere surface; separating the magnetic microsphere adsorbed by beankinase with magnet from the fermentation liquor, cleaning once with buffer solution to remove the foreign matter, then performing analysis with analytic liquor, and collecting the beankinase eluent; finally obtaining beankinase product by cryodesiccation. The separated beankinase has 85% vitality and 6.0 purified factor. The invention has advantages that it is of short cycle, simple operation, low cost of manufacture and is easy for mass production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for synthesizing salidroside under catalysis of beta-glucosidase cross-linked aggregates

ActiveCN103710412AEasy to recycleRecycling operation is fastEnzymesFermentationSalidrosideAlglucerase

The invention provides a process for synthesizing salidroside under catalysis of beta-glucosidase cross-linked aggregates. Reaction conditions for a synthetic stage of salidroside are that a reaction system is 1-butyl-3-methylimidazole hexafluorophosphate (C4MIm.PF6) / 1,4-dioxane / buffer solution; unit enzyme activity of the beta-glucosidase cross-linked aggregates is 1.3-1.6 U / ml; a volume ratio of C4MIm.PF6 to 1,4-dioxane is 2:3-3:2; a volume fraction of the buffer solution is 12-18%; a reaction temperature is 48-52 DEG C; a rotation speed is 245-255 rpm; and a reaction time is 5-9 d. The process can greatly increase the concentration of the product salidroside, and can keep relatively high residual relative enzyme activity of the beta-glucosidase cross-linked aggregates.

Owner:FUZHOU UNIV

Method for synthesizing NADPH through immobilized enzyme catalysis

ActiveCN107557412ASimple production processShorten the production cycleImmobilised enzymesFermentationDivalent metal ionsEnzyme catalysis

The invention discloses a method for synthesizing NADPH through immobilized enzyme catalysis. The method comprises the following steps: (1) in the presence of divalent metal ions, preparing a first reaction liquid by taking NAD and metaphosphate as substrates, adding immobilized NAD kinase into the first reaction liquid, and performing catalyzing synthesis of NADP; and (2) removing immobilized NADkinase in the first reaction liquid, continuously adding glucose for preparing a second reaction liquid, adding immobilized glucose dehydrogenase into the second reaction liquid, and performing catalyzing synthesis of NADPH. The method disclosed by the invention realizes that NADPH is synthesized through continuous reaction, production technology is simple, production period is short, productioncost is low, and product quality is more stable; besides, the immobilized enzyme catalysis is adopted for preparing NADPH, an immobilized enzyme can be continuously and repeatedly used, the productioncost is further reduced, introduction of protein impurities into a product is avoided, and NADPH can be beneficially produced with high purity and high yield when the immobilized enzyme is applied tothe method.

Owner:山东蓝康药业有限公司

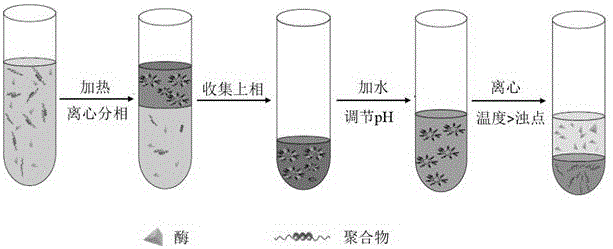

Method for separating and purifying bromelain by circulating aqueous two-phase system

The invention relates to a method for separating and purifying bromelain by circulating an aqueous two-phase system, and belongs to the technical field of separation and purification of effective ingredients of natural products. The method comprises the following steps: firstly, pretreating to obtain coarsely extracted pineapple juice; then, extracting bromelain for the first time by an aqueous two-phase system, detecting the activity and protein content of top-phase bromelain, and determining an extraction effect; thirdly, taking out polymer, and diluting by adding a proper amount of distilled water, regulating the pH value of the solution, and extracting bromelain for the second time by a cloud point method; and finally, taking the separated polymer for circulating extraction experiments in the aqueous next two-phase system. The method has a simple process flow, low cost and mild operation condition and can be used for protecting the structure and activity of target enzyme; and the polymer can be recycled, and has small environmental pollution.

Owner:江西颐迪科技有限公司

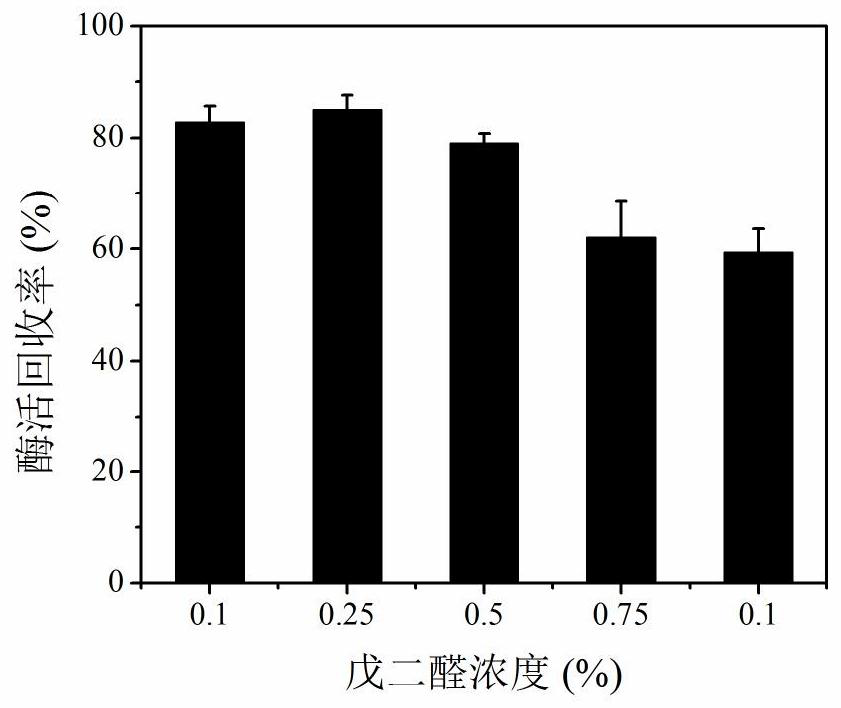

Preparation method of beta-glucosaccharase cross-linked aggregates

The invention provides a preparation method of beta-glucosaccharase cross-linked aggregates, which can obtain a high-enzyme-activity recovery rate. The method comprises the following steps: (1) adding a settling agent into a beta-glucosaccharase solution and oscillating; (2) adding glutaraldehyde; (3) adding a reducing agent into a mixed solution, oscillating, centrifuging and collecting precipitate, wherein the reaction temperature of the entire reaction process is controlled at 4-6 DEG C, and the pH value is 5.0-5.5; the settling agent used in the step (1) is 1,4-dioxane, and the volume ratio of 1,4-dioxane to the beta-glucosaccharase solution is (2-3):1; the concentration of glutaraldehyde in the step (2) is 38-43mM, and crosslinking time is 8-12 minutes; the reducing agent is sodium borohydride (NaBH4), and the concentration of NaBH4 is 20-25mM.

Owner:FUZHOU UNIVERSITY

Bionic process for preparing silicon oxide nano-microcapsule immobilized enzyme

The invention provides a bionic process for preparing silicon oxide nano-microcapsule immobilized enzyme. According to the method, enzyme is coated in liposome nano-microcapsules; with the liposome nano-microcapsules as a template, under the effect of an inducing agent poly dimethyl diallyl ammonium, tetramethyl orthosilicate hydrolysate is dehydrated on the surface of liposome, such that a silicon oxide shell layer is formed. Direct contact of enzyme and a silicon precursor is completely avoided, such that a purpose for maintaining relatively high activity of the immobilized enzyme is realized. Also, with the liposome nano-microcapsules as the template, preparation of the silicon oxide nano-microcapsules with controllable morphology can be realized. Finally, the liposome template is removed by using a low-concentration surfactant octyl polyethylene glycol phenyl ether. With the immobilized enzyme preparation method provided by the invention, an embedding rate can reach approximately 50%, such that problems of free enzyme severe wasting and immobilization cost increasing of a sol-gel method are avoided. The reaction mainly involves water phase, such that the reaction is safe and non-polluting. The preparation process is simple, and conditions are mild. An enzyme activity recovery rate is up to 71.8%.

Owner:HEBEI UNIV OF TECH

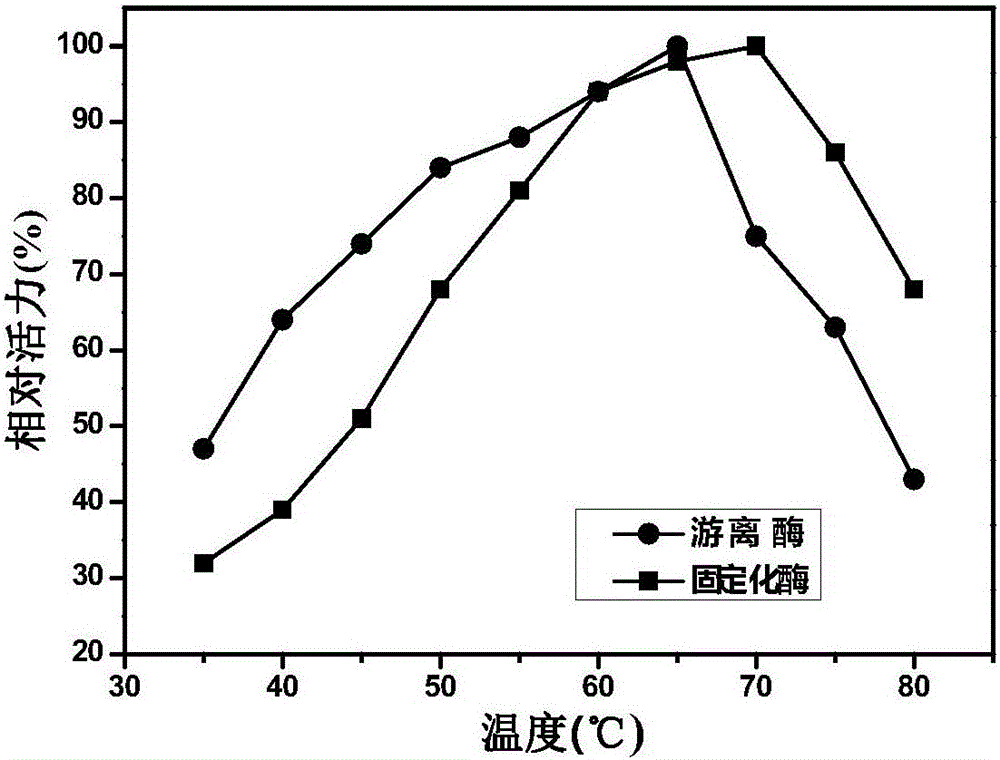

Biocompatible metal organic framework material glutamic acid-zinc as well as preparation and application thereof

InactiveCN105646253ALow costGenerate fastHydrolasesOrganic compound preparationMetal-organic frameworkPhosphoric acid

The invention belongs to the technical field of new materials and particularly relates to biocompatible metal organic framework material glutamic acid-zinc as well as preparation and an application thereof. The biocompatible metal organic framework material glutamic acid-zinc is obtained by dropwise adding a disodium glutamate to a Zn(NO3)2 methanol solution. The method has the characteristics that the production speed of glutamic acid-zinc crystals is high, the preparation condition is mild, the prepared product is good in crystal form and the like, can be applied to a series of amino-rich enzymes such as lipase, protease, epoxide and the like and has the potential of being used as a protein drug carrier. The product is added to an Aspergillus niger lipase phosphate buffer modified with EDC or EDC*HCl and NHS for oscillation immobilization, and immobilized Aspergillus niger lipase is obtained. The method is high in immobilization efficiency, high in enzyme activity recovery rate, convenient to operate, mild in condition and the like.

Owner:SOUTH CHINA UNIV OF TECH

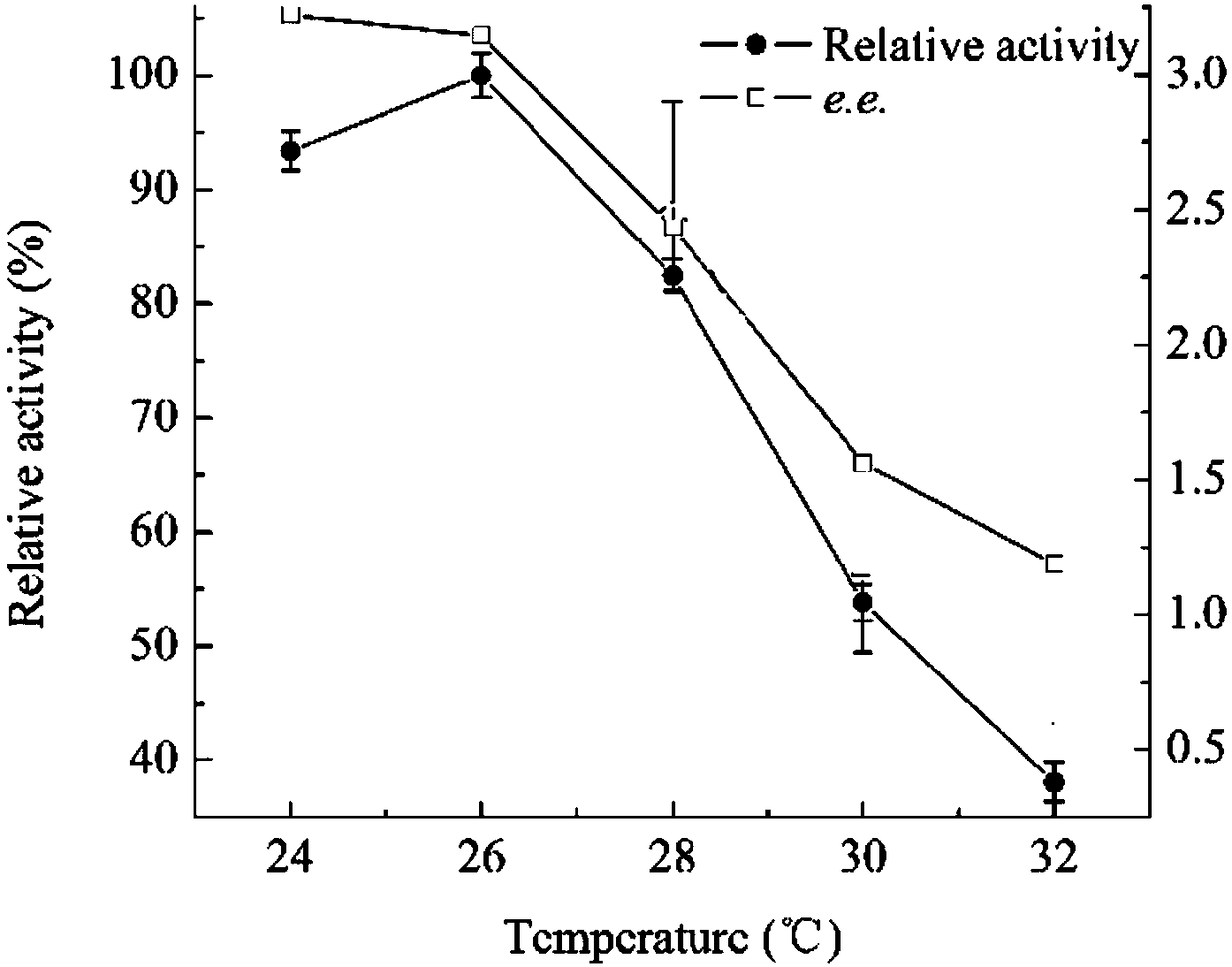

Immobilized halohydrin dehalogenase and application thereof

InactiveCN105838700AWide variety of sourcesReduce fermentation costsCarbon-halide lyasesOn/in organic carrierEpoxyAlcohol

The invention discloses immobilized halohydrin dehalogenase and an application thereof. The immobilized halohydrin dehalogenase has high conversion efficiency on a halohydrin substrate, is strong in substrate tolerance, and has excellent catalysis selectivity on the substrate and structural analogues thereof. In the invention, recombinant halohydrin dehalogenase is successfully fixed on the surface of an epoxy resin carrier through multipoint covalence, and through low-salt adsorption and addition of glycerol as a protection agent of an enzyme activity center, enzyme activity loss during immobilization is effectively reduced. The immobilization method is simple in operation, is low in raw materials cost, and is suitable for large-scale operation. The immobilized halohydrin dehalogenase has homogeneous property, high stability and good repeatability. With the immobilized halohydrin dehalogenase,epoxy chloropropane, (R)-4-cyano-3-hydroxylethyl butyrate, (S)-2,3-dichloro-1-propyl alcohol and the like can be synthesized. The immobilized halohydrin dehalogenase can be continuously used for more than 50 batches before significant reduction of activity of the immobilized halohydrin dehalogenase and also has good industrial application prospect.

Owner:ZHEJIANG UNIV OF TECH

Ferrum-copper composite nanoflowers containing papain and preparation method and application of ferrum-copper composite nanoflowers

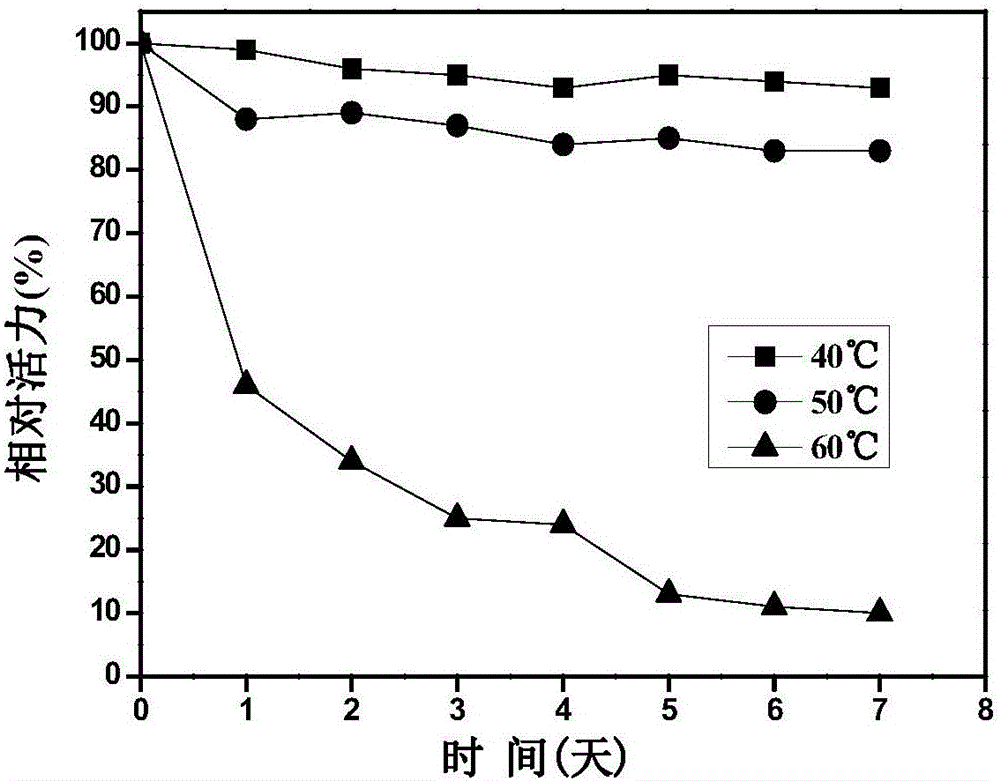

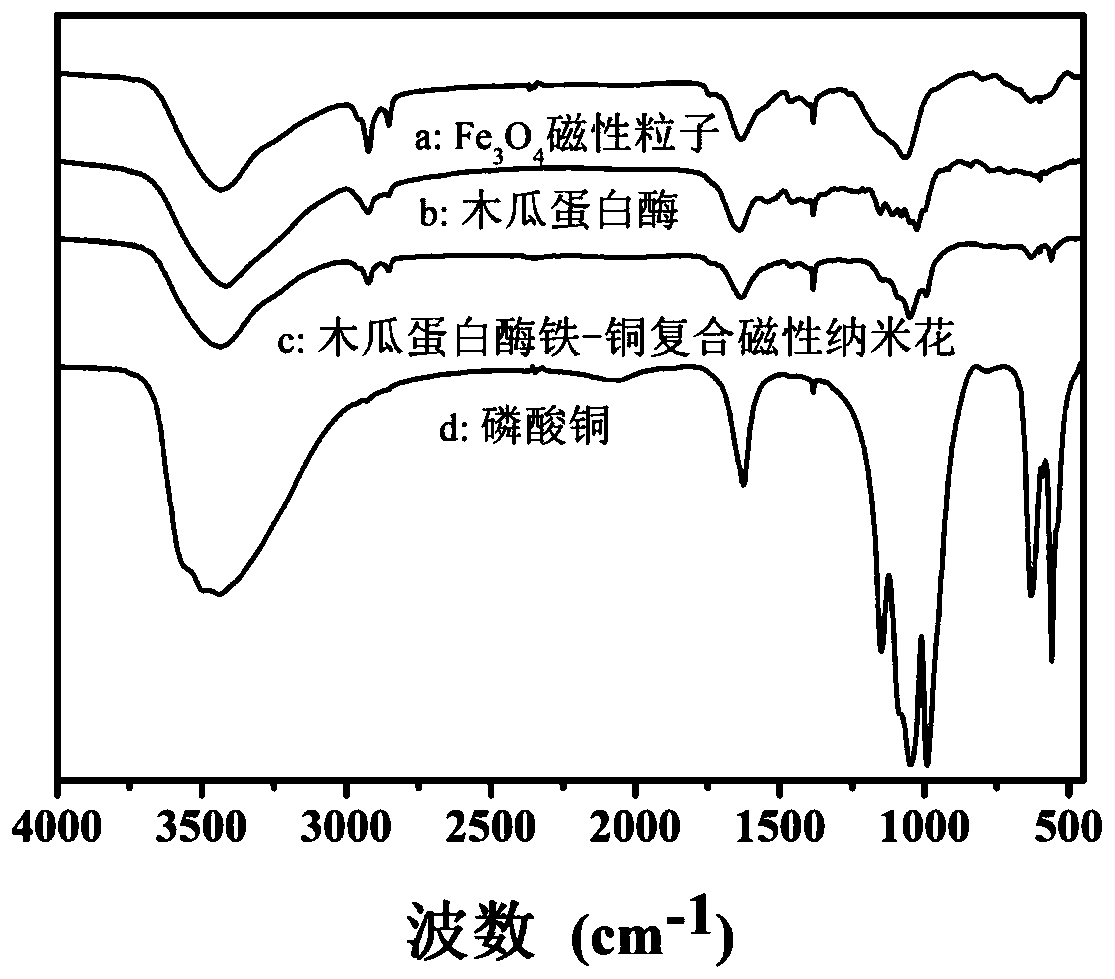

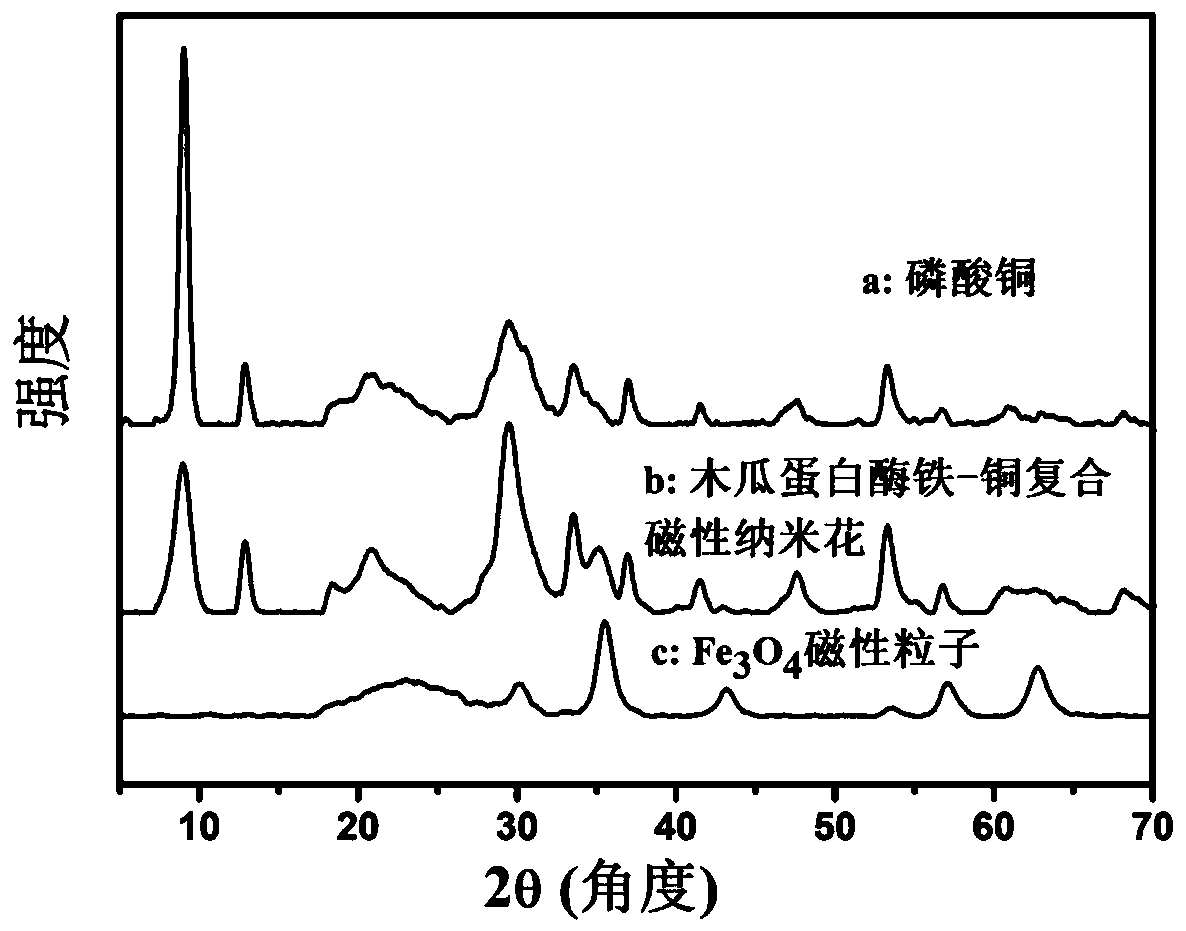

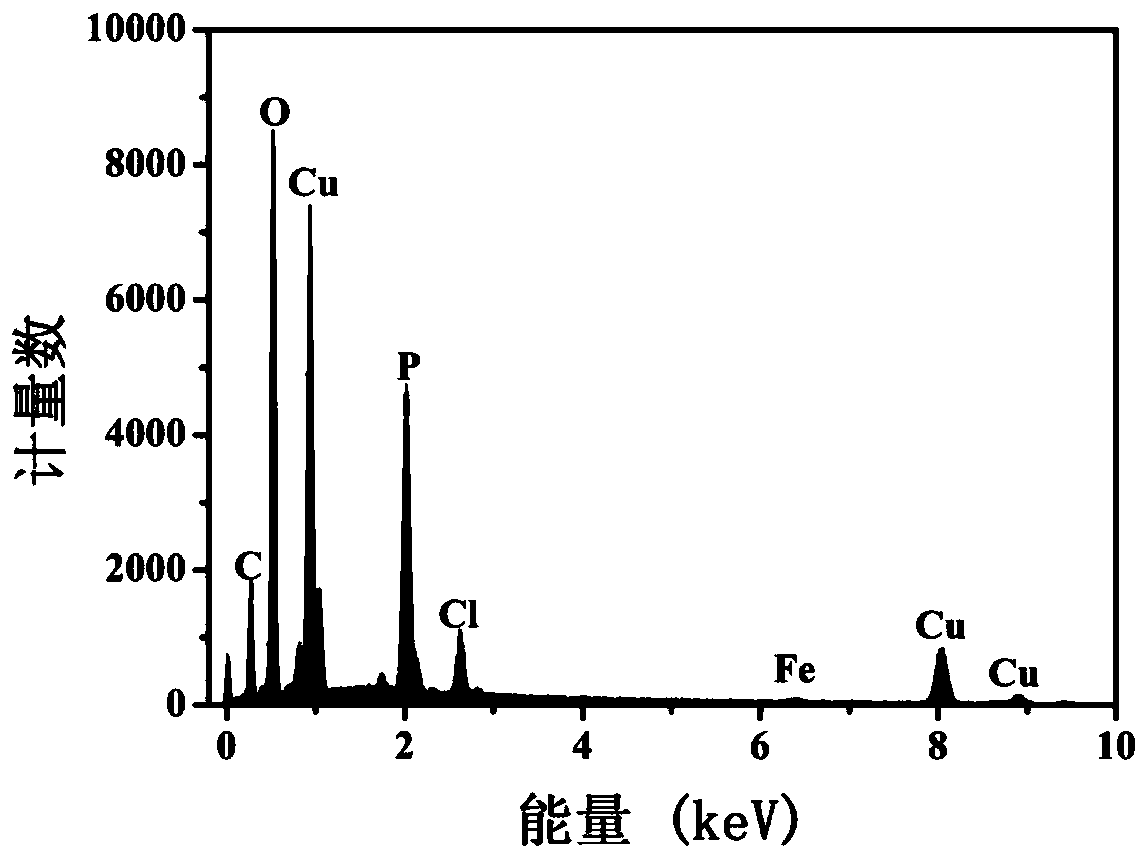

ActiveCN109852603AAllergenicity reductionReduce contentMilk preparationInductances/transformers/magnets manufactureInorganic saltsCopper

The invention relates to ferrum-copper composite nanoflowers containing papain and a preparation method and application of the ferrum-copper composite nanoflowers, and belongs to the field of enzyme fossilization. The preparation method of the ferrum-copper composite nanoflowers containing papain comprises the following steps of mixing a magnetic Fe3O4 nanoparticle solution modified with amino with a papain solution, and then adding a copper ion inorganic salt solution to obtain the ferrum-copper composite nanoflowers containing papain. The synthesized papain ferrum-copper composite magnetic nanoflowers have higher specific surface area than free enzymes, so that the mass transfer obstruction between the enzymes and a substrate is further reduced, and the enzymatic activity of fossilized papain is about 25 times of that of free enzymes.

Owner:DALIAN POLYTECHNIC UNIVERSITY

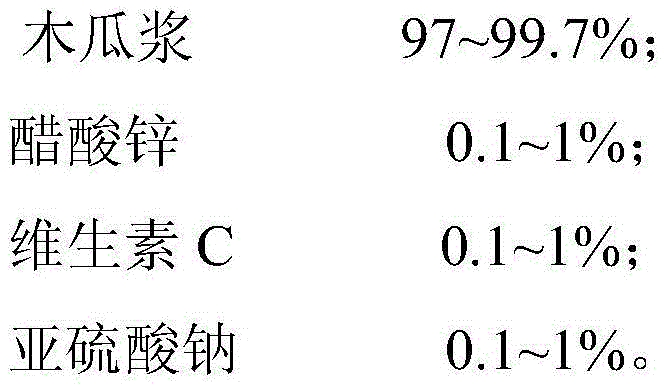

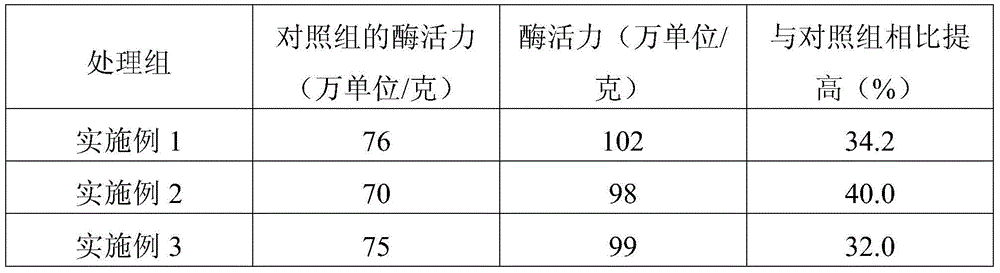

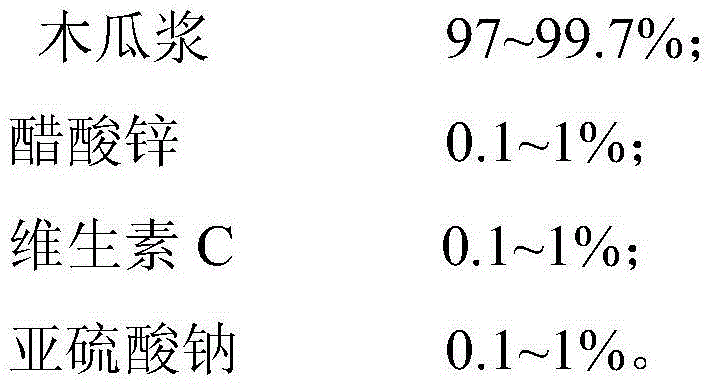

Papain crude enzyme preparation and preparation method thereof

InactiveCN104388415AImprove vitality and stabilityHigh recovery rate of enzyme activityEnzyme stabilisationPeptidasesVitamin CSulfite salt

The invention belongs to the biotechnical field and discloses a papain crude enzyme preparation and a preparation method thereof. The papain crude enzyme preparation is prepared from the following components in percentage by weight: 97-99.7% of papaya pulp, 0.1-1% of zinc acetate, 0.1-1% of vitamin C and 0.1-1% of sodium sulfite. The papain crude enzyme preparation prepared by the preparation method disclosed by the invention is high in enzyme activity stability and has an enzyme activity recovery rate of over 90%. Besides, the preparation method of the papain crude enzyme preparation has the characteristics of being less in equipment investment and easy for yield increase.

Owner:GUANGXI UNIV

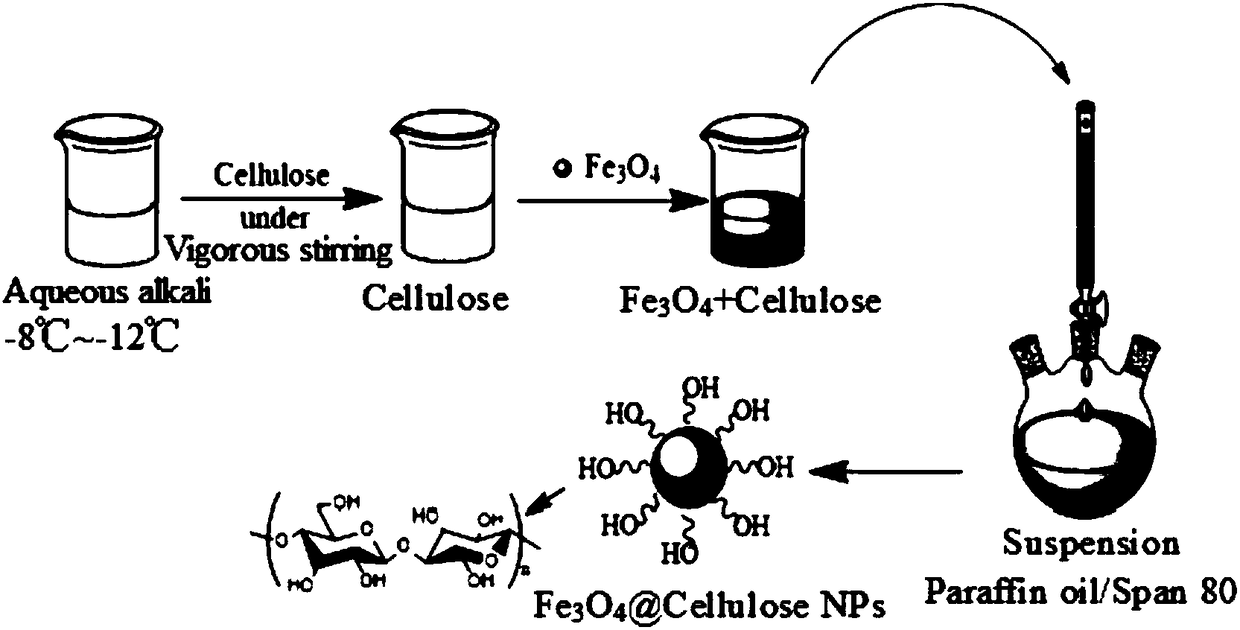

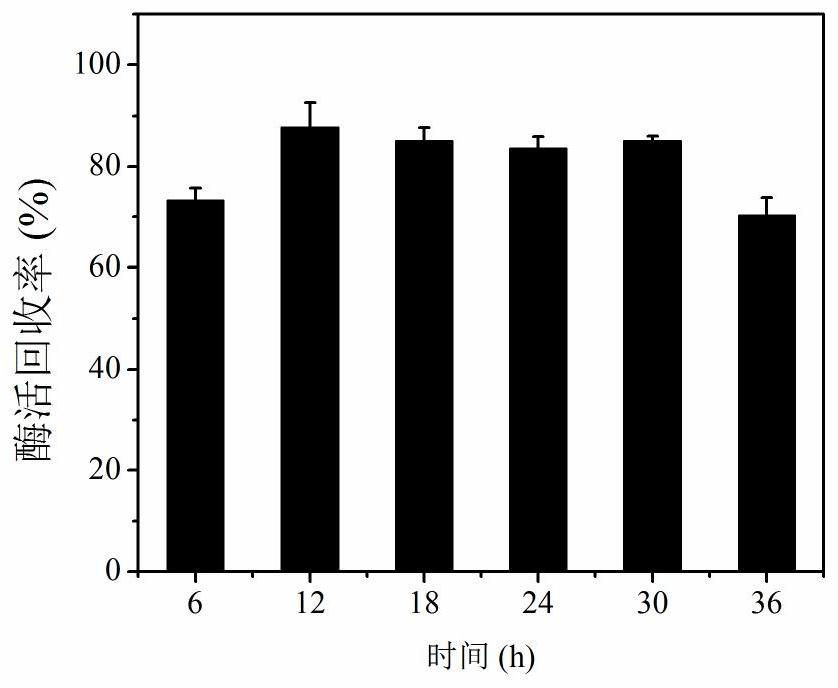

Method for preparing magnetic cellulose immobilized lysozyme

InactiveCN108486096AAchieve reductionImprove dehydration effectSpecific water treatment objectivesOn/in organic carrierCelluloseLysis

The invention relates to a method for preparing magnetic cellulose immobilized lysozyme. The method comprises the following steps: preparing magnetic cellulose nanoparticles, preparing an immobilizedcarrier, and preparing the magnetic cellulose immobilized lysozyme. The immobilized operation is simple, the prepared magnetic cellulose immobilized lysozyme has the advantages of uniform shape, largespecific surface area, high enzyme activity recovery rate, and easy storage, can be used for lysis sludge reduction, also has the advantages of easy recovery, repeated usage and good stability, can reduce the lysis sludge reduction cost by a biological method, and overcomes the disadvantages of difficult enzyme recovery and high cost in a traditional biological method lysis technology.

Owner:DONGHUA UNIV

Method for separating and purifying transglutaminase

The invention provides a method for separating and purifying transglutaminase, which effectively increases the specific enzyme activity of the transglutaminase and solves the problems like influence on application due to deep color of the enzyme. In the invention, the transglutaminase with high purity is separated and purified with only one cation exchange resin; and the method has the advantagesof simplicity, low time consumption and high yield, and can be applied to inductiral production for large-scale preparation.

Owner:TAIXING YIMING BIOLOGICAL PRODS

Modified epoxy resin immobilized enzyme and preparation method and application thereof

ActiveCN113355314AIncrease enzyme activityGood repeatabilityImmobilised enzymesOxidoreductasesEpoxyEnzyme catalysis

The invention discloses a modified epoxy resin immobilized enzyme and a preparation method and application thereof, and belongs to the field of enzyme catalysis. The method comprises the steps that ethylenediamine is added into pretreated epoxy resin for modification, the modified epoxy resin is activated, then an enzyme to be immobilized is added for immobilization, the immobilized enzyme is obtained, and the epoxy resin with double functional groups is obtained. The phenomenon that the immobilization effect of one functional group is poor can be avoided, the enzyme activity of the immobilized enzyme is improved, the immobilization effect can be higher, the better reusability is achieved, and the immobilization time can be shortened. The preparation method is easy to operate and high in operability, and the prepared immobilized enzyme has the wide application prospect.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Biocompatible metal-organic framework material glutamic acid-zinc and preparation and application thereof

ActiveCN106987580ALow costGenerate fastHydrolasesOrganic compound preparationPhosphateMetal-organic framework

The invention belongs to the technical field of novel materials and particularly relates to a biocompatible metal-organic framework material glutamic acid-zinc and preparation and an application thereof. The biocompatible metal-organic framework material glutamic acid-zinc is obtained through dropwise adding a disodium glutamate water solution into a methanol solution of Zn(NO3)2. The method has the characteristics of being high in glutamic acid-zinc crystal growth speed and mild in preparation condition, and the prepared product is good in crystal form, can be applied to a series of enzymes containing abundant amino, such as lipase, protease and epoxide hydrolase, and has the potential as a protein drug carrier. The product is added to an aspergillus niger lipase phosphate buffer solution modified by EDC or EDC.HC and NHS for shock immobilization to obtain the immobilized aspergillus niger lipase. The method is high in immobilization efficiency, high in enzyme recovery rate, simple in operation and mild in condition.

Owner:SOUTH CHINA UNIV OF TECH

Synthesis of salidroside catalyzed by β-glucosidase cross-linked aggregates

ActiveCN103710412BEasy to recycleRecycling operation is fastEnzymesFermentationCross-linkSalidroside

Owner:FUZHOU UNIV

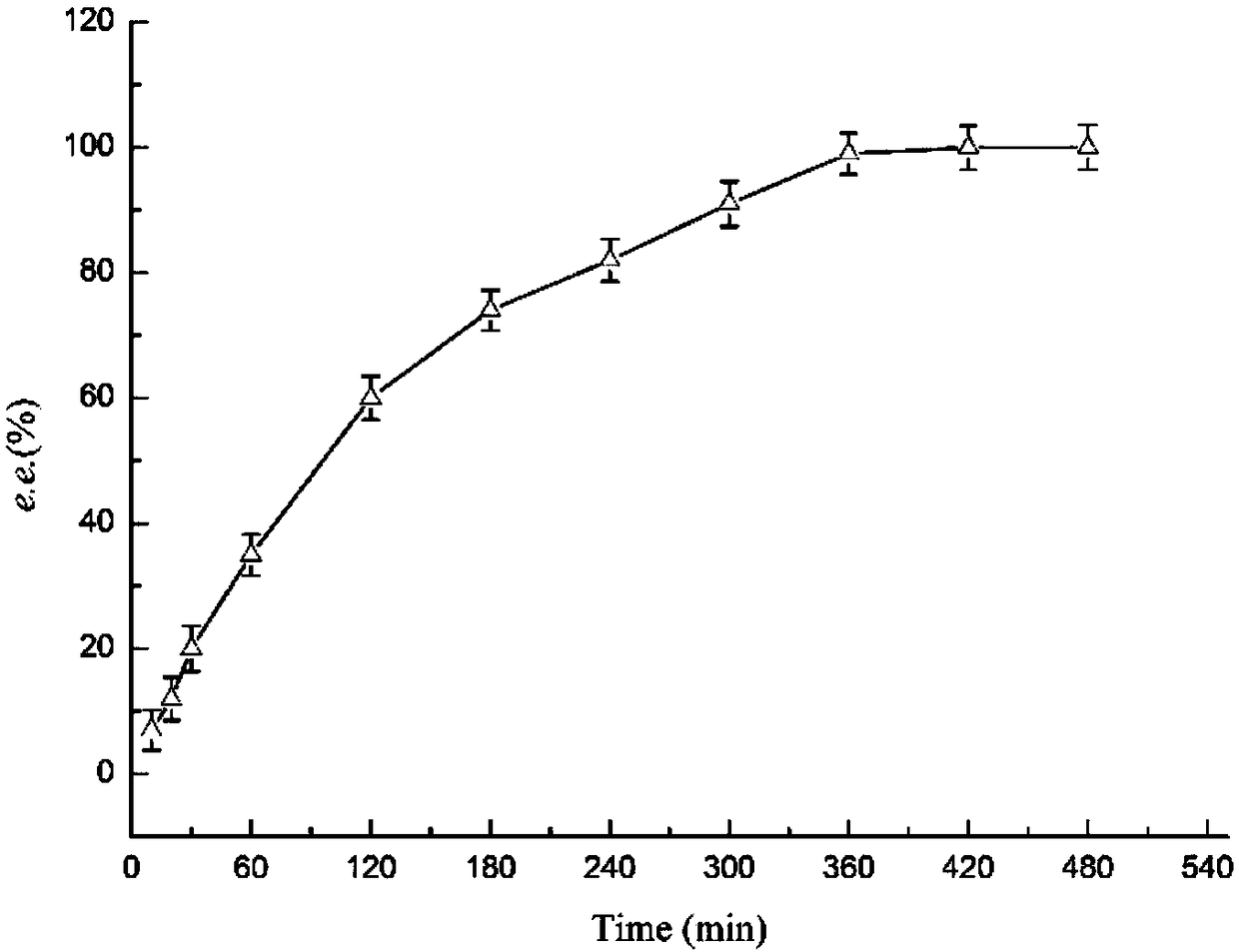

Method for producing (-)gamma-lactam from marine low-temperature gamma-lactamase

The invention discloses a method for producing (-)gamma-lactam from marine low-temperature gamma-lactamase. The method comprises the following steps: 1, production of low-temperature gamma-lactamase by microbial fermentation; 2, obtaining of a crude enzyme solution; 3, concentration of an enzyme solution; 4, production of (-)gamma-lactam. The method for producing (-)gamma-lactam from marine low-temperature gamma-lactamase is raised for the first time. According to the method, the cost of an enzyme production medium is low, and the production period is short; materials used for concentration ofthe enzyme solution can be recycled, the operation process is simple, and the enzyme activity recovery rate is high; bacterial contamination prevention measures are taken in the degradation process,the purpose of efficiently and rapidly producing (-)gamma-lactam with high medical value from (+ / -)gamma-lactam with low value is achieved, and the method has remarkable economic and social benefits.

Owner:DALIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com