Modified epoxy resin immobilized enzyme and preparation method and application thereof

An epoxy resin, immobilized enzyme technology, applied in the field of enzyme catalysis, can solve the problems of low recovery rate of enzyme activity, weak action force, singleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

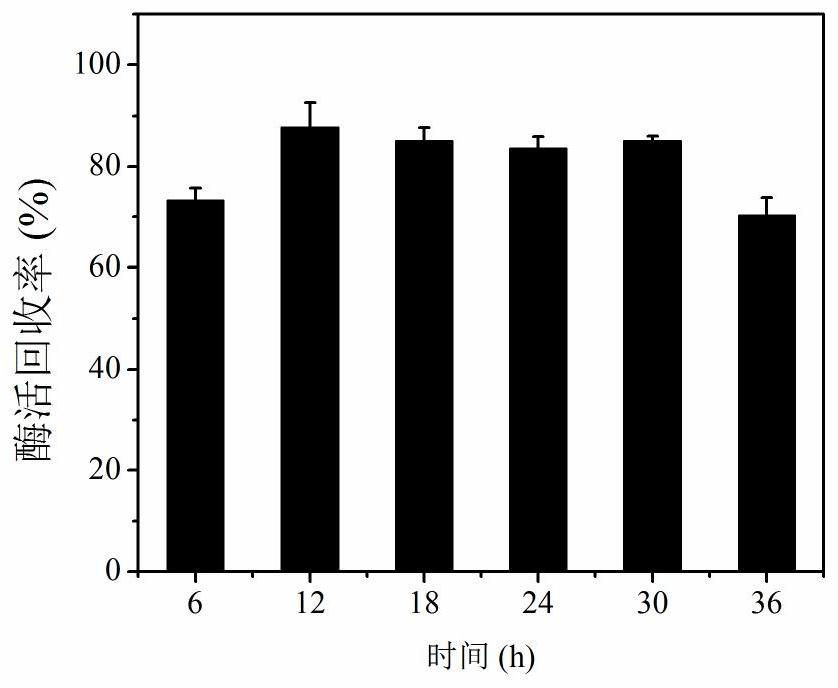

[0097] The preparation method of embodiment 1 modified epoxy resin immobilized inositol-1-phosphate synthase

[0098] Synthesize modified epoxy resin immobilized inositol-1-phosphate synthase according to the following steps:

[0099] Take 4g of epoxy resin 1000EP in a 50mL centrifuge tube, add 15mL of 50mM Tris-HCl buffer and stir for 15 minutes to maintain the pH of the overall system environment = 7.2. Suction filter after 1 hour, and wash the carrier with deionized water.

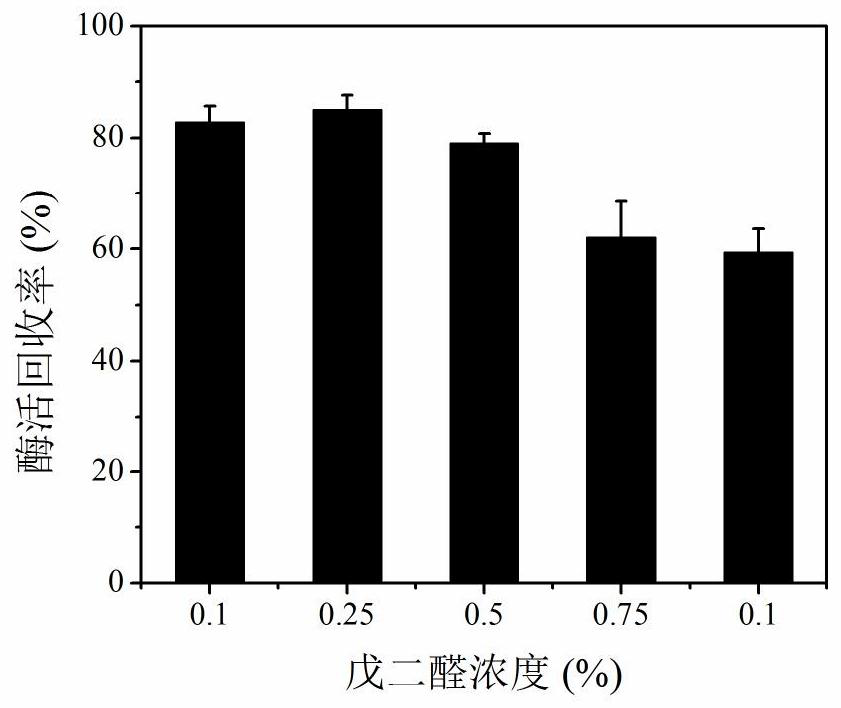

[0100] Weigh 1.0g of activated epoxy resin 1000EP into different 10mL centrifuge tubes, add 6mL of 5% ethylenediamine aqueous solution (pH=9.0) and place it on a rotary shaker for 2 hours. Use milli-Q to wash repeatedly to remove unreacted Ethylenediamine, wash by suction filtration; then add 2mL 0.25% glutaraldehyde to activate on a shaker for 1h, wash with buffer 3 times, then weigh 400mg of resin and place it in 1mL of 70% by mass ammonium sulfate precipitant solution (containing 0.472g of ammonium ...

Embodiment 2

[0108] Embodiment 2 Preparation method of immobilized inositol-1-phosphate synthase

[0109] Synthesize immobilized inositol-1-phosphate synthase according to the following steps:

[0110] Take 5g of epoxy resin 1000EP in a 50mL centrifuge tube, add 20mL of 50mM Tris-HCl buffer solution and stir for 15 minutes to maintain the pH of the overall system environment = 7.2, suction filter after 1 hour, and wash the carrier with deionized water.

[0111] Weigh 1.0g of activated epoxy resin 1000EP into different 10mL centrifuge tubes, add 6mL of 5% ethylenediamine aqueous solution (pH=9.0) and place it on a rotary shaker for 2 hours. Use milli-Q to repeatedly wash away unreacted ethylenediamine , wash by suction filtration; add 2mL of 0.25% glutaraldehyde to activate on a shaking table for 1h, wash 3 times with buffer, then weigh 400mg of resin and place it in 1mL of 70% by mass ammonium sulfate precipitant solution (containing 0.472 g ammonium sulfate), then add 1 mL of IPS enzyme ...

Embodiment 3

[0114] Embodiment 3 Preparation method of immobilized inositol-1-phosphate synthase

[0115] Synthesize immobilized inositol-1-phosphate synthase according to the following steps:

[0116] Take 8g of epoxy resin 1000EP in a 50mL centrifuge tube, add 32mL of 50mM Tris-HCl buffer and stir for 15 minutes to maintain pH = 7.2. Suction filter after 1 hour and wash the carrier with deionized water.

[0117] Weigh 4.0g of activated epoxy resin 1000EP into different 50mL centrifuge tubes, add 24mL of 5% ethylenediamine aqueous solution (pH=9.0) and place it on a rotary shaker for 2 hours, then use milli-Q to repeatedly filter and wash to remove unreacted ethylenediamine, then add 8mL 0.25% glutaraldehyde to activate on a shaking table for 1h, wash with buffer 3 times, then weigh 800mg modified epoxy resin and place it in 2mL, 70% by mass ammonium sulfate precipitant solution (containing 0.944g of ammonium sulfate), then add 2mL of IPS enzyme solution with a final concentration of 0.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com