Method for immobilizing beta-glucosidase and hydrolyzing straw cellulose by cooperating beta-glucosidase with cellulase

A technology of glucosidase and straw cellulose, applied in the direction of immobilization on or in inorganic carriers, on/in organic carriers, fermentation, etc., can solve the problem of low recovery rate of enzyme activity and problems of nano-immobilized enzymes Problems such as complex process and difficult recovery of immobilized enzymes, to achieve the effect of improving the yield of hydrolyzed sugar, good reusability, and simple immobilization operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

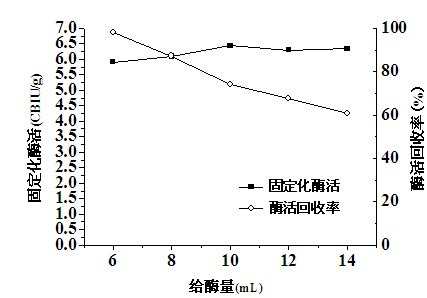

[0033] Example 1 The effect of the amount of enzyme on the preparation of magnetic chitosan microspheres immobilized enzyme

[0034] Dissolve 0.5 g chitosan in 50 mL, 2% propionic acid solution, add 40 μL PEG400 to form a transparent and uniform liquid, then add 0.5 g Fe 3 o 4 Granules, stir well, remove air bubbles. Then it was dropped into 200 mL 2 M NaOH solution for 10 h to form chitosan magnetic microspheres, which were washed repeatedly with distilled water until neutral. Take 1 g of chitosan magnetic microspheres, add them to 20 mL, 2% glutaraldehyde solution, cross-link for 2 h at 25 °C, and wash them repeatedly with distilled water until neutral to obtain the immobilized carrier.

[0035] Take 5 copies of the same 0.5 g immobilized carrier and add them to 6 mL, 8 mL, 10 mL, 12 mL and 14 mL of β-glucosidase solution (pH 4.8, enzyme activity 0.93 CBIU / mL), Adsorption at 20°C, 200 r / min for 10 h. Determination of enzyme activity of immobilized enzymes, such as figu...

Embodiment 2

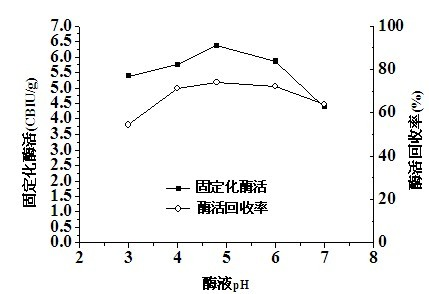

[0036] Example 2 The influence of pH on the preparation of magnetic chitosan microspheres immobilized enzyme

[0037] The immobilized carrier was prepared according to the method in Example 1, and 5 parts of the same 0.5 g immobilized carrier were added to 10 mL of β-glucosidase solutions with pHs of 3.0, 4.0, 4.8, 6.0 and 7.0 (enzyme activity is 0.93 CBIU / mL), and adsorbed at 20°C, 200 r / min for 10 h. Determination of enzyme activity of immobilized enzymes, such as figure 2 As shown, the highest was 6.36 CBIU / mL, and the recovery rate of enzyme activity was 74.0%.

Embodiment 3

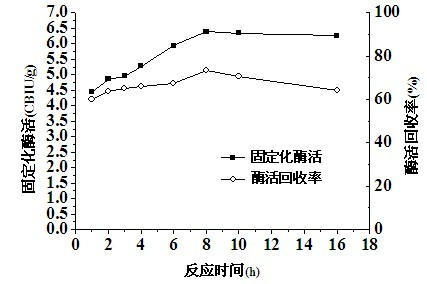

[0038] Example 3 The influence of adsorption time on the preparation of magnetic chitosan microspheres immobilized enzyme

[0039] The immobilized carrier was prepared according to the method in Example 1, and 5 copies of the same 0.5 g immobilized carrier were added to 10 mL of β-glucosidase solution at pH 4.8 (enzyme activity was 0.93 CBIU / mL) , at 20 °C and 200 r / min for 1 h, 2 h, 3 h, 4 h, 6 h, 8 h, 10 h and 16 h, respectively. Determination of enzyme activity of immobilized enzymes, such as image 3As shown, the highest was 6.39 CBIU / mL, and the recovery rate of enzyme activity was 73.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com