Process for separating and purifying natto kinase by reverse micelle method

A nattokinase, separation and purification technology, applied in the field of separation and purification of biologically active substances, can solve the problems of complex nattokinase purification process, numerous steps, etc., and achieve the effects of low cost, high-efficiency extraction, and high recovery rate of enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Separation and purification of nattokinase from the fermentation broth produced by liquid fermentation

[0037] With Bacilliis natto NLSSe (Chinese patent, application number 02121352.6) as the strain, first carry out seed culture, take a glycerol spore strain and inoculate it in a 100ml Erlenmeyer flask with 20ml seed medium, and culture it on a shaker at 37°C and 170rpm for 12 Hours later (OD660nm is about 7-8), refrigerate at 0-4°C for later use. Liquid seeds will keep for a week.

[0038] Then carry out fermentation culture: 100ml Erlenmeyer flask, liquid volume is 20ml, inoculum size is 5%, 37°C, 170rpm shaker culture for 48 hours, 5000rpm, 10min centrifugation, after the supernatant is tested for enzyme activity, cryopreservation, storage time Not longer than 9 days.

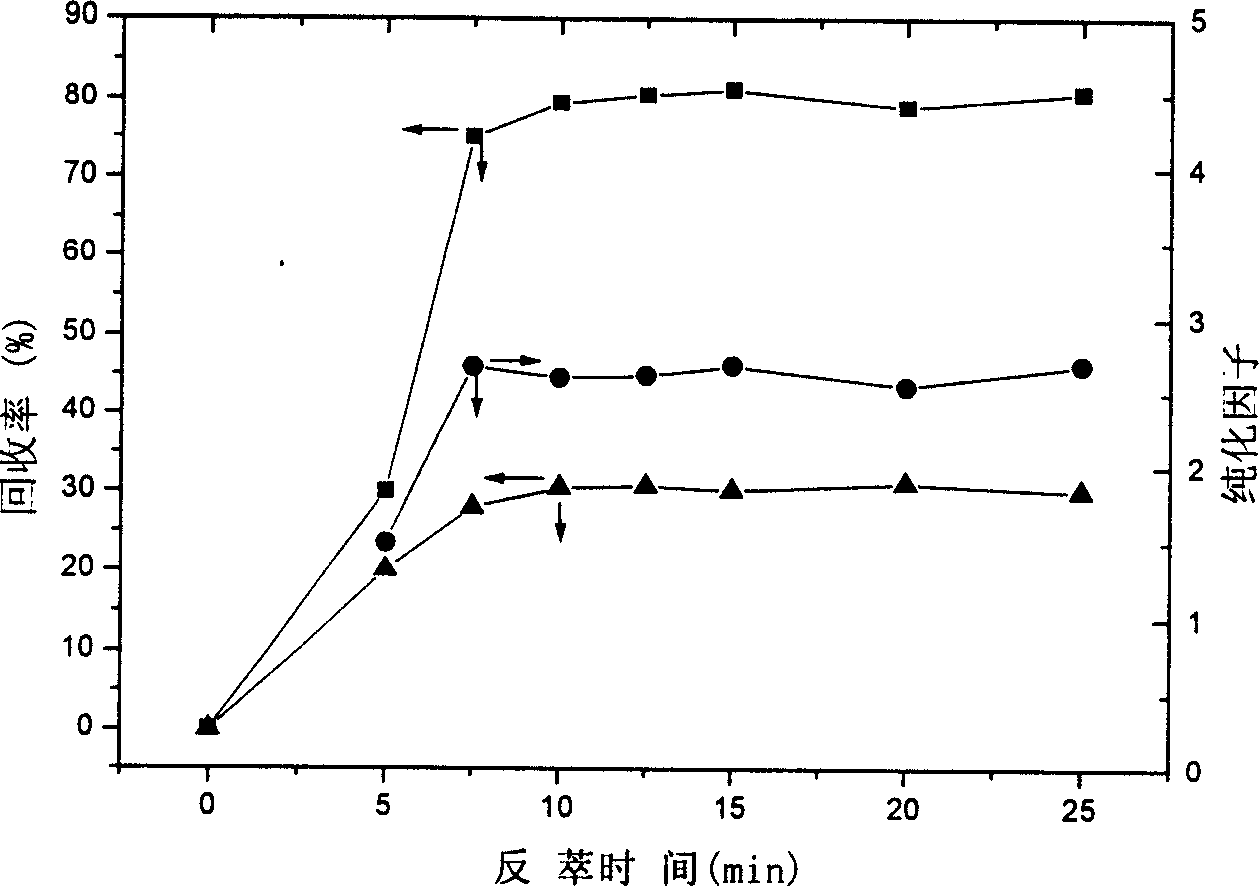

[0039] In this embodiment, the reverse micelles solution is composed of AOT / octane, and its weight ratio is AOT:octane=20:878; AOT and octane are weighed according to the above ratio, mixed eve...

Embodiment 2

[0044] Soybeans are soaked with three times the amount of water for one day and night (room temperature 15°C), then high-pressure cooking, 121°C, 15 minutes, inoculated with 3% inoculum after cooling, and fermented for 24 hours at 40°C to obtain natto. Natto is soaked with twice the amount of normal saline to extract nattokinase to obtain a nattokinase crude extract.

[0045] In this embodiment, the reverse micelles solution is composed of AOT and isooctane, and its weight ratio is AOT:isoctane=100:800. Weigh the AOT and isooctane respectively according to the above proportions, mix them evenly, and let them stand until they are completely dissolved to obtain the reverse micelles solution. Adjust the pH of the fermentation broth to 6; adjust the ionic strength of the fermentation broth to 0.2M with 2M sodium chloride. The fermentation broth and the reverse micelles solution were added into the Erlenmeyer flask at a ratio of 1:1, and the two phases were shaken on a shaker at a...

Embodiment 3

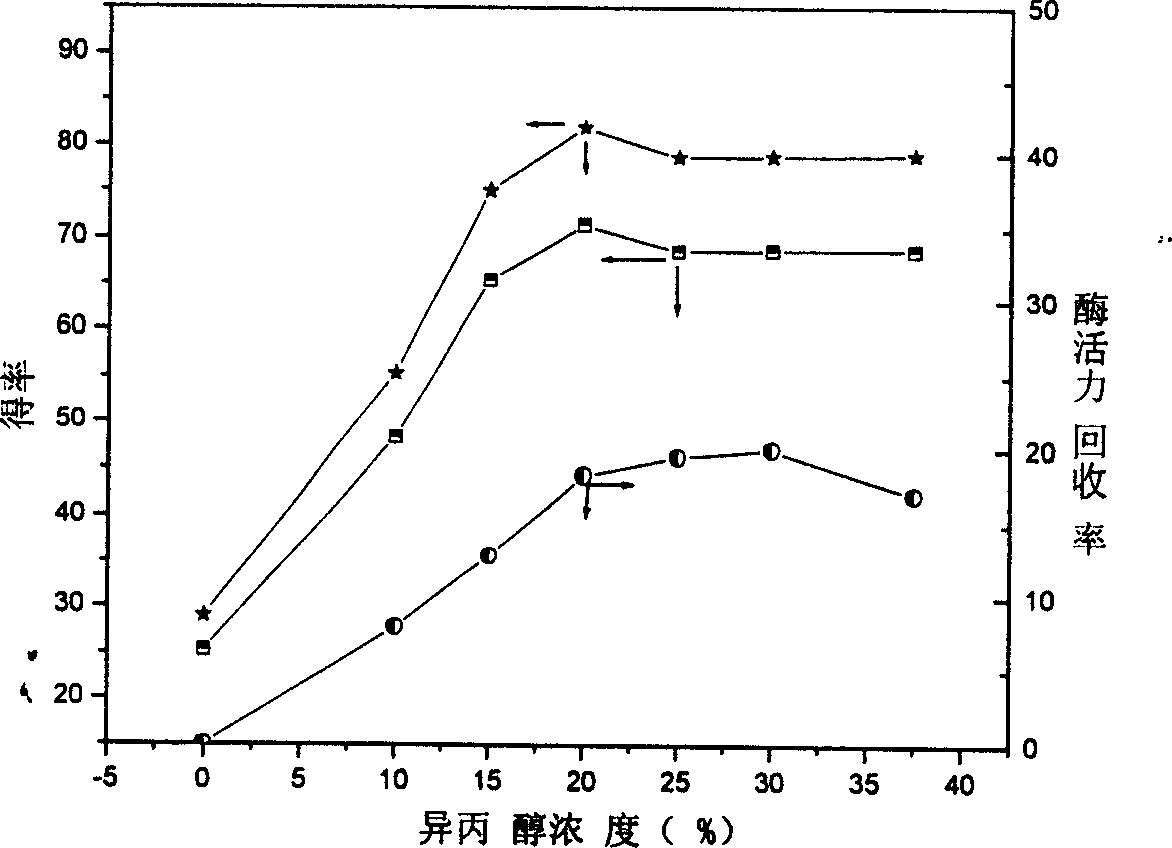

[0049] The preparation method of nattokinase crude extract is as in Example 1. In this embodiment, the reverse micelles solution is composed of cetyltrimethylammonium bromide, n-hexanol, n-hexane and water, and the ratio of parts by weight is 100:100:800:0.5. Mix evenly and let it stand until it is completely dissolved to obtain a reverse micellar solution. Adjust the pH of the fermentation broth to 4.5; adjust the ionic strength of the fermentation broth to 0.2M with 2M sodium chloride. The reverse micelle solution and the fermentation broth were added to the Erlenmeyer flask at a ratio of 1:25, and the two phases were shaken on a shaker at a speed of 240rpm for 5min, and the temperature was controlled at 20°C; the mixed solution was centrifuged at a speed of 4000rpm for 5min to obtain a clear fraction. phase, to obtain the reverse micelles solution loaded with nattokinase;

[0050] The aqueous stripping phase consisted of isopropanol, potassium bromide, glycine-sodium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com