Method for preparing pyruvic oxidase

A technology of pyruvate oxidase and solution, which is applied in the field of bioengineering, can solve the problems of enzyme activity decrease and increase, activity decrease, enzyme activity recovery rate decrease, etc., and achieve the effect of high recovery rate, short production cycle and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

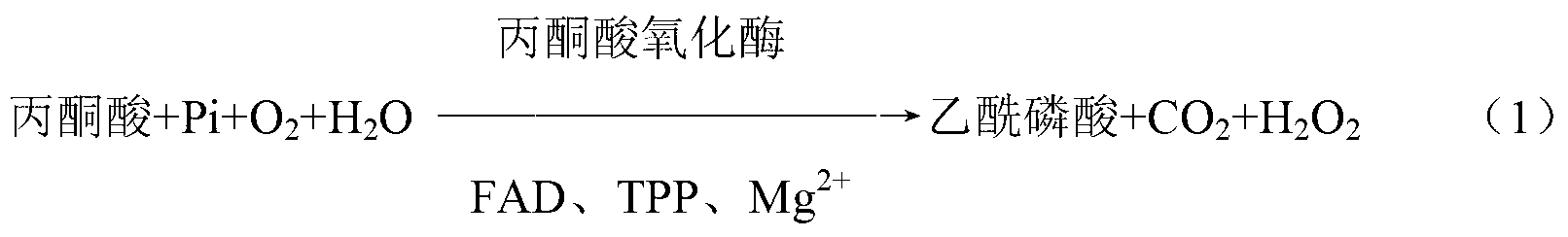

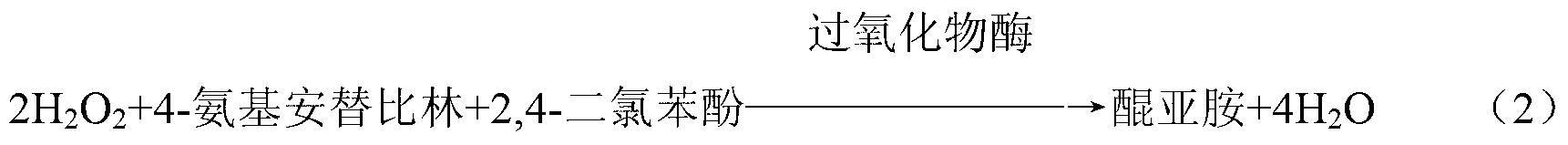

Method used

Image

Examples

Embodiment 1

[0060] The strain used in this example is Lactobacillus plantarum (Lactobacillus plantarum) ATCC8014, which was purchased from the American Type Culture Collection (ATCC).

[0061] The pyruvate oxidase-producing strain Lactobacillus plantarum (Lactobacillus plantarum) ATCC8014 was inoculated into a conical flask containing 20 mL of seed medium, and after standing at 30°C for 24 hours, liquid seeds were prepared; then the inoculation amount was 10% ( V / V) was inoculated in 200mL of fermentation medium, cultured on a shaker at 37°C and 250r / min for 18h, and a bacterial cell culture solution containing pyruvate oxidase was obtained. It has been tested that the enzyme production activity can reach 1562U / L.

[0062] Seed medium (g / L): peptone 10, beef extract 10, yeast extract 5, glucose 20, sodium acetate 5, diammonium citrate 2, Tween-801, K 2 HPO 4 2. MgSO 4 1. MnSO 4 0.5, pH 6.5.

[0063] Fermentation medium (g / L): peptone 10, beef extract 10, yeast extract 5, glucose 20, ...

Embodiment 2

[0076] As described in Example 1, the method for preparing pyruvate oxidase using a two-phase extraction system differs in that:

[0077] In step (2), 200 mL of sodium sulfate aqueous solution was prepared, and polyethylene glycol (PEG1500) with a molecular weight of 1500 was added to the solution so that the mass percentage concentration of sodium sulfate in the total system was 16 wt%, and polyethylene glycol in the total The mass percent concentration in the system was 26 wt%, and the mixture was uniformly mixed to prepare a polyethylene glycol / sodium sulfate two-phase aqueous system solution.

[0078] The recovery rate of the enzyme activity of pyruvate oxidase reached 92.1%, and the purification factor reached about 7.3.

Embodiment 3

[0080] As described in Example 1, the method for preparing pyruvate oxidase using a two-phase extraction system differs in that:

[0081] In step (2), 200 mL of potassium sodium tartrate aqueous solution is prepared, and polyethylene glycol (PEG1000) with a molecular weight of 1000 is added to the solution so that the mass percentage concentration of potassium sodium tartrate in the total system is 20 wt%. The mass percentage concentration in the total system is 20wt%, and they are mixed uniformly to prepare a polyethylene glycol / potassium sodium tartrate two-phase aqueous system solution.

[0082] The recovery rate of the enzyme activity of pyruvate oxidase reached 90.6%, and the purification factor reached about 7.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com