Method for fixing pullulanase with chitosan magnetic nanoparticles

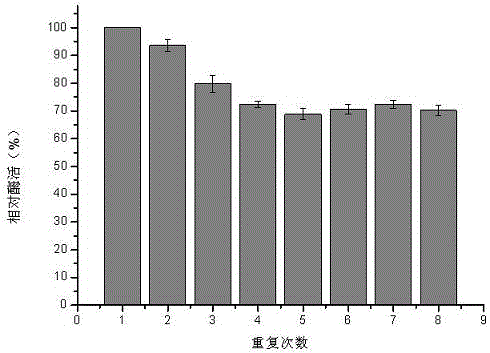

A magnetic nanoparticle, pullulanase technology, applied in the field of enzyme engineering, can solve the problems of complicated process, limited application, harsh conditions, etc., and achieve the effects of high enzyme activity, increased use value, and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

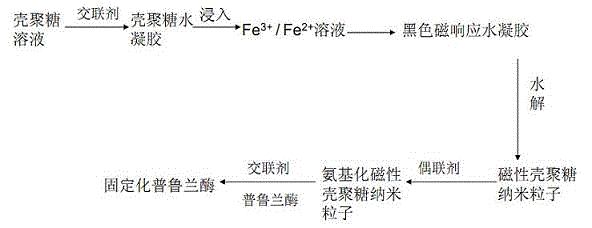

Method used

Image

Examples

Embodiment 1

[0035] Add 3g of chitosan powder to 100ml of 2% acetic acid solution, stir until the chitosan is completely dissolved; slowly add 0.4ml of 25% glutaraldehyde solution, continue to stir at a constant speed for 15min, and then let stand for 24h to obtain chitosan hydrogel Gel; soak the hydrogel in 0.15mol / L Fe 3+ Aqueous solution, water, 0.075mol / L Fe 2+ In the aqueous solution, it was circulated four times, at this time, the chitosan amino group chelated with iron and ferrous ions; the chitosan hydrogel containing iron ions was soaked in 1.25 mol / L NaOH solution for alkalization treatment for 12 hours, and obtained Black hydrogel, the hydrogel is hydrolyzed with 3% acetic acid and 5% hydrogen peroxide solution to obtain black nanoparticles with magnetic response.

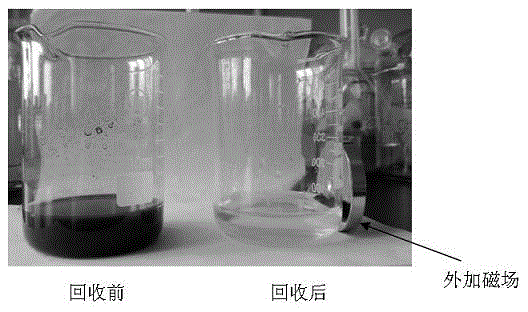

[0036]The magnetically responsive substances were collected under an external magnetic field, and the chitosan magnetic particles aggregated within 10 s. The supernatant was discarded, and then rinsed repeatedly wit...

Embodiment 2

[0041] Add 4 g of chitosan powder into 100 ml of 2% acetic acid solution, stir until the chitosan is completely dissolved; slowly add 0.6 ml of glutaraldehyde solution, continue to stir at a constant speed for 20 minutes, and then let it stand for 12 hours to obtain a chitosan hydrogel; Soak the hydrogel sequentially in 0.2mol / L Fe 3+ Aqueous solution, water, 0.1mol / L Fe 2+ In the aqueous solution, cycle four times; then soak the chitosan hydrogel containing iron ions in 1.5 mol / L NaOH solution for alkaline treatment for 12 hours to obtain a black hydrogel, which is treated with 2% acetic acid and 4 % hydrogen peroxide solution was hydrolyzed to obtain black magnetically responsive nanoparticles, and the magnetically responsive substances were collected under an external magnetic field. The chitosan magnetic particles aggregated within 10 s, and the supernatant was discarded, and then rinsed repeatedly with distilled water to neutral; the obtained magnetic nanoparticles have ...

Embodiment 3

[0046] Add 5 g of chitosan powder to 100 ml of 3% acetic acid solution, stir until the chitosan is completely dissolved; slowly add 0.8 ml of glutaraldehyde solution, continue to stir at a constant speed for 30 min, and then let stand for 24 h to obtain chitosan hydrogel ; Soak the hydrogel sequentially in 0.2mol / L Fe 3+ Aqueous solution, water, 0.1mol / L Fe 2+ In the aqueous solution, cycle four times; soak the chitosan hydrogel containing iron ions in 1.25 mol / L NaOH solution for alkalization treatment for 12 hours, and obtain a black hydrogel, which is treated with 4% acetic acid and 8% The hydrogen peroxide solution was hydrolyzed to obtain black magnetically responsive nanoparticles. The magnetically responsive substances were collected under an external magnetic field. The chitosan magnetic particles aggregated within 10 s. The supernatant was discarded, and then rinsed repeatedly with distilled water until Neutral; the obtained magnetic nanoparticles have good dispersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com