Method for preparing magnetic cellulose immobilized lysozyme

A technology based on cellulose and cellulose solution is applied in the field of preparation of magnetic-based cellulose immobilized lysozyme, which can solve problems such as difficulty in recovering immobilized enzymes, improve dehydration effect, simple immobilization operation, and reduce weight reduction. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039](1) Get 1.35g ferric chloride, 3.6g sodium acetate and 1.0g polyethylene glycol and join in 40ml of ethylene glycol and diethylene glycol mixed solvent (volume ratio is 2:1), mechanically stir, obtain clarification The yellow solution was transferred to a high-temperature reaction kettle made of polytetrafluoroethylene, sealed, and placed in a high-temperature drying oven at 200°C for 8 hours, cooled to room temperature, separated by an external magnetic field, washed several times with methanol and water, and frozen Dry to constant weight to obtain nano ferric oxide.

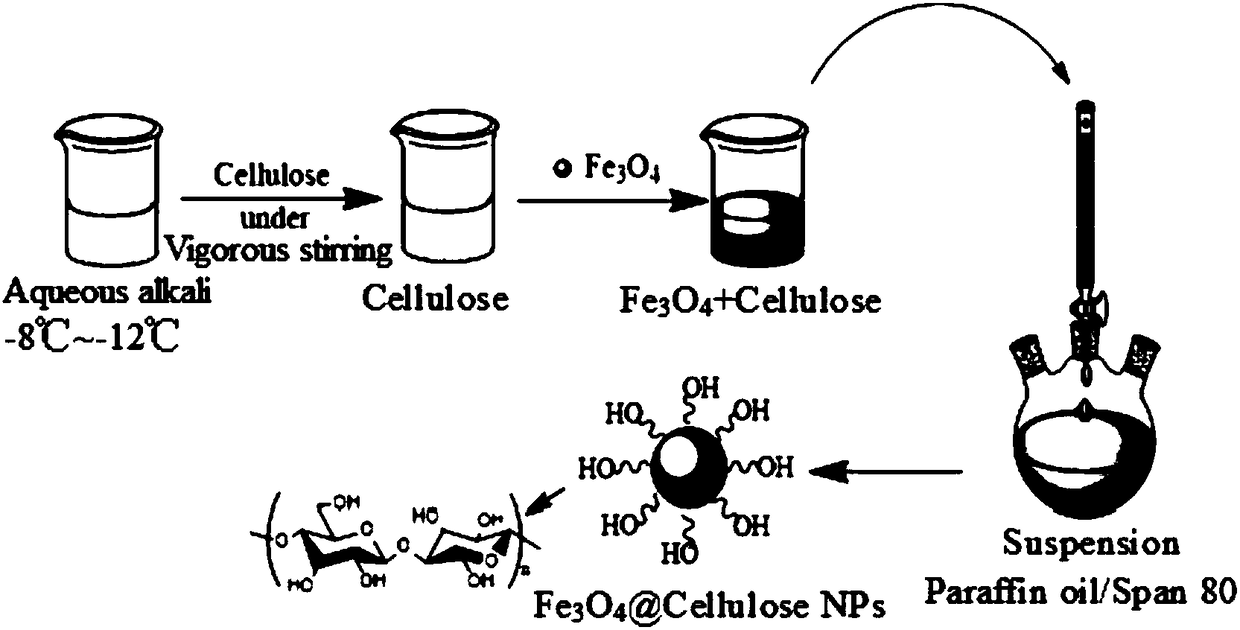

[0040] (2) Prepare a solution of 100g of sodium hydroxide, urea and water mixed at a mass ratio of 7:10:83, pre-cool to a low temperature of -8°C to -12°C, add 5g of microcrystalline cellulose, and stir rapidly to form a transparent and uniform Cellulose solution, then add nanometer iron ferric oxide in 0.3g step (1), stir evenly, remove air bubble, obtain ferric oxide-cellulose solution, add dropwise to ...

Embodiment 2

[0045] Take 6 parts of 1ml of the magnetic-based cellulose nanosphere solution in Example 1, add 400 μL of 1% glutaraldehyde (crosslinking agent) and 4.6mL of pH7.0 phosphate buffer solution, and vibrate on a shaker at 25°C for crosslinking respectively 1h, 2h, 4h, 6h, 8h, 10h, get immobilized carrier after magnetic separation and filtration, wash with phosphate buffer three times, add 100μL 1mg / mL lysozyme solution, shake and adsorb at 150~200r / min, 25℃ After 4 hours, apply an external magnetic field to separate, and wash three times with a phosphate buffer solution with a pH value of 7 to obtain magnetic-based cellulose-immobilized lysozyme. Determination of the immobilized lysozyme enzyme activity, such as Image 6 shown. It can be seen from the figure that when the crosslinking time is 4h, the activity of the immobilized lysozyme is the highest (12U / g), and the recovery rate of the activity of the immobilized lysozyme reaches the maximum (47.8%).

Embodiment 3

[0047] Take 8 parts of 1ml of the magnetic-based cellulose nanosphere solution in Example 1, add 400 μL of 1% glutaraldehyde (crosslinking agent) and 4.6mL of pH7.0 phosphate buffer solution, and vibrate on a shaker at 25°C for crosslinking respectively 4h. The immobilized carrier was obtained after magnetic separation and filtration, washed three times with phosphate buffer, added 100 μL, 200 μL, 400 μL, 500 μL, 600 μL, 700 μL, 800 μL, 1000 μL 1 mg / mL lysozyme solution (1 mg / mL), at 150 ~ 200 r / min at 25°C for 4 hours, separated by an external magnetic field, and washed three times with phosphate buffer with a pH value of 7 to obtain magnetic-based cellulose-immobilized lysozyme. Determination of the immobilized lysozyme enzyme activity, such as Figure 7 shown. It can be seen from the figure that when the enzyme dosage reaches 500 μL (1 mg / mL), the activity recovery rate reaches the highest, which is 68.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com