Immobilization method of sucrose phosphorylase

A technology of sucrose phosphorylase and immobilized carrier, which is applied in the field of immobilization of sucrose phosphorylase, and can solve the problems of low recovery rate of immobilized enzyme activity and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Shake flask fermentation produces enzyme

[0032] (1) Fermentation culture

[0033] The recombinant Bacillus subtilis SPase / pBSMuL3 strain (Wu Jing, Wu Dan, Wang Miaomiao, Zhang Kang: A recombinant Bacillus subtilis producing sucrose phosphorylase and its application, CN107236696A) was inoculated in LB medium, at 37°C Cultivate for 8-10 hours, transfer to TB fermentation medium with 5% inoculation amount, and cultivate at 33° C. and 200 rpm for 48 hours. After the cultivation, the obtained fermentation liquid was centrifuged at 8000 rpm and 4° C. for 15 min, and the supernatant was collected to be the SPase crude enzyme liquid.

[0034] (2) Enzyme activity assay

[0035] Enzyme activity assay method: Mix 1mL of 5% (w / v) sucrose solution and 0.9mL of 50mmol / L, pH 7.5 phosphate buffer well, preheat at 55°C for 10min, add 100μL of crude enzyme solution, After reacting for 10 minutes, add 3 mL of DNS, boil for 7 minutes and cool rapidly, add distilled water...

Embodiment 2

[0038] Embodiment 2: the pretreatment of aminated resin

[0039]Take 10g of aminated resin LX-1000EA, add it to 40mL, 0.1M, pH 8.0 PBS buffer solution, place it on a constant temperature water bath shaker at 25°C, set it aside at room temperature for 1h at 200rpm for 15min, filter it with filter paper, weigh 10g of resin and add Into 50ml of 2% glutaraldehyde, in a constant temperature water bath shaker at 25°C, 200rpm cross-linking treatment for 5h, then wash with distilled water 3 times to remove residual glutaraldehyde, and filter to obtain the treated aminated resin LX-1000EA , and store in the refrigerator for later use.

[0040] Treat the aminated resin LX-1000HA in the same way.

Embodiment 3

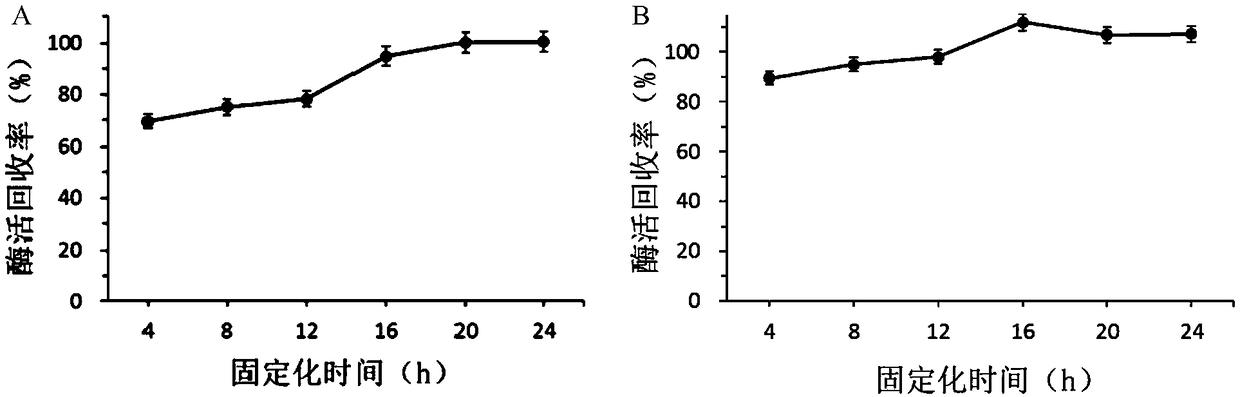

[0041] Embodiment 3: The impact of immobilization time on the recovery rate of immobilized enzyme activity

[0042] Take 1g of the crude enzyme solution obtained in Example 1, add it to 1g of aminated resin LX-1000EA or aminated resin LX-1000HA after treatment in Example 2, place it in a constant temperature water bath shaker at 25°C, and culture it under the condition of 100rpm 4h, 8h, 12h, 16h, 20h or 24h. After the cultivation, wash the immobilized enzyme with deionized water for 2 to 3 times, and obtain LX-1000EA immobilized SPase or LX-1000HA immobilized SPase after suction filtration. Weigh 0.1g LX-1000EA immobilized SPase or LX-1000HA immobilized SPase For HeSPase, utilize the enzymatic assay method in the example 1 to measure the enzymatic activity, and calculate the enzymatic activity recovery rate.

[0043] The result is as figure 1 As shown, the enzyme activity recovery rates of LX-1000EA immobilized SPase and LX-1000HA immobilized SPase showed a trend of first in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com