Preparation method of immobilized enzyme

An enzyme immobilized, time-fixed technology, applied in biochemical equipment and methods, immobilized on or in inorganic carriers, oxidoreductase, etc. , fierce reaction and other problems, to avoid adverse effects of enzyme activity, high recovery rate of enzyme activity, and not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The mensuration of embodiment 1 enzyme solution protein concentration

[0044] The protein concentration was determined by the Bradford method. Coomassie Brilliant Blue G-250 dye was light red in acidic ethanol solution, and the blue solution formed after combining with protein had the maximum light absorption at 595nm. The absorbance value is directly proportional to the protein concentration, so detect the light absorbance value of the solution at 595nm to calculate the protein content.

[0045] (1) Bradford stock solution: Weigh 350 mg of Coomassie Brilliant Blue G-250, dissolve it in 100 mL of 95% ethanol, add 200 mL of 85% phosphoric acid, and store it in a refrigerator at 4°C;

[0046] (2) Bradford working solution: Add 15mL 95% ethanol, 30mL 85% phosphoric acid and 30mL Bradford stock solution to 425mL double-distilled water, mix well and store in a refrigerator at 4°C. Before each use, filter with filter paper before use;

[0047] (3) Standard bovine serum alb...

Embodiment 2

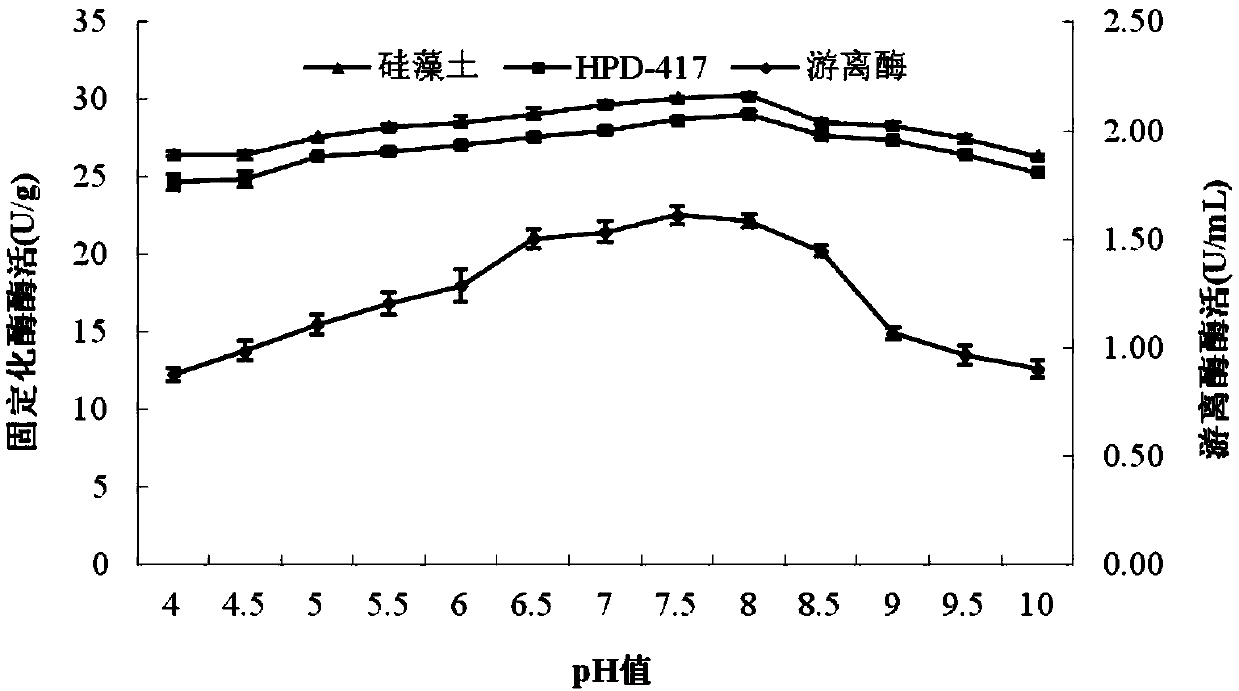

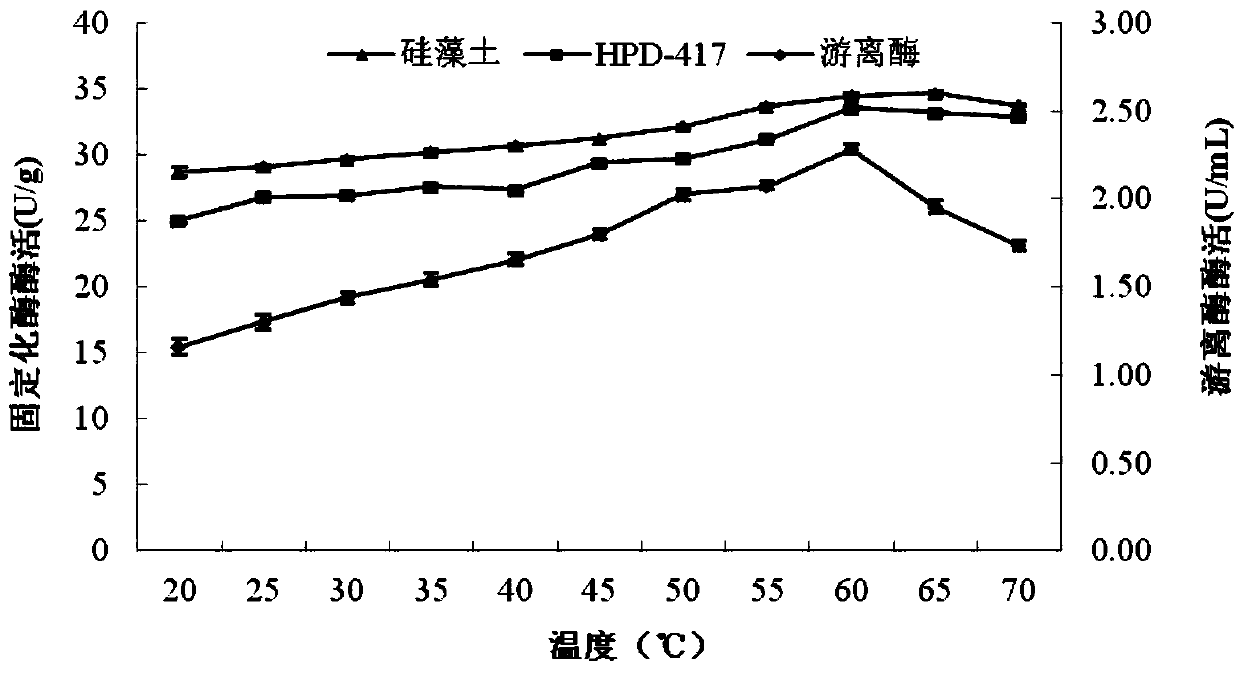

[0050] Embodiment 2 Enzyme solution and the determination of the activity of immobilized enzyme

[0051] Enzyme activity, also known as enzyme activity, refers to the ability of an enzyme to catalyze a certain chemical reaction. The unit of enzyme activity is U, which means that under certain conditions, the amount of enzyme required to convert 1 micromole of substrate or generate 1 micromole of product per unit time is an activity unit (U). The certain conditions are usually the optimum temperature and optimum pH conditions of the enzyme. In the actual enzyme activity determination, a certain volume of enzyme solution or a certain mass of immobilized enzyme is used to catalyze a chemical reaction of a certain concentration of substrate under certain conditions. The activity of the enzyme solution is expressed as U / mL, and the activity of the immobilized enzyme is expressed as U / g.

Embodiment 3

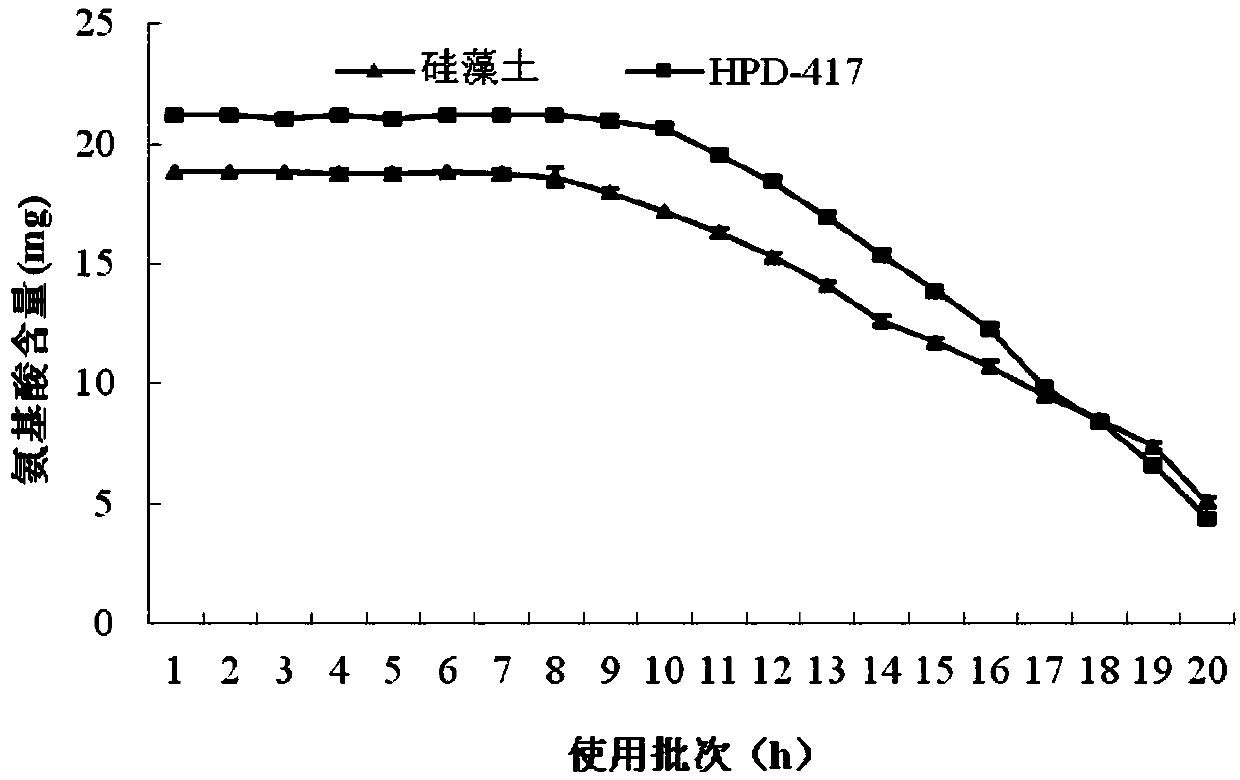

[0052] Example 3 Immobilization rate of enzyme and recovery rate of immobilized enzyme enzyme activity

[0053] Enzyme immobilization rate=(protein amount of enzyme solution before immobilization−protein amount in supernatant of immobilization solution after immobilization) / protein amount of enzyme solution before immobilization×100%. Recovery rate of immobilized enzyme enzyme activity = enzyme activity of immobilized enzyme / (enzyme activity of input enzyme solution-enzyme activity of supernatant of immobilized solution after immobilization)×100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com