Process of chitosan-arginine resin anion immobilizing chymotrypsin

A chymotrypsin and anion resin technology, which is applied in the field of enzyme immobilization, can solve the problems of difficult nano-magnetic chitosan carrier, weak interaction between enzyme and carrier, low efficiency of cross-linking immobilization enzyme, etc. The effect of recycling, low production cost, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

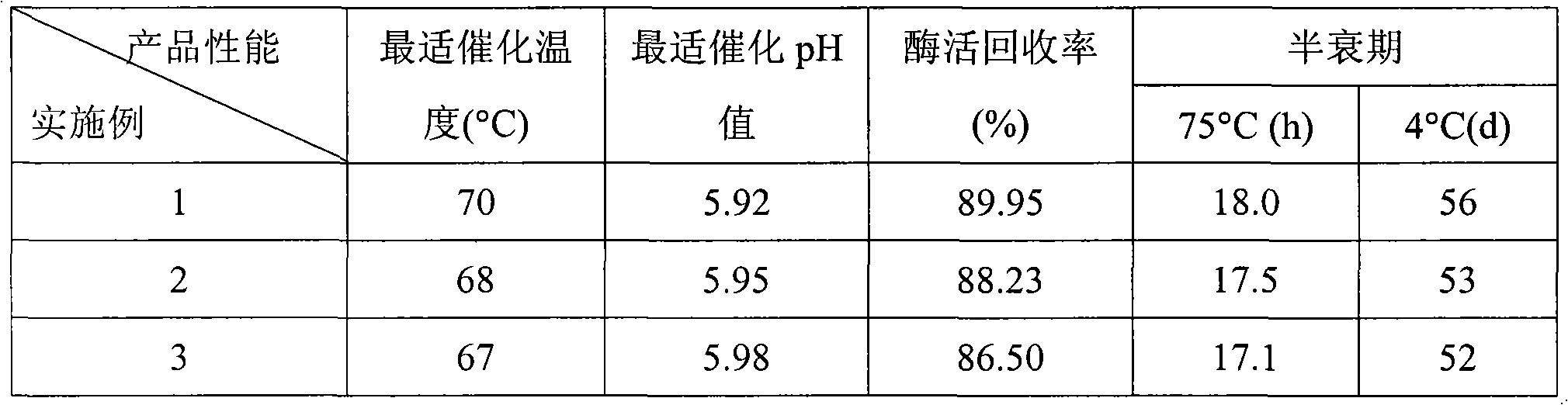

Embodiment 1

[0024] A kind of concrete steps of the method for chitosan-arginine anion resin immobilization chymotrypsin are as follows:

[0025] (1) Preparation of cross-linked chitosan resin

[0026]Using commercially available chitosan as a raw material, the chitosan is firstly added into dilute hydrochloric acid with a mass percentage of 2% hydrochloric acid, stirred and dissolved, and a chitosan acid sol with a mass percentage of chitosan of 2% is prepared. Afterwards, the volume ratio of chitosan acid sol: liquid paraffin is 1: 1, chitosan acid sol is slowly added in liquid paraffin, stirred for 25min, and heated to 40°C to obtain the chitosan paraffin solution, Adding and accounting for chitosan paraffin solution volume fraction is 0.1% Tween 80 again, carry out emulsification 25min, then add and account for chitosan paraffin solution volume fraction and be 0.15% glutaraldehyde cross-linking agent, make the part amino group of chitosan molecule Participate in the cross-linking reac...

Embodiment 2

[0032] A kind of concrete steps of the method for chitosan-arginine anion resin immobilization chymotrypsin are as follows:

[0033] (1) Preparation of cross-linked chitosan resin

[0034] Same as Example 1, the feature is that chitosan is added into dilute hydrochloric acid with a mass percentage of 1% hydrochloric acid to prepare a chitosan acidic sol with a mass percentage of chitosan. Chitosan acidic sol: the volume ratio of liquid paraffin is 1: 2, stir for 20min, and heat up to 35°C, then add Tween 80 accounting for 0.05% of the chitosan paraffin solution volume fraction, emulsify for 20min, and then add The volume fraction of the chitosan paraffin solution is 0.05% glutaraldehyde crosslinking agent, and then the chitosan paraffin solution mass fraction is 0.01% calcium carbonate porogen, and the pore-forming reaction is carried out for 50 minutes. Use sodium hydroxide solution to adjust the pH value of the chitosan microsphere suspension to 9, heat to 55 ° C, stir and ...

Embodiment 3

[0040] A kind of concrete steps of the method for chitosan-arginine anion resin immobilization chymotrypsin are as follows:

[0041] (1) Preparation of cross-linked chitosan resin

[0042] Same as Example 1, the feature is that chitosan is added into dilute hydrochloric acid with a mass percentage of 5% hydrochloric acid to prepare a chitosan acidic sol with a mass percentage of chitosan of 4%. Chitosan acidic sol: the volume ratio of liquid paraffin is 1: 4, stir for 30min, and heat up to 45°C, then add Tween 80 accounting for 0.25% of the chitosan paraffin solution volume fraction, emulsify for 30min, and then add The volume fraction of the chitosan paraffin solution is 0.3% glutaraldehyde crosslinking agent, and the mass fraction of the chitosan paraffin solution is 0.1% calcium carbonate porogen, and the pore-forming reaction is carried out for 70 minutes. Use sodium hydroxide solution to adjust the pH value of the chitosan microsphere suspension to 10, heat to 75°C, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com