Method for assisting lysozyme renaturation by temperature sensitive type poly N-isopropyl acrylamide gel

An isopropyl acrylamide gel, lysozyme renaturation technology, applied in biochemical equipment and methods, enzymes, immobilized on/in organic carriers, etc., can solve problems such as troublesome operation and protein loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation of thermosensitive type PNIPA gel (total monomer concentration 10%, cross-linking degree 5%)

[0021] The reaction was carried out in a 250mL three-necked bottle, and the stirring speed was adjusted to 420rpm by an electronic constant speed stirrer. The whole reactor is submerged in a super constant temperature tank, and the polymerization temperature is 25°C. Dissolve 75mg of surfactant Tween80 in 75mL of liquid paraffin in the continuous phase, add it to the reactor, and feed an appropriate flow rate of N 2 , stirred for about 20 minutes to mix the solution evenly, then slowly added the aqueous solution of the reactant with a total monomer concentration of 10% and a cross-linking degree of 5% into the reactor dropwise with a pipette gun, continued to stir for 30 minutes, and then slowly added 1 μL initiator TEMED 20 μL, polymerize for 3 hours and discharge. The final product is repeatedly soaked with different volume ratios of absolute ...

Embodiment 2

[0024] Embodiment 2: the preparation of granular PNIPA gel (total monomer concentration 14%, degree of cross-linking 10%)

[0025] The reaction was carried out in a 250mL three-necked bottle, and the stirring speed was adjusted to 420rpm by an electronic constant speed stirrer. The whole reactor is submerged in a super constant temperature tank, and the polymerization temperature is 25°C. Dissolve 75mg of surfactant Tween80 in the continuous phase, add to the reactor, and feed into the N of appropriate flow rate 2 , stirred for about 20 minutes to mix the solution evenly, and then slowly added the aqueous solution of the reactant with a total monomer concentration of 14% and a cross-linking degree of 10% into the reactor dropwise with a pipette gun, continued to stir for 30 minutes, and then slowly added 1 μL initiator TEMED, polymerized at 25°C for 3 hours and discharged. The final product is repeatedly soaked with different volume ratios of absolute ethanol / water solution,...

Embodiment 3

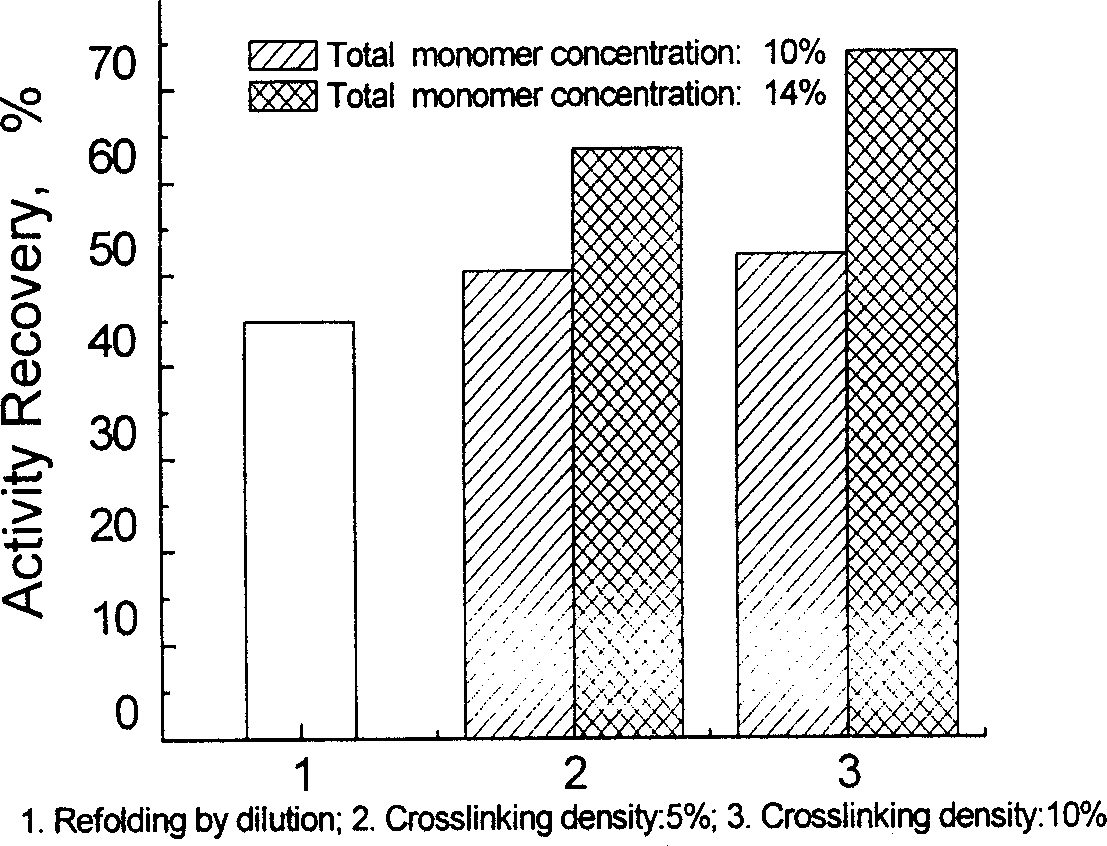

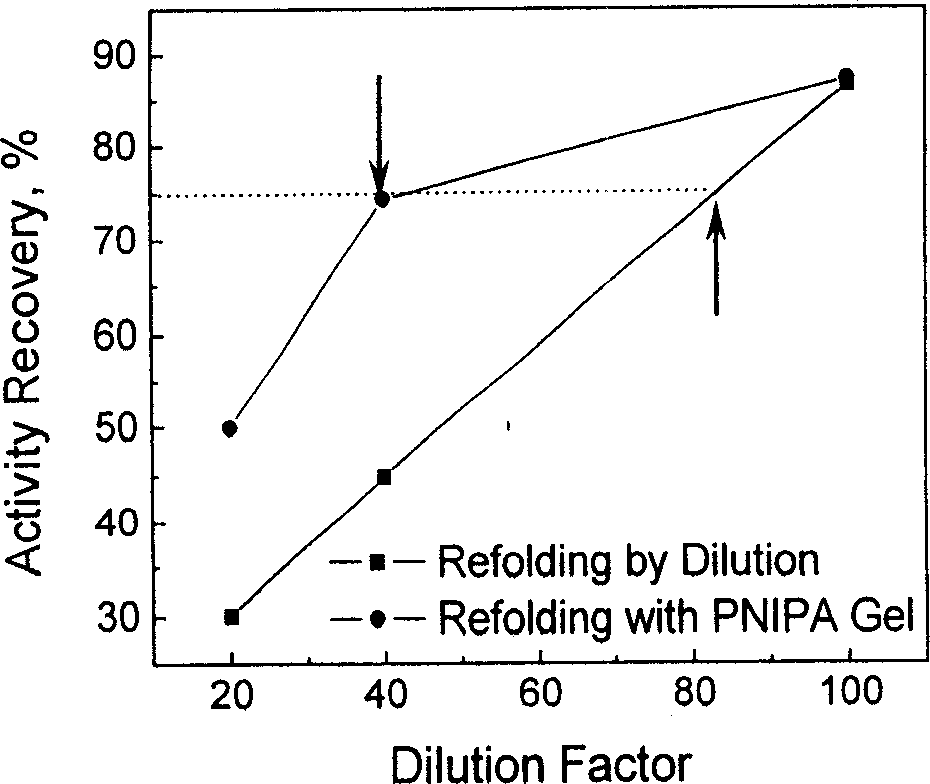

[0027] Embodiment 3: granular PNIPA gel assists lysozyme refolding (10% of the total monomer concentration of preparation gel, cross-linking degree 5%)

[0028] After adding 10mg / mL inactive lysozyme solution in the extended state to the refolding buffer (the dilution factor is 40), add 100mg / mL granular PNIPA gel to it, fully shake and disperse evenly, then shake at 30°C and 120rpm Refolding in bed for 3 hours, the results are as follows figure 1 shown. After renaturation, the activity recovery rate of lysozyme reached 50.34%, but under the same conditions, the recovery rate of activity was only 44.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical temperature | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com