Chitosan microspheres for enzyme immobilization and preparation method and application thereof

A chitosan microsphere and enzyme immobilization technology, which is applied in the preparation of microspheres, immobilization on/in organic carriers, microcapsule preparations, etc., can solve the problems of sample dilution and large loss of carrier recovery, etc. Achieve the effect of easy separation and recovery, high recovery rate of enzyme activity and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Take by weighing 0.5g chitosan powder in a 100mL three-neck bottle, add 30ml mass fraction of 5% acetic acid solution, stir at room temperature, after chitosan is fully dissolved, add 30ml liquid paraffin, stir for 10 minutes;

[0048] (2) Warm up the product of step (1) to 50°C, add 2-3 drops of emulsifier Span80 dropwise, and emulsify for 10 minutes to form fine chitosan droplets;

[0049] (3) Add 1.0 mL of formaldehyde solution to the obtained product of step (2), and stir and react for 1.5 hours;

[0050] (4) Warm up the product of step (3) to 70°C, add dropwise 5-6 drops of NaOH solution with a mass fraction of 10%, keep the pH of the solution alkaline, and slowly add 2.0mL of epoxy chloride Propane, reacted for 5 hours;

[0051] (5) Filter the product of step (4), wash with distilled water, then wash with petroleum ether, absolute ethanol, and water successively until the pH value of the washing liquid reaches neutrality;

[0052](6) Heat the product obtaine...

Embodiment 2

[0086] (1) Accurately weigh 10 mg of chitosan microsphere carrier, and separate after swelling with 10 mL of phosphate buffer solution (PBS, pH=7) for 24 hours;

[0087] (2) Add 10 mL of 5% glutaraldehyde solution to the obtained product of step (1), shake and activate at 25° C. for 5 hours and filter, and wash off excess glutaraldehyde with distilled water;

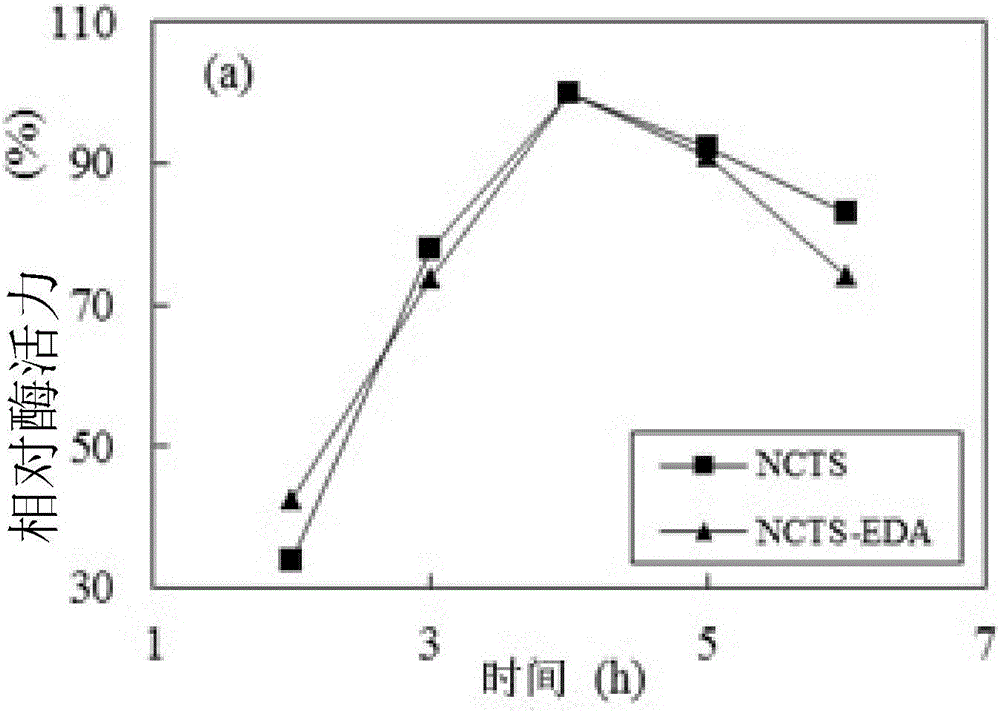

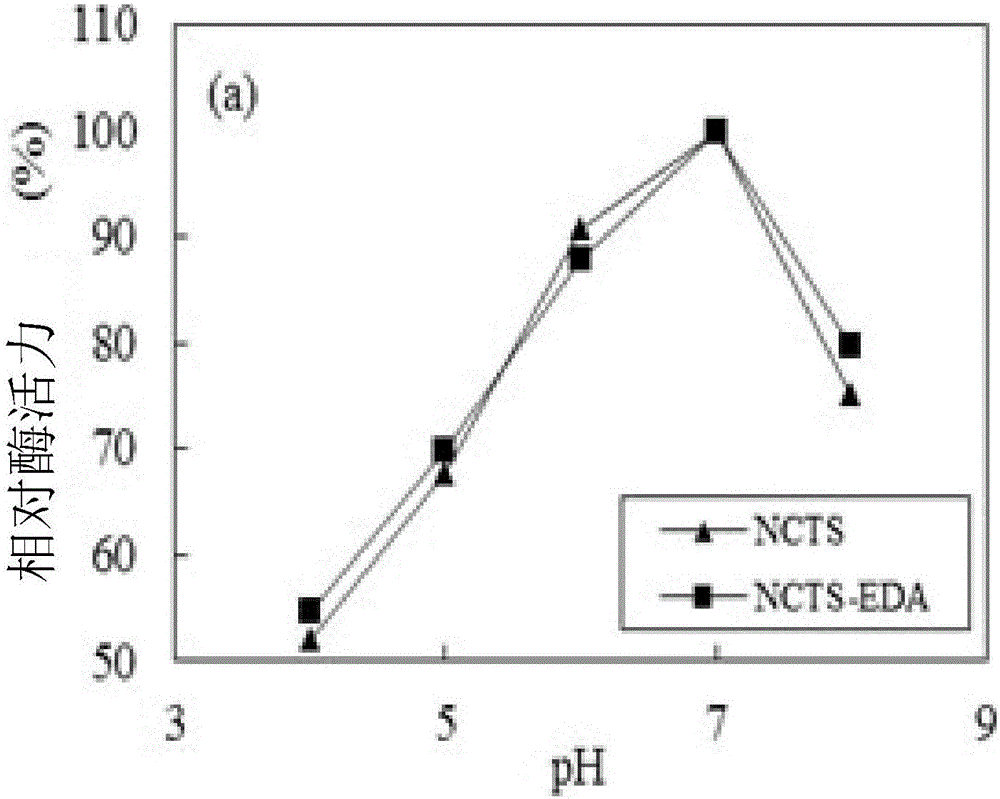

[0088] (3) Add 2.0 mg of cellulase enzyme solution to the obtained product of step (2), shake and fix at 30° C. for 4 hours, filter, and wash the filter residue repeatedly with phosphate buffer to obtain immobilized enzyme. The immobilized enzymes were stored in the refrigerator (4°C) for later use.

[0089] The method for measuring cellulase activity and the method for measuring the enzyme activity of the immobilized enzyme obtained in Example 2 will be described below.

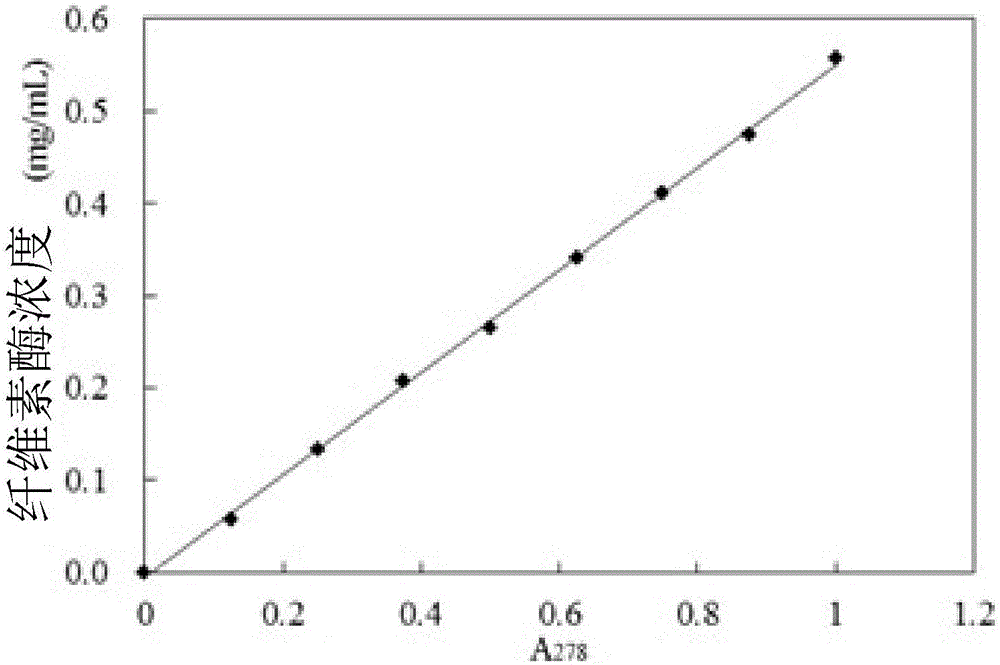

[0090] Determination of free enzyme activity: Take an appropriate amount of cellulase and dissolve it in HAc-NaAc buffer to prepare a cellulase solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com