Method for assisting lysozyme in vitro refolding by means of linear poly N-isopropyl acrylamide

A technology of isopropylacrylamide and lysosome, which is applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of protein loss, cumbersome preparation steps, insoluble, etc., achieve fewer parameters, inhibit aggregation tendency, Easy to control and amplify effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

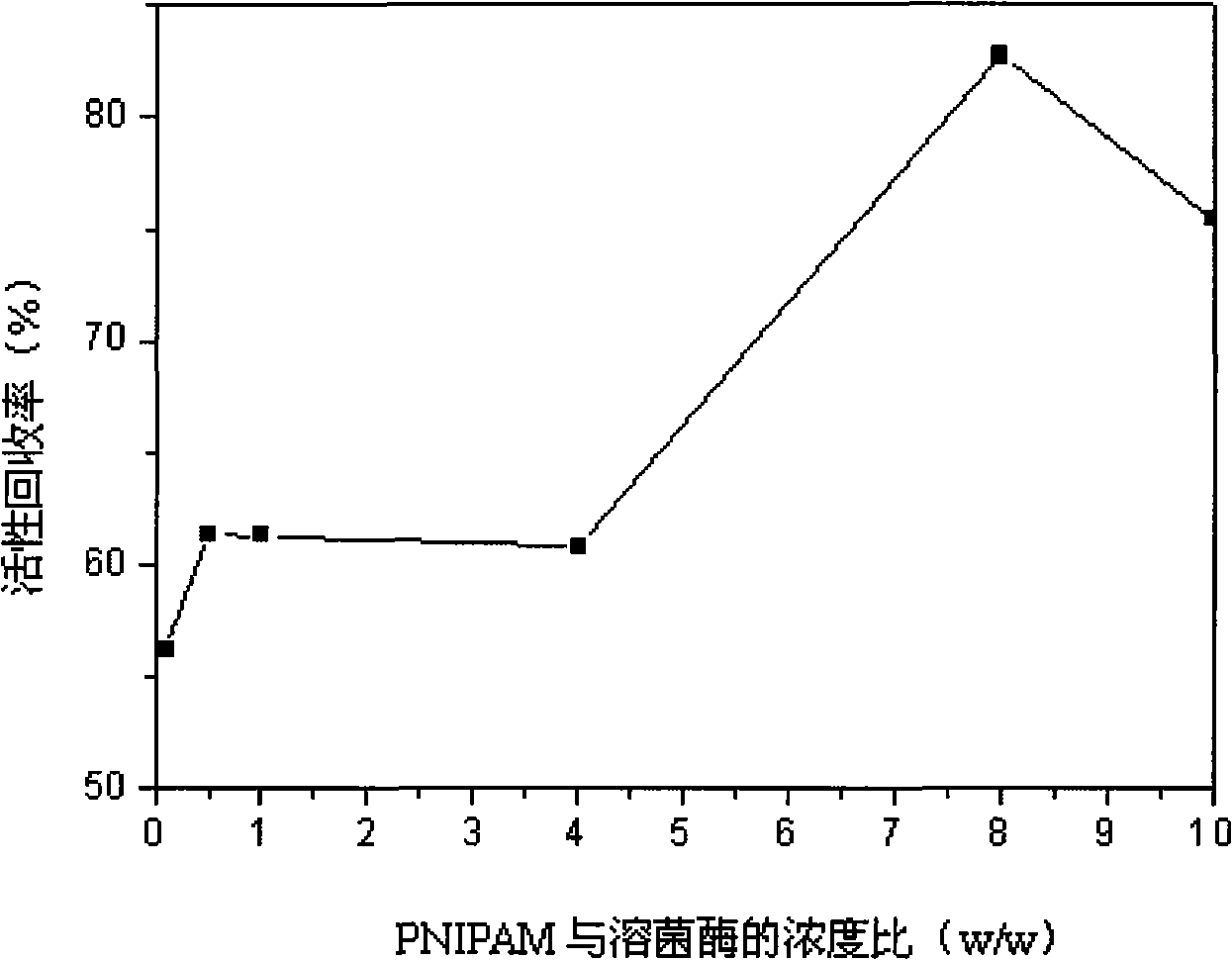

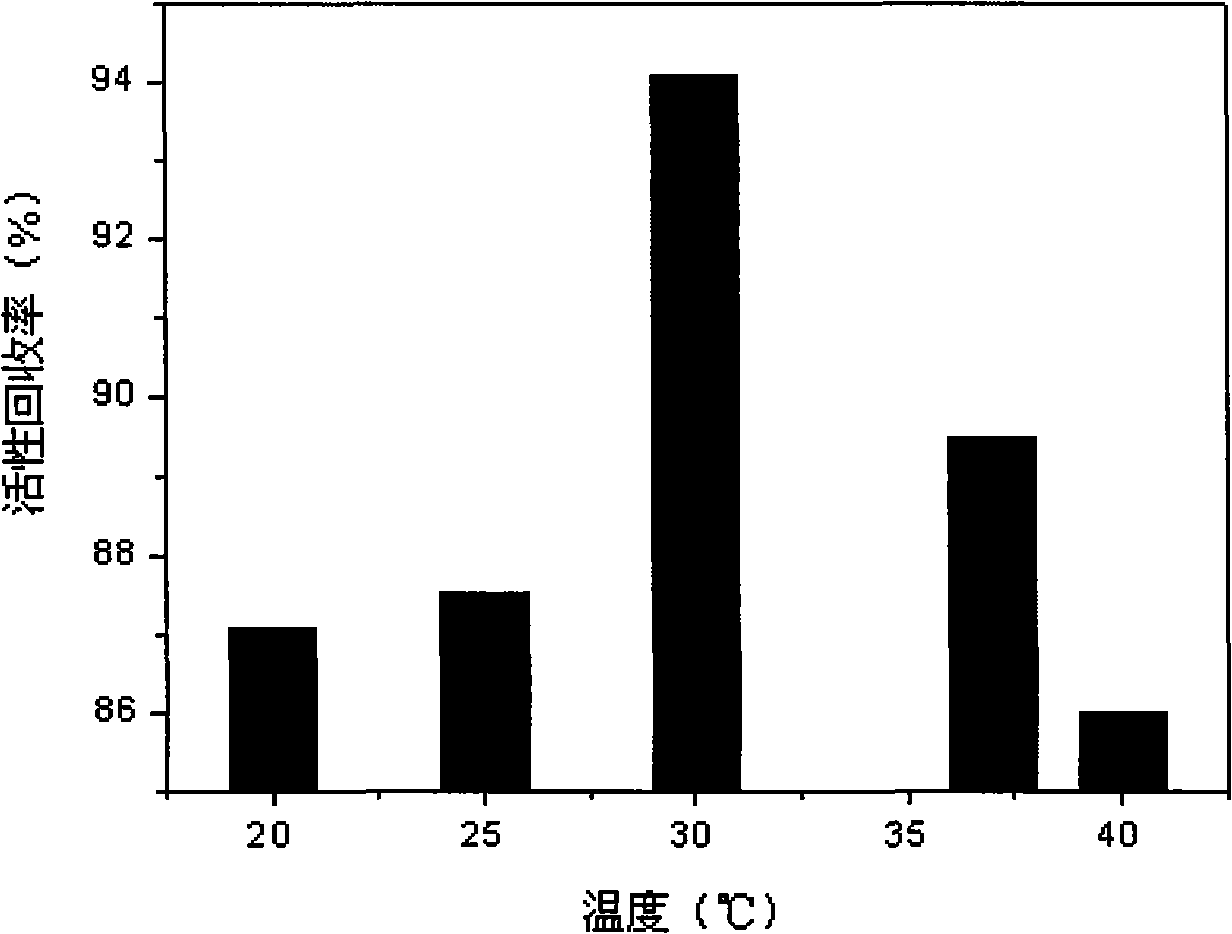

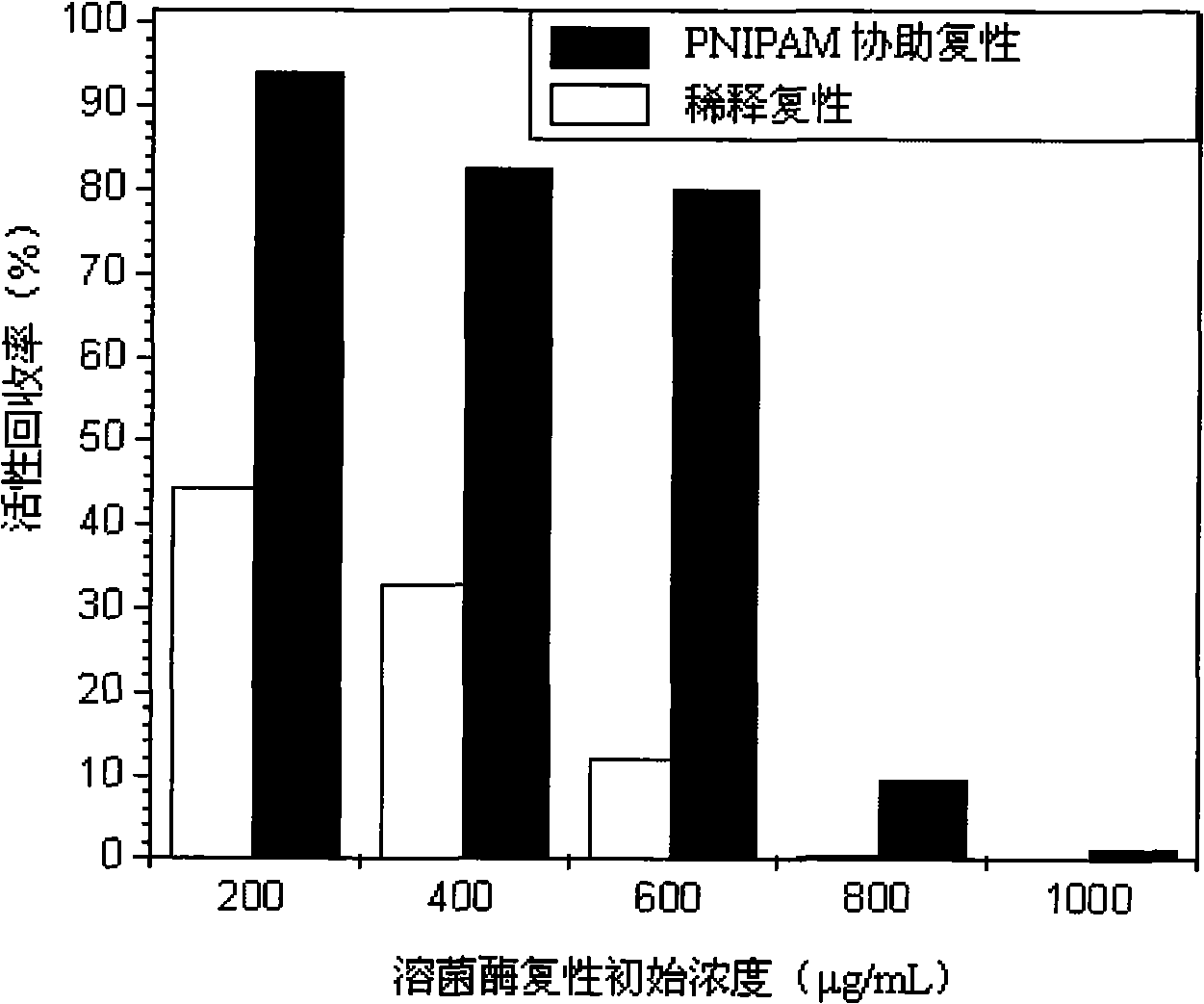

Method used

Image

Examples

Embodiment 1

[0018] 1) Dissolve N-isopropylacrylamide and azobisisobutyronitrile with a molar concentration ratio of 10:1 in absolute ethanol. The concentration of N-isopropylacrylamide is 1mol / L, and it is protected under nitrogen at 60℃. After reacting for 12 hours and evaporating under reduced pressure to remove most of the ethanol, the resulting reaction product was dissolved in acetone, and the dissolved solution was slowly dropped into the constantly stirring n-hexane to obtain a white precipitate. The reaction product dissolution and precipitation steps were repeated 3 times to obtain a linear polymer N-isopropyl acrylamide, dried in a vacuum dryer to constant weight. The number average molecular weight of the resulting linear poly-N-isopropylacrylamide is M n =20.4kDa, the weight average molecular weight is M w = 30.8 kDa, polydispersity = 1.51.

[0019] 2) Dissolve lysozyme in denaturation buffer to prepare a solution with a concentration of 10 mg / mL, and place the solution in a shake...

Embodiment 2

[0021] 1) Dissolve N-isopropylacrylamide and azobisisobutyronitrile with a molar concentration ratio of 10:1 in absolute ethanol. The concentration of N-isopropylacrylamide is 1mol / L, and it is protected under nitrogen at 60℃. After reacting for 12 hours and evaporating under reduced pressure to remove most of the ethanol, the resulting reaction product was dissolved in acetone, and the dissolved solution was slowly dropped into the constantly stirring n-hexane to obtain a white precipitate. The reaction product dissolution and precipitation steps were repeated 3 times to obtain a linear polymer N-isopropyl acrylamide, dried in a vacuum dryer to constant weight. The number average molecular weight of the resulting linear poly-N-isopropylacrylamide is M n =20.4kDa, the weight average molecular weight is M w = 30.8 kDa, polydispersity = 1.51.

[0022] 2) Dissolve lysozyme in denaturation buffer to prepare a solution with a concentration of 10 mg / mL, and place the solution in a shake...

Embodiment 3

[0024] 1) Dissolve N-isopropylacrylamide and azobisisobutyronitrile with a molar concentration ratio of 10:1 in absolute ethanol. The concentration of N-isopropylacrylamide is 1mol / L, and it is protected under nitrogen at 60℃. After reacting for 12 hours and evaporating under reduced pressure to remove most of the ethanol, the resulting reaction product was dissolved in acetone, and the dissolved solution was slowly dropped into the constantly stirring n-hexane to obtain a white precipitate. The reaction product dissolution and precipitation steps were repeated 3 times to obtain a linear polymer N-isopropyl acrylamide, dried in a vacuum dryer to constant weight. The number average molecular weight of the resulting linear poly-N-isopropylacrylamide is M n =20.4kDa, the weight average molecular weight is M w = 30.8 kDa, polydispersity = 1.51.

[0025] 2) Dissolve lysozyme in denaturation buffer to prepare a solution with a concentration of 10 mg / mL, and place the solution in a shake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com