Knock controlling device and method

An adjustment device and knocking technology, which is applied in the direction of forward/reverse ignition, spark ignition controller, engine components, etc., can solve the problems of improper adjustment of ignition delay angle, uncertain knock intensity, etc., and suppress the occurrence of knocking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

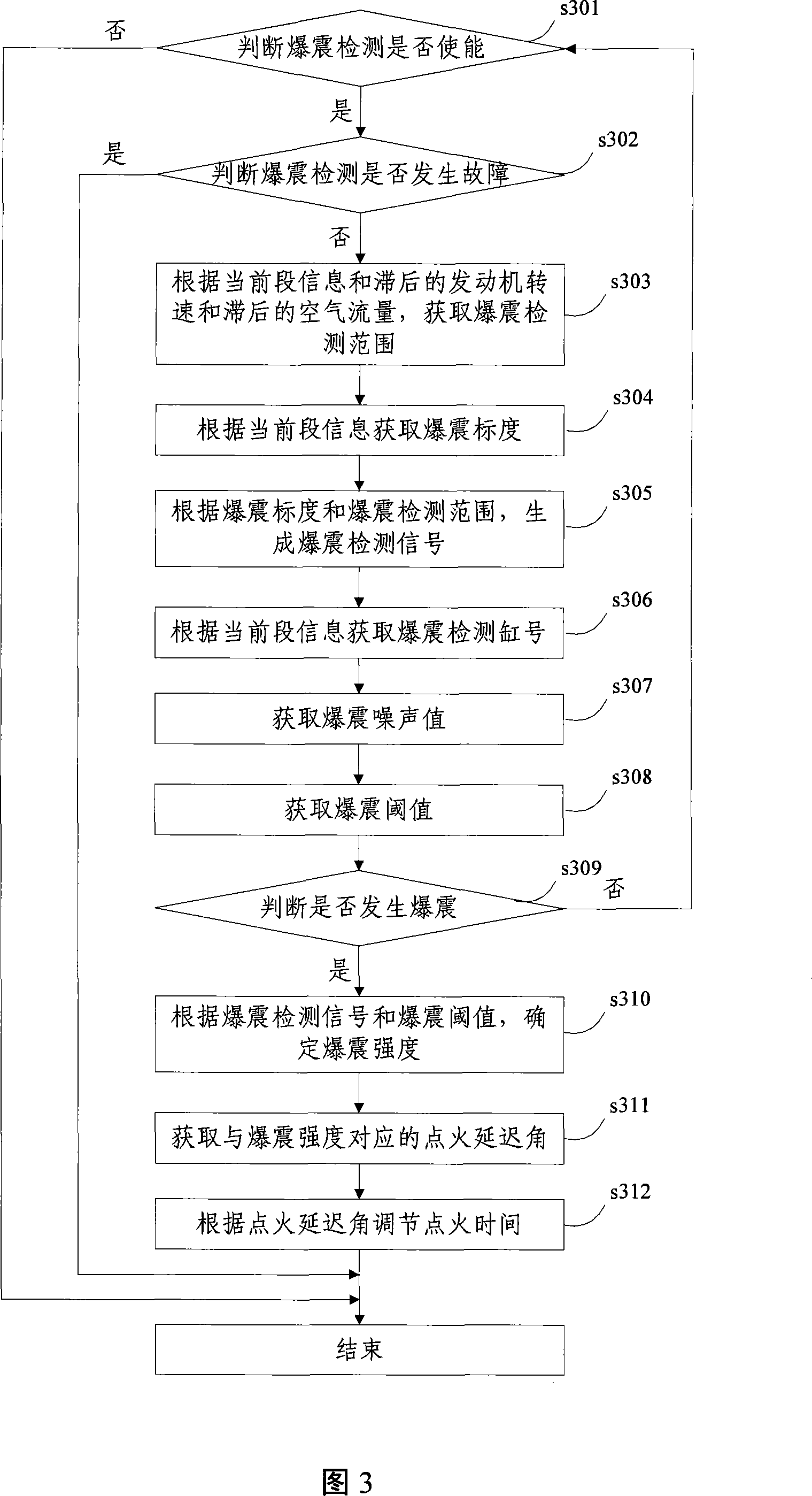

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

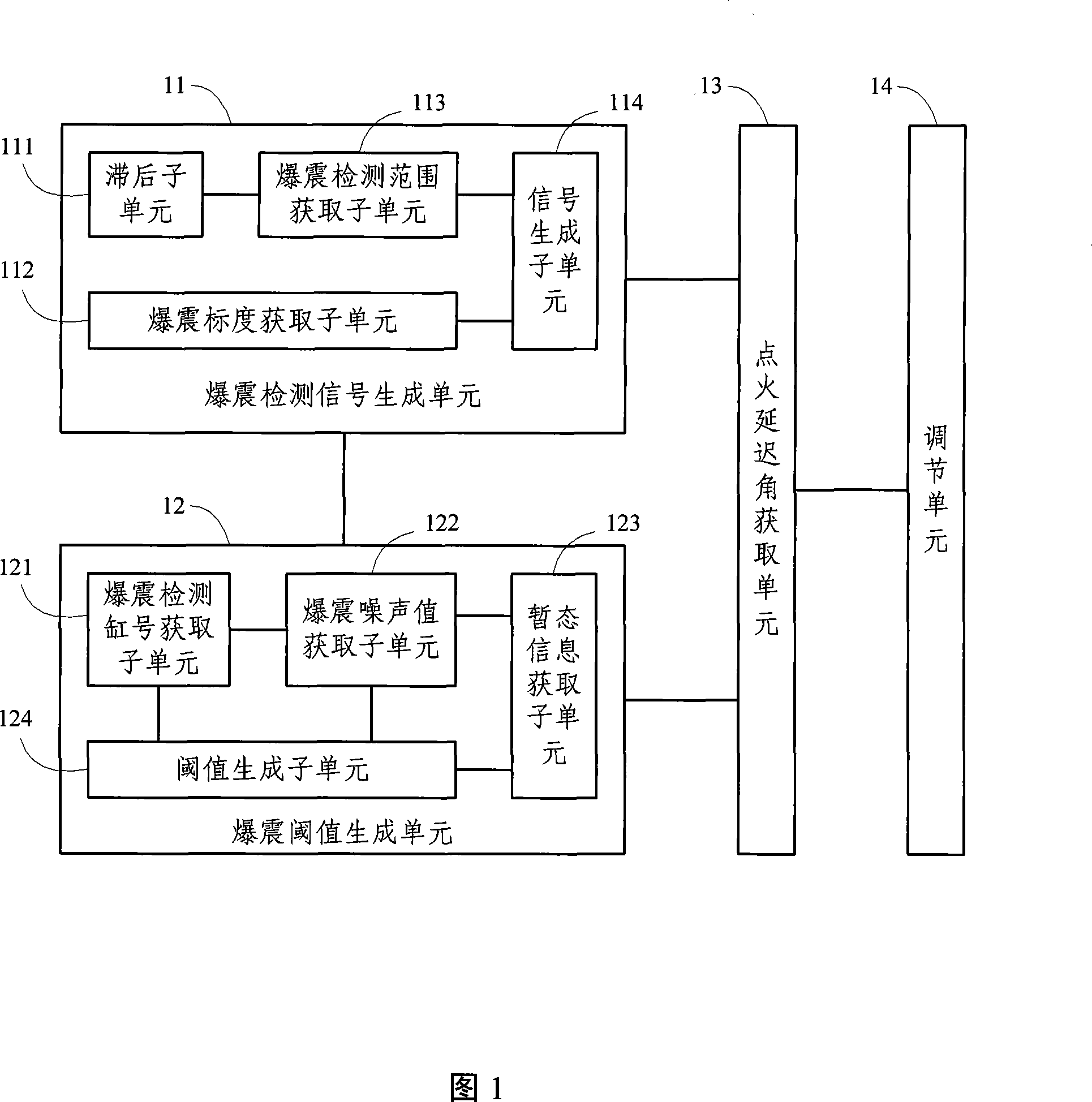

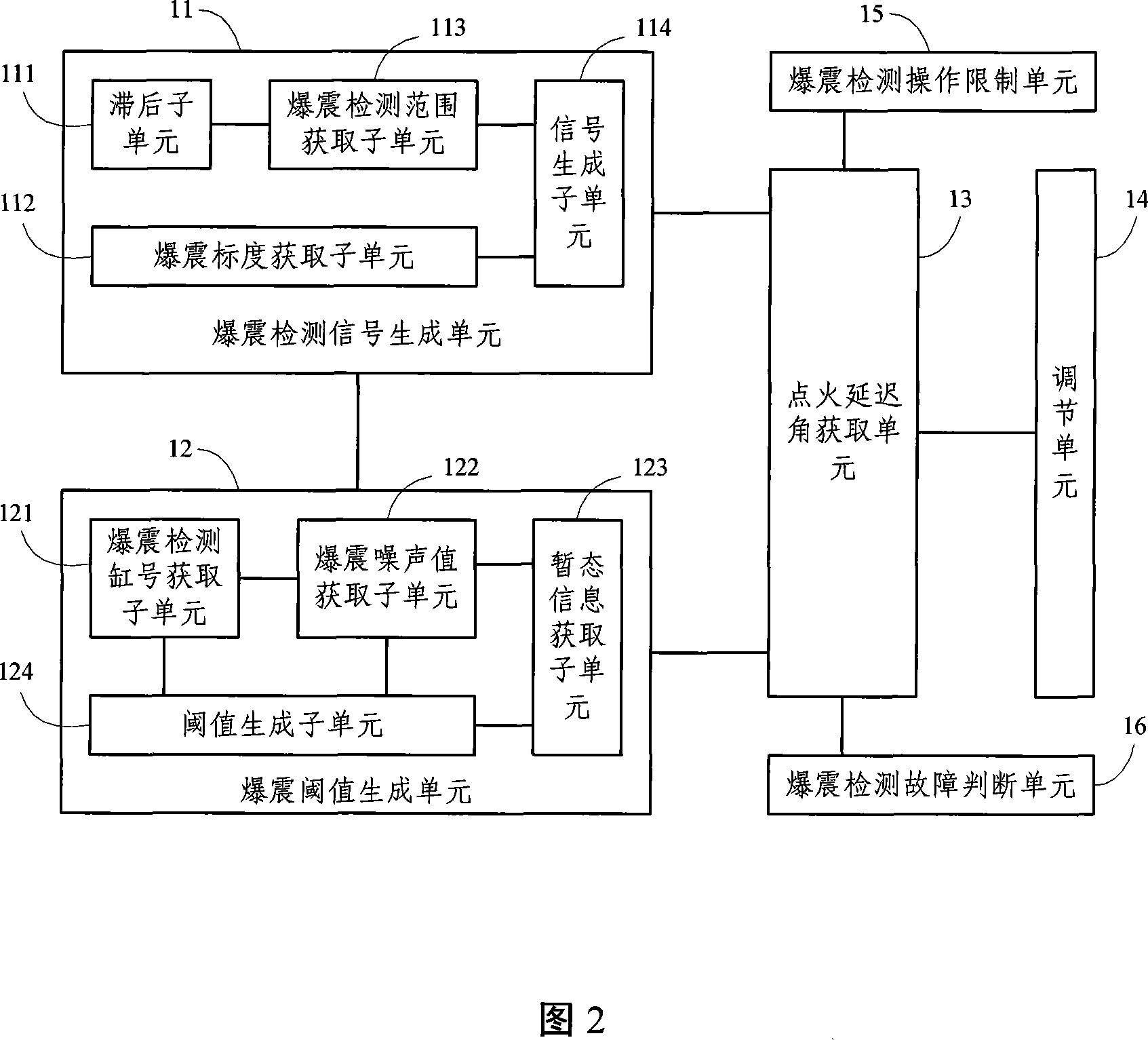

[0022] A knock adjustment device according to an embodiment of the present invention is shown in FIG. 1 , including a knock detection signal generation unit 11, a knock threshold value generation unit 12, an ignition delay angle acquisition unit 13, and an adjustment unit 14; wherein, the knock detection The signal generation unit 11 is connected to the knock threshold generation unit 12 , and the ignition delay angle acquisition unit 13 is connected to the knock detection signal generation unit 11 , the knock threshold generation unit 12 and the adjustment unit 14 respectively.

[0023] The knock detection signal generation unit 11 is used to generate a knock detection si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com