Combustion organization method of methanol/alcohol hydrogen fuel internal combustion engine and application thereof

A methanol fuel and internal combustion engine technology, applied in the direction of internal combustion piston engines, combustion engines, fuel injection control, etc., can solve the problems of increased cost and space requirements, particle emissions, and unreported issues, so as to improve ignition reliability and reduce particle emissions , the effect of increasing the speed of flame spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

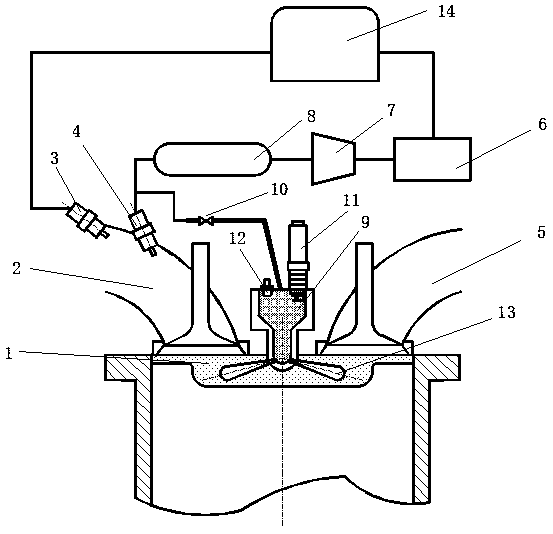

[0033] figure 1 It is a schematic diagram of a methanol / alcohol hydrogen fuel internal combustion engine refitted on the basis of a medium-speed diesel engine with a cylinder diameter of 210mm according to the method provided by the present invention. Such as figure 1 As shown, a methanol injection system 3 and an alcohol hydrogen main injection system 4 are installed in the medium-speed diesel engine intake port 2, an ignition chamber 9 and an alcohol hydrogen enrichment injection system 10 are arranged on the cylinder head, and the ignition chamber 9 is installed spark plug 11 and glow plug 12. The methanol fuel tank 14 supplies methanol fuel to the methanol injection system 3 and the methanol catalytic reformer 6, and the alcohol hydrogen is produced by the methanol catalytic reformer 6 using part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com