Heat jet mechanism of lean-burn engine and combustion system of heat jet mechanism

A technology of combustion system and heat jet, applied in the direction of combustion engine, internal combustion piston engine, engine components, etc., can solve the problems of structural complexity and application cost increase, and achieve the goal of improving combustion stability, suppressing detonation, and simplifying the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

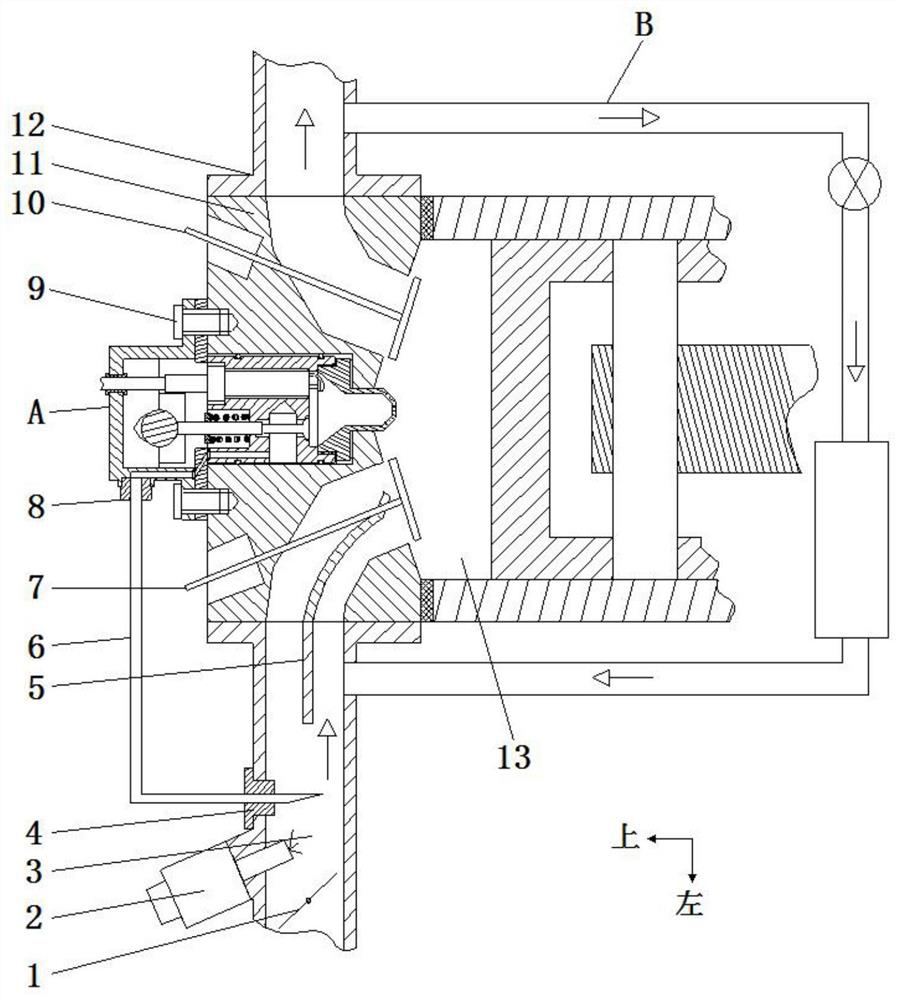

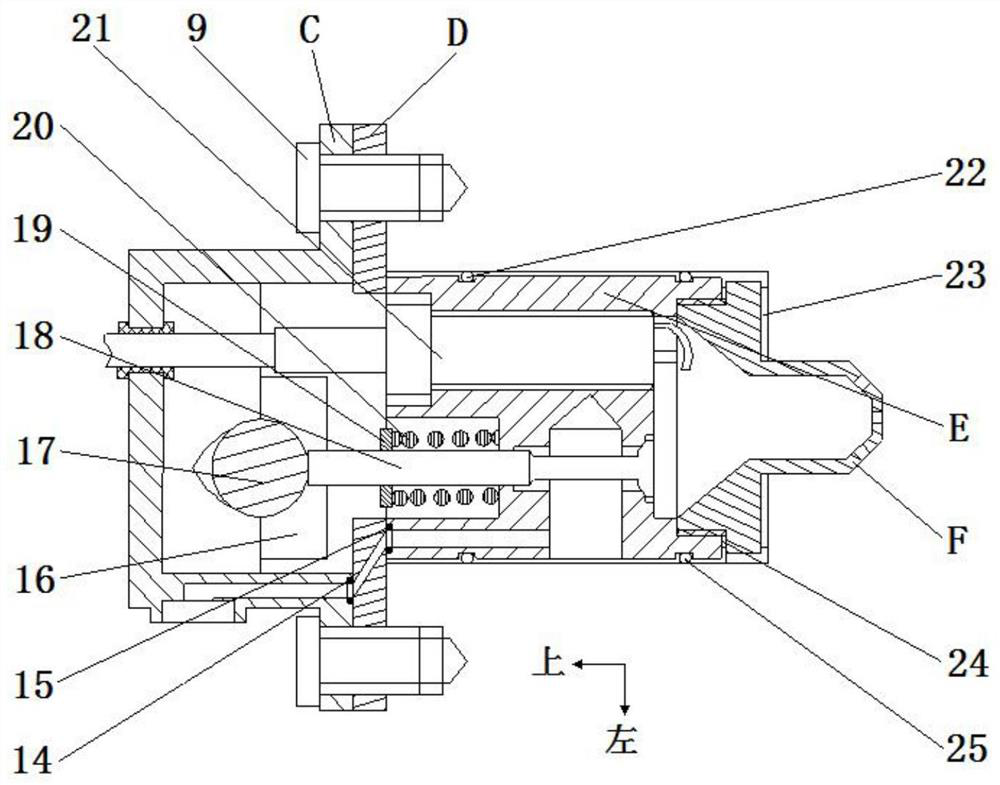

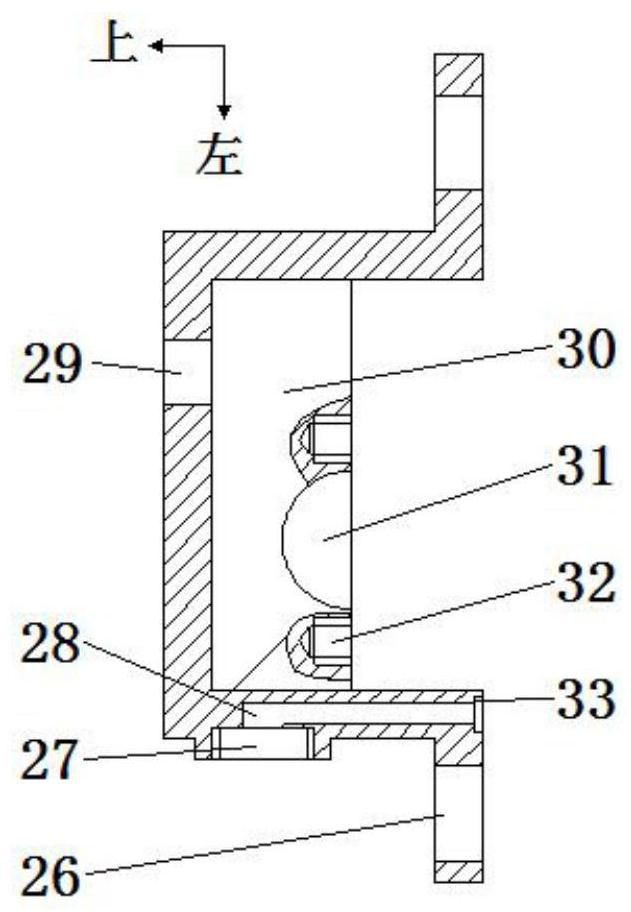

[0027] Such as figure 1 As shown, the present invention consists of hot jet ignition system A, exhaust gas recirculation system B, throttle valve 1, fuel injector 2, intake manifold 3, joint a4, deflector 5, pre-combustion chamber intake pipe 6, intake valve 7. Joint b8, bolt group 9, exhaust valve 10, engine cylinder head 11, exhaust manifold 12 and combustion chamber 13, among which throttle valve 1 and deflector 5 are fixedly connected to intake manifold 3 from left to right Inside; the fuel injector 2 is fixedly connected to the left part of the intake manifold 3; the right end of the pre-combustion chamber intake pipe 6 communicates with the hole a27 of the support block C in the hot jet ignition system A through the joint b8; the left lower end of the pre-combustion chamber intake pipe 6 passes through The joint a4 communicates with the left part of the intake manifold 3; the bolt group 9 fixes the thermal jet ignition system A to the center of the cylinder head 11 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com