Engine and piston

a technology of engine and piston, applied in the direction of machines/engines, mechanical equipment, heat inorganic powder coating, etc., can solve the problem of limiting the improvement of engine fuel efficiency, and achieve the effect of improving engine fuel efficiency, high heat insulation, and high surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

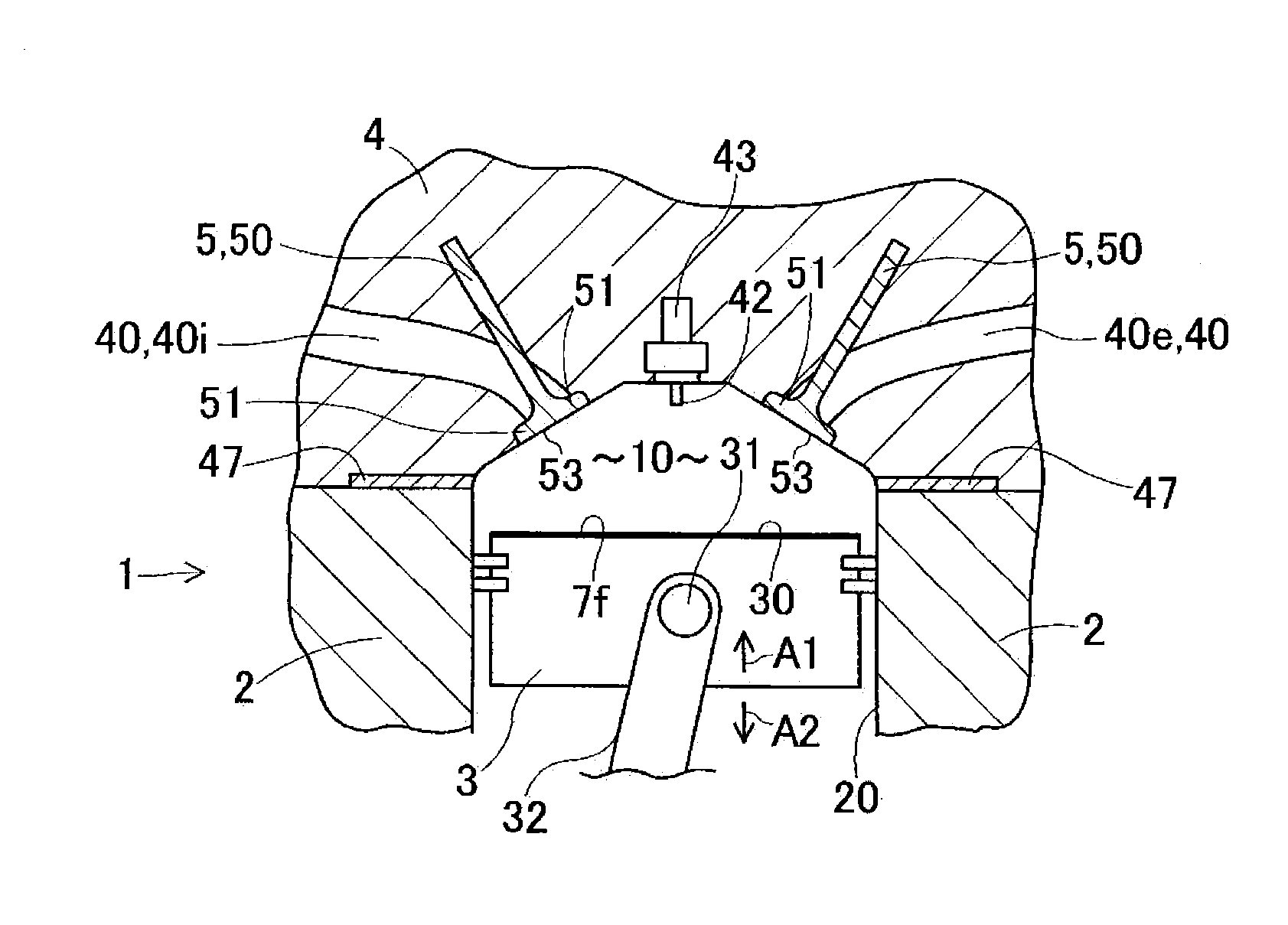

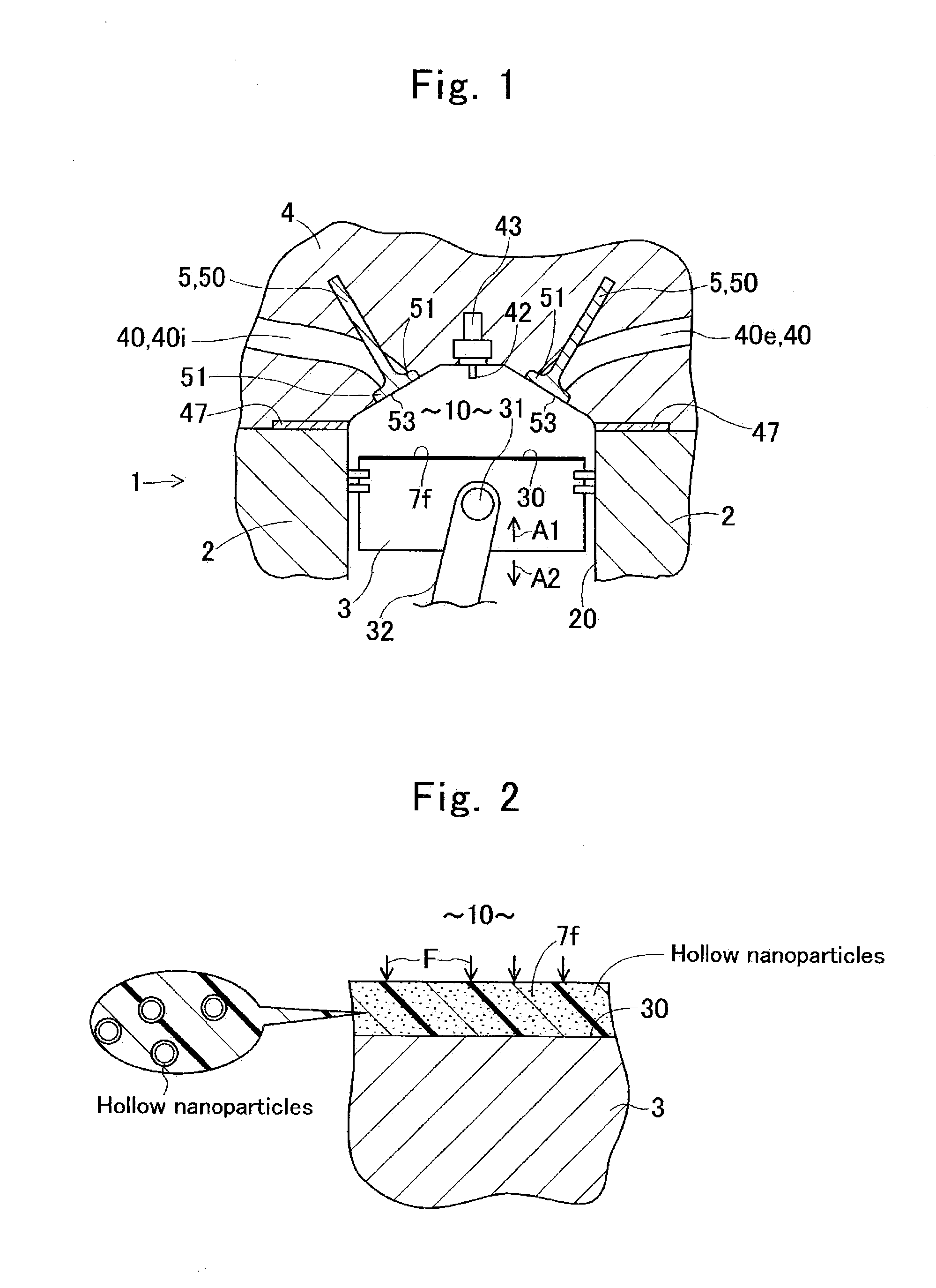

[0039]FIGS. 1 and 2 schematically show a concept of a first embodiment. FIG. 1 schematically shows a section near a combustion chamber 10 of an engine 1. The engine 1 is a piston-type internal combustion engine. FIGS. 1 and 2 are merely conceptual sketches and not intended to specify the details. The engine 1 includes a cylinder block 2 having a bore 20, a piston 3 fitted into the bore 20 so as to form the combustion chamber 10 on a top 30 side and to be able to reciprocate in directions of arrows A1 and A2, a cylinder head 4 for closing the combustion chamber 10 and having valve bores 40 communicating with the combustion chamber 10, and valves 5 for opening and closing the valve bores 40. The valve bores 40 include an intake valve bore 40i and an exhaust valve bore 40e which can communicate with the combustion chamber 10. The cylinder head 4 is mounted to the cylinder block 2 with a gasket 47 interposed therebetween. The cylinder block 2, the cylinder head 4, and the piston 3 are m...

second embodiment

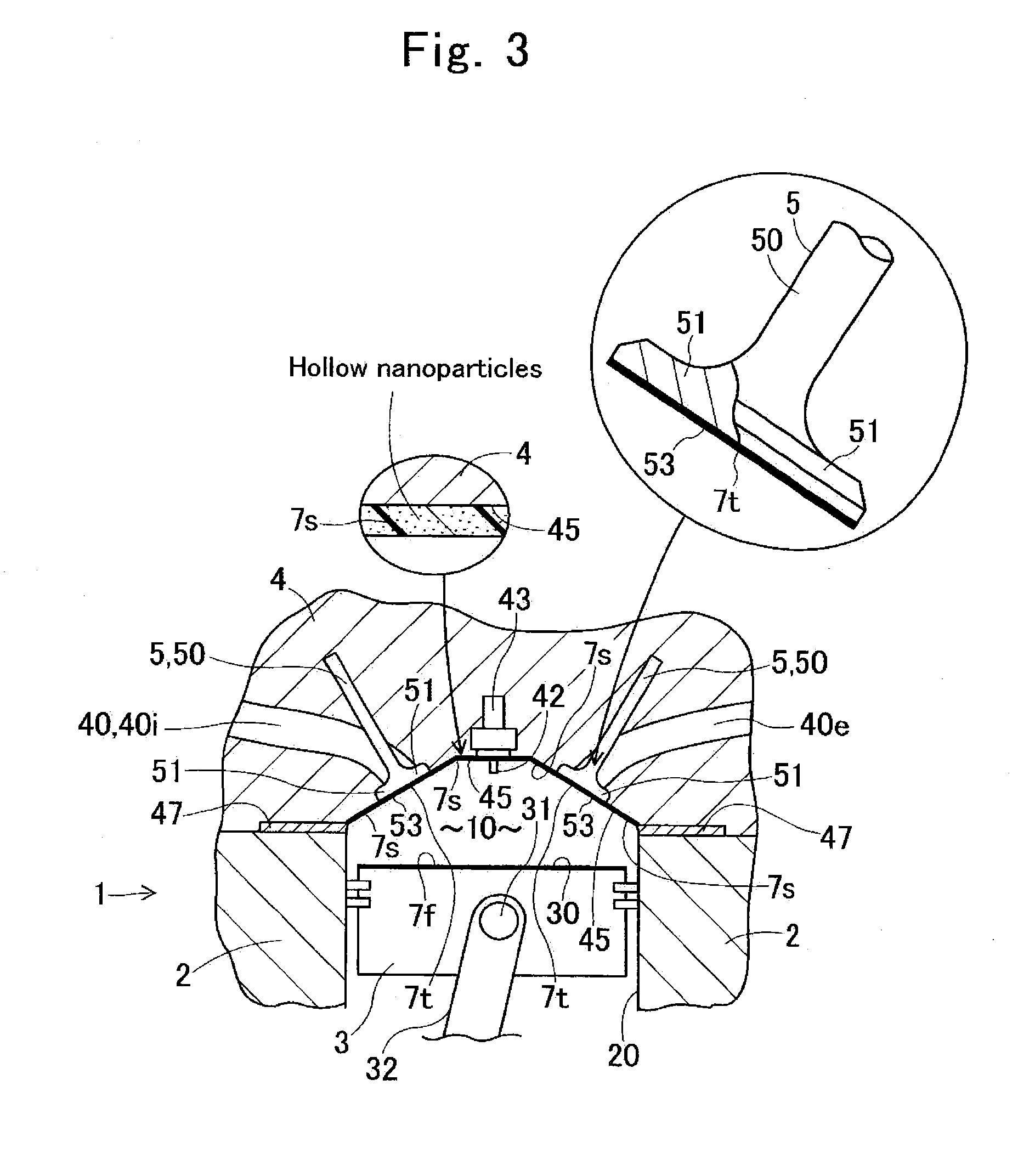

[0048]FIG. 3 shows a second embodiment. The present embodiment has basically the same structure, operation, and effects as the first embodiment. FIG. 3 schematically shows a section near a combustion chamber 10 of an engine 10. A first heat insulating coating 7f is applied on a top 30 which is a wall face of the piston 3 and facing the combustion chamber 10. Moreover, a second heat insulating coating 7s is applied on a wall face 45 of a cylinder head 4 and facing the combustion chamber 10. Because the first heat insulating coating 7f and the second heat insulating coating 7s are formed, heat insulation of the combustion chamber 10 is improved. Depending on circumstances, if the second heat insulating coating 7s is formed on the wall face 45 of the cylinder head 4, the first heat insulating coating 7f may be omitted. Surface roughness of the wall faces after the application of the heat insulating coatings 7f and 7s is smaller than surface roughness before the application.

third embodiment

[0049]The present embodiment has basically the same structure and effects as the first and second embodiments and therefore FIGS. 1 to 3 can be used with modifications. A first heat insulating coating 7f is applied on a top 30 which is a wall face of a piston 3 and facing a combustion chamber 10. Furthermore, a second heat insulating coating 7s is applied on a wall face 45 of the cylinder head 4 and facing the combustion chamber 10. In addition, a third heat insulating coating 7t is formed on a valve face 53 of each of valves 5 and facing the combustion chamber 10. In this manner, the first heat insulating coating 7f is formed on the top 30 of the piston 3, the second heat insulating coating 7s is formed on the wall face 45 of the cylinder head 4 and facing the combustion chamber 10, and the third heat insulating coating 7t is formed on the valve face 53 of each of the valves 5 and facing the combustion chamber 10. Therefore, heat insulation of the combustion chamber 10 is further i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com