Method and system for in-cylinder direct-injection gasoline engine stratified equivalent proportion combustion

An in-cylinder direct injection, equivalence ratio technology, applied in combustion engines, internal combustion piston engines, mechanical equipment, etc., can solve problems such as easy knocking, and achieve the effect of suppressing knocking and high fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

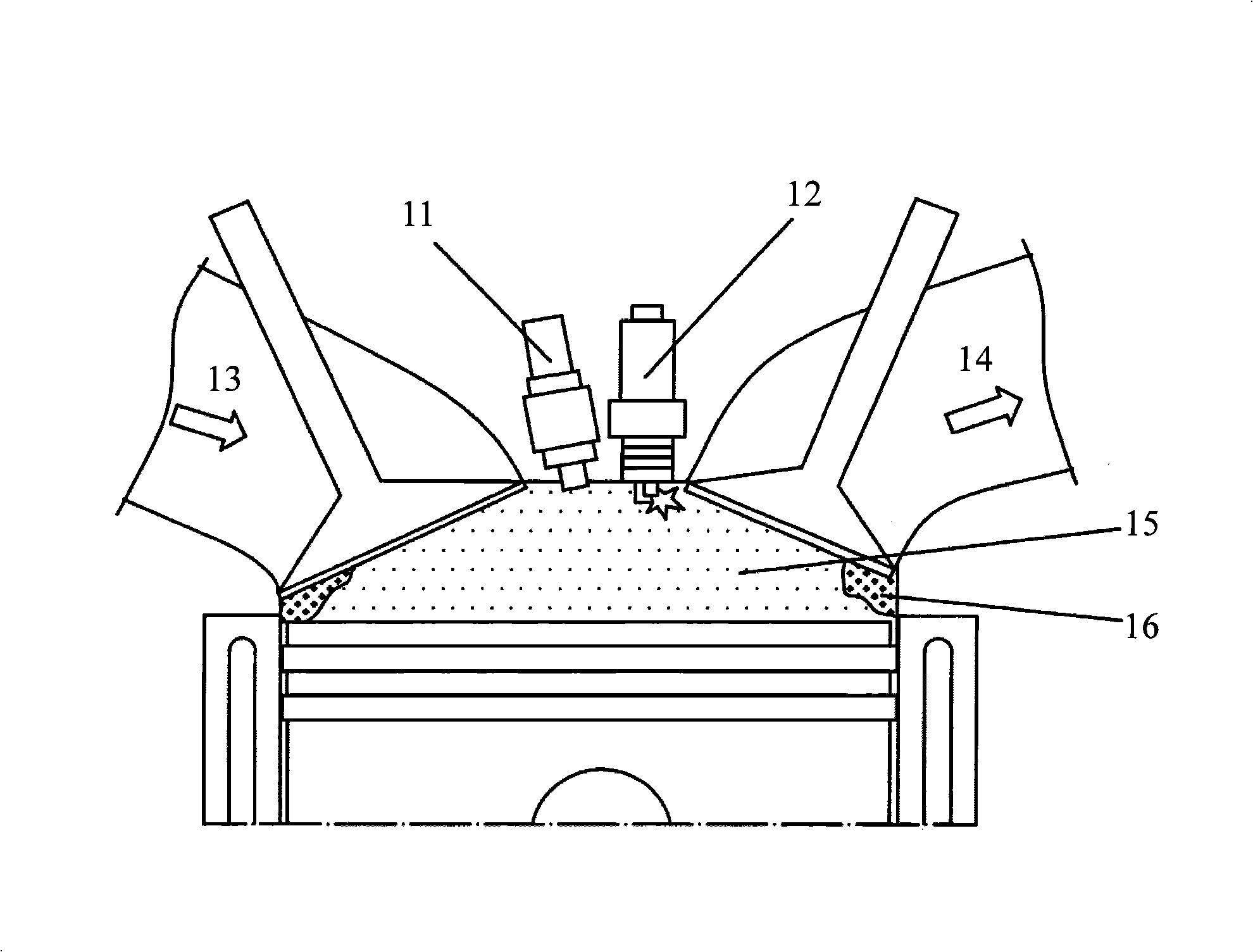

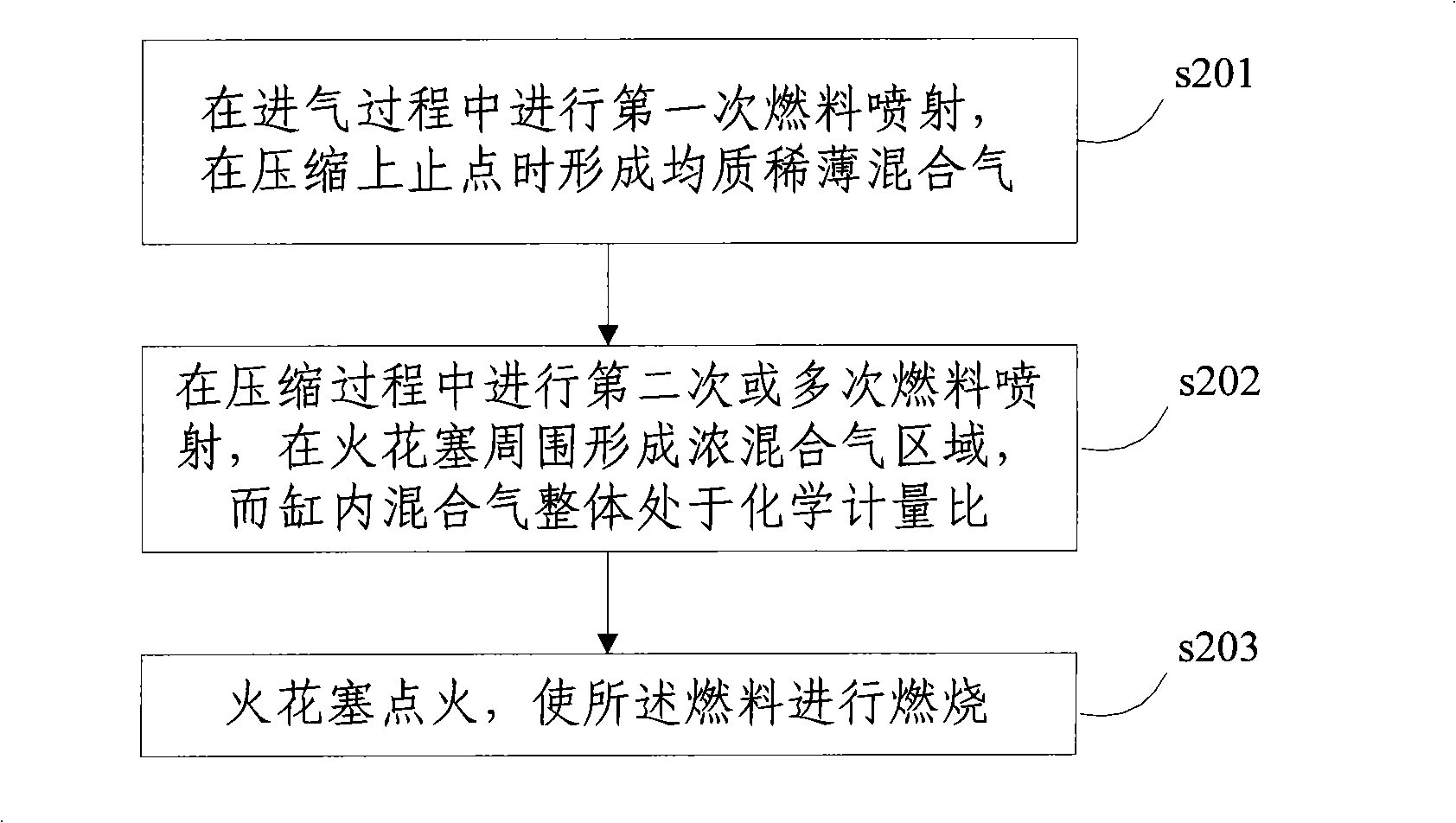

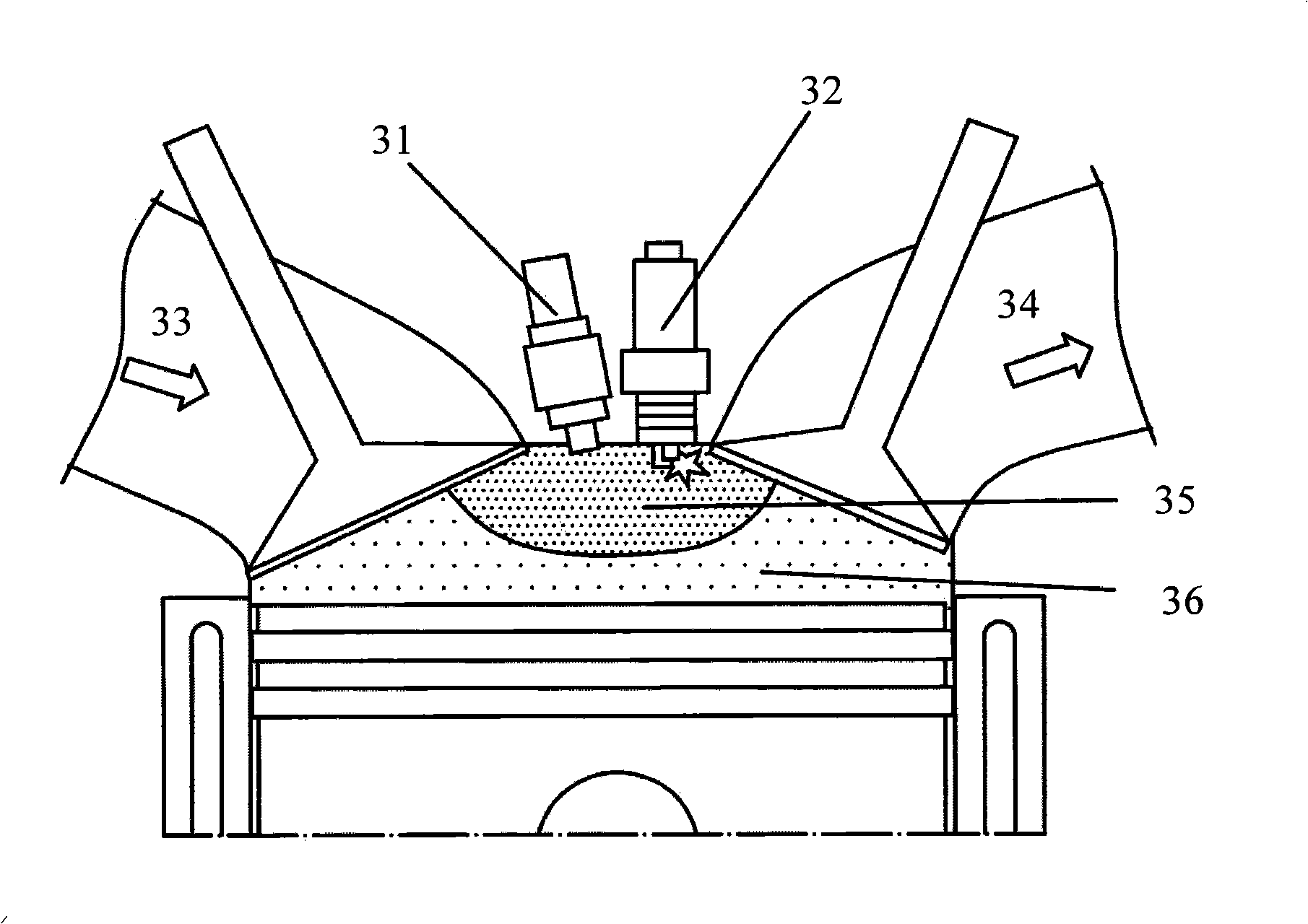

[0020] A method for stratified equivalence ratio combustion of an in-cylinder direct-injection gasoline engine in an embodiment of the present invention is as follows: figure 2 shown, including the following steps:

[0021] In step s201, the first fuel injection is performed during the intake process, and a homogeneous lean mixture is formed at compression top dead center. The fuel-air equivalence ratio λ>1 of the lean mixture may range from 1.2 to 2.0.

[0022] In step s202, the second or more fuel injections are performed during the compression process to form a rich mixture area around the spark plug. The fuel-to-air equivalence ratio λ<1 of the rich mixture may ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com