Tunnel yielding type shoring system

A technology for tunnels and systems, applied in tunnels, tunnel linings, pillars/supports, etc., can solve problems such as large deformation disasters, easy softening in contact with water, and unsatisfactory shrinkage effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

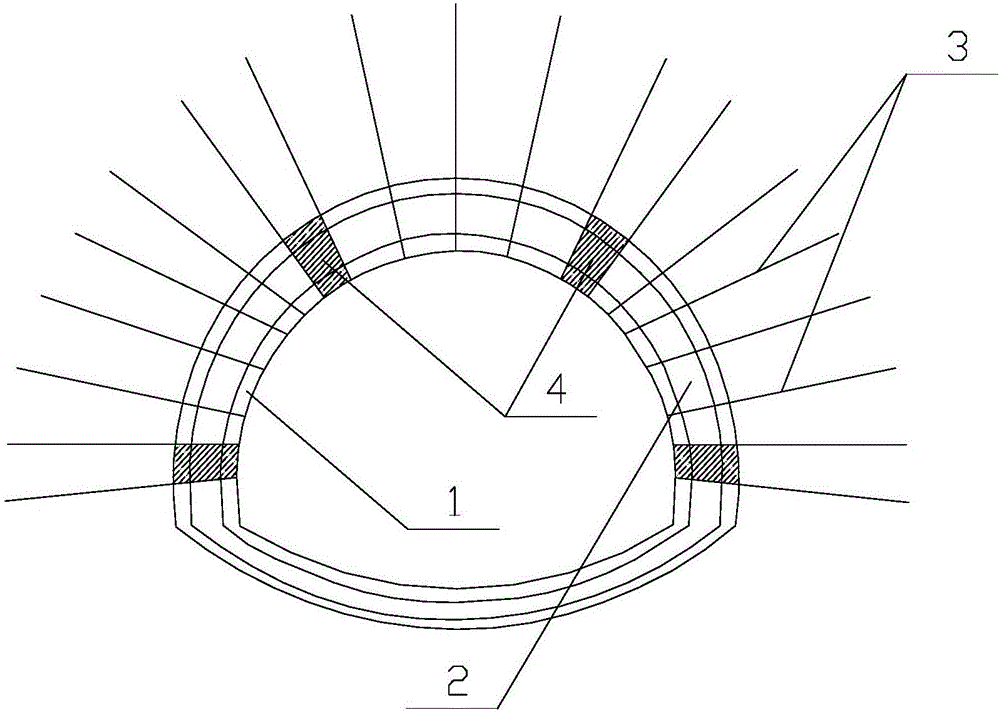

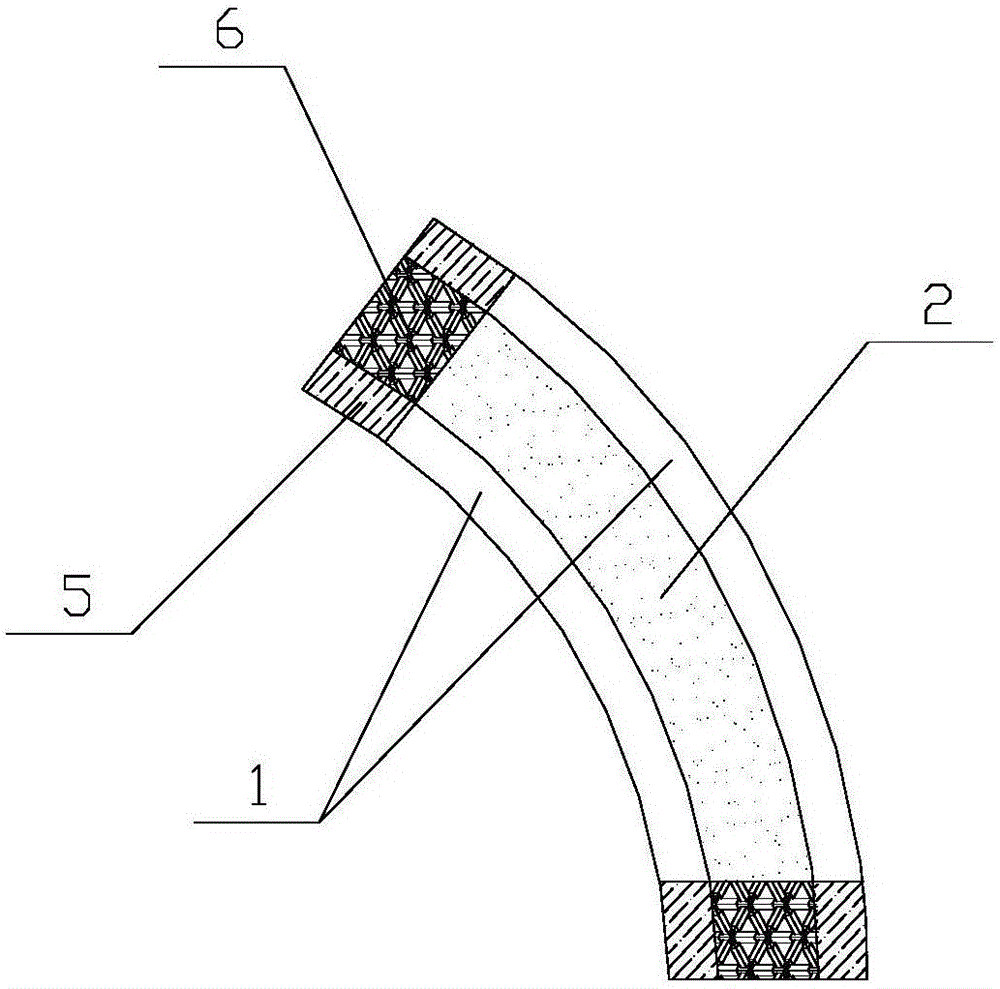

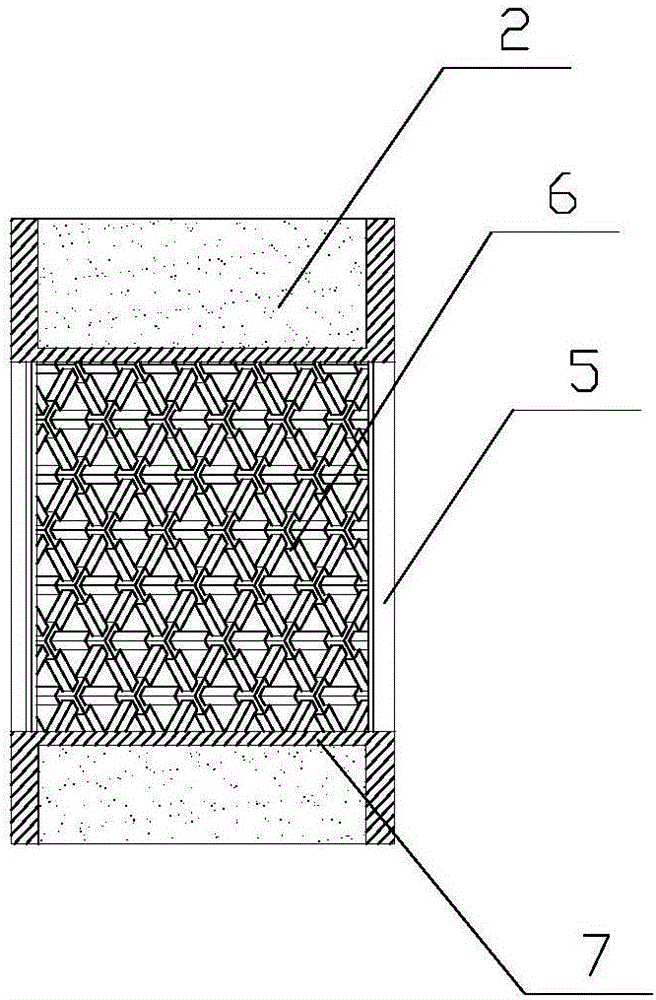

[0023] Such as Figure 1-Figure 9 As shown, this specific embodiment adopts the following technical scheme: it includes a steel arch 1, a shotcrete layer 2, a pressure anchor 3 and a retractable unit 4, and a steel arch 1 is arranged in sequence from inside to outside along the longitudinal direction of the tunnel. , the shotcrete layer 2 and the pressure anchor rod 3, wherein the steel arch 1 is composed of four units, and the shoulder and waist of each steel arch 1 are provided with a retractable unit 4, and the flange and the The steel arch 1 is connected, and the retractable unit 4 is composed of a retractable member 5 and a rectangular rubber shock absorber 6. Both ends of each steel arch 1 are provided with a retractable member 5, and the retractable member 5 A deformation groove is reserved between them, and a rectangular rubber shock absorber 6 is arranged in the deformation groove, and a partition 7 is arranged between the rectangular rubber shock absorber 6 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com