Oil seal detection system

A detection system and measurement system technology, applied in the measurement device, by measuring the acceleration and deceleration rate of the fluid, using the liquid/vacuum degree for liquid tightness measurement, etc. long-term issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

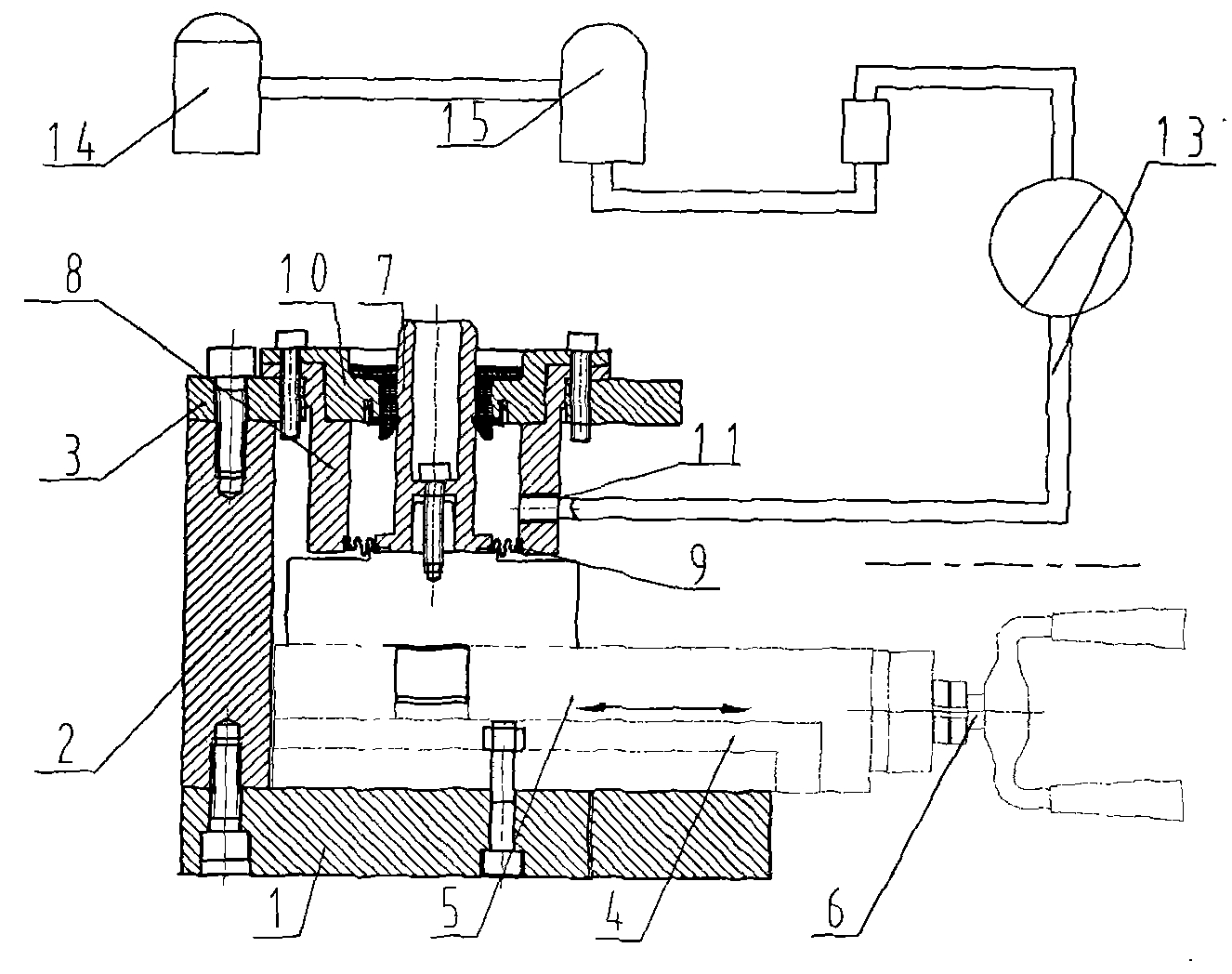

[0011] Embodiment 1, a kind of oil seal detection system, refer to figure 1 , is made up of air conditioning system 12 and measuring system, and air conditioning system 13 is that air compressor 14 connects air storage tank 15, and the air pressure regulating valve and air pressure gauge that control air pressure are installed on the air outlet pipeline of air storage tank 15, and measuring system is A vertical arm 2 is fixed on one side of the base 1, a cross arm 3 is fixed on the upper end of the vertical arm 2, a bracket slideway 4 is fixed on the base 1, a moving arm 5 is arranged in the bracket slideway 4, and a moving arm 5 is arranged inside the moving arm 5. A push rod 6 is threadedly connected, and one end of the push rod 6 is in contact with the vertical arm 2, and the other end is provided with a rotating handle. The upper end is fixed on the cross arm 3, the corrugated flexible seal 9 is provided between the lower end and the test shaft 7, the flange 10 is fixed in...

Embodiment 2

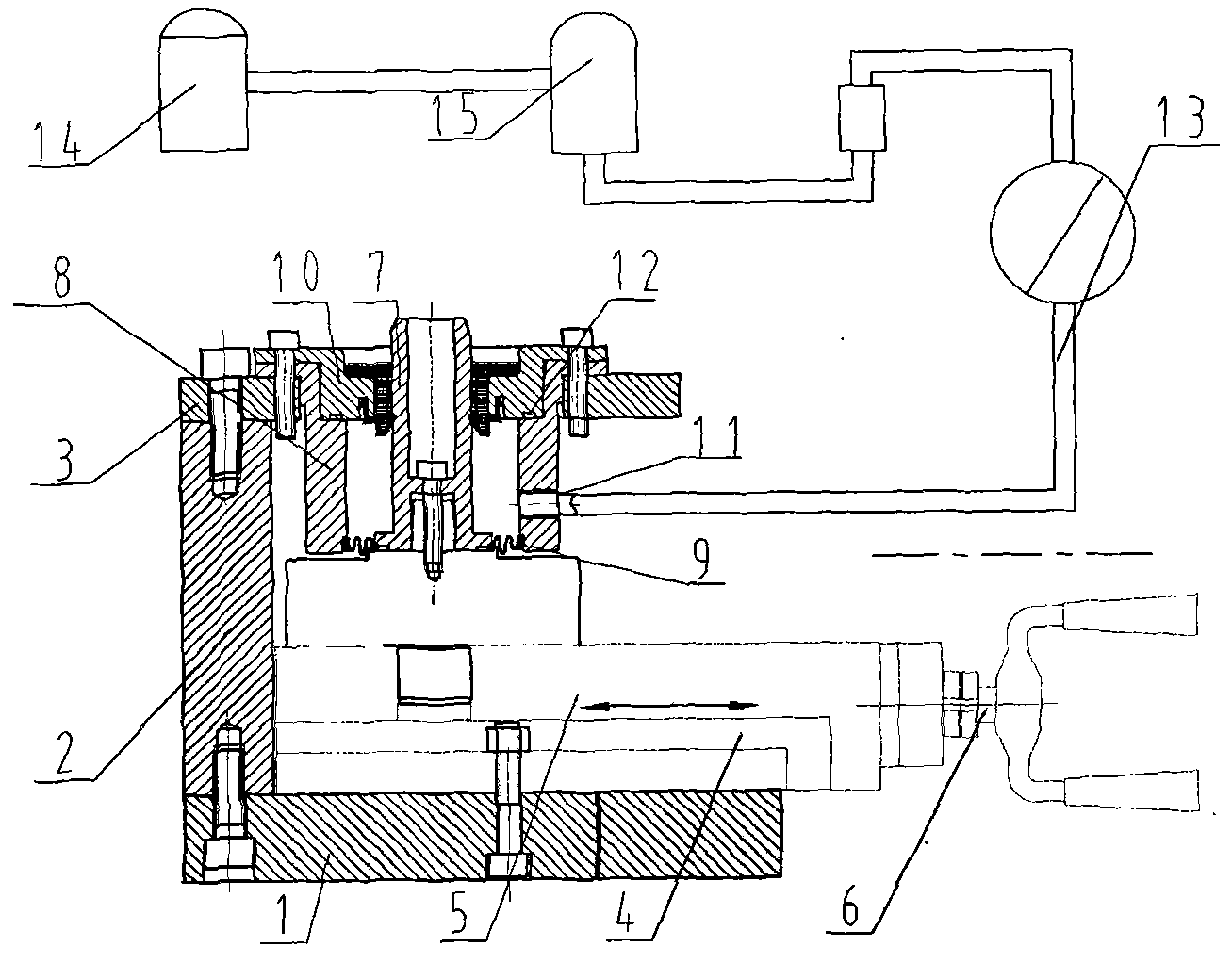

[0012] Embodiment 2, a kind of oil seal detection system, refer to figure 2 , On the basis of Embodiment 1, a sealing ring 12 is provided between the flange 10 and the outer casing 8, and the others are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com