Composite freezing clamping device

A clamping device and compound technology, applied in the field of mechanical processing, can solve the problems of low refrigeration capacity and refrigeration efficiency, small volume, and damage to transfer pressure, and achieve the effect of good refrigeration effect, improved processing quality and fast refrigeration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

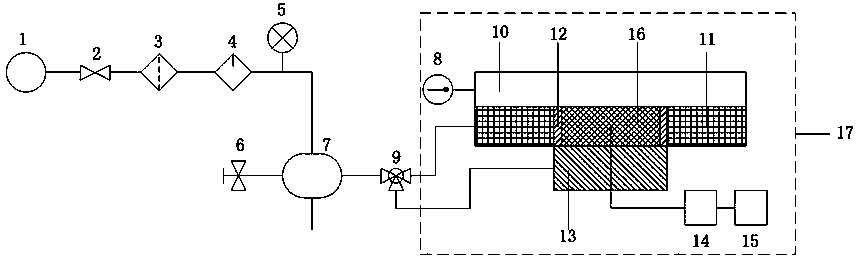

[0023] The workpiece to be processed is a circular copper sheet with a diameter of 80mm and a thickness of 3mm.

[0024] a. On the workbench 10, the adhesive layer is water, and the copper sheet is placed on the adhesive layer;

[0025] b. Turn on the controller 15, set the output of the rectifier power supply 14 to 10A, and the semiconductor refrigerator 16 is in the cooling state; turn the vortex tube valve 6 to the right to make the vortex tube refrigerator in the cooling state, adjust the pipeline control valve, and open the cooling pipe 13 connected pipes;

[0026] c. Wait for one minute, the adhesive layer changes from water to ice, and the composite freezing clamping device completes the clamping of copper sheets;

[0027] d. to process;

[0028] e. After processing, close the controller 15 and the rectifier power supply 14, turn the vortex tube valve 6 to the left, make the vortex tube refrigerator in the heating state, adjust the pipeline control valve, and open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com