Non-roadside supporting gob-side entry retaining process

A roadside support and technology technology, applied in the direction of mine roof support, pillar/bracket, filling, etc., can solve the problems of heavy workload, slow construction speed, high cost, etc., and achieve the effect of low cost, small impact and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

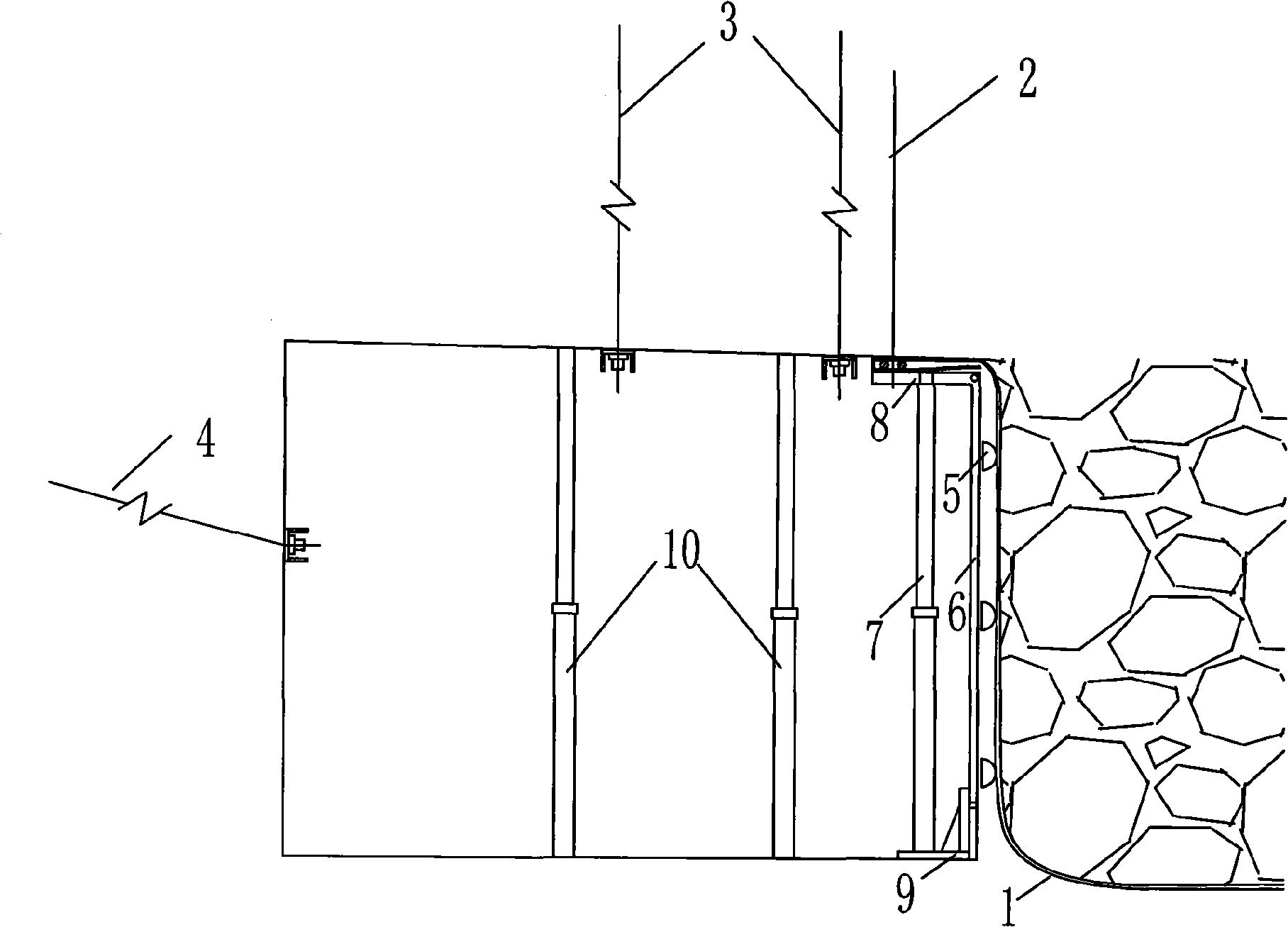

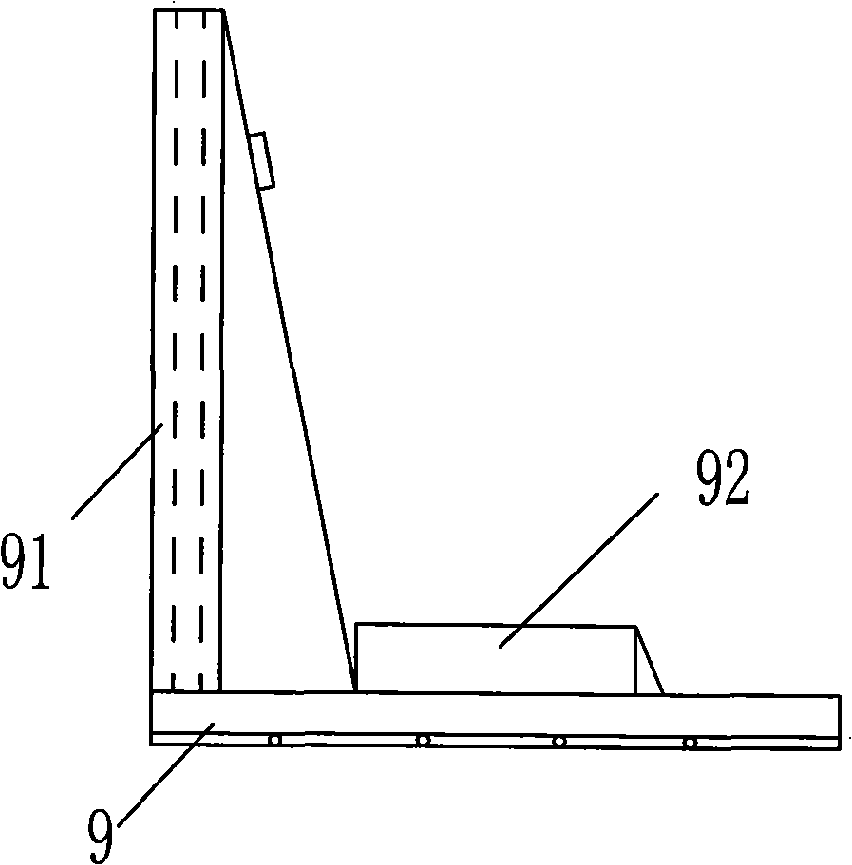

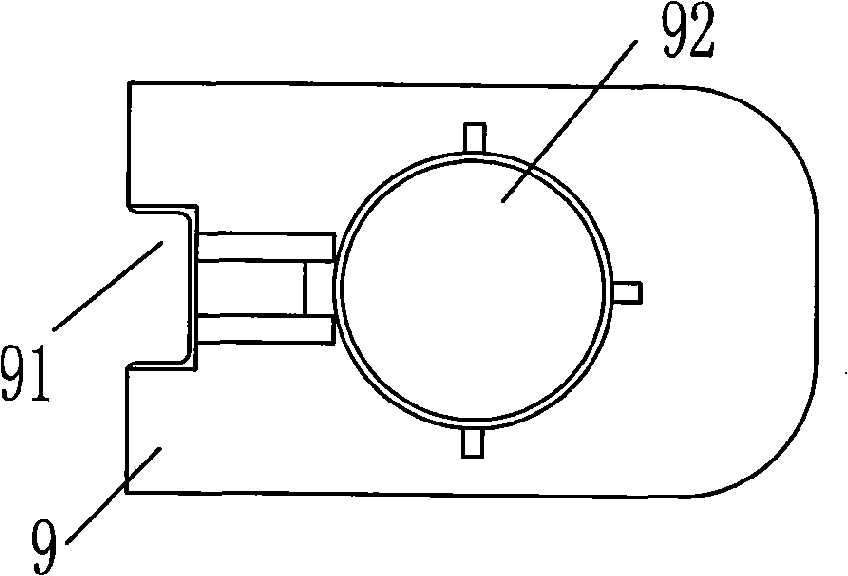

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

[0018] The gob-side entry retaining process without roadside support of the present invention is suitable for gob-side entry retention in roadways with medium-thick and thin coal seams, coal seam roofs of Class III and above that are mining and caving roofs, and supported by anchor cables and anchor nets . Firstly, the anchor rod 2, the anchor cable beam 3 and the side anchor cable beam 4 are added in front of the mining face, and the anchor cable of the anchor cable beam 3 is anchored in the stable layer of the coal seam roof to ensure that there is sufficient strength to hang the roadway roof in the later stage, and One end of the metal mesh 1 is fixed by the bolt 2 at the top of the roadway about 0.4m away from the side of the working face; secondly, the metal mesh 1 is laid on the top beam of the fully-mechanized mining face support at the working face, and placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com