Thick seam large mining height working face gob-side entry retaining method

A technology with large mining height and working face, which is applied to mining equipment, earthwork drilling, filling materials, etc. It can solve problems such as deformation of entryways, increase of mine pressure, and crushing of filling bodies, so as to ensure production safety and prevent coal mining. Effects of self-ignition and prevention of gas explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below take coal mine as an example to further illustrate the technical scheme of the present invention.

[0028] The 1302 working face of a certain mine mines the third lower coal seam, the full height is mined at one time, the thickness of the mining height is h=6.2m, the strike length is 1600m, and the inclination length is 180m. Roof lithology from bottom to top is: siltstone (1.09m), fine sandstone (9.81m), coarse sandstone (17m), fine sandstone (2.45m), claystone (16.12m), fine sandstone (38m).

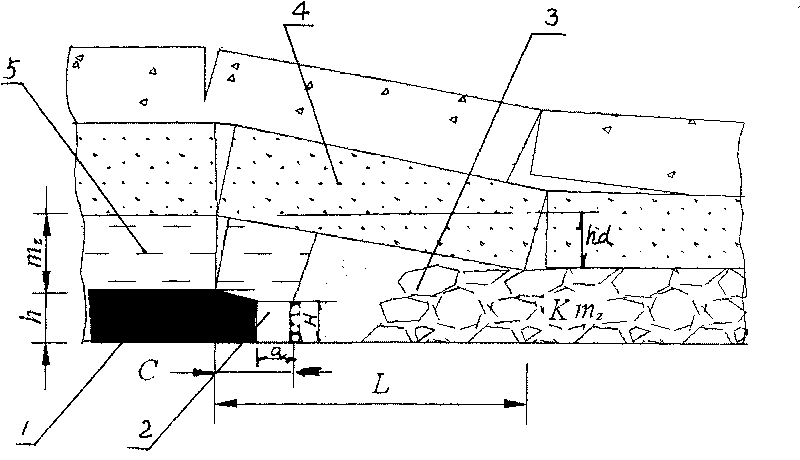

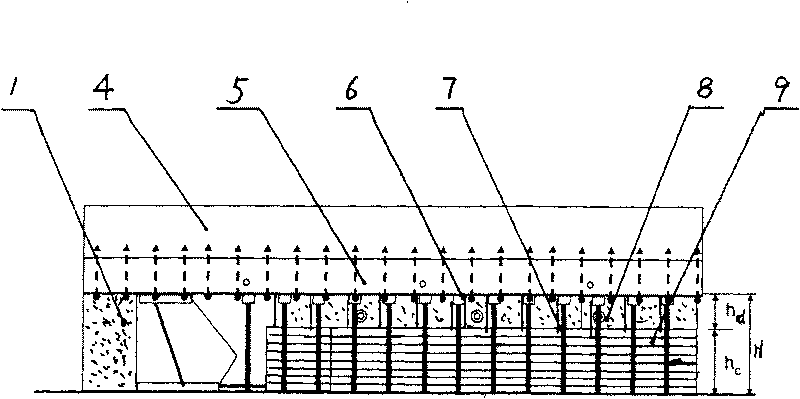

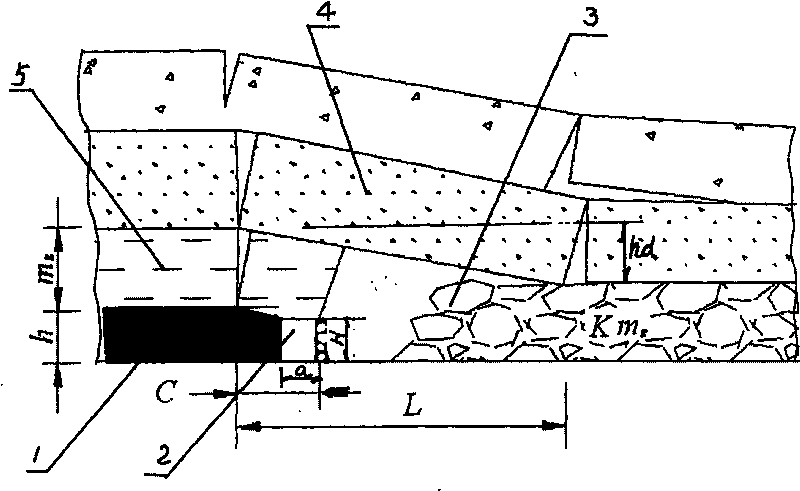

[0029] According to the existing mine pressure observation results, the main mine pressure parameters of the 1302 working face are (see figure 1 ):

[0030] (1) Thickness of direct roof 5 (caving layer) m z =11m;

[0031] (2) The distance from the roadside filling body 9 to the fracture line at the end of the old top rock beam 4 is C=6.5;

[0032] (3) the old top period to press the step distance (that is, the span of the old top rock beam 4) L=20m;

[0033] (4) Minin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com