Support-type comprehensive tunneler

A technology of roadheader and hydraulic support, which is applied in the directions of propulsion, cutting machinery, mine roof support, etc., can solve the problems that the support roof and roadheader cannot achieve parallel operation, long working time, low production efficiency, etc., and can improve the time Effectiveness of utilization and labor productivity, increased safety, and fast turning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

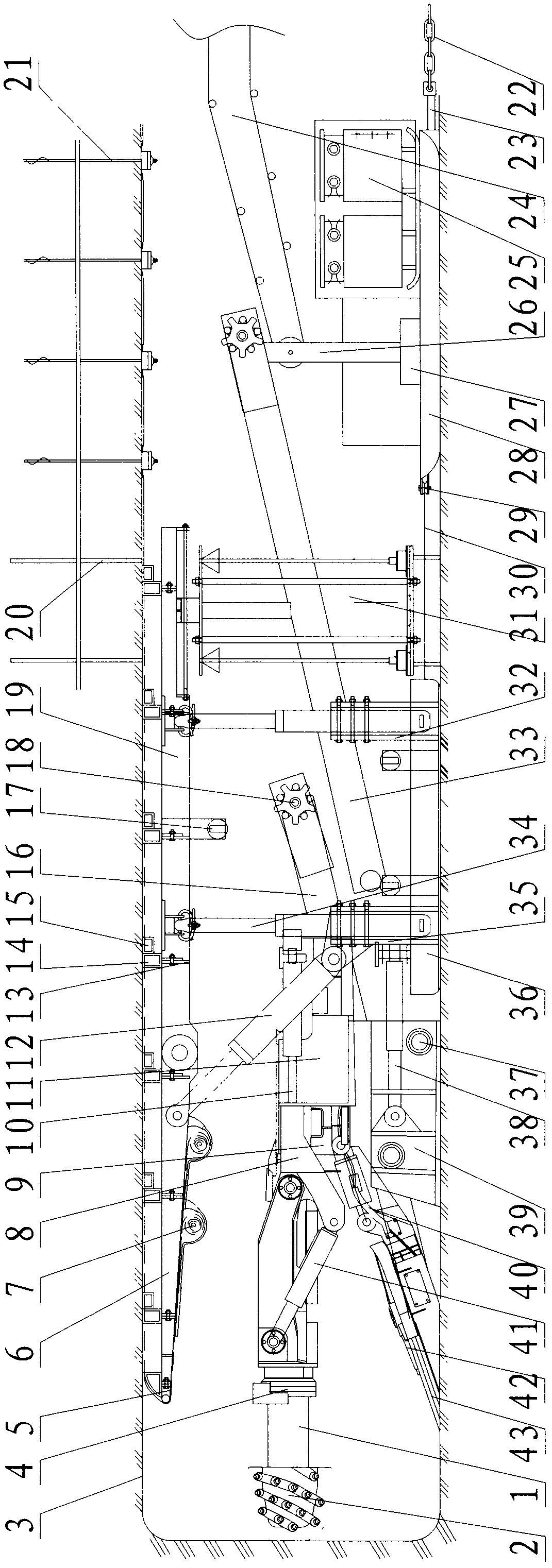

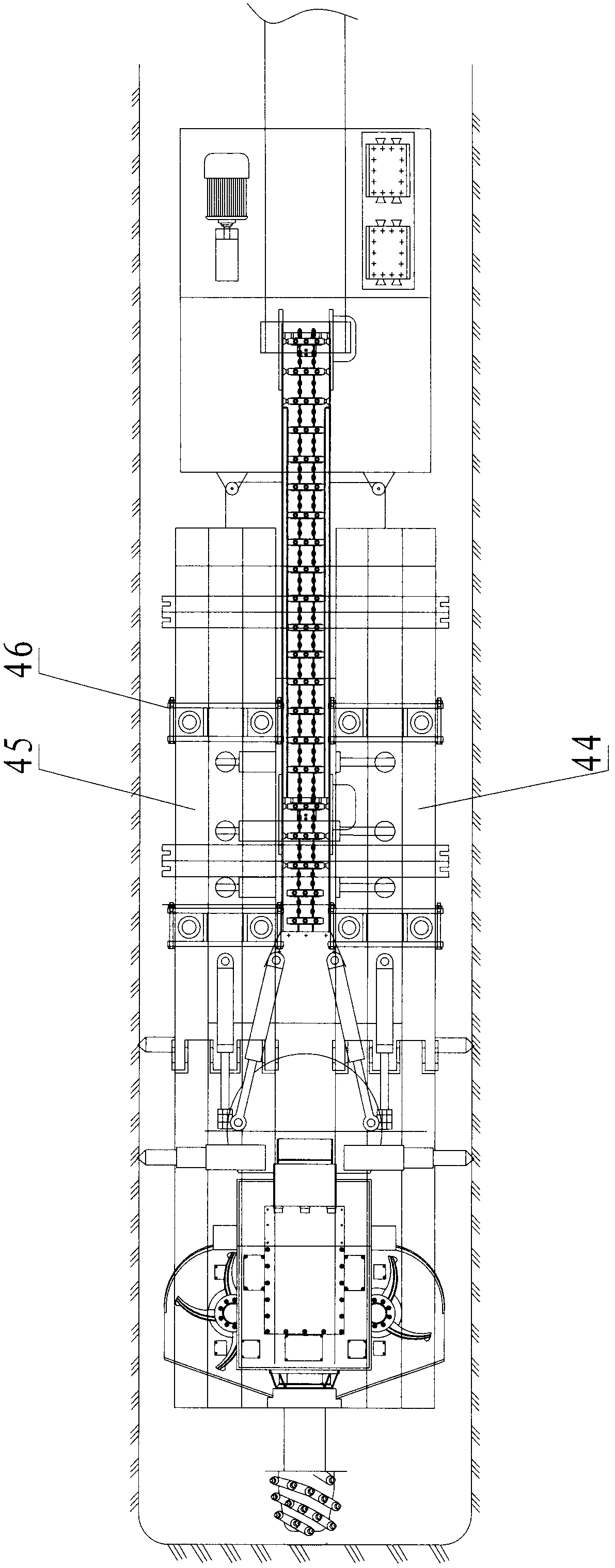

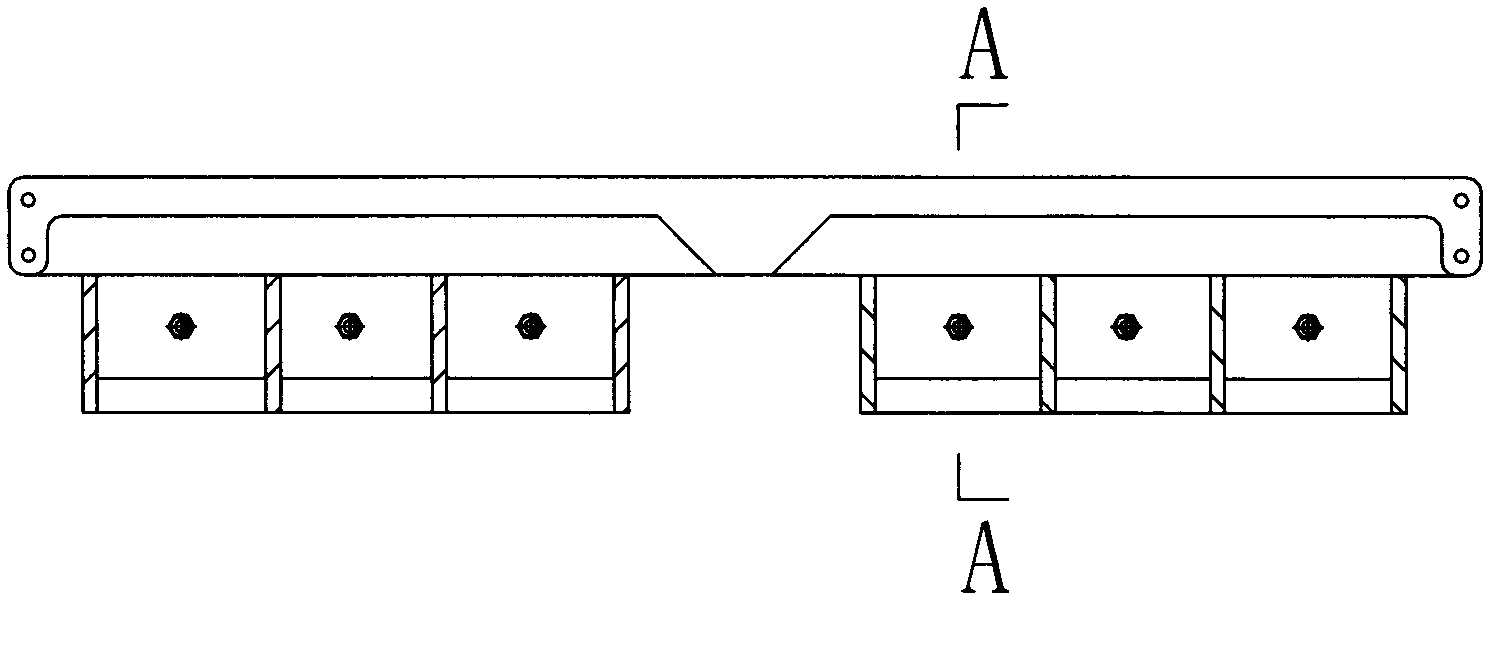

[0031] The supporting type comprehensive roadheader of the present invention is composed of a roadheader 1 without a crawler walking part, a roadheader chassis 39, a left hydraulic support 44, a right hydraulic support 45, a first scraper conveyor 16, and a second scraper conveyor 33. , belt transfer machine 24 and skid 28 are formed. The roadheader 1 is installed on the roadheader chassis 39, and the front end of the roadheader chassis 39 rises under the shovel plate 43 of the roadheader, and two moving jacks 38 are installed on the roadheader chassis 39, and the other ends of the two moving jacks 38 are respectively connected to The left hydraulic support 44 is connected with the right hydraulic support 45. On the front probe beam 6 of the left hydraulic support 44 and the right hydraulic support 45, one group of metal mesh memory storage 7 is respectively installed, and the support main top beam 19 afterbody of two hydraulic supports is hung with drilling rig 31. There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com