Comprehensive dredging machine

A technology of bolt digger and machine head, applied in cutting machinery, temporary shields, mining equipment and other directions, can solve the problems that accessories are easy to affect production, frequent failures, low production efficiency, etc., to improve time utilization and labor. Productivity, increased safety, fast cornering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

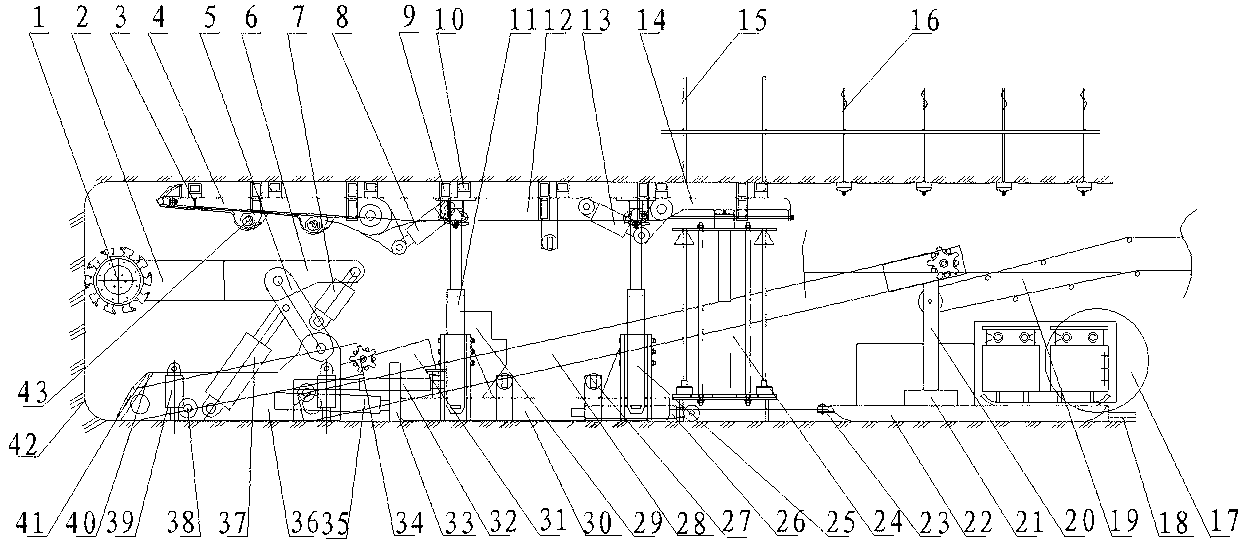

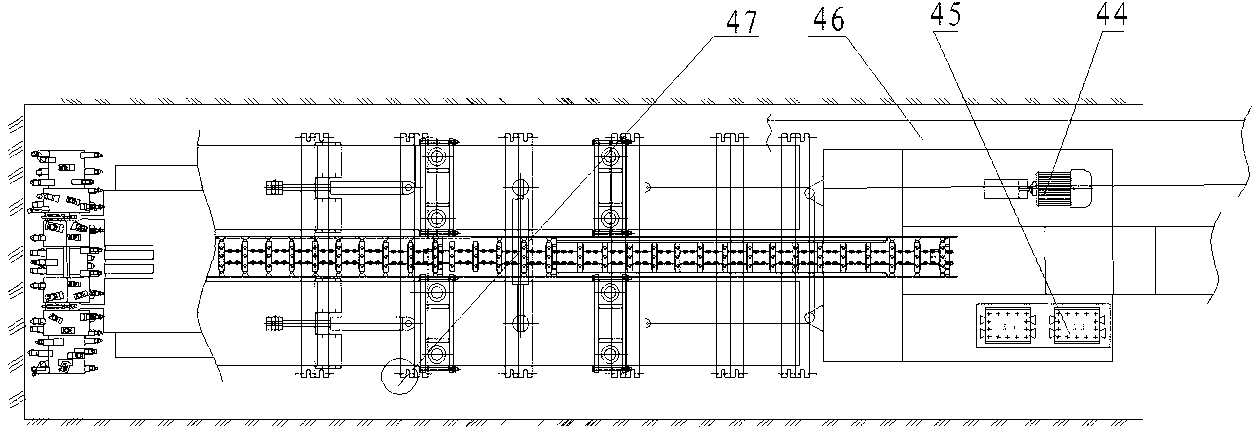

[0034] The comprehensive bolter of the present invention is as figure 1 , figure 2 It consists of a trackless bolter, a hydraulic support, a first scraper conveyor 34, a second scraper conveyor 28, a bridge belt loader 19, a skid 22, a console 29, an electromagnetic starting device 45 and a hydraulic oil pump 44 composed.

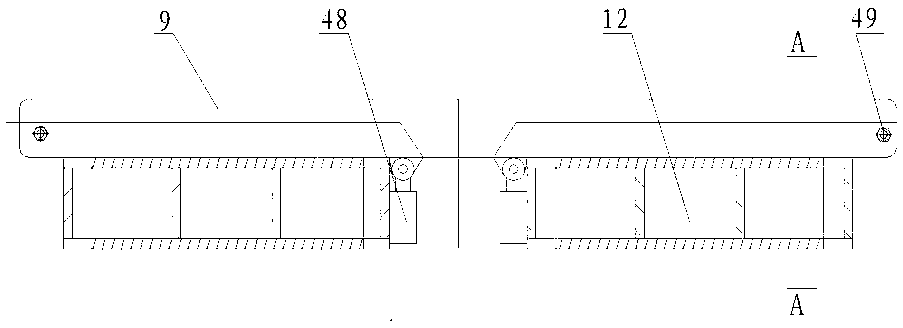

[0035] Among them, the hydraulic support includes a symmetrical left hydraulic support and a right hydraulic support, both of which are composed of a support base box 30, a front and rear bridge 25, a hydraulic column 11, a main top beam 12, a front probe beam 4, a rear probe beam 14 and a crossbeam 9. The hydraulic support belongs to the support type (stack type) hydraulic support. Its main top beam 12 is hinged with the front probe beam 4 and the rear probe beam 14 respectively through the front probe beam jack 8 and the rear probe beam jack 13. The bridge 25 is welded into one body, and the front and rear crossing bridges 25 are both used for connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com