Tunnel self-advancing support shed

A technology of supporting shed and self-moving, applied in the field of transportation, can solve the problems of lack of supporting equipment, affecting the progress of the project, time-consuming and labor-intensive safety effects of supporting equipment, and achieving the effect of saving time and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

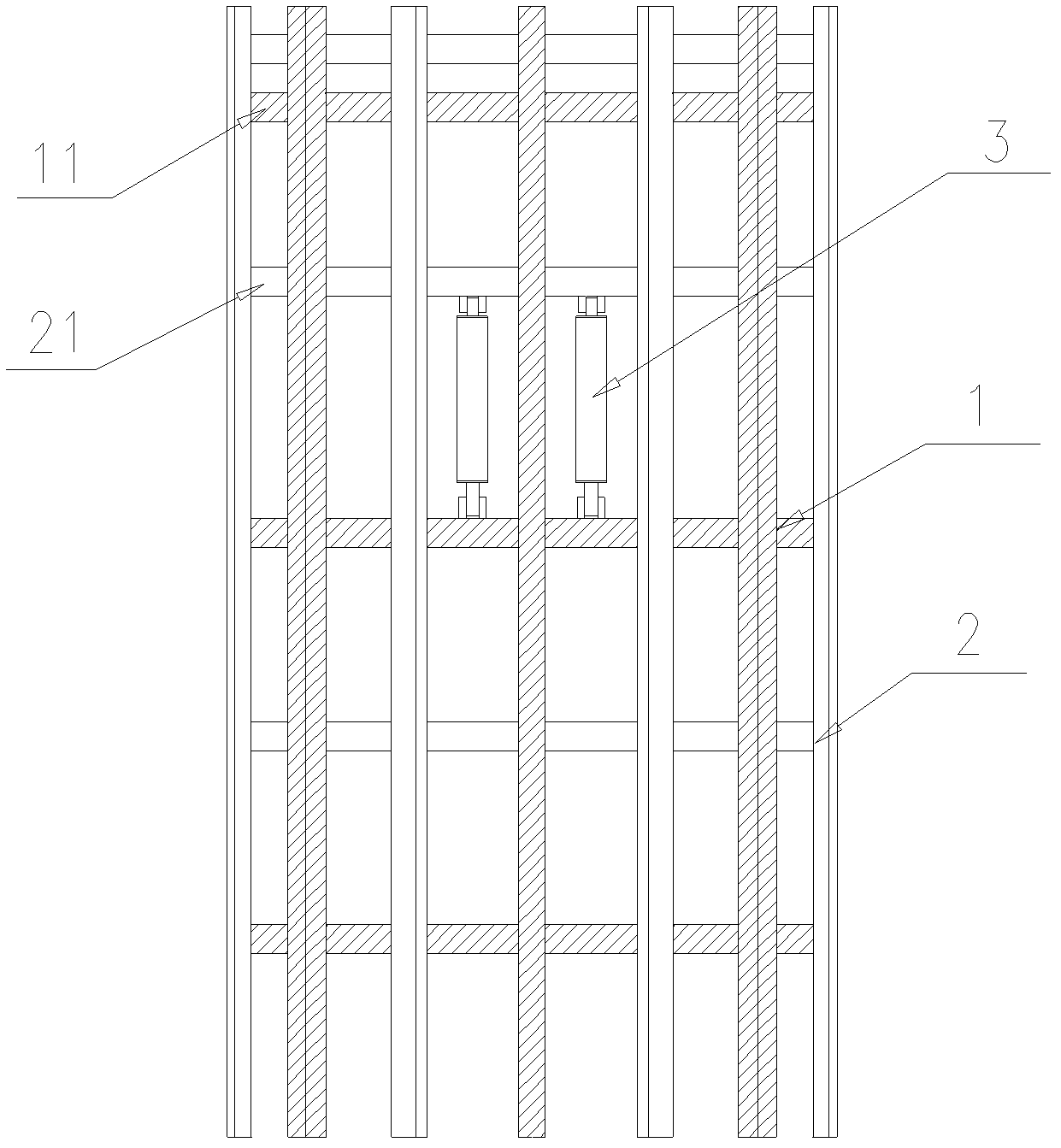

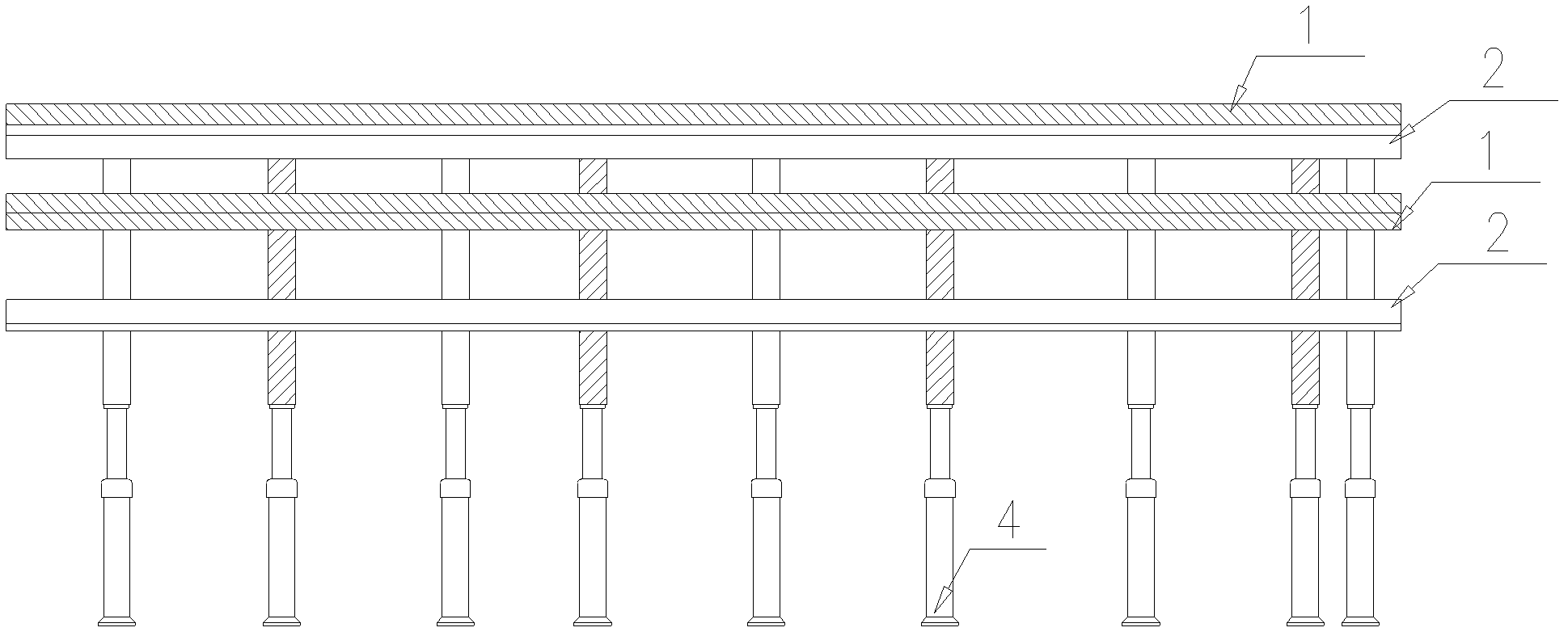

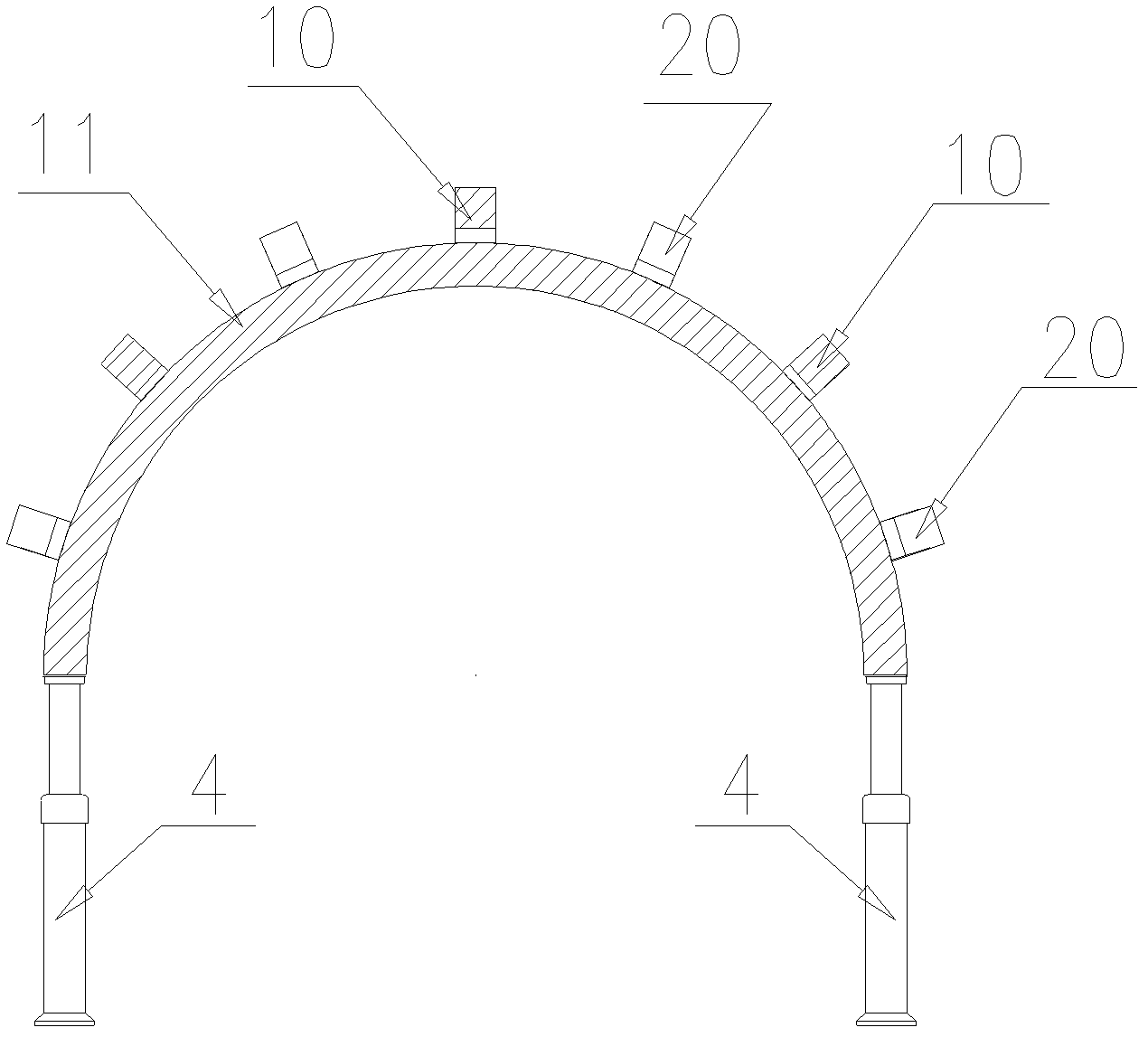

[0046] see figure 1 , figure 2 and image 3 , a self-moving support shed for a tunnel, comprising a front arch 1, a rear arch 2, a forward jack 3 and a support jack 4, the front arch 1 includes more than three front longitudinal beams 10 and more than three front arch beams 11 , all the front longitudinal beams 10 are longitudinally and evenly arranged along the arched upper surface of the front arch beams 11, each front longitudinal beam 10 is connected to all the front arch beams 11, and a pad is added at the junction of the front longitudinal beams 10 and the front arch beams 11 block 12, and then fixed as a whole, the front arch 1 is provided with a support jack 4; the rear arch 2 includes more than three rear longitudinal beams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com