Patents

Literature

31results about How to "Make sure not to break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

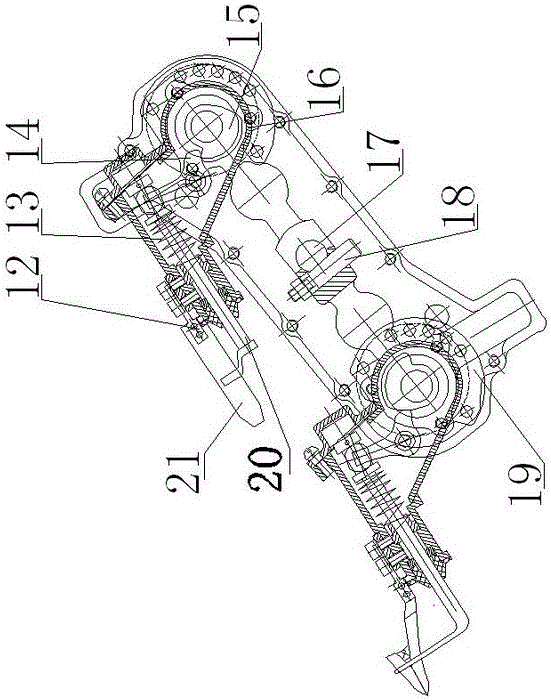

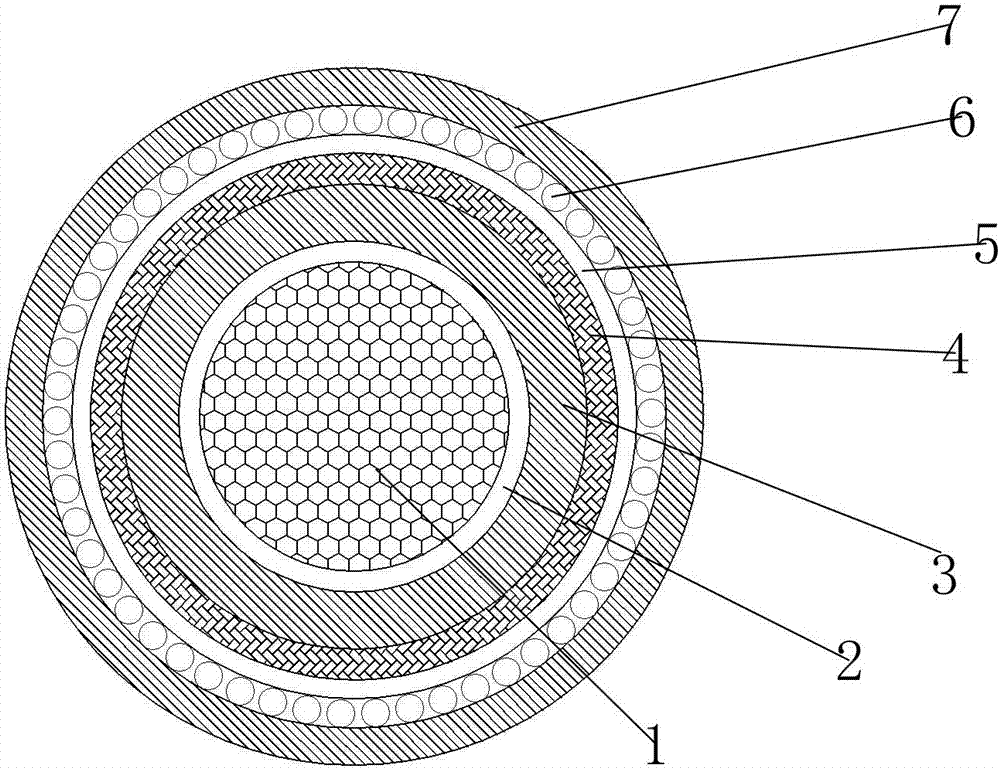

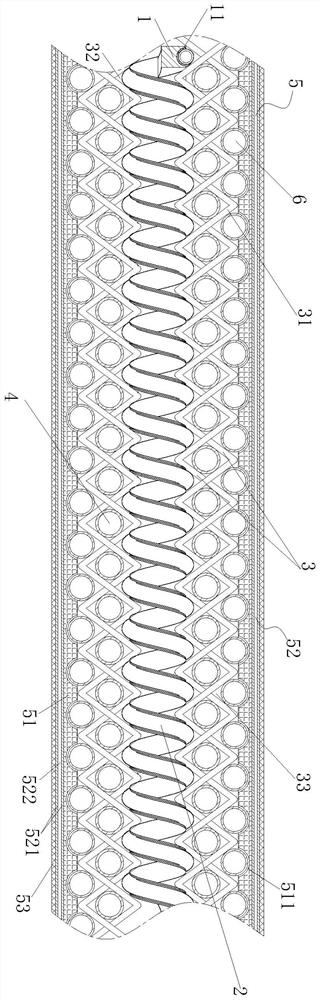

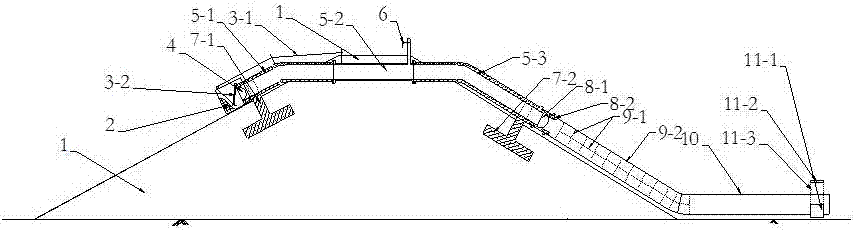

Dam exceeding-standard flood diversion siphon frieze group

InactiveCN105735208ASolve the worldwide problem of dike burstReduce single-width trafficBarrages/weirsSiphonSynthetic materials

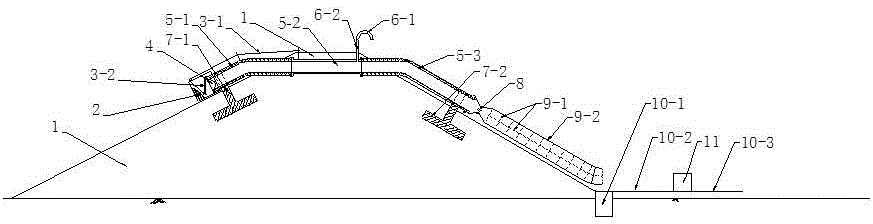

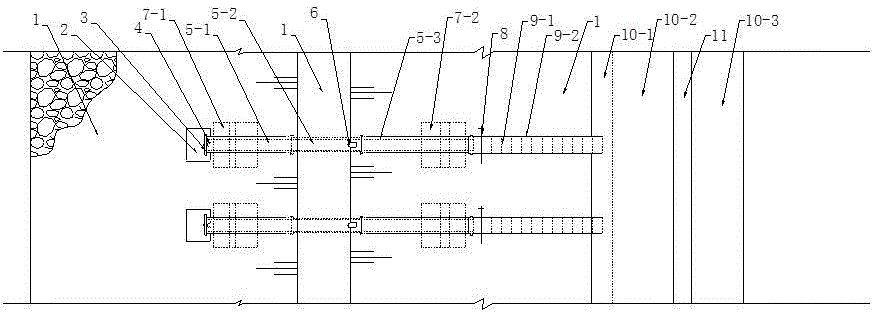

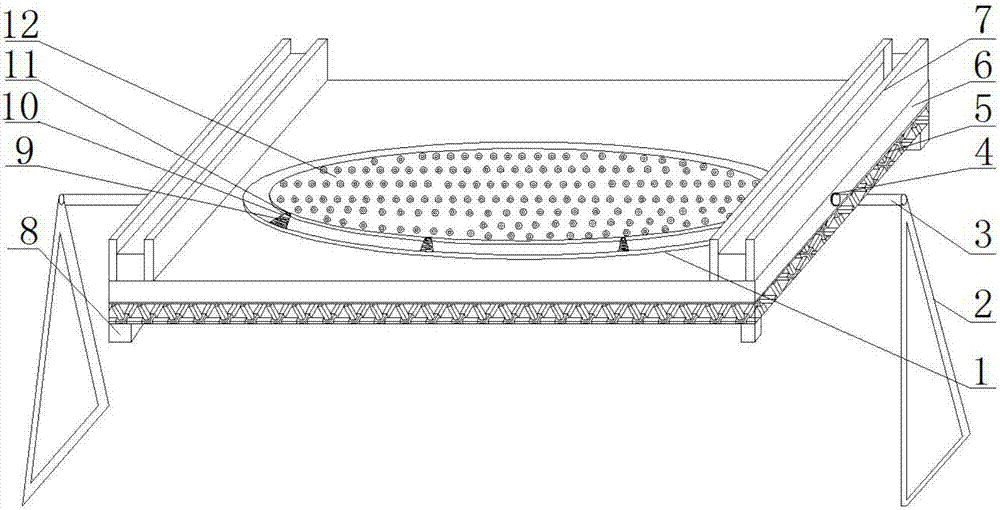

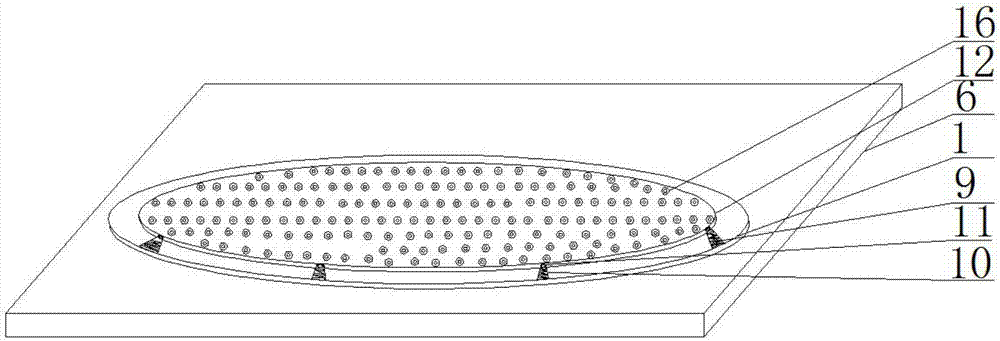

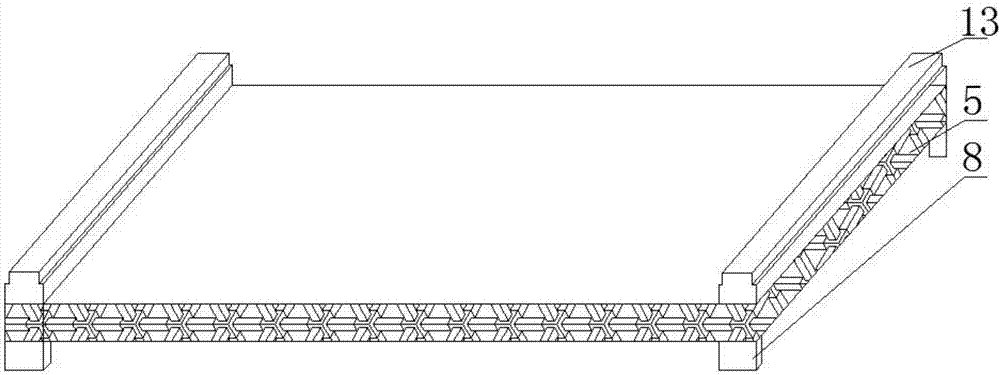

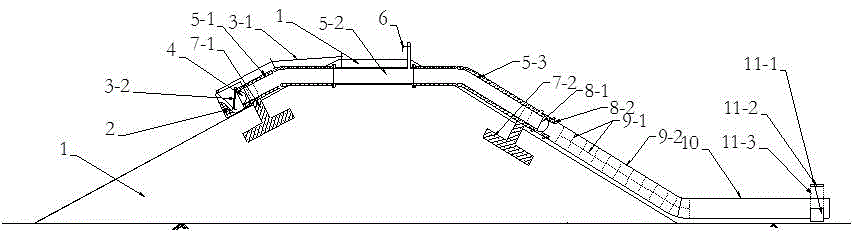

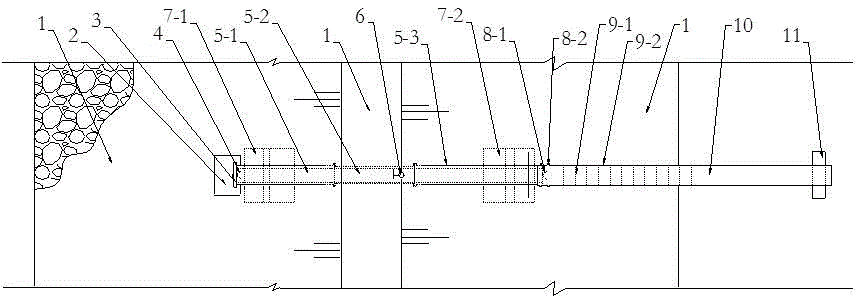

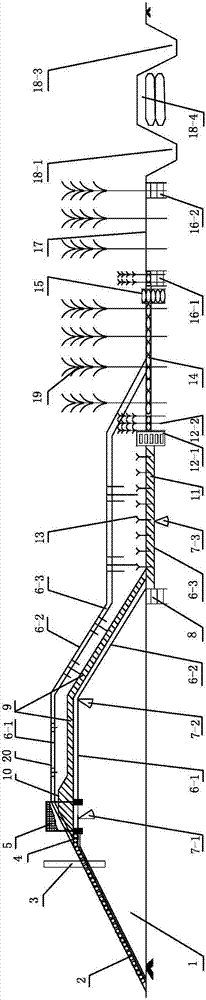

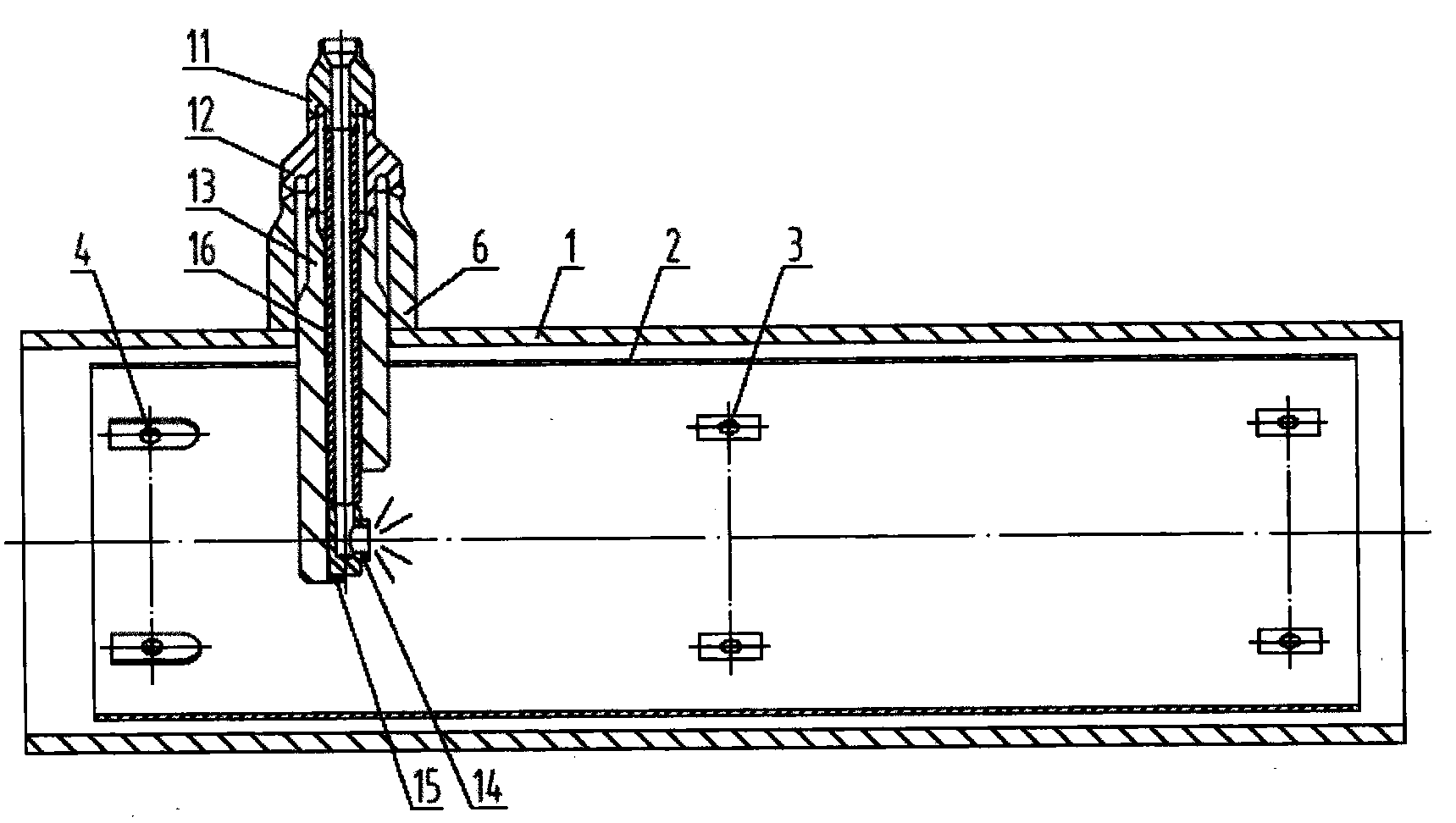

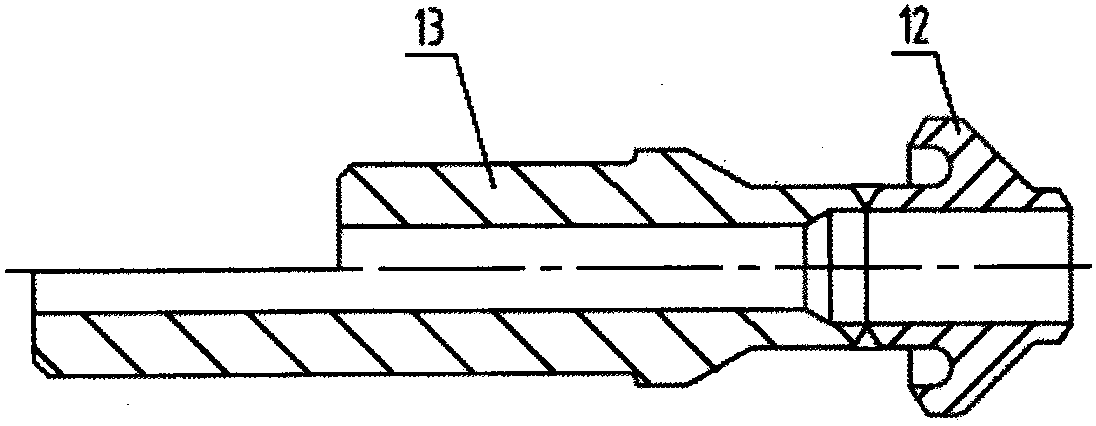

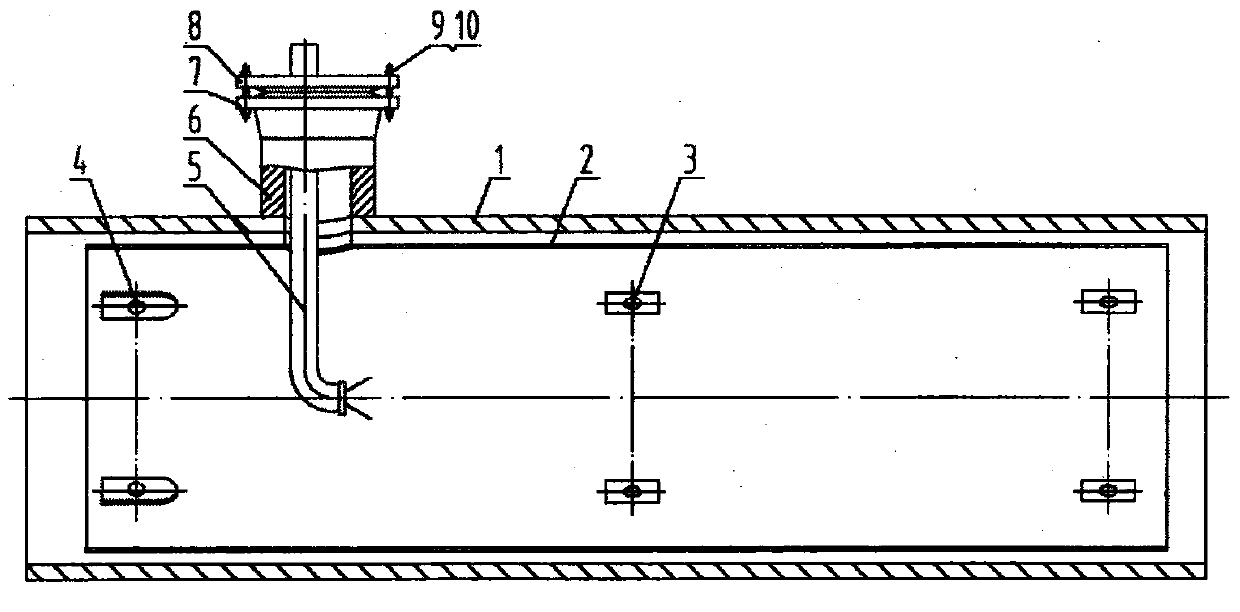

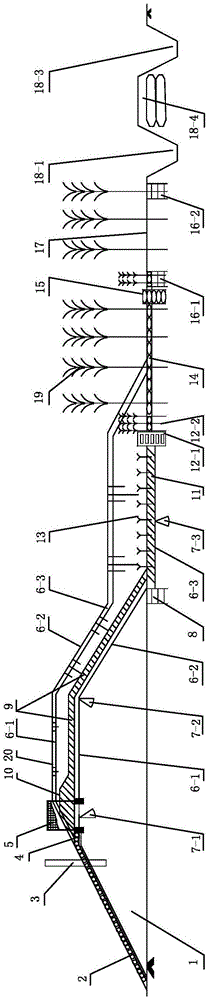

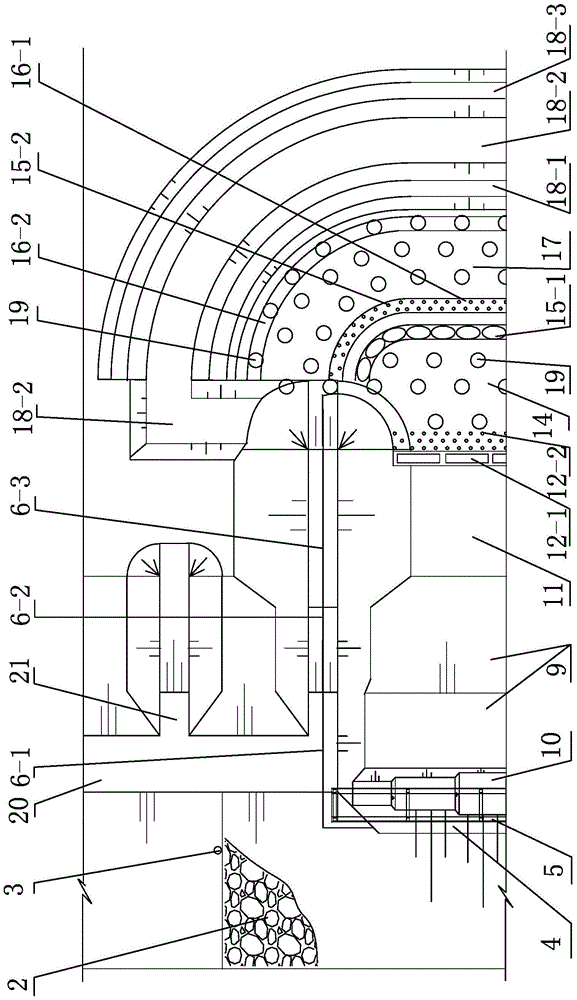

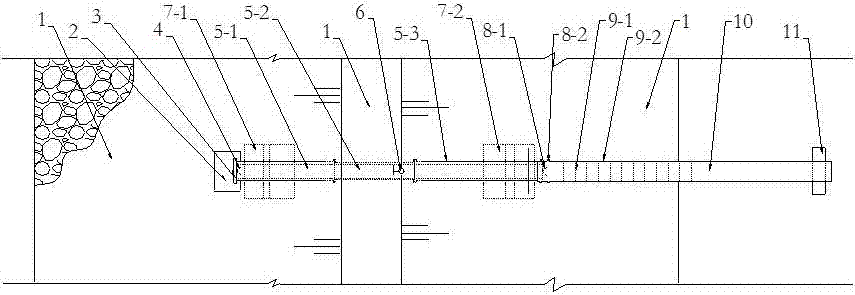

The invention discloses a dam exceeding-standard flood diversion siphon frieze group and belongs to the technical field of dam flood diversion hydraulic engineering. The siphon frieze group can disperse and bleed the exceeding-standard flood to farmland directly to protect the dam and is simple in structure, convenient to finalize, design, produce and transport, convenient and fast to construct, and low in cost. The siphon frieze group comprises a trash rack (2) arranged at the outside of an inlet of a siphon body (5); the siphon body (5) is connected with a water input tube belt valve (6); the tail end of the siphon body (5) is provided with a water output belt clamp valve (8); the water output belt clamp valve (8) is connected with a water output belt (9) made of a rigid body framework artificial synthetic material; an outlet of the water output belt (9) made of the rigid body framework artificial synthetic material is arranged above an apron (10-2) made of an artificial synthetic material; the downstream of the apron (10-2) made of the artificial synthetic material is connected with a rope net pile sandbag baffle sill (11); and the downstream of the rope net pile sandbag baffle sill (11) is connected with an apron extension (10-3) made of an artificial synthetic material. The siphon frieze group is suitable for controllable flood diversion of exceeding-standard floods for dikes, dams and auxiliary dams and dam flood diversion and rescue.

Owner:HEILONGJIANG UNIV +1

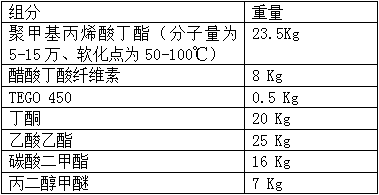

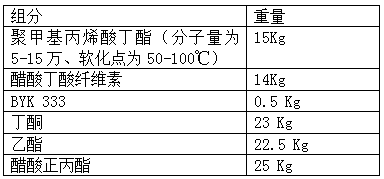

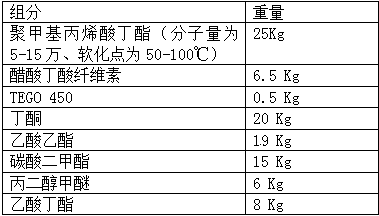

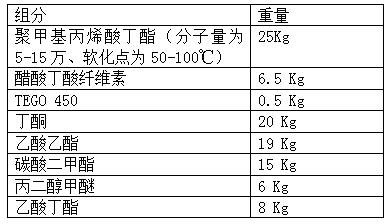

High-speed strippable aluminum paper transfer release coating

The invention provides a high-speed strippable aluminum paper transfer release coating. The high-speed strippable aluminum paper transfer release coating is composed of, by weight percentage, 15-25% of poly-n-butyl methacrylate, 5-14% of cellulose acetate butyrate, 0.5-1% of polyether modified polysiloxane, 23-25% of butanone, 20-23% of ethyl acetate and other solvent as balance. The high-speed strippable aluminum paper transfer release coating is prepared by stirring and dispersing the poly-n-butyl methacrylate, the cellulose acetate butyrate, and half of the butanone as well as the ethyl acetate inside a high-speed dispersing machine at a rotating speed of 500-1000 rpm / second for 30 minutes, controlling the temperature to be 40-50 DEG C, then continuing to mix in the rest of the butanoneand the ethyl acetate, the other solvent and the polyether modified polysiloxane for 30 minutes, cooling the mixture down to 20-30 DEG C, and performing filtering to obtain the high-speed strippablealuminum paper transfer release coating. The high-speed strippable aluminum paper transfer release coating is applied to transferring aluminum paper and released and sliced on a high-speed online stripping machine to avoid flying aluminum scraps and ensure intactness and cleanliness, avoids drops and is high in solvent resistance.

Owner:汕头市龙湖昌丰化工有限公司

Steel for high-frequency resistance welding petroleum casing pipe, casing pipe and manufacturing method thereof

ActiveCN102839324AGood resistance to carbon dioxide corrosionIncrease the equivalentDrilling rodsDrilling casingsCarbon corrosionButt welding

The invention relates to steel for a petroleum casing pipe. The steel for the petroleum casing pipe comprises the components in percentage by mass: 0.05 to 0.10 percent of C, 0.10 to 0.30 percent of Si, less than 0.015 percent of P, less than 0.003 percent of S, 0.1 to 0.3 percent of Mn, 2 to 2.5 percent of Cr, 0.01 to 0.04 percent of Al and the balance of Fe and unavoidable impurities, wherein the total amount of impurity elements is less than 0.05 weight percent; and the carbon equivalent is not greater than 0.6. The invention also relates to the petroleum casing pipe made of the steel. The manufacturing method for the steel comprises the following processes of: a hot rolling process of the steel for the petroleum casing pipe: the finish rolling temperature is 850 to 890 DEG C, and the coiling temperature is 620 to 660 DEG C; a carbon dioxide gas protection welding process for coiled plate butt welding: the wire feeding speed is 12 to 14 m / min, the current is 557 to 561 A, the welding speed is 52 to 54 cm / min, and the gas flow is 23 to 25 L / min; and overall pipe heat treatment: heating and keeping the temperature of 900 to 950 DEG C for 40 to 70 minutes, tempering at the temperature of 620 to 650 DEG C after water quenching, and keeping the temperature for 60 to 80 minutes. The high-frequency resistance welding petroleum casing pipe provided by the invention has the steel grade of 80 ksi and high carbon dioxide corrosion resistance; and the annual average corrosion rate of a finished pipe is below 1 / 3 of that of a conventional N80 oil well pipe.

Owner:BAOSHAN IRON & STEEL CO LTD

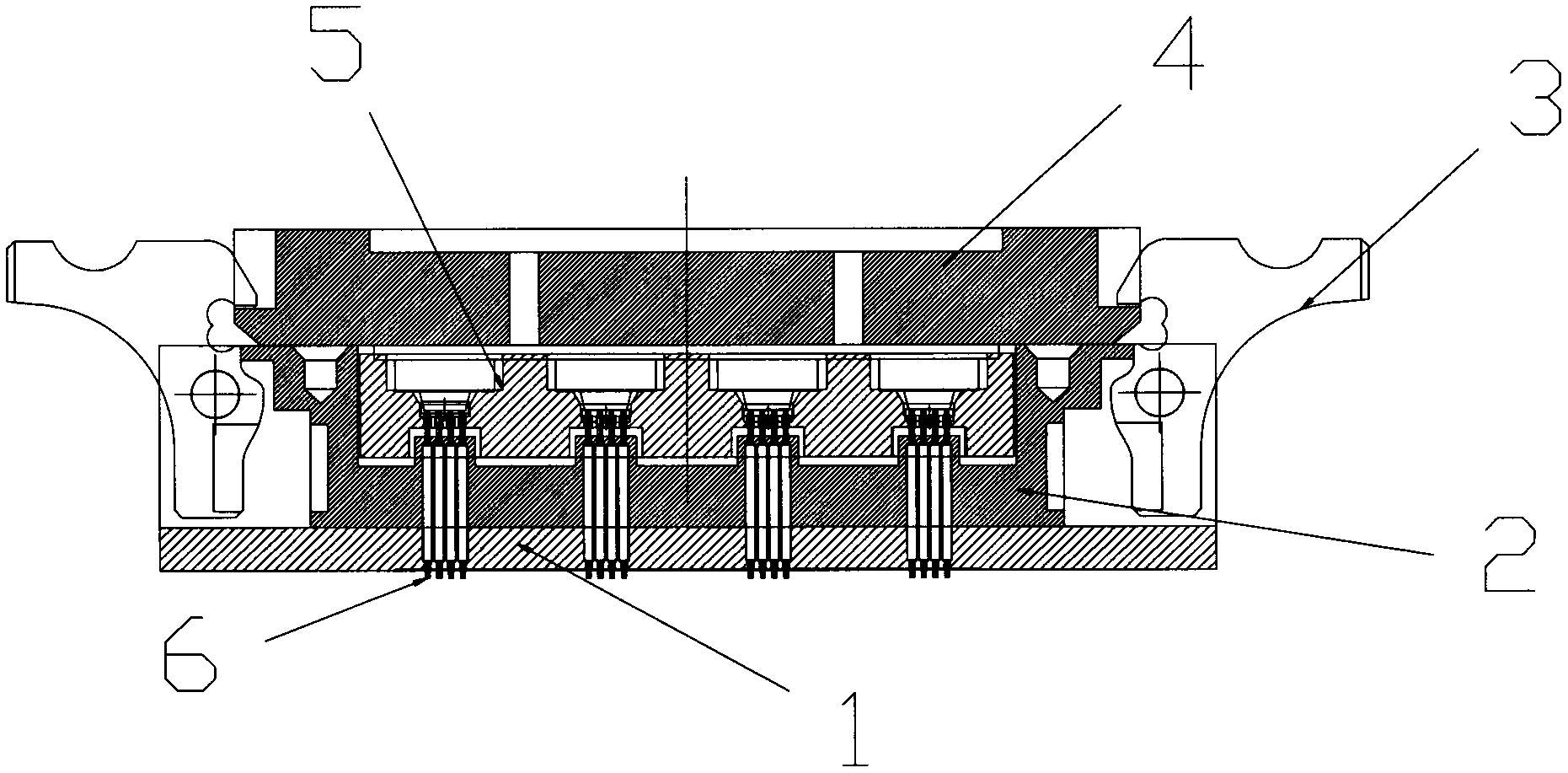

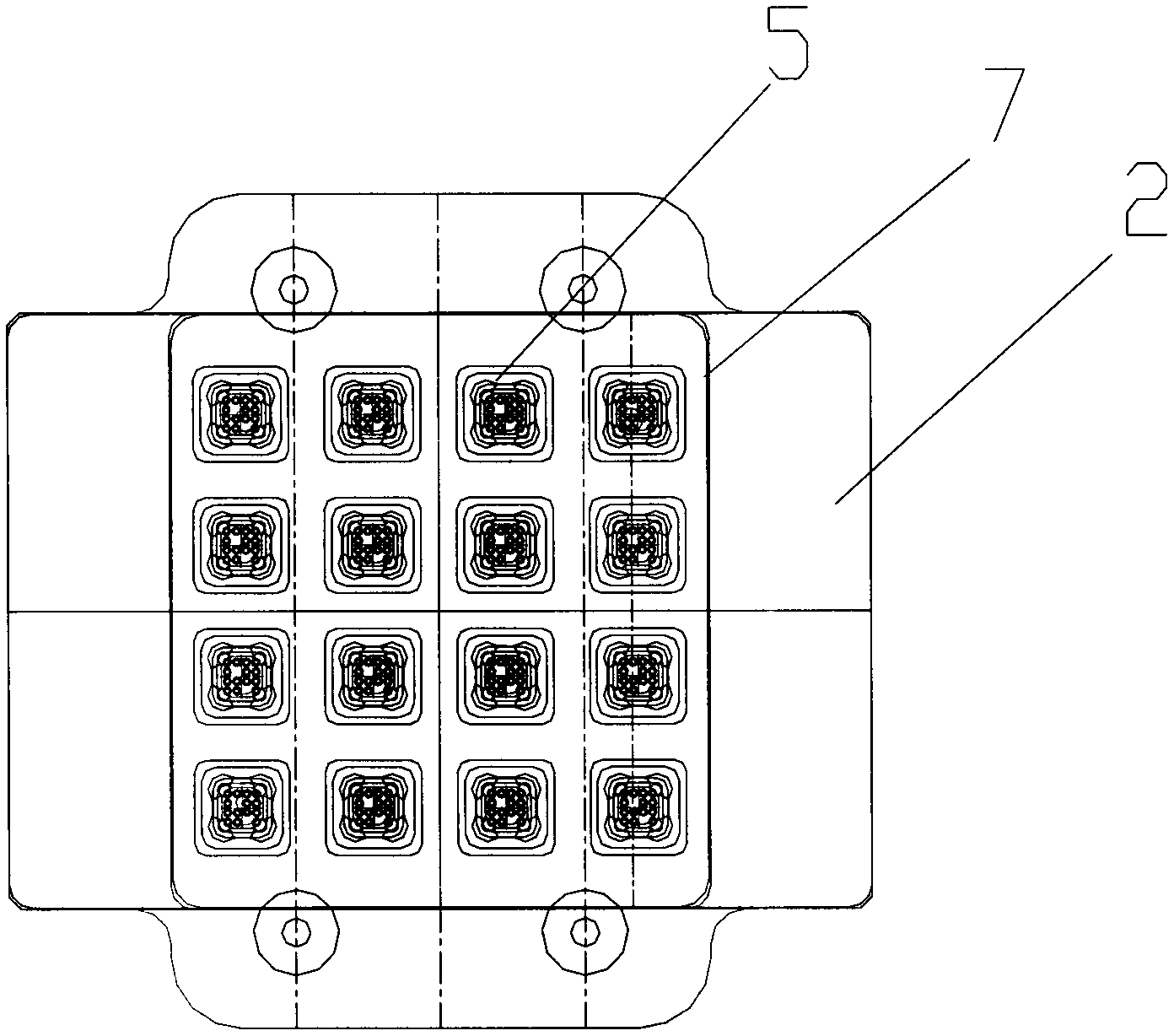

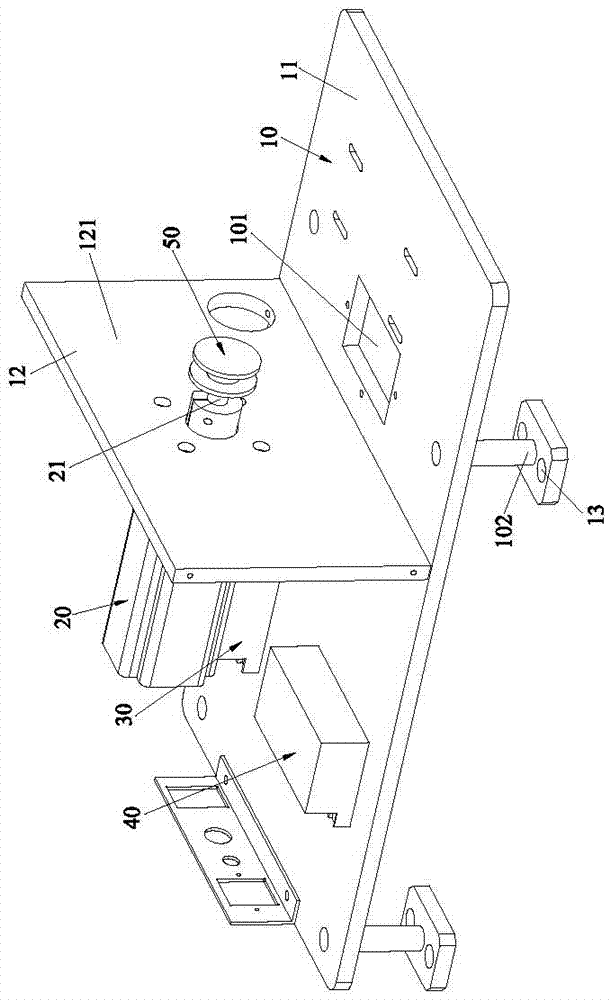

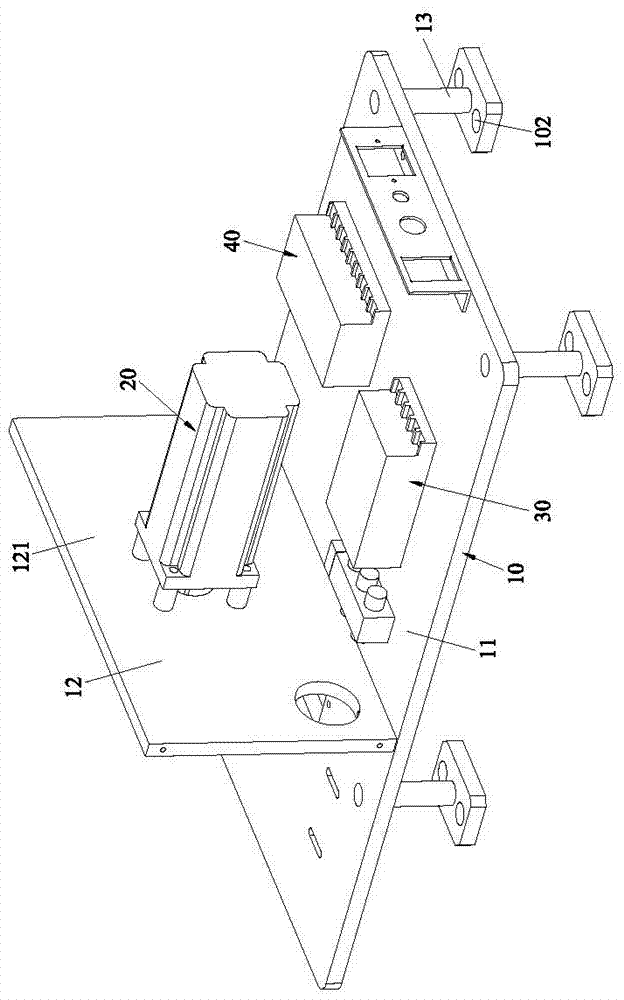

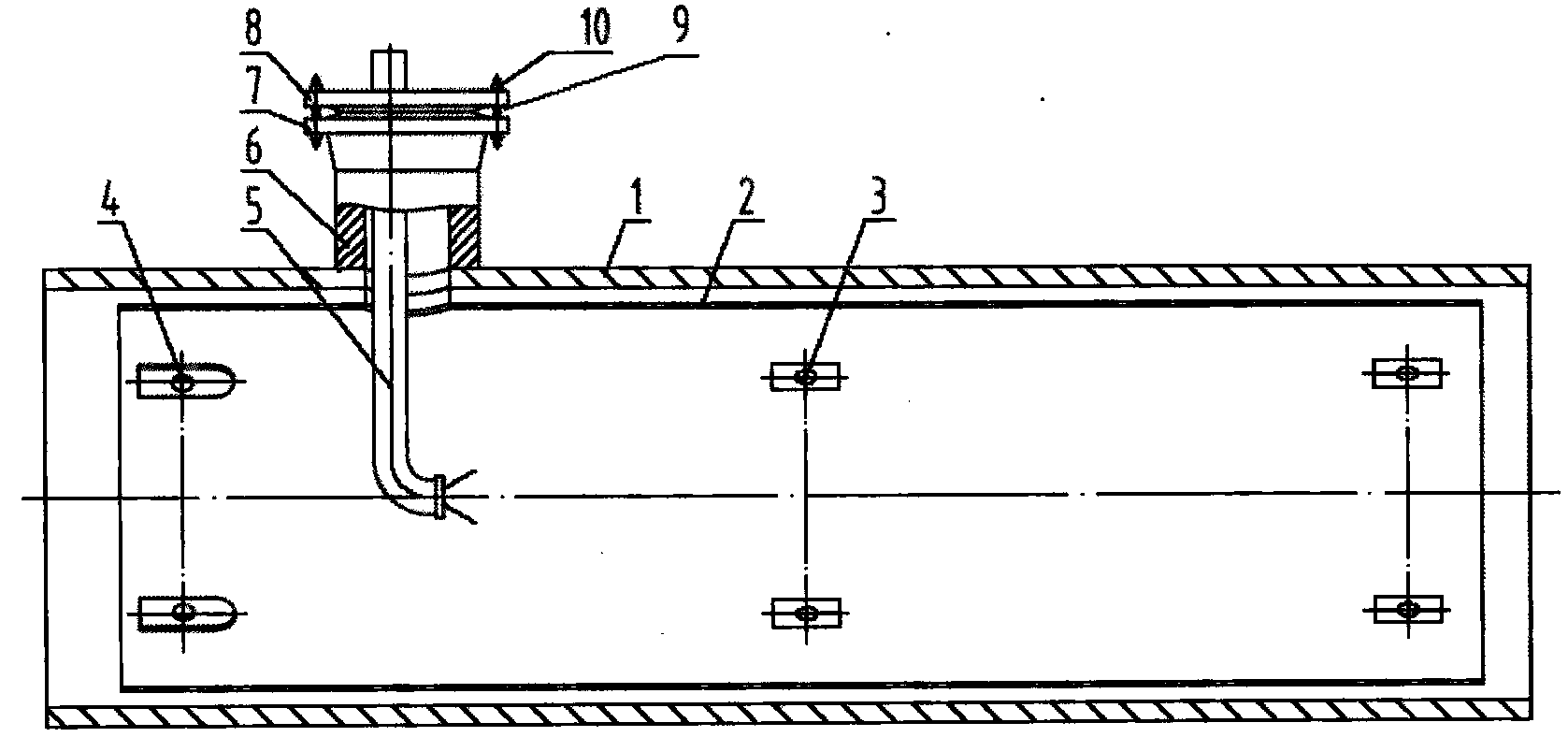

Multi-station MEMS gyro testing socket

InactiveCN104061946AImprove test accuracySolve the slow test speedMeasurement devicesArray data structureEngineering

The invention provides a multi-station MEMS gyro testing socket which comprises an upper pressing plate and a base. The base is pressed by the upper pressing plate. The multi-station MEMS gyro testing socket is characterized in that a floating plate containing groove is formed in the base, a floating plate is arranged in the floating plate containing groove, an elastic piece is arranged at the bottom of the floating plate, a plurality of element containing grooves are formed in the floating plate, a plurality of protrusions corresponding to the element containing grooves in position are arranged on the upper pressing plate, a plurality of sets of probes are arranged on the base, the upper ends of the multiple sets of probes movably penetrate through the floating plate and are located in the element containing grooves respectively, and the lower ends of the multiple sets of probes are connected with an adapter PCB. By means of the multi-station MEMS gyro testing socket, the testing accuracy of an MEMS gyro can be effectively improved, the testing speed of the MEMS gyro can be effectively increased, and the working efficiency is improved.

Owner:SUZHOU CHUANGRUI MACHINERY & ELECTRICAL TECH

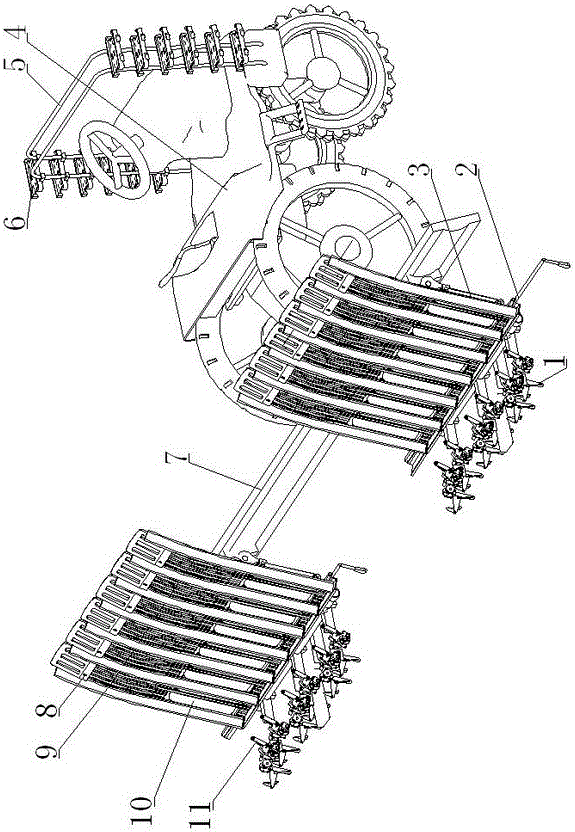

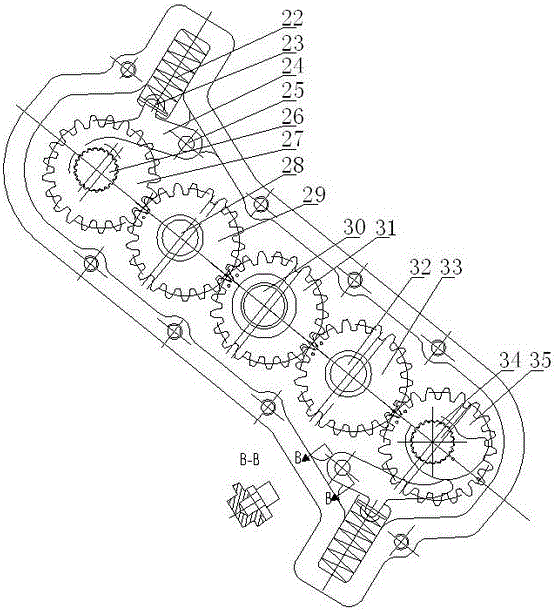

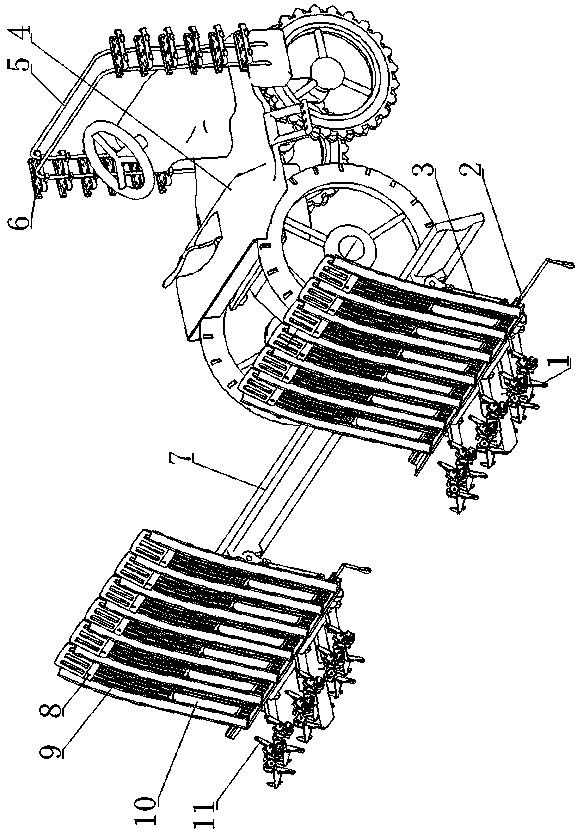

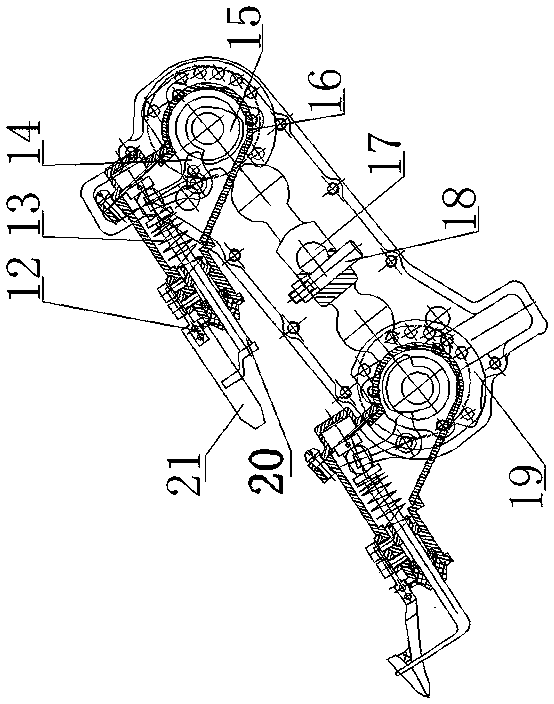

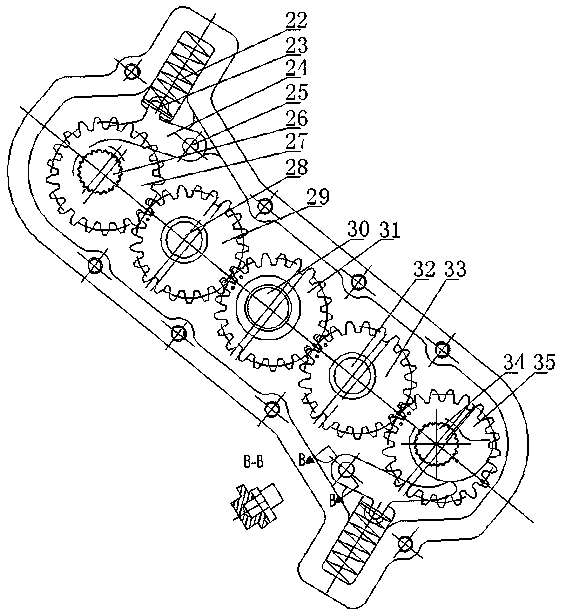

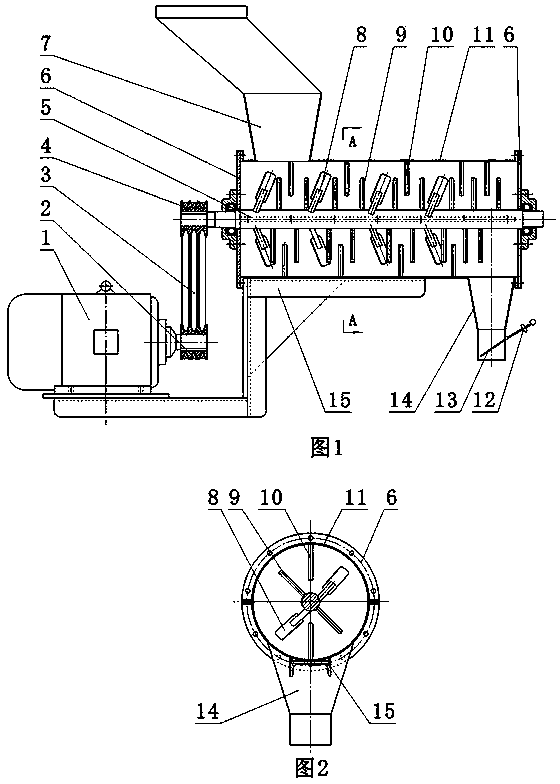

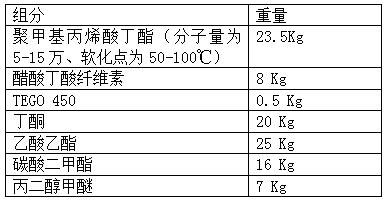

Onion seedling transplanting machine

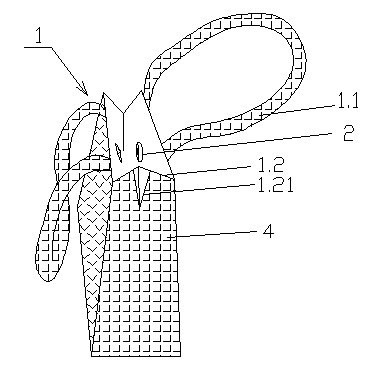

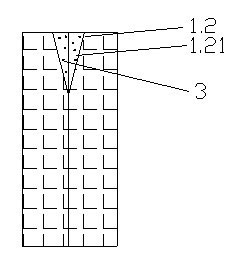

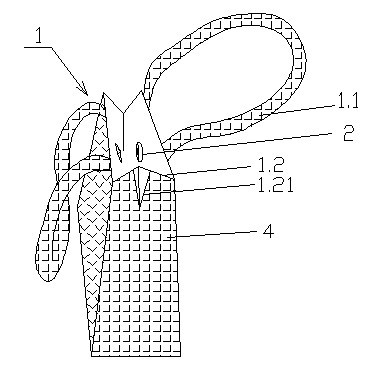

ActiveCN106664914ANot easy to hurt seedlingsMake sure not to breakTransplantingAgricultural engineeringTransplanting

The invention discloses an onion seedling transplanting machine. The onion seedling transplanting machine comprises a tractor, a seedling guide plate, a tray and a transplanter, wherein a front bracket is mounted at the front end of the tractor, tray racks are arranged at the two side ends of the front bracket, the tray is placed on the tray racks; a supporting frame is arranged at the rear end of the tractor, the rear end of the supporting frame is connected with a crossbeam frame, the seedling guide plate is placed at the rear end of the crossbeam frame, an upper guard plate is arranged at the upper end of the seedling guide plate, a lower guide plate is arranged at the lower end of the seedling guide plate, an adjusting lever is arranged at the rear end of the lower guide plate, travelling land wheels are arranged at the lower end of the lower guide plate, a power transmission device is arranged at the front end of the lower guide plate and is connected with the transplanter, the transplanter is arranged in a manner that the front part is lower and the rear part is higher, and a seedling falling device is mounted at the upper end of the transplanter; a right size for transplanted seedlings is changed through changing the transmission ratio of the transplanting mechanism. The duckbill-type transplanter can be used for carrying out direct-perforated transplanting on films, seedlings are not damaged easily, and the requirements of a variety of pot-seedling crops on transplanting operation can be met, so that the onion seedling transplanting machine has been evolves as an ideal model for on-film transplanting; the condition that the onion seedlings are not damaged is ensured.

Owner:QIQIHAR UNIVERSITY

PCB fixing device

InactiveCN107283341AMake sure not to breakSolve difficult work problemsWork holdersSocial benefitsEconomic benefits

The invention discloses a PCB board fixing device, comprising a PCB groove, a bracket, a cross bar, a bearing, an insulating protection layer, a fixing plate, a first chute, a base, a spring, a convex column, a groove, a PCB board, and a slider , the second chute, steel ball and electric hole. The beneficial effects of the present invention are: the inner edge of the PCB groove of the present invention is provided with several convex posts, the springs are embedded inside the convex posts, and the convex posts are engaged with the grooves on the surface of the PCB board, so that the PCB board is fixed in the PCB groove , and ensure that the PCB board is not broken, the first chute is set on the front of the fixed plate, and the second chute is set on the back, and both the first chute and the second chute can be slidably connected with the slider on the surface of the insulating protective layer, The front and back of the PCB board can be exchanged by rotating the bearing, so that both the first chute and the second chute can be slidably connected with the slider, which effectively solves the problem that the back is not easy to work. The structure is compact, and the work on both sides can be solved on the front. Strong, good economic and social benefits, conducive to popularization.

Owner:姚潘涛

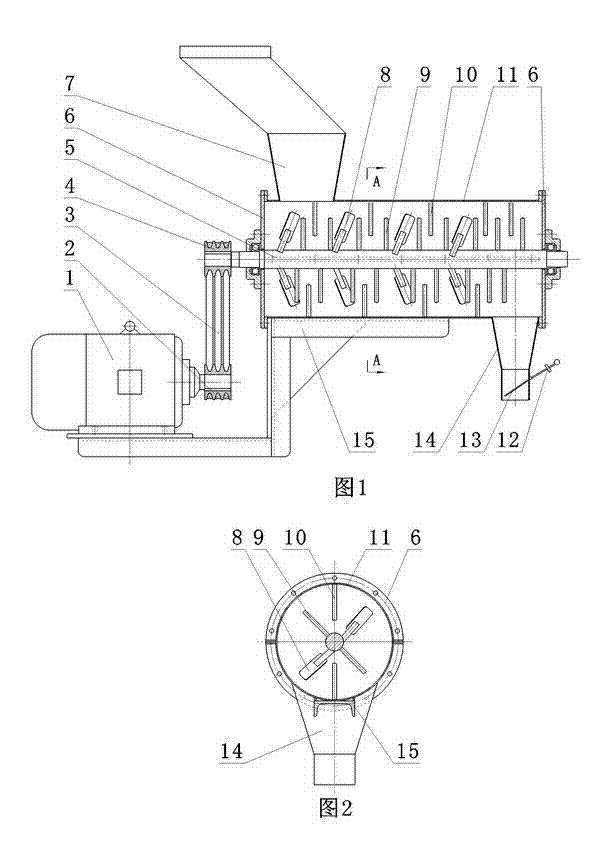

Plukenetia volubilis linneo shelling process and special segment breaking device

ActiveCN102894450AQuality assuranceGuaranteed to proceed normallyHuskingHullingComputer scienceDeep processing

The invention discloses a plukenetia volubilis linneo shelling process and a special segment breaking device. The plukenetia volubilis linneo shelling process comprises the following steps of: performing segment breaking treatment on picked and dried plukenetia volubilis linneo; performing sorting and impurity removal on the plukenetia volubilis linneo subjected to segment breakage; classifying single segments of the impurity-free plukenetia volubilis linneo according to sizes; performing primary shelling and sorting treatment on the classified single segments of the plukenetia volubilis linneo; classifying the plukenetia volubilis linneo with inner shell according to the size of the inner shell of the plukenetia volubilis linneo; and performing secondary shelling and sorting treatment on the classified plukenetia volubilis linneo with the inner shell to obtain the impurity-free plukenetia volubilis linneo kernel. The plukenetia volubilis linneo shelling process and the special segment breaking device have the advantages that mechanical production of lukenetia volubilis linneo shelling is realized, the production efficiency is greatly increased, raw material treatment capacity of 1.5-2 ton / hour is reached, the rate of perfect kernel of the kernels reaches over 95 percent, the product quality of the kernels is improved, the process and the device are suitable for large-scale industrial production and conditions are created for industrial development of the lukenetia volubilis linneo and deep processing of a product.

Owner:JINZHOU QIAOPAI MACHINERIES +1

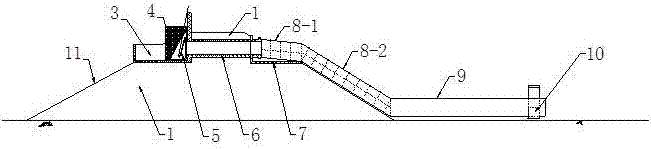

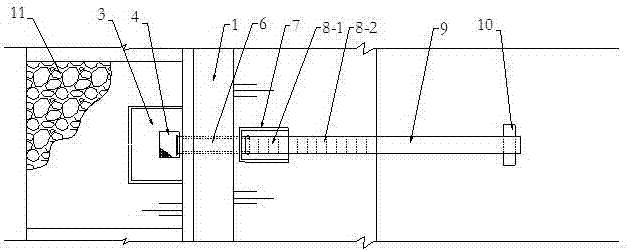

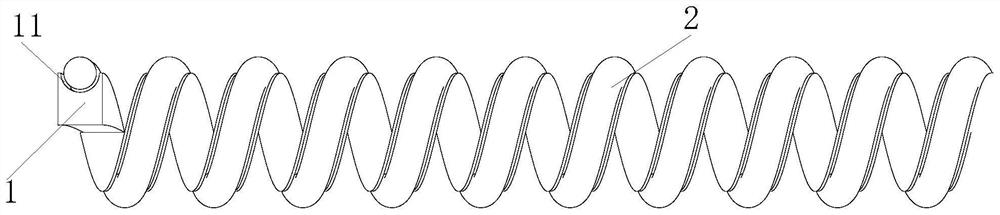

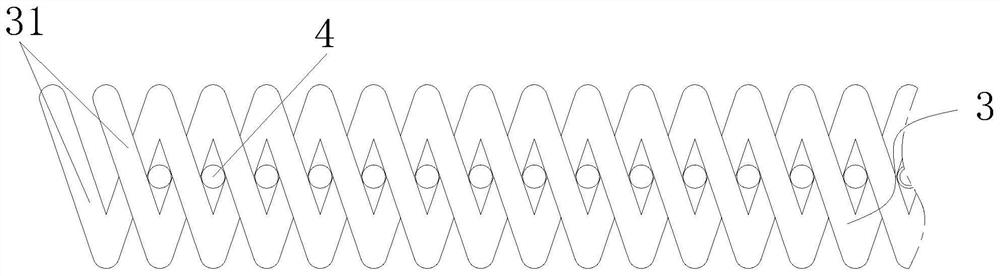

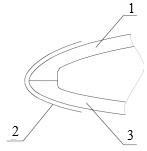

Dam over-standard flood diversion siphon belt

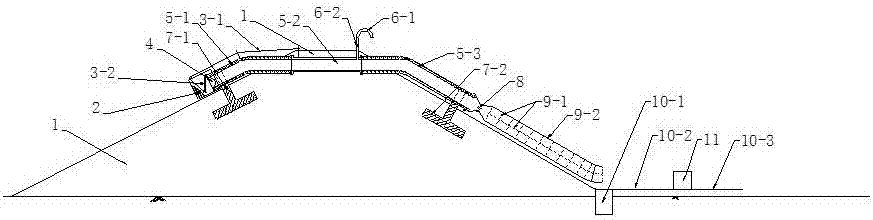

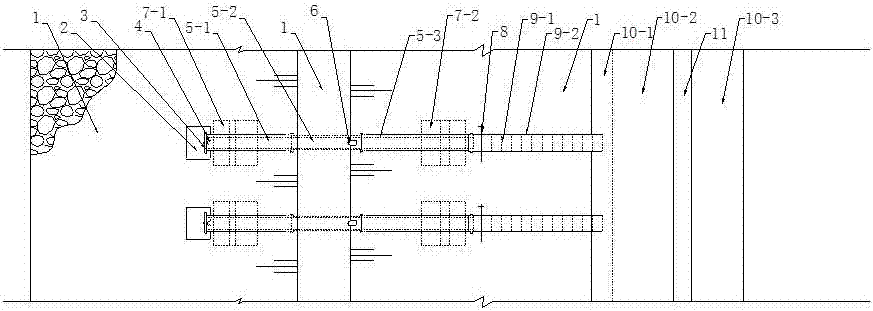

ActiveCN105603942AChange design conceptMake sure not to breakBarrages/weirsArtificial islandsSiphonEmergency rescue

The invention discloses a dam over-standard flood diversion siphon belt and belongs to the technical field of dam flood diversion water conservancy projects. The dam over-standard flood diversion siphon belt can achieve farmland controllable floor diversion over-standard flood dam protection and dynamic floating body outlet novel energy dissipation, has the advantages of deflecting flow, face flow and bottom flow, and is applicable to any topographic and geologic condition. The dam over-standard flood diversion siphon belt is simple in structure, fast to build and low in manufacturing and is characterized in that a trash rack (2) is installed on the outer side of an inlet of a siphon body (5), the siphon body (5) is connected with a water injection pipe valve (6), the downstream tail end of the siphon body (5) is provided with a check butterfly valve (8), the outer side of the downstream tail end of the siphon body (5) is connected with a rigid framework artificial synthetic material water conveying belt (9) which is connected with an artificial synthetic material water conveying belt (10), and the tail end of the artificial synthetic material water conveying belt (10) is connected with a dynamic floating body outlet (11). The dam over-standard flood diversion siphon belt is applicable to dike and dam controllable emergency flood diversion and flood-fighting and emergency rescues.

Owner:HEILONGJIANG UNIV +2

Self-adhesion copper foil waste recycling machine

The invention discloses a self-adhesion copper foil waste recycling machine. The self-adhesion copper foil waste recycling machine comprises a rack, a motor, a driver, a power source and a receiving plate; the rack comprises a supporting board and a box arranged on the supporting board; a discharging opening is formed in the supporting board; the motor, the driver and the power source are all arranged inside the box; an output shaft of the motor extends out of a front side board of the box; the driver is connected with the motor; the power source is connected with the driver; the receiving plate is installed at the outer end of the output shaft of the motor; the output shaft of the motor drives the receiving plate to rotate; and the receiving plate is located over the discharging opening. The motor drives the receiving plate to rotate so as to collect waste and separate copper foil out, it is ensured that the copper foil is not pulled broken, the operation fatigue of workers is relieved, manual waste tearing action is reduced, and accordingly the efficiency is improved and quality is perfected.

Owner:DONGGUAN JIALONG HAIJIE ELECTRONICS TECH CO LTD

Method for preparing chitosan fibers

InactiveCN102199810BOvercoming instabilityEnsure no hydrolysisFibre chemical featuresWet spinning methodsFiberLithium hydroxide

The invention discloses a method for preparing chitosan fibers, which comprises the following steps: mixing 2.0 to 6.0 weight percent of chitosan, 4.0 to 6.0 weight percent of lithium hydroxide, 0.5 to 4.0 weight percent of urea, 0.1 to 3.0 weight percent of glycerol and the balance of water, and swelling to prepare chitosan spinning solution; and spinning by a wet-process spinning method, coagulating and precipitating in a coagulating bath to form protofilaments, washing, drawing, and drying to obtain the chitosan fibers. In the invention, the spinning solution is prepared by dissolving chitosan in an alkaline solvent, the chitosan macromolecular chains exist in a high-swelling state, the arrangement of the chitosan macromolecular chains is more compact, the high instability of the chitosan in acidic solution is overcome, the hydrolysis of the chitosan macromolecular chains and the breakage of the glucosidic bonds are avoided, the oriented arrangement of the macromolecular chains is promoted, and the mechanical properties of the chitosan fibers are improved.

Owner:ZHEJIANG UNIV

Method for cleaning extruding machine and die head of multilayer co-extrusion film blowing equipment

ActiveCN102431141AIncrease flushing powerReduce cleaning timeHollow article cleaningProcess engineeringNew materials

The invention discloses a method for cleaning an extruding machine and a die head of multilayer co-extrusion film blowing equipment. The method comprises the following steps of: after the last batch of formulated products are produced by extruding the last batch of formulated materials out of all extruding machines respectively, adding new materials into corresponding extruding machines respectively to start cleaning the machine until the new materials clean the last batch of materials out of the extruding machine and the die head completely; and in the machine cleaning process, making the extrusion speeds of all the extruding machines continuously fluctuated and changed up and down by using a central controller, wherein the maximum extrusion speed of all the extruding machines at the highest speed reaches 1.4 to 1.8 times the normal extrusion speed of the extruding machine, but the sum of the extrusion speeds of all the extruding machines is kept constant at all time points in the machine cleaning process. In the method, an oscillating extrusion mode is used for all the extruding machines, so that the time consumed in the machine cleaning process is short, and a small number of raw materials are consumed.

Owner:GUANGDONG JINMING MACHINERY +1

Flood diversion siphon belt group of superstandard flood in embankment

InactiveCN105735208BReduce single-width trafficMake sure not to breakBarrages/weirsSiphonSynthetic materials

The invention discloses a dam exceeding-standard flood diversion siphon frieze group and belongs to the technical field of dam flood diversion hydraulic engineering. The siphon frieze group can disperse and bleed the exceeding-standard flood to farmland directly to protect the dam and is simple in structure, convenient to finalize, design, produce and transport, convenient and fast to construct, and low in cost. The siphon frieze group comprises a trash rack (2) arranged at the outside of an inlet of a siphon body (5); the siphon body (5) is connected with a water input tube belt valve (6); the tail end of the siphon body (5) is provided with a water output belt clamp valve (8); the water output belt clamp valve (8) is connected with a water output belt (9) made of a rigid body framework artificial synthetic material; an outlet of the water output belt (9) made of the rigid body framework artificial synthetic material is arranged above an apron (10-2) made of an artificial synthetic material; the downstream of the apron (10-2) made of the artificial synthetic material is connected with a rope net pile sandbag baffle sill (11); and the downstream of the rope net pile sandbag baffle sill (11) is connected with an apron extension (10-3) made of an artificial synthetic material. The siphon frieze group is suitable for controllable flood diversion of exceeding-standard floods for dikes, dams and auxiliary dams and dam flood diversion and rescue.

Owner:HEILONGJIANG UNIV +1

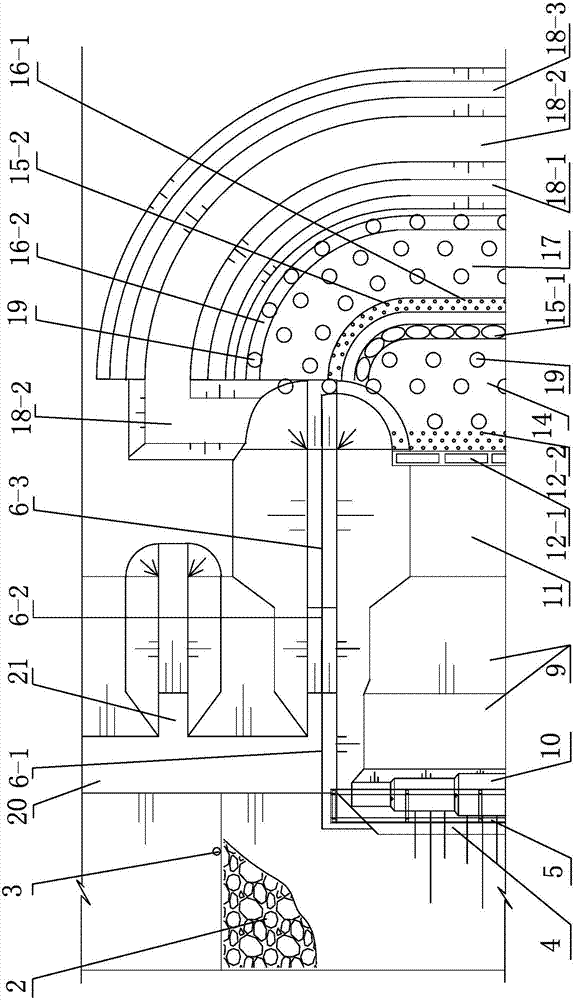

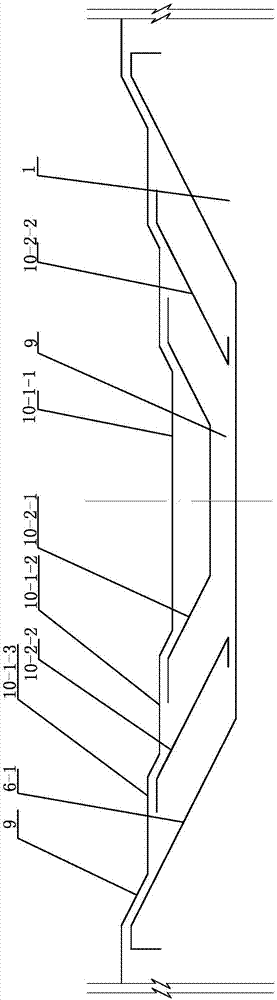

Multi-stage self-collapsing soil flood diversion dam protected by geosynthetics

ActiveCN105625259BMake sure not to breakEnsure safetyDamsClimate change adaptationDiversion damEngineering

Owner:HEILONGJIANG UNIV

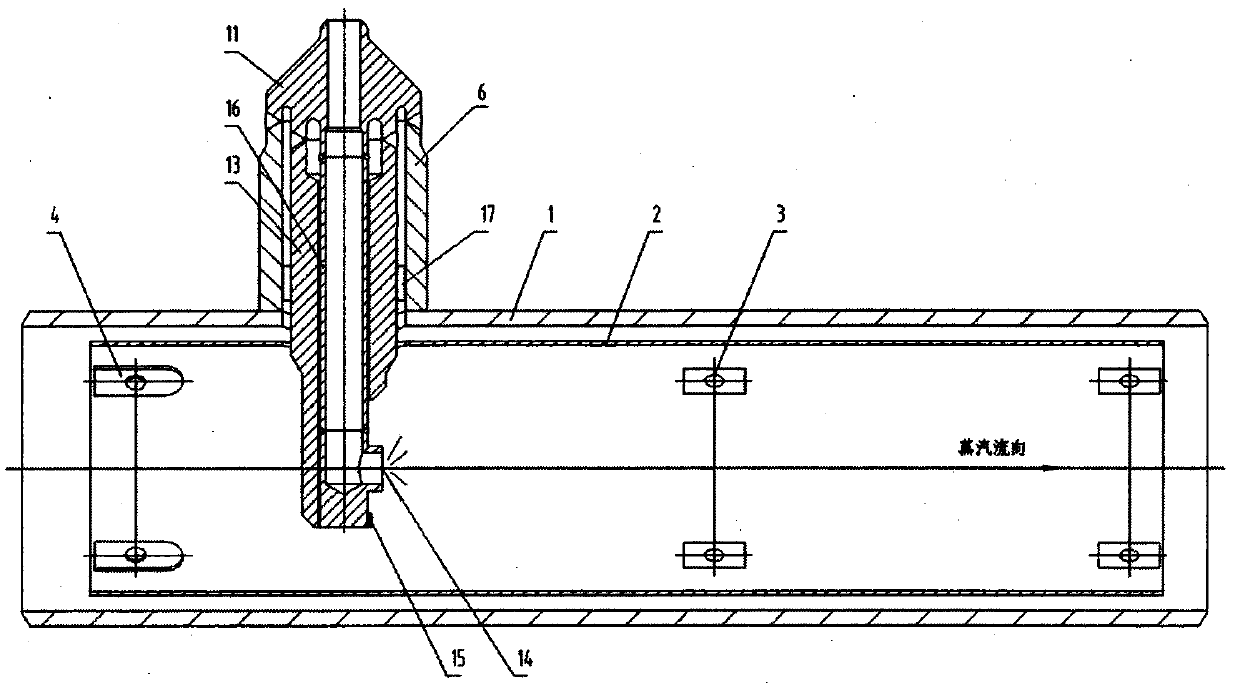

Composite bushing type water spraying desuperheater

The invention provides a composite bushing type water spraying desuperheater which comprises a cylinder body and an inner bushing arranged inside the cylinder body, wherein a body pipe seat is arranged above one end of the cylinder body. The composite bushing type water spraying desuperheater is characterized in that a spray nozzle strengthened protection pipe is coaxially arranged inside the body pipe seat; an outer-layer pipe mouth of the composite seat pipe is connected with the spray nozzle strengthened protection pipe; the lower end of an inner-layer pipe mouth of the composite pipe seat is arranged inside the upper end of the outer-layer pipe mouth of the composite pipe seat; the upper end of a spray nozzle pipe which is coaxially arranged inside the spray nozzle strengthened protection pipe is connected with the inner-layer pipe mouth of the composite pipe seat; and a fixed support block is arranged below the spray nozzle pipe. According to the composite bushing type water spraying desuperheater disclosed by the invention, the defects in the prior art are overcome; due to the adoption of the sealed composite bushing seat and the spray nozzle strengthened protection pipe, the application range of the composite bushing type water spraying desuperheater is widened and the safety and the reliability of the operation process of the composite bushing type water spraying desuperheater are enhanced. The composite bushing type water spraying desuperheater has the advantages of simple structure, convenience in manufacture and assembly and convenience in maintenance.

Owner:SHANGHAI BOILER WORKS

Steel for high-frequency resistance welding petroleum casing pipe, casing pipe and manufacturing method thereof

ActiveCN102839324BGood resistance to carbon dioxide corrosionIncrease the equivalentDrilling rodsDrilling casingsButt weldingCarbon dioxide corrosion

The invention relates to steel for a petroleum casing pipe. The steel for the petroleum casing pipe comprises the components in percentage by mass: 0.05 to 0.10 percent of C, 0.10 to 0.30 percent of Si, less than 0.015 percent of P, less than 0.003 percent of S, 0.1 to 0.3 percent of Mn, 2 to 2.5 percent of Cr, 0.01 to 0.04 percent of Al and the balance of Fe and unavoidable impurities, wherein the total amount of impurity elements is less than 0.05 weight percent; and the carbon equivalent is not greater than 0.6. The invention also relates to the petroleum casing pipe made of the steel. The manufacturing method for the steel comprises the following processes of: a hot rolling process of the steel for the petroleum casing pipe: the finish rolling temperature is 850 to 890 DEG C, and the coiling temperature is 620 to 660 DEG C; a carbon dioxide gas protection welding process for coiled plate butt welding: the wire feeding speed is 12 to 14 m / min, the current is 557 to 561 A, the welding speed is 52 to 54 cm / min, and the gas flow is 23 to 25 L / min; and overall pipe heat treatment: heating and keeping the temperature of 900 to 950 DEG C for 40 to 70 minutes, tempering at the temperature of 620 to 650 DEG C after water quenching, and keeping the temperature for 60 to 80 minutes. The high-frequency resistance welding petroleum casing pipe provided by the invention has the steel grade of 80 ksi and high carbon dioxide corrosion resistance; and the annual average corrosion rate of a finished pipe is below 1 / 3 of that of a conventional N80 oil well pipe.

Owner:BAOSHAN IRON & STEEL CO LTD

Onion Transplanter

ActiveCN106664914BMake sure not to breakNot easy to hurt seedlingsTransplantingAgricultural engineeringTractor

The invention discloses an onion seedling transplanting machine. The onion seedling transplanting machine comprises a tractor, a seedling guide plate, a tray and a transplanter, wherein a front bracket is mounted at the front end of the tractor, tray racks are arranged at the two side ends of the front bracket, the tray is placed on the tray racks; a supporting frame is arranged at the rear end of the tractor, the rear end of the supporting frame is connected with a crossbeam frame, the seedling guide plate is placed at the rear end of the crossbeam frame, an upper guard plate is arranged at the upper end of the seedling guide plate, a lower guide plate is arranged at the lower end of the seedling guide plate, an adjusting lever is arranged at the rear end of the lower guide plate, travelling land wheels are arranged at the lower end of the lower guide plate, a power transmission device is arranged at the front end of the lower guide plate and is connected with the transplanter, the transplanter is arranged in a manner that the front part is lower and the rear part is higher, and a seedling falling device is mounted at the upper end of the transplanter; a right size for transplanted seedlings is changed through changing the transmission ratio of the transplanting mechanism. The duckbill-type transplanter can be used for carrying out direct-perforated transplanting on films, seedlings are not damaged easily, and the requirements of a variety of pot-seedling crops on transplanting operation can be met, so that the onion seedling transplanting machine has been evolves as an ideal model for on-film transplanting; the condition that the onion seedlings are not damaged is ensured.

Owner:QIQIHAR UNIVERSITY

Method for cleaning extruding machine and die head of multilayer co-extrusion film blowing equipment

ActiveCN102431141BIncrease flushing powerShorten cleaning timeHollow article cleaningProcess engineeringNew materials

The invention discloses a method for cleaning an extruding machine and a die head of multilayer co-extrusion film blowing equipment. The method comprises the following steps of: after the last batch of formulated products are produced by extruding the last batch of formulated materials out of all extruding machines respectively, adding new materials into corresponding extruding machines respectively to start cleaning the machine until the new materials clean the last batch of materials out of the extruding machine and the die head completely; and in the machine cleaning process, making the extrusion speeds of all the extruding machines continuously fluctuated and changed up and down by using a central controller, wherein the maximum extrusion speed of all the extruding machines at the highest speed reaches 1.4 to 1.8 times the normal extrusion speed of the extruding machine, but the sum of the extrusion speeds of all the extruding machines is kept constant at all time points in the machine cleaning process. In the method, an oscillating extrusion mode is used for all the extruding machines, so that the time consumed in the machine cleaning process is short, and a small number of raw materials are consumed.

Owner:GUANGDONG JINMING MACHINERY +1

Sleeve base type water spraying desuperheater

ActiveCN107606597AImprove structural strengthIncrease recoilSuperheating controlArchitectural engineeringWater spray

The invention discloses a sleeve base type water spraying desuperheater. The sleeve base type water spraying desuperheater comprises a cylinder; a lining sleeve is arranged in the cylinder; and the cylinder is fixedly connected with the lower end of a main body pipe base. The sleeve base type water spraying desuperheater is characterized in that a nozzle reinforcing protective pipe and a nozzle pipe are coaxially arranged in the main body pipe base; the nozzle reinforcing protective pipe sleeves the outer side of the nozzle pipe; the upper end of the main body pipe base, the upper end of the nozzle reinforcing protective pipe and the upper end of the nozzle pipe communicate with outer, middle and inner layers of pipe orifices at the lower end of a sleeve base with the outer, middle and inner layers of pipe orifices; the pipe orifice at the upper end of the sleeve base with the outer, middle and inner layers of pipe orifices is connected with an external water spraying pipe; the tail end of the nozzle pipe is arranged in the cylinder; and a nozzle is arranged at the tail end of the nozzle pipe. Through totally sealed sleeve base with the outer, middle and inner layers of pipe orifices and the nozzle reinforcing protective pipe, the application range of the water spraying desuperheater is widened, and the safety and the reliability in the operating process of the water spraying desuperheater are improved; and the water spraying desuperheater is simple in structure and convenient to manufacture, assemble and maintain.

Owner:SHANGHAI BOILER WORKS

Plukenetia volubilis linneo shelling process

ActiveCN102894450BQuality assuranceGuaranteed to proceed normallyHuskingHullingComputer scienceDeep processing

The invention discloses a plukenetia volubilis linneo shelling process and a special segment breaking device. The plukenetia volubilis linneo shelling process comprises the following steps of: performing segment breaking treatment on picked and dried plukenetia volubilis linneo; performing sorting and impurity removal on the plukenetia volubilis linneo subjected to segment breakage; classifying single segments of the impurity-free plukenetia volubilis linneo according to sizes; performing primary shelling and sorting treatment on the classified single segments of the plukenetia volubilis linneo; classifying the plukenetia volubilis linneo with inner shell according to the size of the inner shell of the plukenetia volubilis linneo; and performing secondary shelling and sorting treatment on the classified plukenetia volubilis linneo with the inner shell to obtain the impurity-free plukenetia volubilis linneo kernel. The plukenetia volubilis linneo shelling process and the special segment breaking device have the advantages that mechanical production of lukenetia volubilis linneo shelling is realized, the production efficiency is greatly increased, raw material treatment capacity of 1.5-2 ton / hour is reached, the rate of perfect kernel of the kernels reaches over 95 percent, the product quality of the kernels is improved, the process and the device are suitable for large-scale industrial production and conditions are created for industrial development of the lukenetia volubilis linneo and deep processing of a product.

Owner:JINZHOU QIAOPAI MACHINERIES +1

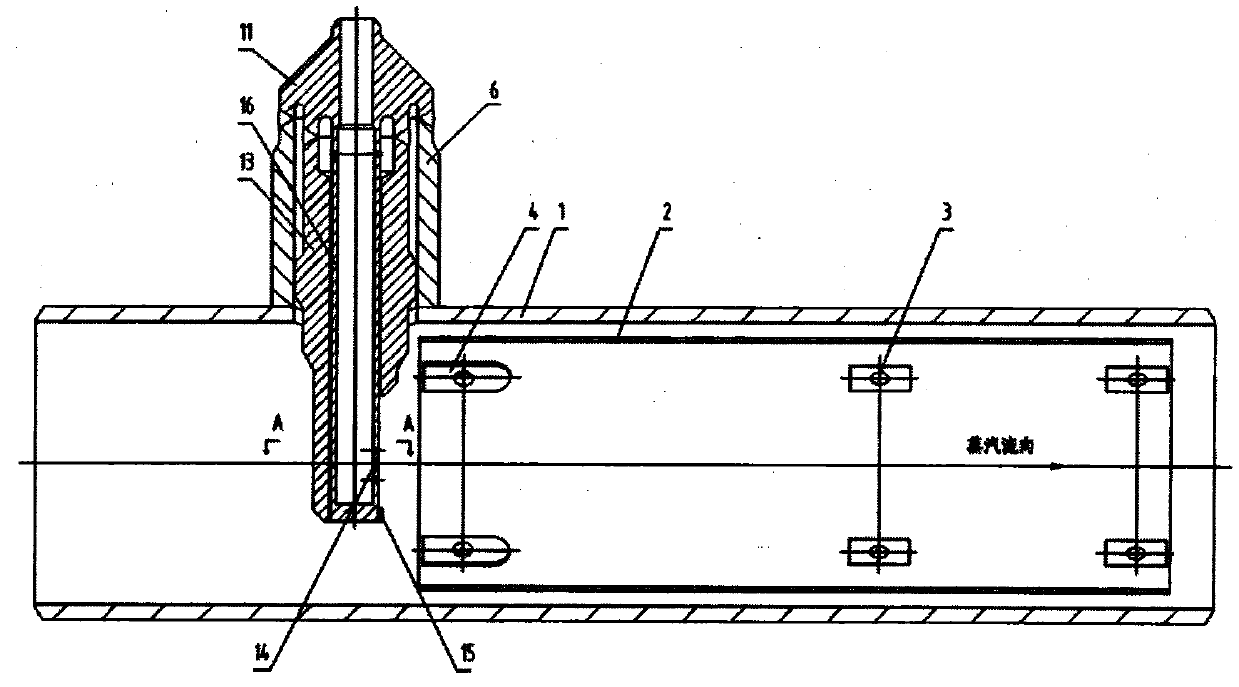

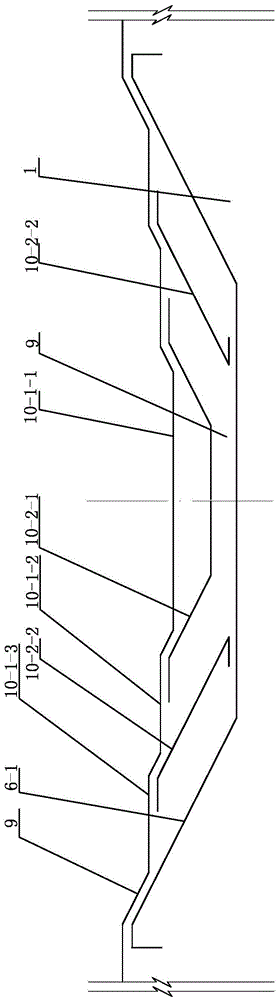

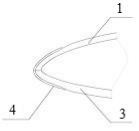

Multistage self-bursting soil flood diversion dam protected through geosynthetic materials

ActiveCN105625259AMake sure not to breakEnsure safetyDamsClimate change adaptationDiversion damEngineering

Disclosed is a multistage self-bursting soil flood diversion dam protected through geosynthetic materials. According to the multistage self-bursting soil flood diversion dam protected through the geosynthetic materials, a slope protection (2) is arranged within the upstream scouring protection range of a soil water passing dam (1), and an automatic water level indicator (3) is arranged on an upstream slope of the soil water passing dam (1); a platform (4) is laid at the upstream end of the soil water passing dam (1), and the weir crest of the soil water passing dam (1) is connected with a trapezoidal weir surface geosynthetic material protection surface (6-1); a downstream slope of the soil water passing dam (1) is connected with a trapezoidal discharge chute geosynthetic material protection surface (6-2); a rope-tied non-woven fabric threading fixing foot (8) is arranged at the bottom of a downstream slope foot of the soil water passing dam (1); and a fixing body I (7-1) is arranged at the bottom of the upstream end of the trapezoidal weir surface geosynthetic material protection surface (6-1), and a fixing body II (7-2) is arranged at the bottom of the downstream end of the trapezoidal weir surface geosynthetic material protection surface (6-1). The multistage self-bursting soil flood diversion dam is used for flood diversion of the soil dam.

Owner:HEILONGJIANG UNIV

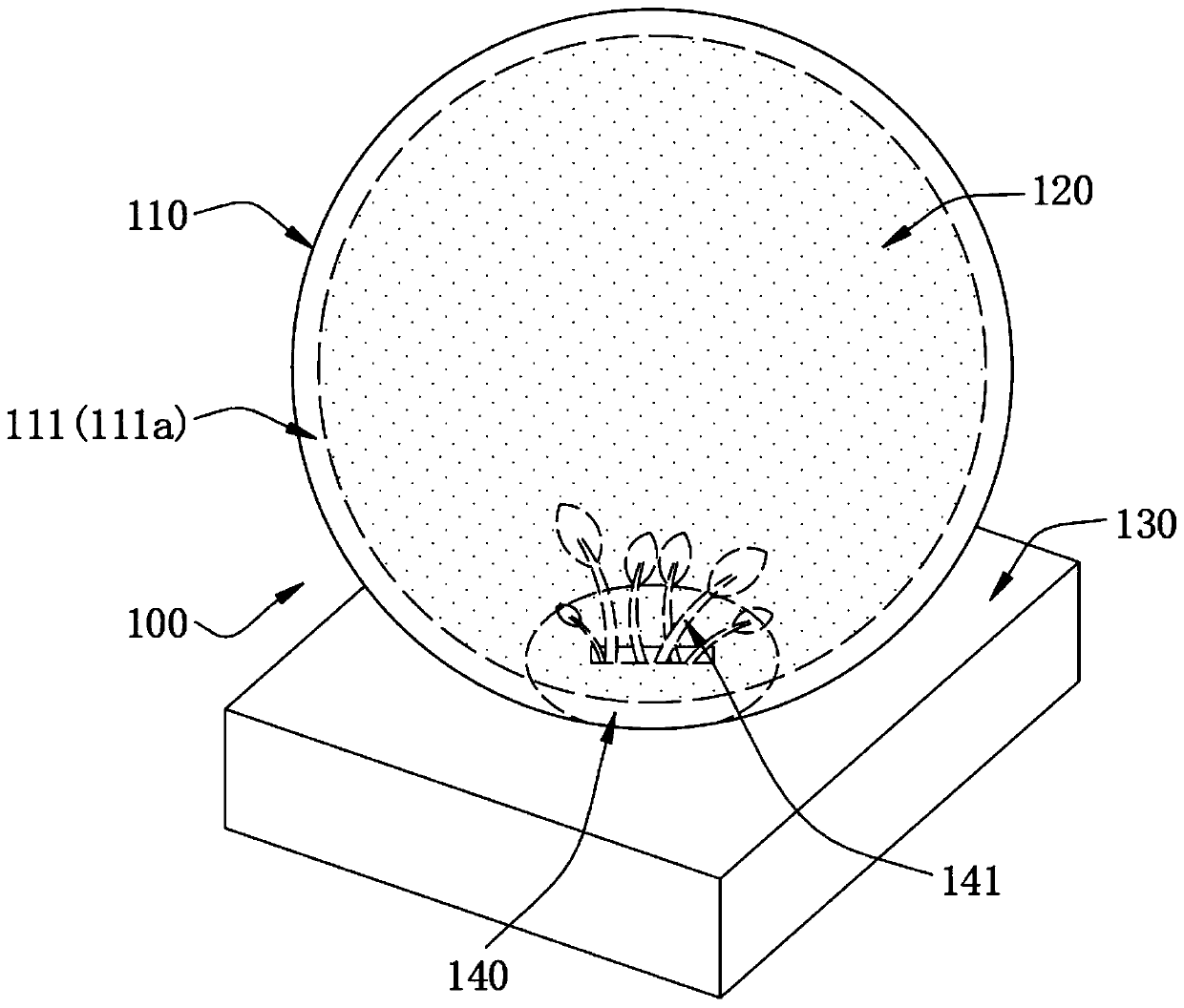

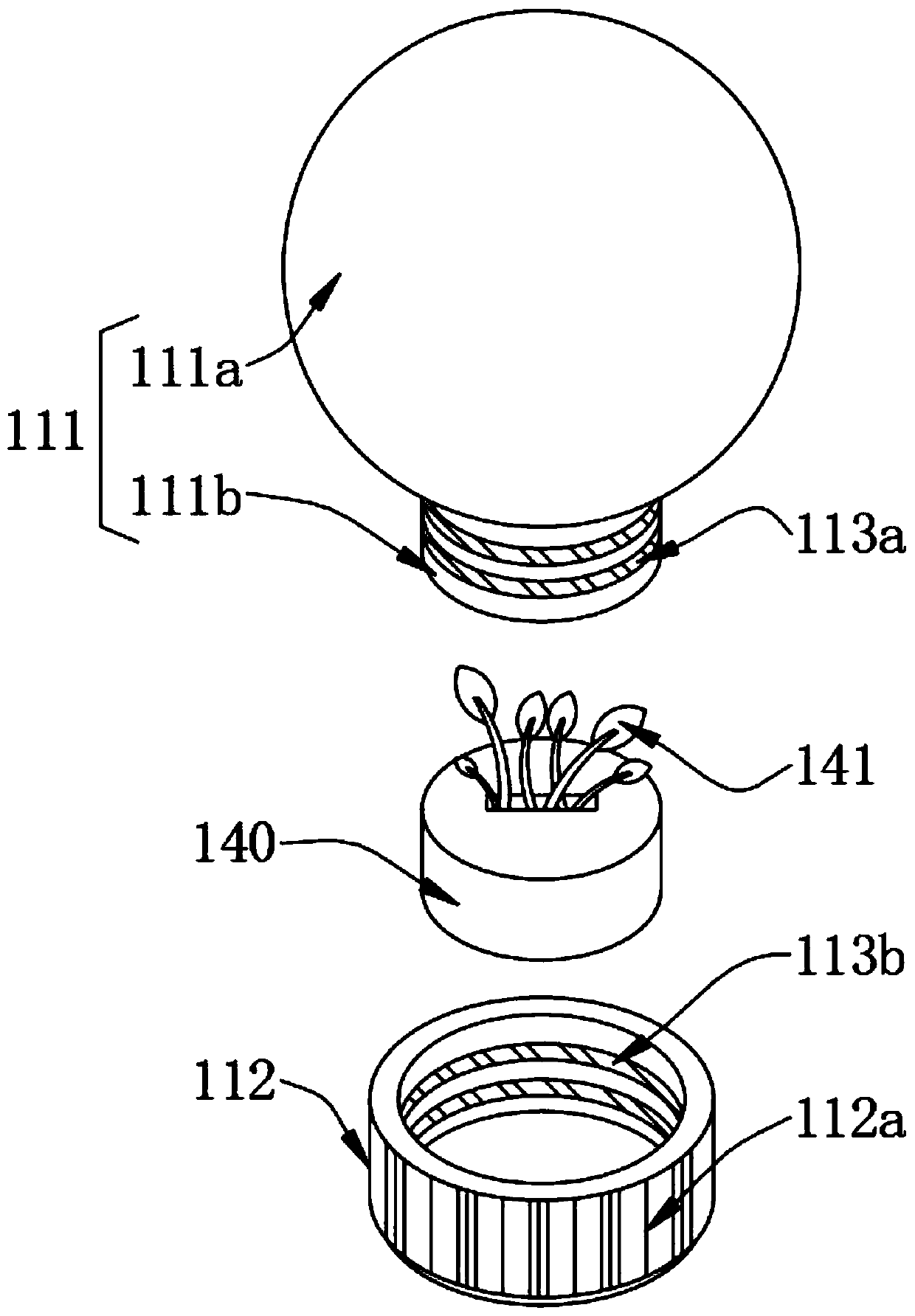

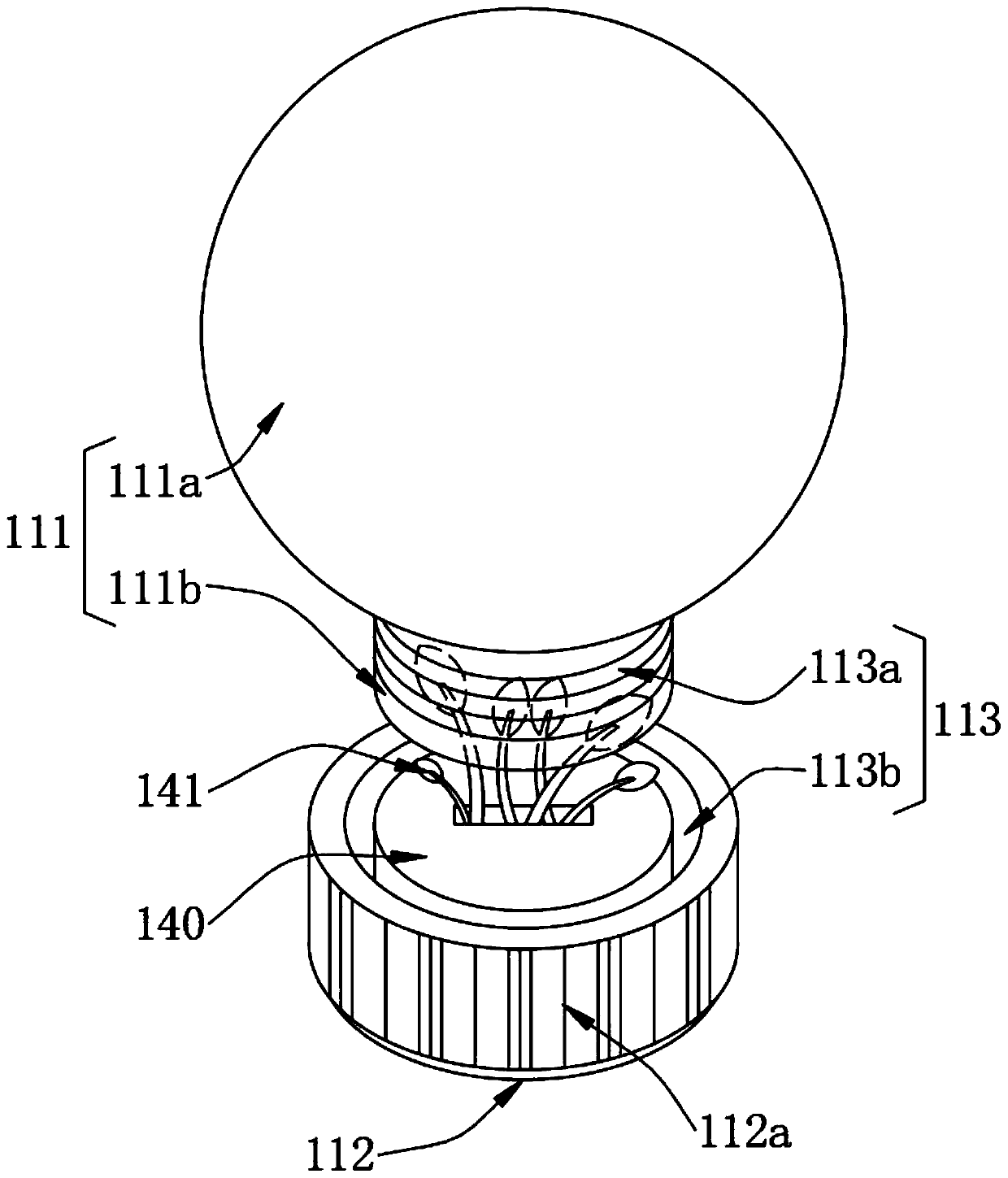

Snowball-type hand-throwing fire extinguisher

PendingCN110433422AConvenience guaranteedMake sure not to breakFire rescueFire extinguisherFire detectionEngineering

The invention belongs to the technical field of fire fighting equipment, and particularly relates to a snowball-type hand-throwing fire extinguisher. The snowball-type hand-throwing fire extinguishercomprises a fire extinguisher body, wherein the fire extinguisher body comprises a fire extinguishing liquid receptor, fire extinguishing liquid filling the fire extinguishing liquid receptor, a placement support clamped at the bottom of the fire extinguishing liquid receptor, and a decoration part located inside the fire extinguishing liquid receptor to achieve a decoration effect. The fire extinguishing liquid receptor comprises a receptor main body used for bearing the fire extinguishing liquid and a plug component used for placing the decoration component. The snowball-type hand-throwing fire extinguisher can be thrown into a fire source as a fire extinguisher for fire extinguishing when a fire occurs, and can be used as a decoration at ordinary times, thereby ensuring decoration effect and the convenience of visual position confirmation, improving the placement by ensuring that the fire extinguishing liquid receptor is not damaged, and is placed stably and safely, and improving the product competitiveness after realizing various functions of music, illumination, fire detection, reminding and the like besides the functions of fire extinguishing and the indoor decoration.

Owner:卓振雄

Dike and dam superstandard flood flood diversion belt

ActiveCN105544455BMake sure not to breakEnsure safetyHydraulic engineering apparatusSynthetic materialsEmergency rescue

Owner:HEILONGJIANG UNIV +1

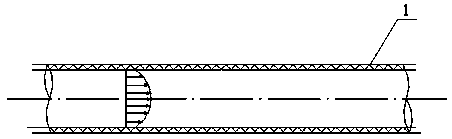

A low voltage power cable

ActiveCN105913948BFlame retardantHalogen freePower cables with screens/conductive layersFlexible cablesElectricityElectrical conductor

The invention discloses a low-voltage power cable, which comprises a conductor, a shielding and wrapping layer, an insulating layer, a shielding layer, a wrapping layer, a steel wire armor layer and an outer sheath, wherein the shielding and wrapping layer wraps the outside of the conductor; the insulating layer wraps the outside of the shielding and wrapping layer in an extruding manner; the shielding layer coats the outside of the insulating layer; the wrapping layer wraps the outside of the shielding layer; the steel wire armor layer coats the outside of the wrapping layer; and the outer sheath coats the outside of the steel wire armor layer in an extruding manner. A special structure and a special cable material for the insulating layer and the outer sheath are adopted by the cable, so that the cable has the characteristics of high temperature resistance, ageing resistance, excellent electrical property and the like, also has very outstanding fireproof performance, can withstand certain water spraying and vibration of certain strength, has outstanding bending performance and flexible performance and can ensure that a circuit is not broken and is not in a short circuit. The cable has the characteristics of being flame-retardant, free of halogen and low in smoke, accords with the European Union ROHS instruction, and does not generate a corrosive and toxic substance or gas during combustion and does not generate a secondary hazard to affected people.

Owner:QINGDAO CABLE

Tensile photovoltaic cable capable of adapting to severe environment

PendingCN114121364AProtect genuine useMake sure not to breakCommunication cablesInsulated cablesEngineeringStructural engineering

The invention is applicable to the technical field of photovoltaic cables, and provides a tensile photovoltaic cable capable of adapting to a severe environment. A spiral sleeve is arranged at the center, and a plurality of insulating rope groups are annularly arranged on the outer side of the spiral sleeve along the axial direction of the photovoltaic cable; each insulating rope group is formed by mutually crossing and winding two S-shaped ropes, and the whole insulating rope group is a plurality of diamonds which are connected end to end, so that each insulating rope group can be deformed through the diamonds when the two ends are pulled, the two ends are lengthened, the middle is narrowed, and the pulling deformation of the two ends is adapted; meanwhile, the spiral sleeve can also adapt to pulling deformation of the two ends, and a first wire core located between the spiral sleeve and the insulating rope set, a second wire core located in the middle of the insulating rope set and a third wire core spirally arranged between the insulating rope set and the flame-retardant layer can relieve the pulling situation through spiral arrangement; therefore, the adaptation of the tensile state is completed, and the internal wire core is ensured not to be broken.

Owner:张家港南源光电科技有限公司

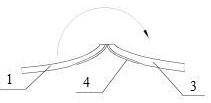

Wing leading edge structure, forming mold and preparation method thereof for micro-miniature unmanned aerial vehicle

ActiveCN108248824BReduce workloadReduce weightWing shapesWeight reductionLeading edgeUncrewed vehicle

The invention provides a micro-miniature unmanned aerial vehicle wing leading edge structure, a forming mold and a preparation method thereof, which belong to the technical field of unmanned aerial vehicles, can avoid cracking of the wing leading edge during use, and reduce production and processing costs while controlling the weight of the structure . In the present invention, the upper and lower wall panels are connected together through the flexible cloth layer at the leading edge. When the airfoil is not assembled into a complete airfoil, the upper and lower wall plates can be turned over along the axis of the flexible cloth layer at the leading edge, which is an integral joint structure. It can ensure that the leading edge of the airfoil does not crack without increasing the structural weight, labor intensity and cost; the corresponding forming mold is that the surface of the airfoil and the lower wall plate are in the same mold, and the upper wall plate is separated along the leading edge of the airfoil The axis is flipped by 180°, and the front edge of the upper wall plate is close to the front edge of the lower wall plate along the separation axis.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Dike super standard flood flood diversion siphon belt

ActiveCN105603942BMake sure not to breakEnsure safetyBarrages/weirsArtificial islandsSiphonSynthetic materials

Owner:HEILONGJIANG UNIV +2

Wide-body bead string handbag

Owner:朱留平

A release coating suitable for high-speed peeling transfer aluminum-coated paper

The invention provides a kind of release coating that is suitable for the transfer aluminized paper of high-speed stripping, and this release coating is to be to comprise the polybutyl methacrylate of 15-25%, the acetic acid butyric acid of 5-14% by weight percentage Cellulose, 0.5%-1% polyether-modified silicone, 23-25% methyl ethyl ketone, 20-23% ethyl acetate and the rest of other solvents are firstly mixed with polybutyl methacrylate and acetic acid butyric acid Put half of the cellulose, butanone and ethyl acetate into the high-speed disperser, stir and disperse at a speed of 500-1000rpm / sec for 30 minutes, control the temperature between 40-50°C, and then add the remaining butanone and ethyl acetate Esters, other solvents, and polyether-modified silicone, continue to mix and stir for 30 minutes, let the materials cool naturally to between 20-30°C, and filter to obtain. The release coating of the present invention is applied to transfer aluminum-plated paper, and it is peeled and cut on a high-speed in-line peeling machine with a machine speed of 200-280m / min, so that no flying aluminum will occur, the coating is complete and clean, and there is no drop point. , and the coating has good solvent resistance.

Owner:汕头市龙湖昌丰化工有限公司

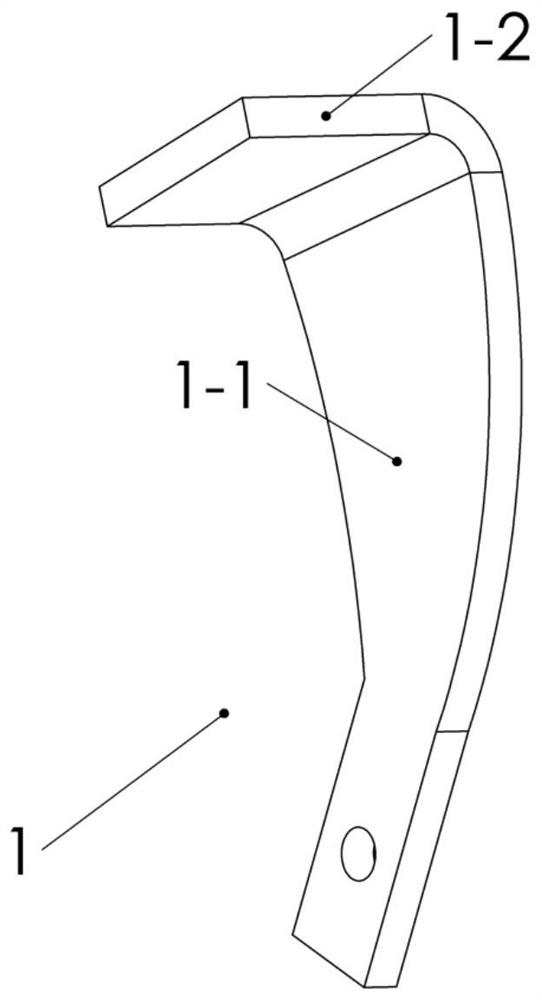

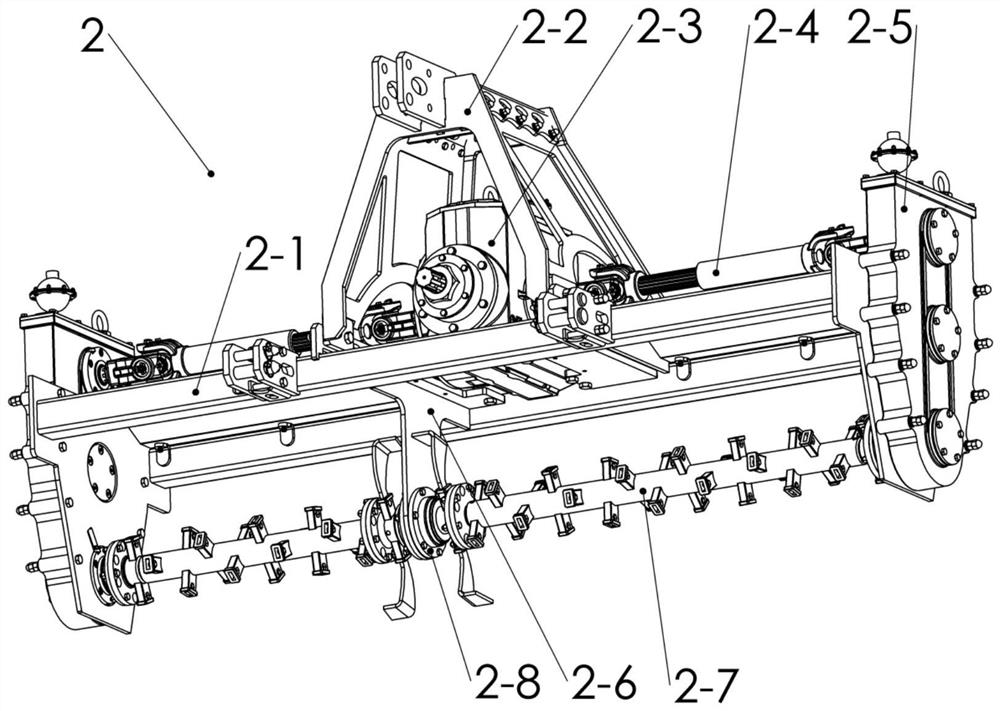

Supporting seat between rotary tillage shafts and rotary cultivator

PendingCN114097317AMake sure not to breakCrop conditionersMowersAgricultural engineeringStructural engineering

The invention discloses a bearing seat between rotary tillage shafts and a rotary cultivator, belongs to the field of agricultural machinery, and aims to solve the problems that the rotary tillage shafts of the conventional rotary cultivator are broken, soil at a bearing plate cannot be crushed by a rotary blade, and straws of crops cannot be cut and returned to the field by the rotary blade. Comprising a mounting end arranged on a rack of the rotary cultivator and a mounting end of a bearing seat, the mounting end of the bearing seat is provided with a bolt hole, or the mounting end of the bearing seat is provided with a bolt hole and a passing hole of a transition shaft. Trapezoidal steps or grooves are arranged between the mounting end of the rack of the rotary cultivator and the mounting end of the bearing seat, the trapezoidal steps or the grooves are arc-shaped, and the rotary tillage shaft is provided with a soil returning blade part of the rotary tillage blade and the rotary tillage blade which is matched with the trapezoidal steps or the grooves on the bearing seat between the rotary tillage shafts. The soil at the supporting seat between the rotary tillage shafts is crushed by the rotary tillage cutter, and straws of crops can be cut and returned to the field by the soil returning cutting edge part of the rotary tillage cutter.

Owner:戴红亮

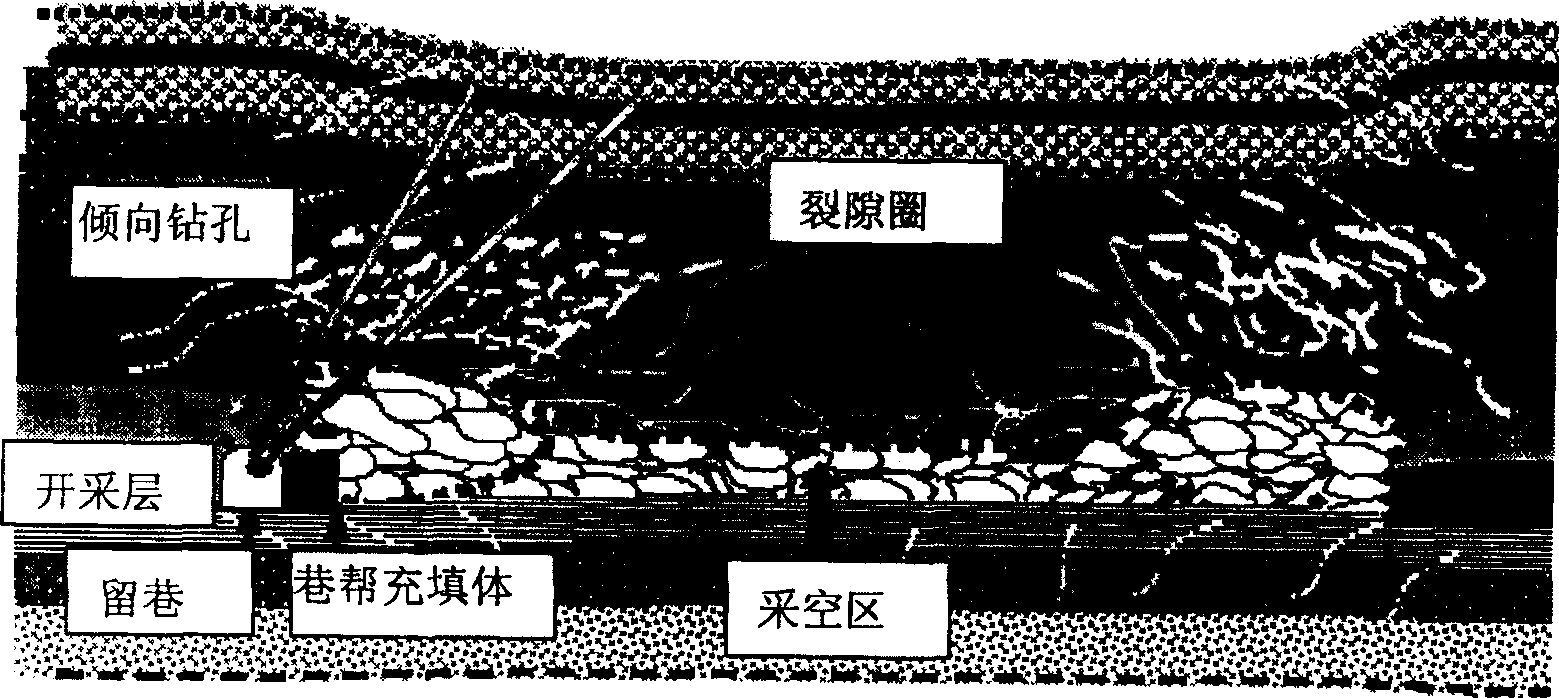

Method of supporting along spatially keeping lane end

ActiveCN100464057CSelf-leveling denseWell mixedMaterial fill-upProps/chocksSpontaneous combustionArchitectural engineering

A method for supporting and protecting gob roadway walls built along the gob road-way is characterized in that the filling bodies of gob roadway walls are built along the working surface at the side of the goaf to establish a supporting and protecting belt for gob roadway walls. The method can effectively control the roof delamination of a direct roof and can timely cut off the roof and the lower basic roof and also can fill out goaf with the falling recrement, thereby reducing the bending of the basic roof, and the loading of the inner supporting and protecting structure and the deformation of the wall rock of the gob roadway, as well as keeping the stability of the gob roadway, meanwhile, the method also can seal the goaf, prevent air leaking and spontaneous combustion of coal, and avoid harmful air coming into the working area.

Owner:HUAINAN MINING IND GRP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com