Sleeve base type water spraying desuperheater

A technology of spraying water for desuperheating and casing seat, which is applied in the control of superheating temperature, steam superheating, steam generation, etc., can solve the problems of low application range of design temperature and design pressure, cumbersome assembly process, complex structure, etc., to avoid Leakage defects and limitations of low temperature and low pressure use, reasonable and convenient operation procedures, and the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

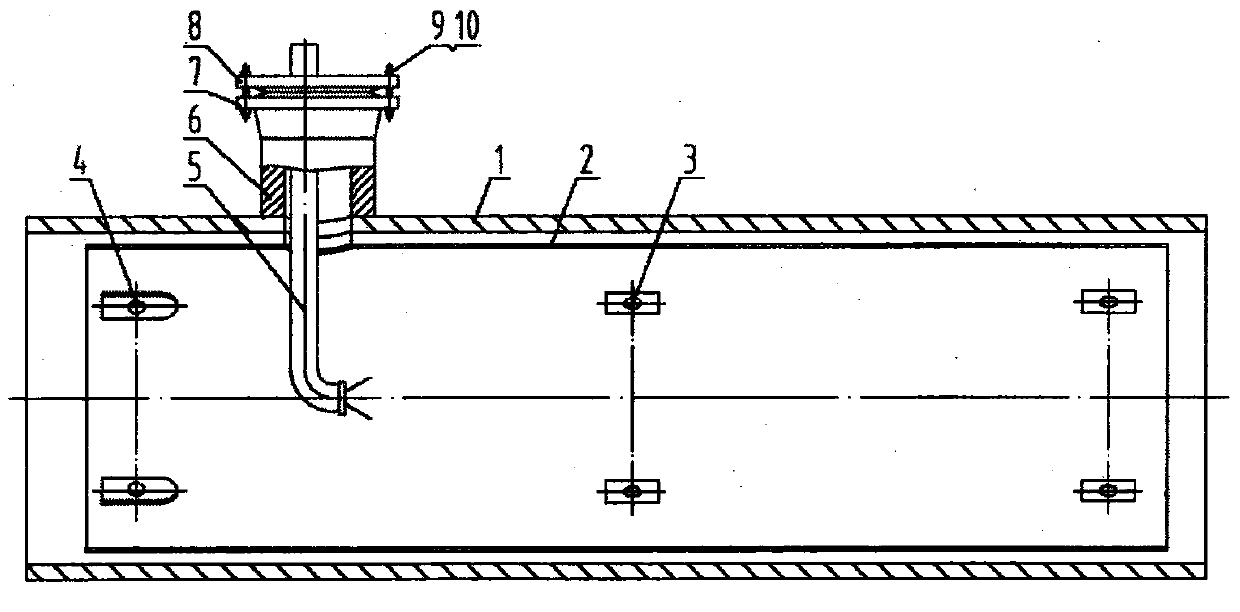

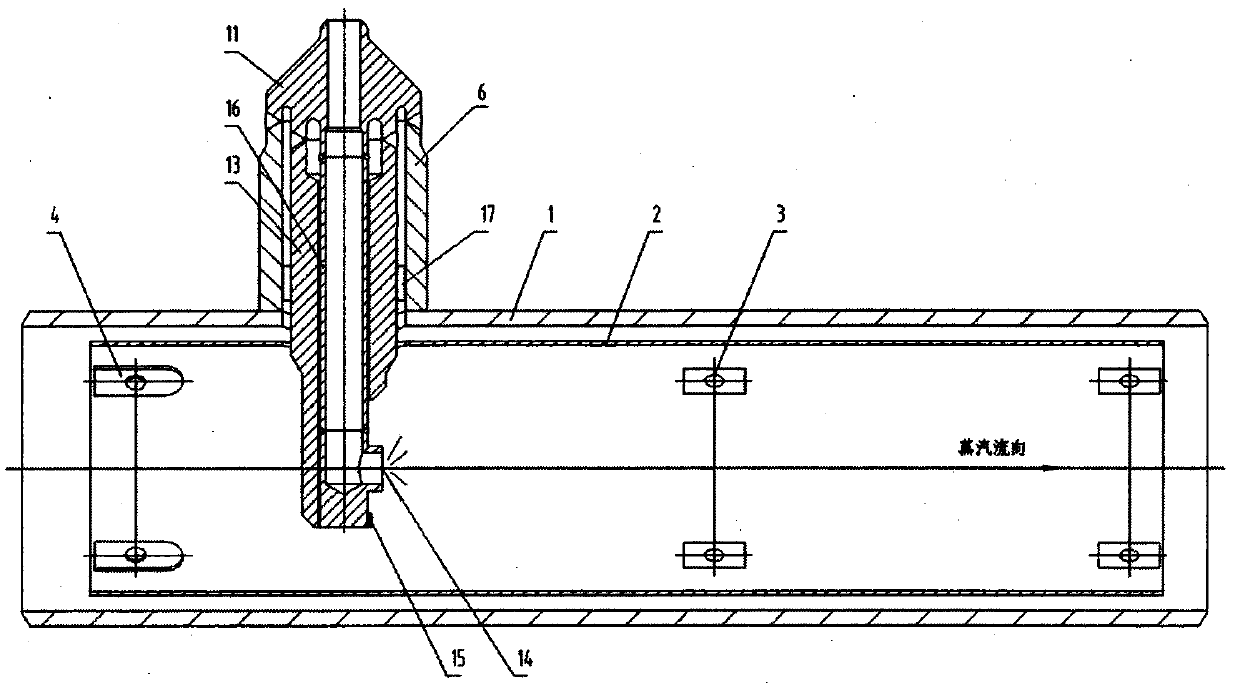

[0024] The present invention is a casing seat type water spray desuperheater, such as figure 2 As shown, it includes a cylinder body 1, and an inner bushing 2 is built in the cylinder body 1, and the inner bushing 2 is fixed and supported on the cylinder body 1 by fixing bolts 4 and support bolts 3. One end of the inner bushing 2 is fixed in the axial direction of the desuperheater by a fixing bolt 4, and the other end of the inner bushing 2 is a free end, which can expand freely. At other appropriate positions of the inner bushing 2, the supporting bolts 3 are used to support and position the inner bushing 2 in the radial direction. The cylinder body 1 and the inner bushing 2 are provided with matching openings at the corresponding positions of the body pipe seat 6 , the lower end of the body pipe seat 6 is fixedly connected with the cylinder body 1 , and the body pipe seat 6 is arranged above one end of the cylinder body 1 . A nozzle pipe 16 is inserted into the body pipe ...

Embodiment 2

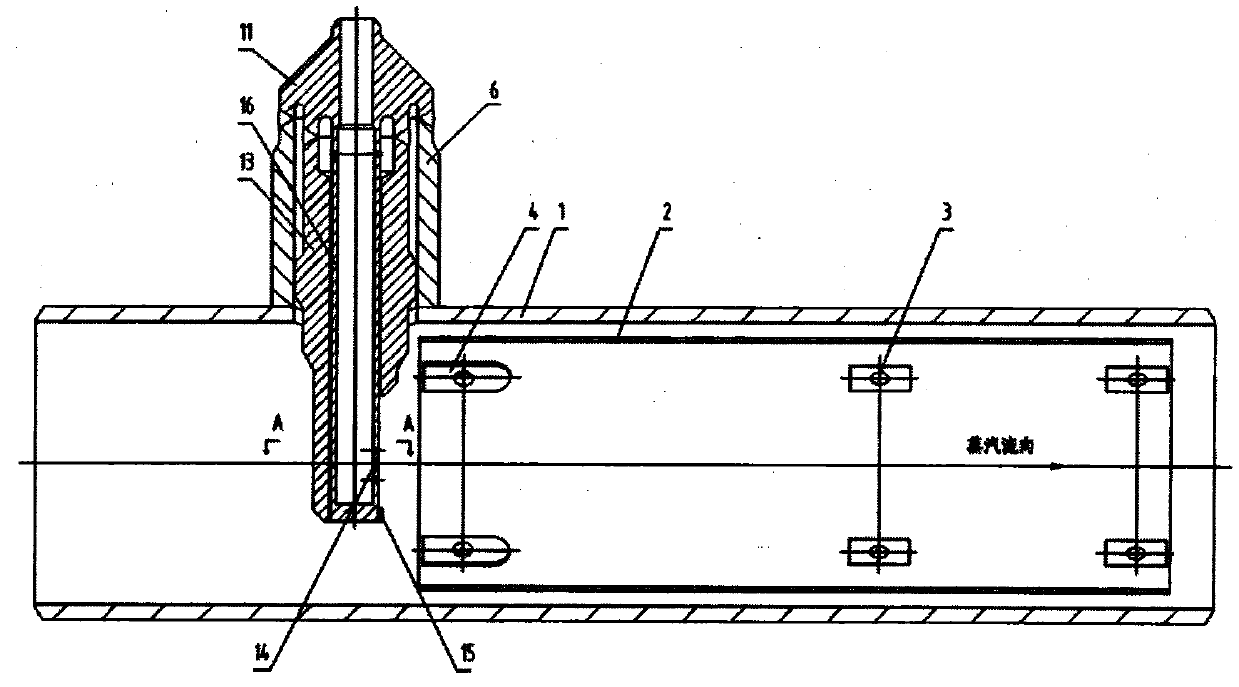

[0027] Such as image 3 , Figure 4 As shown, in this embodiment, the end of the nozzle pipe 16 is located inside the cylinder body 1 and outside the inner bushing 2. This end is a blind end, and there are holes on the end to form a flute-shaped nozzle 14. The coaxial positioning steel plate 17 can be replaced by a protrusion on the outer peripheral surface of the nozzle reinforcing protection tube 13 for coaxial positioning.

[0028] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com