A release coating suitable for high-speed peeling transfer aluminum-coated paper

A high-speed peeling, aluminized paper technology, applied in the direction of coating, can solve the problems of intolerant solvent, poor layability, poor aluminizing effect, etc., and achieve the effect of good solvent resistance and complete and clean coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

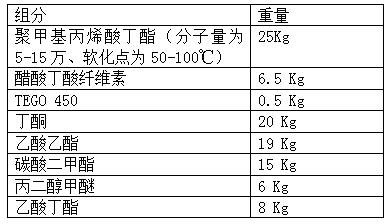

[0017] 1. Formula

[0018]

[0019] 2. Preparation

[0020] (1) Weigh polybutyl methacrylate and cellulose acetate butyrate according to the above formula, and mix them uniformly for later use;

[0021] (2) Weigh half of butanone and ethyl acetate (butanone 11.5kg, ethyl acetate 11.25kg) into the high-speed disperser, turn on the high-speed disperser, control the speed at 800-1000rpm, and then mix step (1) Add all the good resin slowly, continue to stir and disperse at a speed of 1000rpm / second for 30 minutes, and control the temperature between 40-50°C;

[0022] (3) Add the remaining butanone, ethyl acetate and n-propyl acetate, and calculate the amount of solvent volatilized in step (2), and fill in the corresponding mixed solvent (butanone: ethyl acetate = 1:1 mixture), Add BYK 333, mix and stir for 30 minutes, let the material cool naturally to between 25-30°C, filter the material through a 600-mesh filter bag, and obtain a powder with a solid content of 31% and a vis...

Embodiment 2

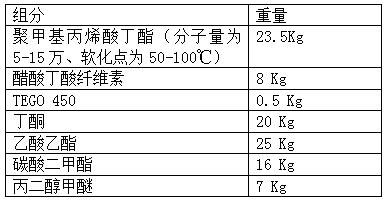

[0029] 1. Formula

[0030]

[0031] 2. Preparation

[0032] (1) Weigh polybutyl methacrylate and cellulose acetate butyrate according to the above formula, and mix them uniformly for later use;

[0033] (2) Weigh half of butanone and ethyl acetate (butanone 10kg, ethyl acetate 12.5kg) into the high-speed disperser, turn on the high-speed disperser, control the speed at 500-800rpm / s, and then step (1) Slowly add all the mixed resin, continue to stir and disperse for 30 minutes at a speed of 800rpm / sec, and control the temperature between 40-50°C;

[0034] (3) Add the remaining butanone, ethyl acetate, dimethyl carbonate and propylene glycol methyl ether, and calculate the amount of solvent volatilized in step (2), and fill in the corresponding mixed solvent (butanone: ethyl acetate = 1: 1 mix), and add TEGO 450, mix and stir for 30 minutes, let the material cool naturally to between 20-25°C, filter the material through a 600-mesh filter bag, and obtain a solid content of 3...

Embodiment 3

[0041] 1. Formula

[0042]

[0043] 2. Preparation

[0044] (1) Weigh polybutylmethacrylate and cellulose acetate butyrate according to the above formula, and mix them uniformly for later use;

[0045](2) Weigh half of butanone and ethyl acetate (butanone 10kg, ethyl acetate 9.5kg) into the high-speed disperser, turn on the high-speed disperser, control the speed at 700-900rpm / s, and then step (1) Slowly add all the mixed resin, continue to stir and disperse at a speed of 900rpm / second for 30 minutes, and control the temperature between 40-50°C;

[0046] (3) Add the remaining butanone, ethyl acetate, dimethyl carbonate, propylene glycol methyl ether and butyl acetate, and calculate the amount of solvent volatilized in step (2), and fill in the corresponding mixed solvent (butanone: ethyl acetate =1:1 mixing), and add TEGO 450, mix and stir for 30 minutes, let the material cool naturally to between 20-25°C, filter the material through a 600-mesh filter bag, and obtain a so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com