Self-adhesion copper foil waste recycling machine

A recycling machine, waste technology, applied in thin material processing, coiling, transportation and packaging, etc., can solve the problems of low efficiency, labor-intensive, affecting the production line 6S, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

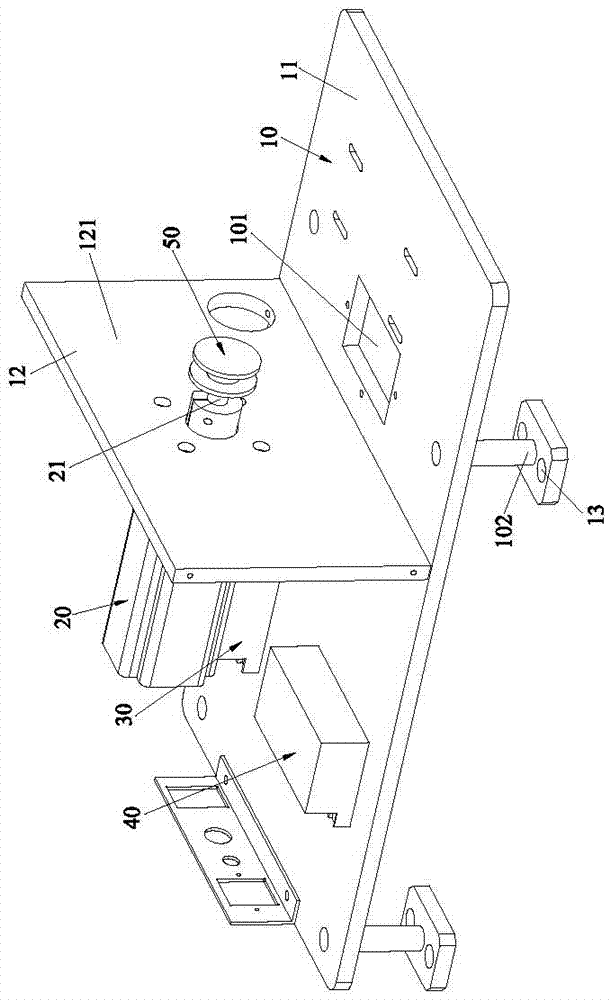

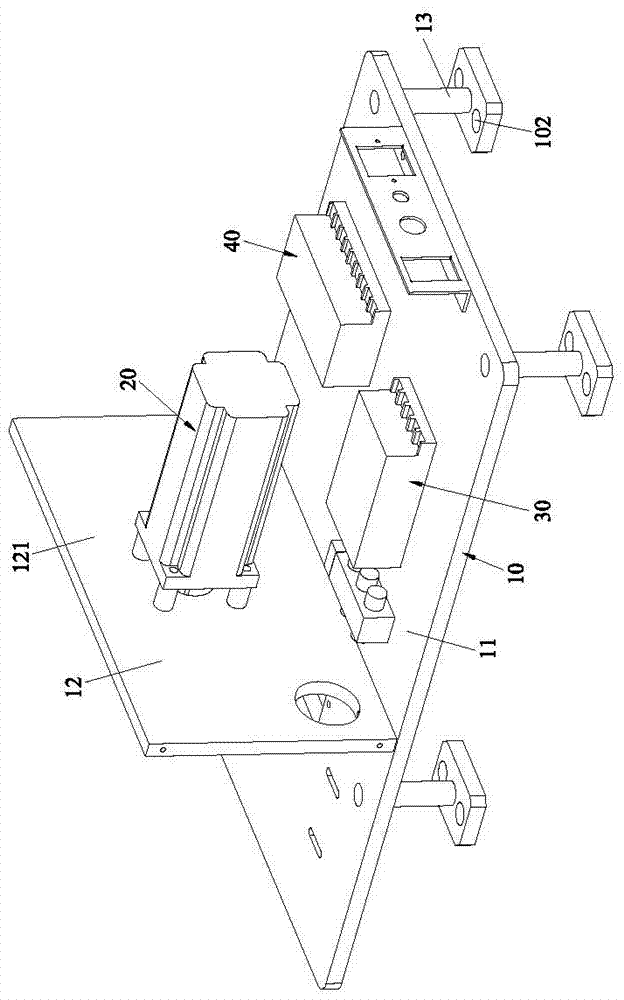

[0021] Please refer to figure 1 and figure 2 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a frame 10 , a motor 20 , a driver 30 , a power supply 40 and a receiving tray 50 .

[0022] The frame 10 includes a support plate 11 and a box body 12 arranged on the support plate 11, the support plate 11 is provided with a discharge port 101; in this embodiment, the bottom of the support plate 11 is provided with a plurality of The supporting foot 13, and the supporting foot 13 is provided with a mounting hole 102, and the mounting hole 102 is used for mounting and fixing with the outside.

[0023] The motor 20, driver 30 and power supply 40 are all arranged in the box body 12, the output shaft 21 of the motor 20 stretches out the front side plate 121 of the box body 12, the driver 30 is connected to the motor 20, and the power supply 40 is connected to the driver 30; In this embodiment, the motor 20 is a stepping motor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com