Supporting seat between rotary tillage shafts and rotary cultivator

A technology of bearing seat and rotary tiller, which is applied in the direction of tillage machines, agricultural machinery and implements, harvesters, etc. It can solve the problems that the rotary tiller cannot be installed, the soil cannot be crushed by the rotary tiller, and the rotary tiller shaft is broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

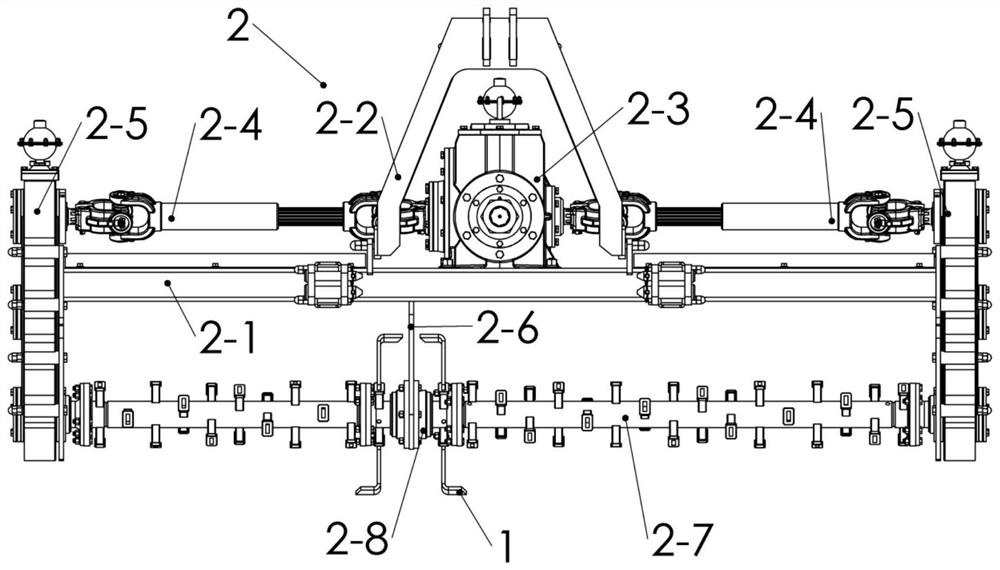

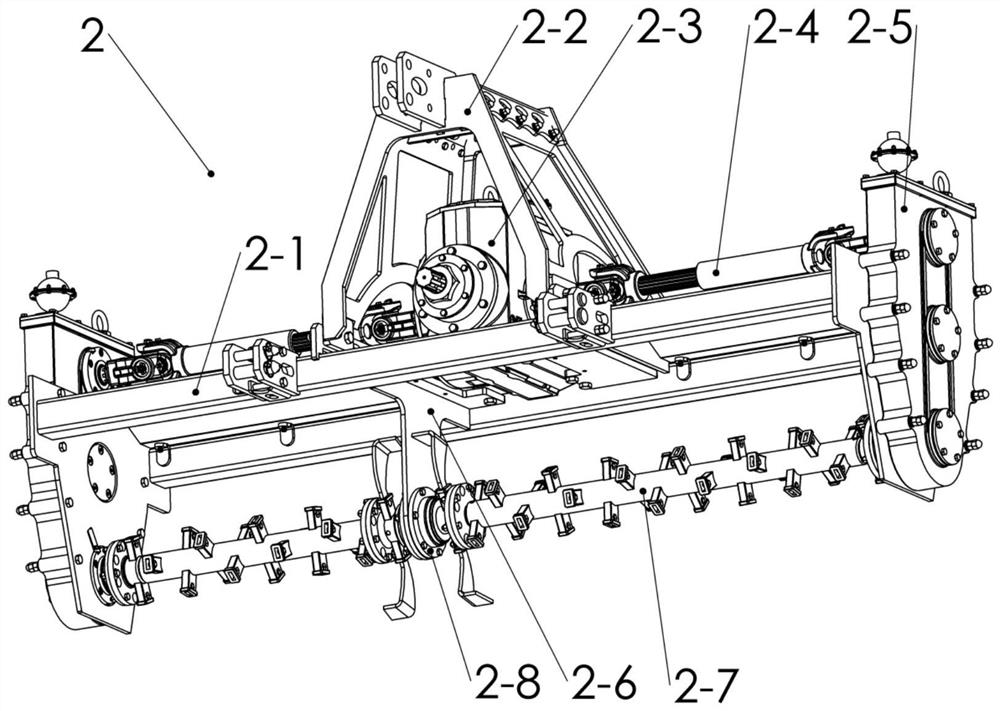

[0050] Such as Figure 11 to Figure 22 As shown, the support seat between the rotary tiller shafts of the present invention includes the installation end 2-6-1 arranged on the rotary tiller frame and the installation end 2-6-2 of the bearing seat, and the installation end 2 of the bearing seat 2 -6-2 is provided with bolt holes 2-6-2-1 (see Figure 11 ), or the mounting end 2-6-2 of the bearing seat is provided with a bolt hole 2-6-2-1 and a passing hole 2-6-2-2 for the transition shaft (see Figure 17 ); a trapezoidal step 2-6-4 or a groove is arranged between the installation end 2-6-1 of the rotary tiller frame and the installation end 2-6-2 of the bearing seat (see Figure 13 and Figure 22 ).

[0051] Further, the trapezoidal steps 2-6-4 or grooves arranged between the installation end of the rotary tiller frame and the installation end of the bearing seat are arc-shaped (such as Figure 16 and Figure 22 ).

Embodiment 2

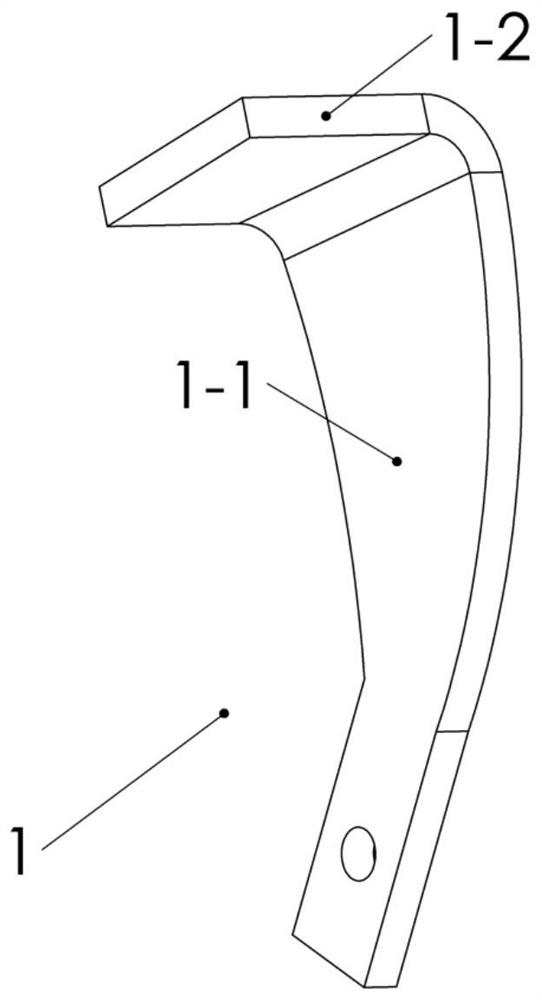

[0053] Such as Figure 11 , Figure 20 , Figure 24 and Figure 25 As shown, the rotary tiller of the present invention includes bearing seats between rotary tiller shafts (see Figure 11 and Figure 20 ), including the installation end 2-6-1 arranged on the rotary tiller frame and the installation end 2-6-2 of the bearing seat, the installation end 2-6-2 of the bearing seat is provided with a bolt hole 2-6 -2-1 (see Figure 11 ), or the mounting end 2-6-2 of the bearing seat is provided with a bolt hole 2-6-2-1 and a through hole 2-6-2-2 of the transition shaft (see Figure 20 ); a trapezoidal step 2-6-4 or a groove is arranged between the installation end 2-6-1 of the rotary tiller frame and the installation end of the bearing seat (see Figure 12 and Figure 21 ), on the rotary tiller shaft 2-7, the rotary tiller blade 1-2 of the rotary tiller is provided with the trapezoidal step 2-6-4 or the groove on the supporting seat between the rotary tiller to match the rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com