Laneway disposed by using large U to sleeve small u

A technology of roadway and connecting roadway, which is used in earth-moving drilling, ventilation of mine/tunnel, surface mining, etc., to achieve the effect of improving gas control capacity, improving driving efficiency and reducing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

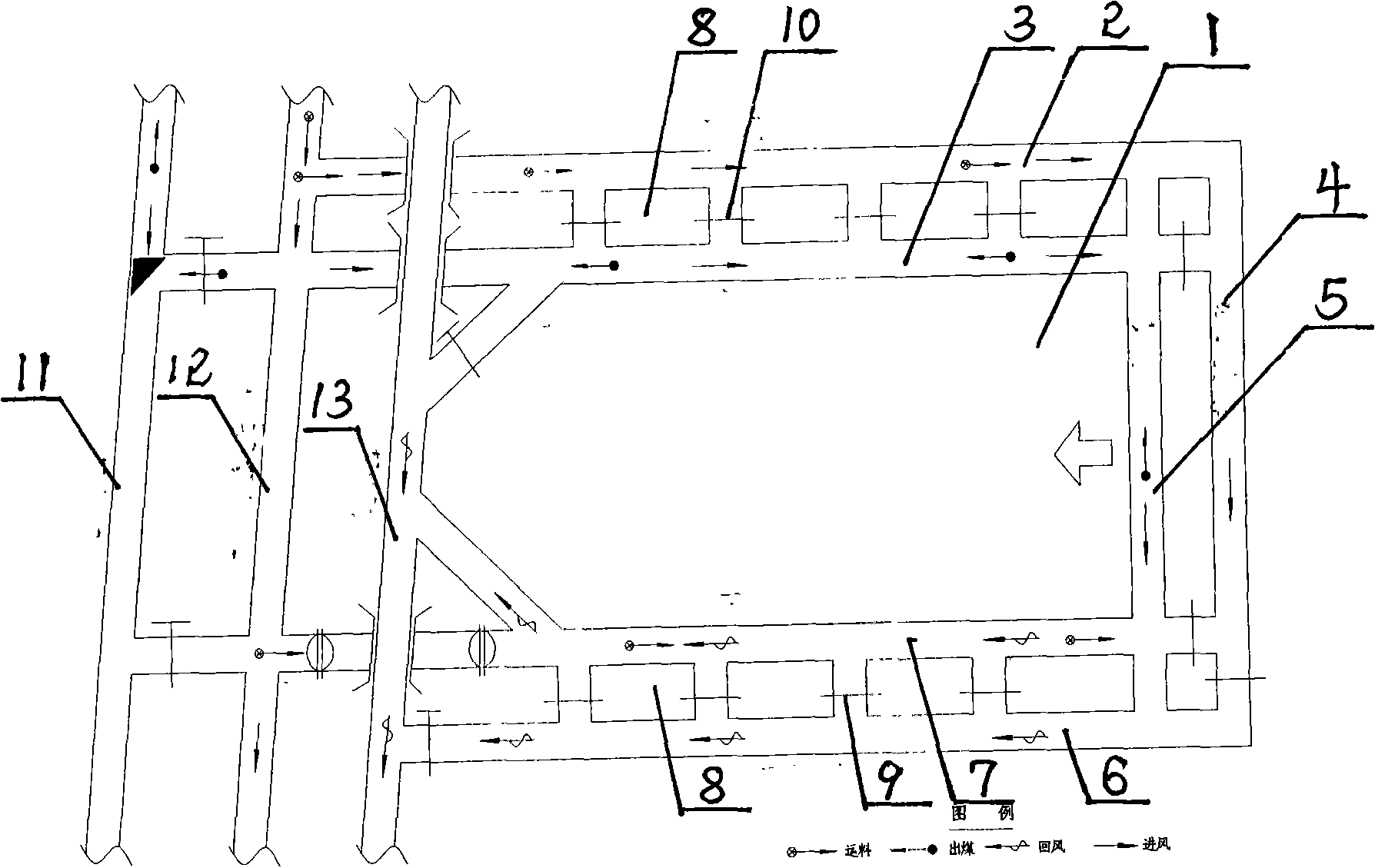

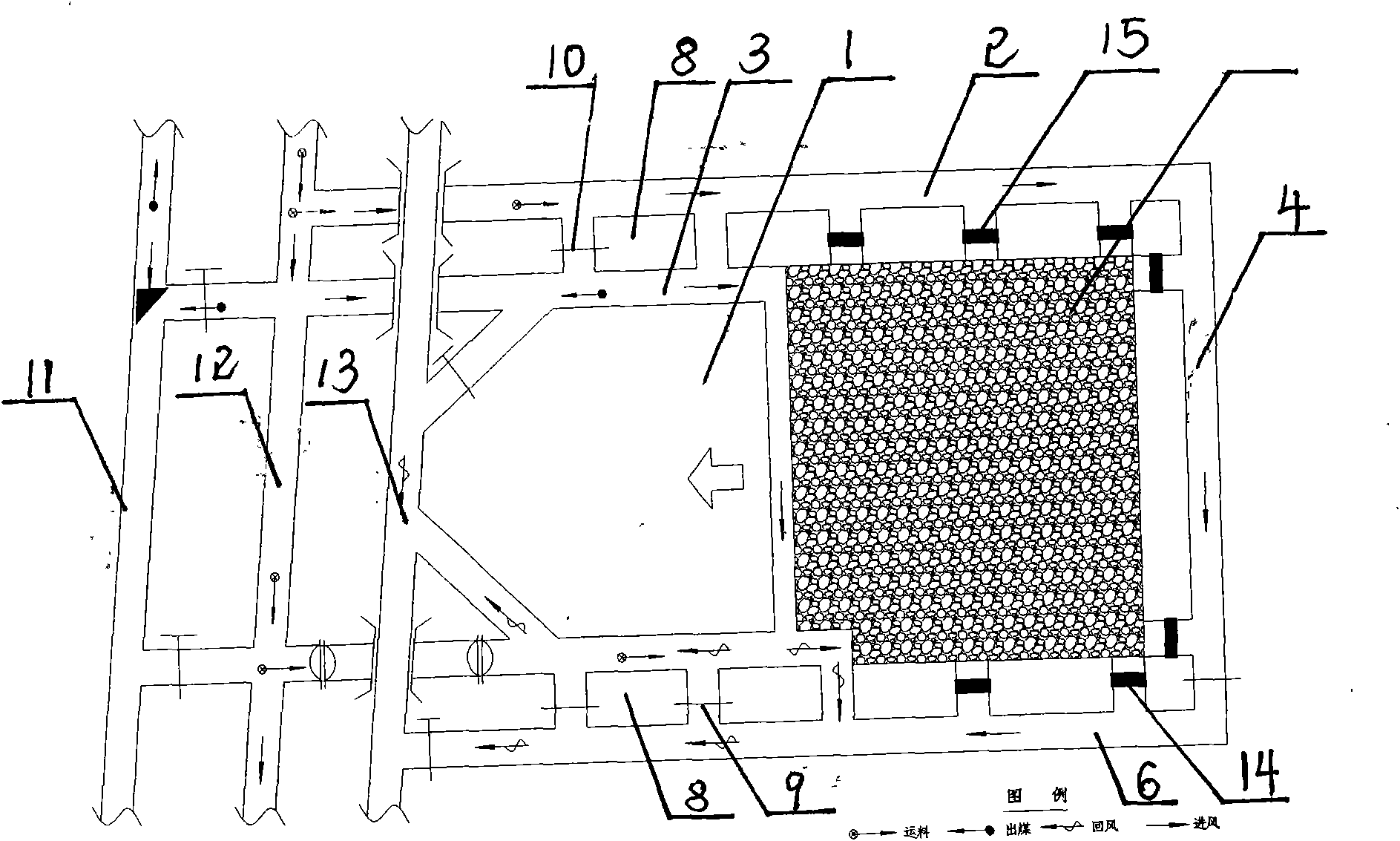

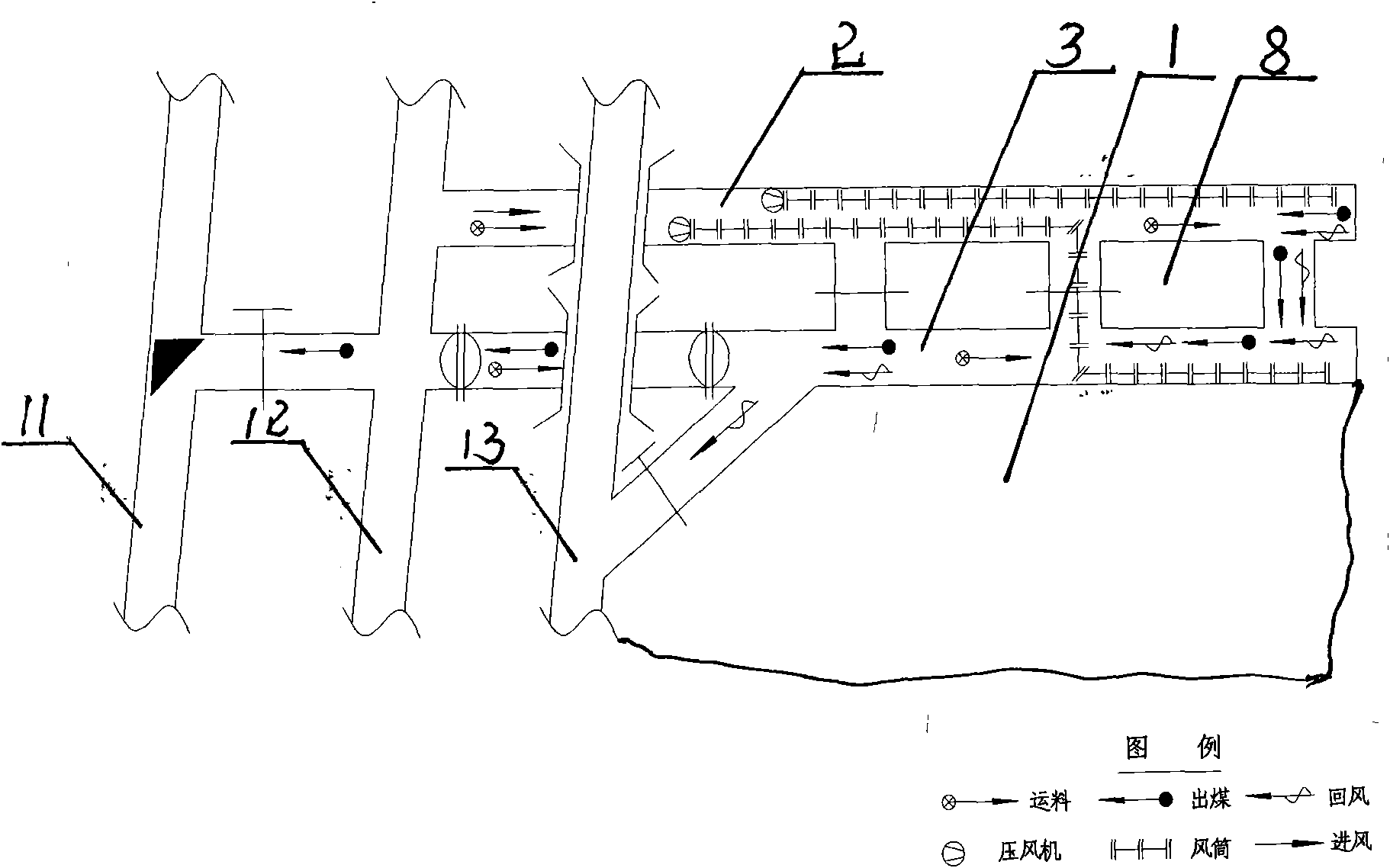

[0015] A roadway arranged in a way of big U and small U, such as figure 1 As shown, including the mining face 1, the periphery of the mining face 1 is provided with a small u roadway, and the small u roadway is the belt lane 3 and the return air lane 7 on both sides of the mining face, and the cutting on the side of the mining face Eye 5, a big U lane is set outside the small u lane, the big U lane is the equipment and ventilation lane 2, the ventilation connection lane 4, and the gas tail lane 6 connected end to end, and the equipment and ventilation lane 2 are located in the belt lane 3 On the outside, the ventilation connection lane 4 is located outside the cutout 5, the gas tail lane 6 is located outside the return air lane 7, and several solid support coal pillars 8 are arranged between the big U laneway and the small U laneway.

[0016] A 35-meter-thick solid support coal pillar 8 is arranged between the big U roadway and the small u roadway. At the same time, the big U ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com