Splitting and propelling mechanism and drill jumbo containing same

A technology of propulsion mechanism and splitting machine, which is applied in the direction of earth drilling, mining equipment, tunnels, etc. It can solve the problems of low work efficiency, the splitting head of the splitting machine sticks to the ground, and improper operation, so as to improve the construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] see Figure 7 , the existing splitting machine 60 includes a splitting head 601, a splitting machine body 602, a cross shaft 603 and a connection plate 604, wherein the splitting machine body 602 and the connection plate 604 are connected by the cross shaft 603 to realize splitting. The fuselage of the cracked machine can move freely.

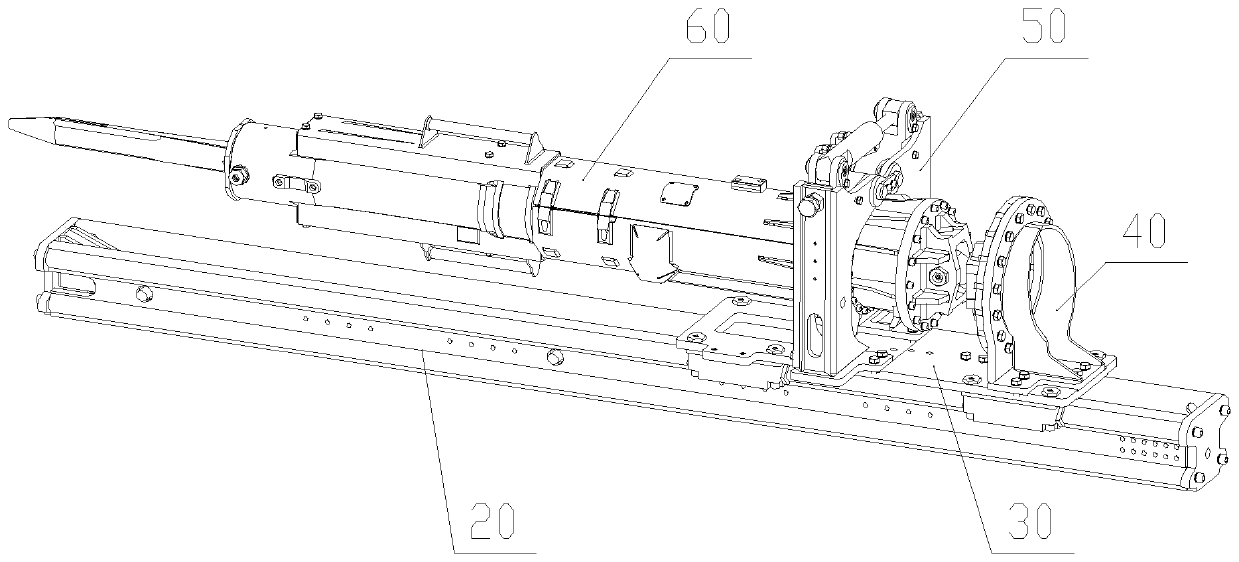

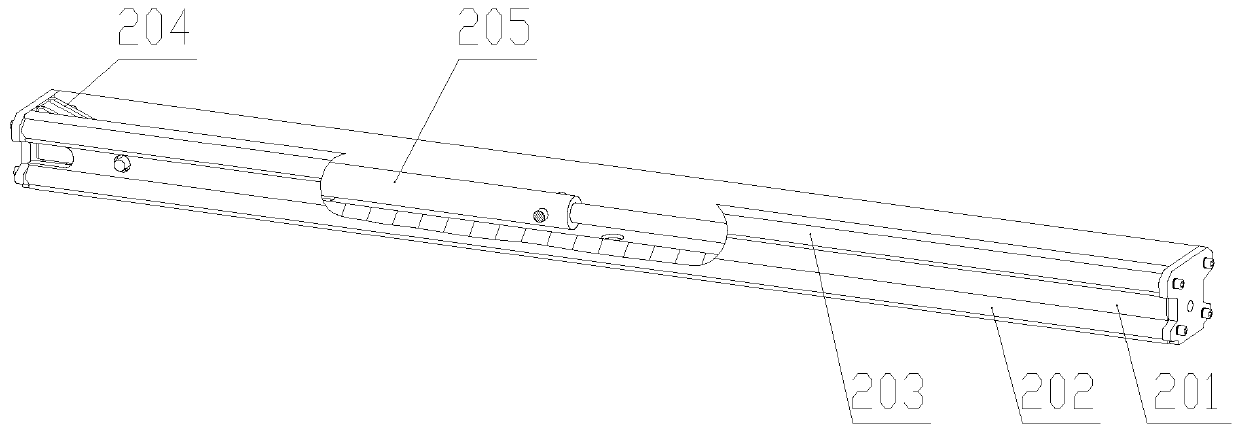

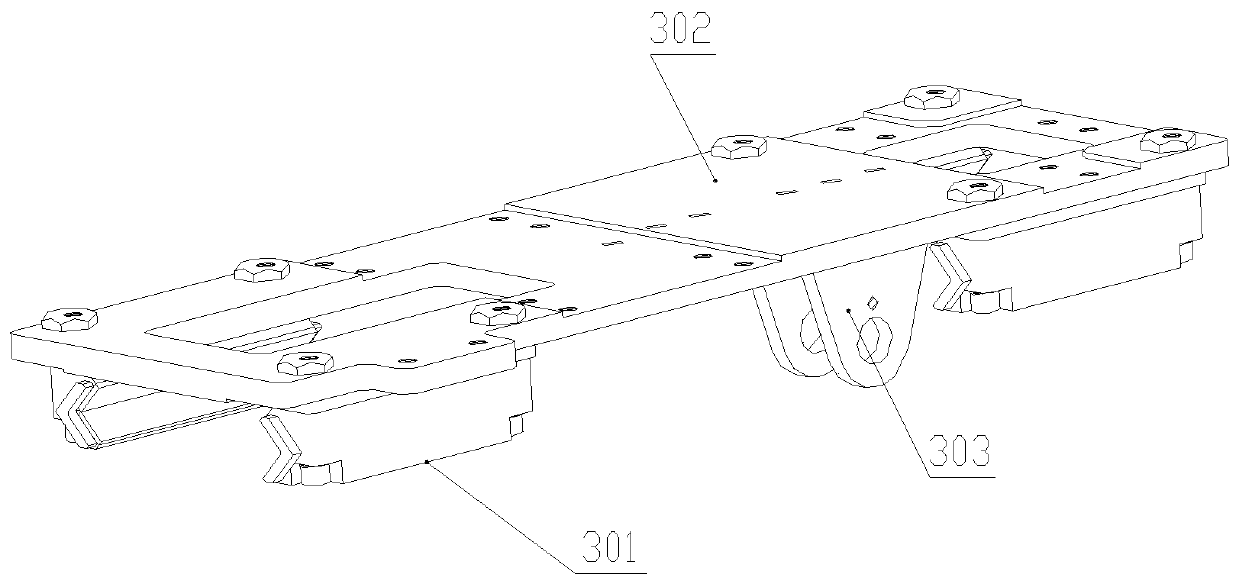

[0033] see Figure 1-6 , a splitting propulsion mechanism, comprising a propulsion guide rail 20, a slider tray 30, a splitting mount 40, a clamping device 50 and a splitter 60, the slider tray 30 can be slidably arranged on the propulsion guide rail 20, the The splitting mounting seat 40 and the clamping device 50 are both arranged on the slider tray 30, the clamping device 50 is used to clamp the splitter body 602, and the splitting mounting seat 40 is used to fix the splitting machine body 602. Connecting plate 604 on cracker 60.

[0034] see Figure 4-Figure 6 , the clamping device 50 includes a second telescopic member 504, a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com