Self-feeding continual tunneling device and method for rock tunnel

A self-propelled, rock-based technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of deteriorating engineering economic and social benefits, affecting the tunnel construction period, reducing the utilization rate of tunneling devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

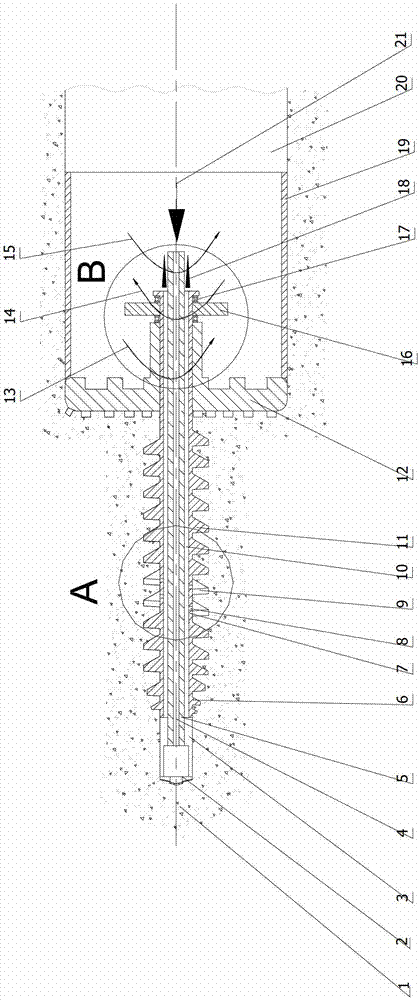

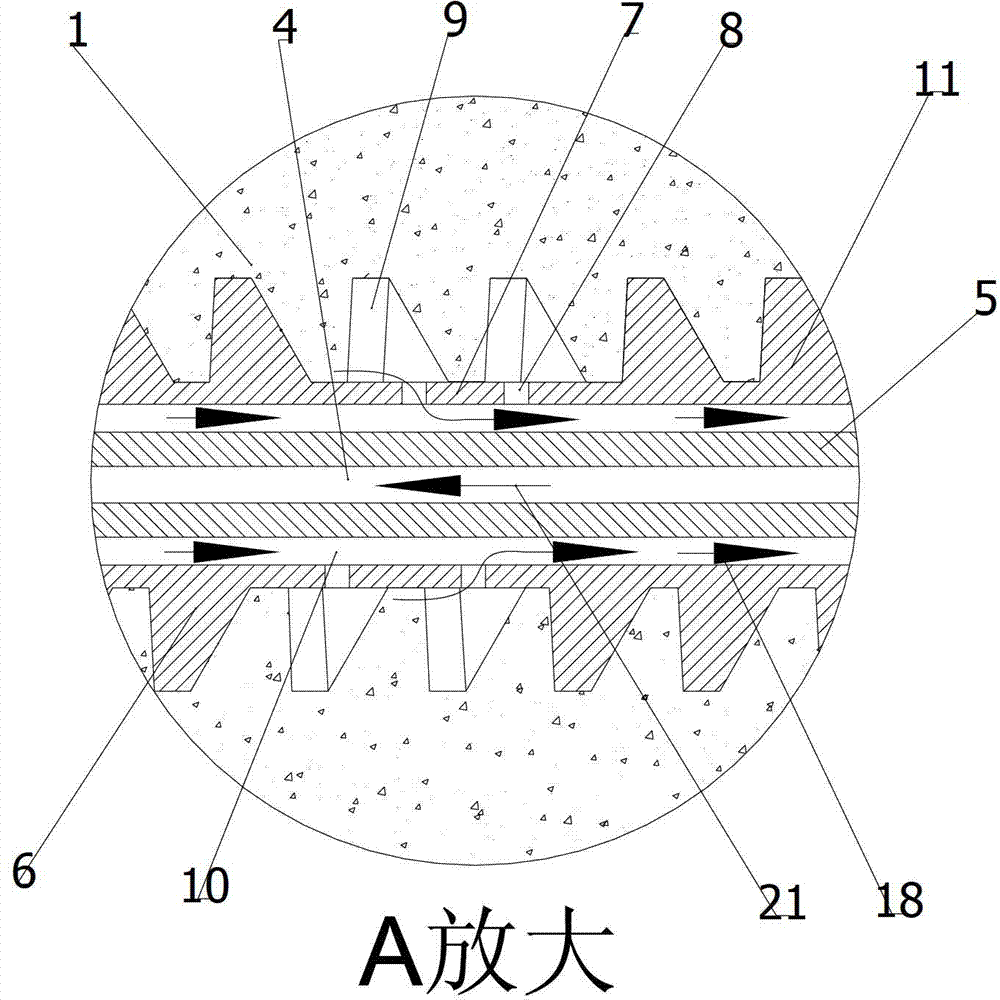

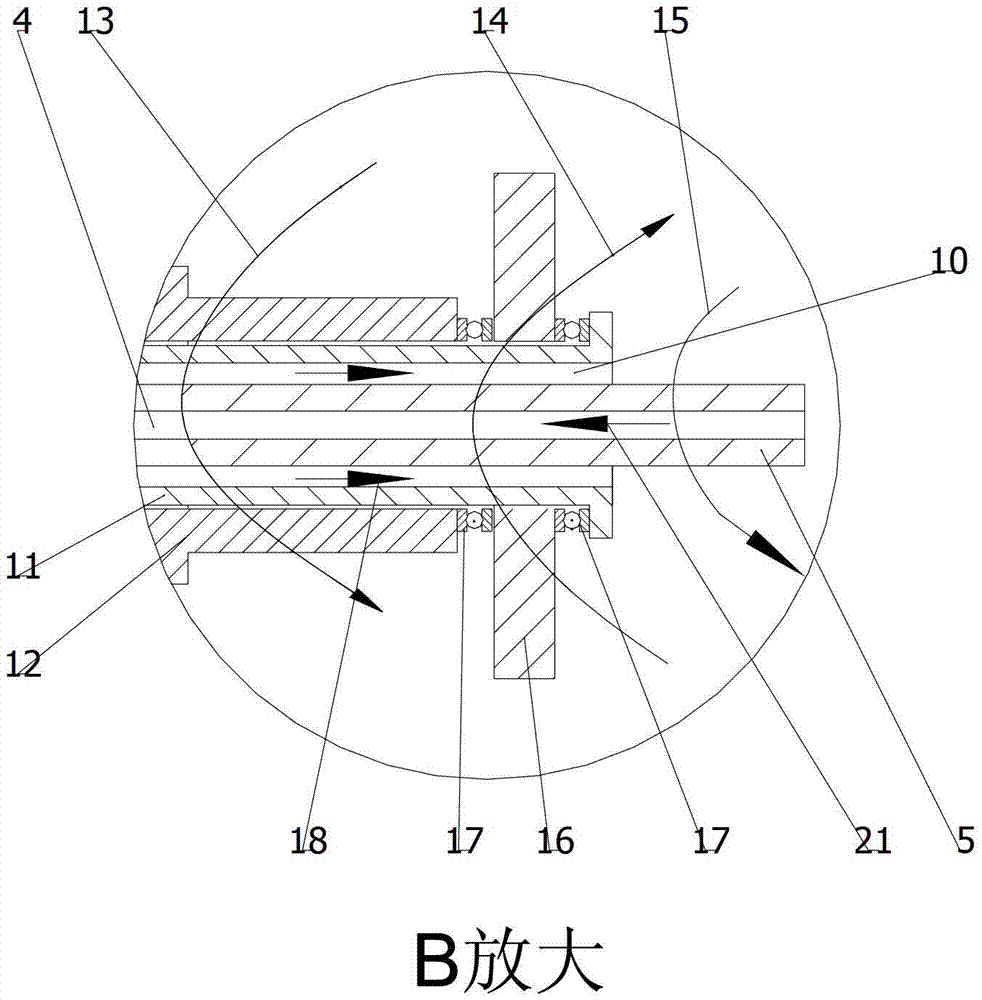

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] like figure 1 Shown: a kind of self-propelled rock tunnel continuous excavation device, it comprises advance drilling drill rod 5, is installed in the advance drilling drill bit 2 of advance drilling drill rod 5 front ends, is sleeved on the advance drilling drill rod 5 The rock tapping drill bit 6 behind the advanced drilling bit 2, the spiral tube 11 behind the rock tapping drill bit 6 set on the advanced drilling drill rod 5, and the end of the spiral tube fixedly connected with the outer cylinder body 19 of the excavation device The thrust plate 16 and the other end of the advance hole drill rod 5 are installed inside the outer cylinder body 19 of the tunneling device, and under the action of the drill rod driving torque 15, the advance drill hole 3 is drilled.

[0020] The non-spiral part of the helical tube 11 rear portion is cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com