Laser cladding method for mining hydraulic support column and mining stainless steel hydraulic column

A technology of hydraulic support columns and laser cladding, which is applied in the direction of pillars/supports, laser welding equipment, mining equipment, etc., can solve the problems of poor wear resistance of the coating, corrosion of columns, peeling and peeling of the coating, and achieve Improved anti-corrosion performance, extended service life, and strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

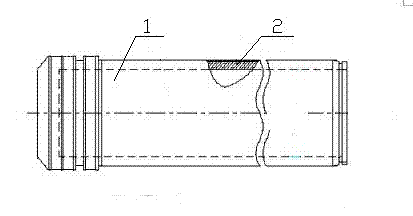

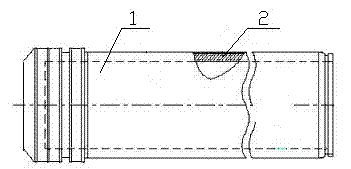

[0018] Accompanying drawing is the first embodiment of the present invention, this embodiment is described in detail in conjunction with accompanying drawing, is used for the first embodiment of the laser cladding method of mining hydraulic support column, and its steps are:

[0019] A. Clamp the live column of the column body 1 that has been derusted, leveled and textured to the laser processing machine tool, so that the live column of the column body 1 is driven by the main shaft C to rotate at a speed of 0.5 rpm. A laser head and a nickel-based alloy powder output nozzle are provided on the axial centerline of the live column of the column body 1. The laser head and the powder feeder move at a speed of 0.05 mm / s on the X linear axis. A laser cladding layer 2 with a thickness of 0.4mm is formed on the living column of the body 1, and the overlapping ratio of adjacent laser cladding layers 2 is set to 50%.

[0020] B. The laser beam is focused by the integrating mirror to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com